Automatic Casting Machine for Jewellery

Fully Automatic Jewelry Casting Machine – China's Leading Supplier of Jewelry Casting Equipment.

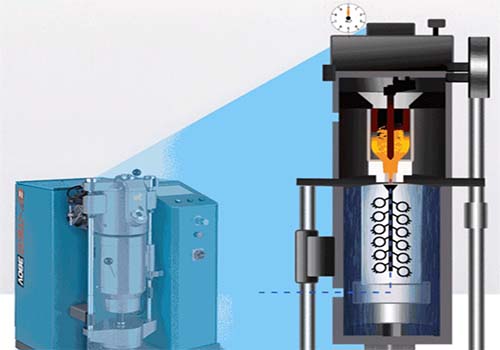

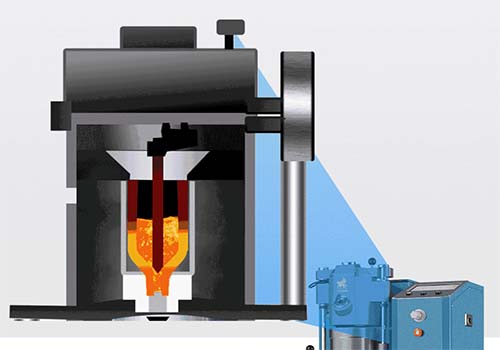

SuperbMelt Automatic Casting Machine for Jewelry can cast 2kg of gold, silver, copper, K gold, and other metals in just three minutes. The entire machine is constructed with aerospace materials, ensuring excellent sealing properties that result in flawless, smooth, and high-quality finished products. This makes it ideal for customers aiming to produce high-quality items.

This fully automatic casting machine requires just a single button press to initiate the casting process, significantly saving on labor costs and boosting production efficiency. The Automatic Casting Machine for Jewelry features electromagnetic stirring, intelligent temperature control, overvoltage protection, short-circuit protection, and other functions, ensuring the quality of the finished products. These added features create a safe and user-friendly operating environment for workers.

If you’d like to learn more about casting machines, such as the gold jewellery casting machine, please contact us immediately.

We specialize in providing tailored solutions for jewelry casting.

| Model | SPB-IPM2 |

| Power RequirementPower | 380v |

| Power Consumption | 10kw |

| Maximum Temperature | 1600 ℃ |

| Dissolution Time | 3min |

| Capacity | 2KG |

| Application | Gold, silver, platinum, palladium, steel, copper |

| Control System | PLC |

| Casting Mode | Automatic/Manual |

| Using gas | Argon gas or nitrogen gas |

| Cooling method | Water-cooled |

| Dimensions | 840*800*1430mm |

| Machine Weight | 210KG |

- Large Casting Capacity: Capable of casting up to 2kg of various metals, including gold, silver, copper, and aluminum, in a single operation, accommodating the production of larger jewellery pieces.

- Versatile Application: Suitable for casting a wide range of jewellery items, including rings, art pieces, and eyeglass frames, offering versatility for different design requirements.

- Electromagnetic Stirring for Uniform Melting: The electromagnetic stirring function ensures a uniform and well-mixed metal melt, contributing to consistent quality and improved aesthetic appeal of the final jewellery products.

- Integrated Safety Features: Equipped with multiple safety measures, including over-temperature protection and short-circuit protection, creating a secure operating environment for the machine operators.

- User-Friendly Operation: The system features a simple and intuitive UI interface, allowing operators to control and monitor the casting process with ease, reducing the learning curve for new users.

- Quick Casting Cycle: With an approximately 3-minute casting cycle, the machine enables rapid production turnaround, making it suitable for high-demand manufacturing environments.

- Enhanced Product Density: The vacuum pressure casting capability contributes to higher product density, minimizing the occurrence of sand holes and ensuring the overall quality of the cast jewellery.

- Energy-Efficient Design: The machine incorporates energy-efficient elements in its design, optimizing the casting process while minimizing energy consumption, resulting in cost savings over time.

Jewelry Production:

Use: Perfect for casting a variety of jewelry pieces, including as pendants, rings, and artwork.

Benefits: Makes casting more effective and accurate, which helps produce jewelry with complicated patterns that is of excellent quality.

The Crafts and Art Sector:

Application: Ideal for creating sculptures and other works of metal art.

Benefits: Increases artistic possibilities by giving artists a tool to create intricate, personalized metal artworks.

Manufacturing of Eyewear:

Application: Casts components and frames for eyeglasses.

Benefits: Makes it easier to produce well-made, long-lasting metal eyeglass frames that adhere to industry requirements.

Customized Jewelry Manufacturing:

Application: Worked with workshops that make personalized jewelry.

Benefits: Fulfills the needs of the bespoke jewelry markets by assisting in the manufacture of distinctive and customized jewelry items.

Small-Scale Foundries for Metal:

Application: Applied in tiny foundries that make modest quantities of metal products.

Benefits: Reduces the requirement for large infrastructure by providing a small-scale production with an effective and portable casting solution.

Repair and restoration of jewelry:

Application: Used in establishments that provide services for repairing and restoring jewelry.

Advantages: Allows for exact casting to preserve the original quality and design while mending or restoring jewelry.

Academic Establishments:

Application: Used to instruct students in metal casting procedures in educational environments.

Benefits: Gives students a practical introduction to the casting technique used in jewelry and metalworking.

Development of Prototypes:

Application: Used in product development to create metal prototypes.

Benefits: Promotes speedy testing and iteration in fields like engineering and product design by supporting rapid prototyping.

Customized Metal Fabrication Establishments:

Application: Used by companies that specialize in the manufacturing of bespoke metal.

Benefits: Provides a dependable and effective way to create one-of-a-kind metal goods and components according to customer requirements.

Electromagnetic Stirring Function

Significantly increases the density of finished products, achieving virtually pore-free casting.

Vacuum Pressure Casting

Greatly enhances the density of finished products, achieving virtually pore-free casting

High Efficiency

Can cast one crucible in 3 minutes.

Why SuperbMelt Automatic Casting Machine for Jewellery

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

More SuperbMelt jewelry casting machines for you to choose from

Any Question About SuperbMelt Automatic Casting Machine for Jewellery

About SuperbMelt Automatic Casting Machine for Jewelery Guide

Overview of automatic mold pouring machine

1.1, Introduction

SuperbMelt Automatic Casting Machine for Jewelry is an advanced solution designed to streamline and enhance the jewelry casting process. With cutting-edge technology and innovative features, this machine sets new standards in the industry.

1.2, Functions

A number of features are available on the Automatic Casting Machine to enhance the casting experience:

Vacuum and Pressure Casting: Almost completely sand-free casting is achieved by utilizing the vacuum and pressure functions to achieve high casting density.

Electromagnetic churning: This feature guarantees a homogeneous distribution of metal for excellent casting quality by using special churning during heating and melting.

Efficiency: The machine has a great degree of efficiency; in only three minutes, it can cast around 2 kg of gold, silver, copper, aluminum, and other metals.

PID Intelligent Temperature Control: Consistent and excellent casting is facilitated by the PID system’s accurate temperature control, which is maintained to within ±2°C.

1.3, Key Features

- Discover the unique qualities that set the SuperbMelt Automatic Casting Machine apart.

- User-Friendly Interface: The system offers operators an easy-to-use and effective casting experience with its sleek and user-friendly interface.

- Quick Casting Cycle: This machine guarantees time efficiency without sacrificing casting quality, with a quick casting cycle of around three minutes each crucible.

- Safety precautions: The Automatic Casting Machine’s short-circuit and overpressure protections provide a safe working environment for its users.

- Versatile Applications: Suitable for a range of applications, such as the creation of jewelry, crafts, eyeglasses, and more.

Ring Casting Process

2.1,Design Drawing

This initial phase requires creating a visual representation of the ring you intend to cast. This design drawing serves as a blueprint for the entire process. It includes details such as the ring’s shape, size, intricate patterns, and any specific features you want in the final product.

2.2, Making the flask

Once you have the design, the next step is to manufacture the steel cup. This cup, often referred to as a mold or crucible, will hold the metal during the casting process. It’s typically made from durable materials like steel to withstand the high temperatures involved in melting metals. The steel cup is crafted to match the design specifications of the ring.

2.3, Casting Process

With the design and steel cup ready, you move on to the casting phase. This involves melting the chosen metal—such as gold, silver, or other alloys—until it becomes a liquid. The molten metal is then carefully poured into the prepared steel cup, taking the shape of the ring design. After the metal cools and solidifies, the steel cup is removed, revealing the newly cast ring.

Conclusion

SuperbMelt Automatic Casting Machine for Jewelry stands out as a sophisticated and efficient tool that revolutionizes the jewelry casting process. With features like vacuum pressure casting for enhanced product density, electromagnetic stirring for uniform metal melting, and a high-speed casting capability of approximately 1 crucible in 3 minutes, it sets a new standard in the industry.

The machine is not only known for its high efficiency but also boasts a PID intelligent temperature control system, ensuring precise temperature differentials of ±2℃. The user-friendly interface with a simple UI design makes operations intuitive, and the multiple protective measures embedded in the system guarantee a safe and secure casting environment.

Whether you are a jewelry manufacturer aiming for top-notch quality with minimal defects or a craftsman seeking to optimize your production workflow, the SuperbMelt Automatic Casting Machine for Jewelry is a game-changer. Its applications extend across various industries, offering a reliable solution for creating flawless jewelry pieces efficiently and safely. Explore the world of advanced casting technology with SuperbMelt – your partner in elevating jewelry casting to new heights.

FAQ Guide of Automatic Casting Machine for Jewellery

- 1. What is a jewelry casting machine?

- 2. What are the two types of casting machines?

- 3. Which casting method is suitable for making jewellery?

- 4. What is an Automatic Casting Machine for Jewelry?

- 5. How does a Ring Casting Machine work?

- 6. What makes a Gold Jewellery Casting Machine different from other casting machines?

- 7. Can a Casting Machine for Gold Jewellery be used for other metals?

- 8. What is the significance of using a Copper Casting Machine?

- 9. How does a Brass Casting Machine contribute to jewelry production?

- 10. Are Automatic Casting Machines suitable for small-scale jewelry production?

- 11. What are the key features to consider when choosing an Automatic Casting Machine for Jewellery?

- 12. Can a Gold Jewellery Casting Machine be used for casting intricate designs?

1. What is a jewelry casting machine?

A jewelry casting machine is a specialized piece of equipment used in the jewelry manufacturing process to create metal jewelry items through the casting technique. The casting machine makes this process precise and efficient by facilitating the melting and pouring of metal into a mold to obtain the desired shape. The metal, usually gold, silver, platinum, or other alloys, are melted to a liquid state in the casting machine’s mold, which is designed to shape the molten metal into the desired jewelry form. Silicone, rubber, or metal can be used as the mold.

Vacuum or Pressure System: To provide a smoother and more detailed cast, several casting machines utilize vacuum or pressure systems to remove air bubbles from the molten metal.

Temperature Control: To get the proper consistency of melted metal, precise temperature control is essential. Temperature control systems are a common component of advanced casting machines.

Cooling System: Following casting, a cooling system aids in the effective solidification of the metal within the mold.

Automation: To speed up the casting process, modern casting machines may have automation features like programmable settings and user-friendly interfaces.

For jewelry designers and manufacturers, jewelry casting machines are essential because they enable them to consistently and efficiently create complex and unique patterns.

2. What are the two types of casting machines?

Machines for Centrifugal Casting:

- Principle: The molten metal is distributed into the mold by use of centrifugal force in these devices. The metal is forced into the mold cavity by centrifugal force while the crucible holding the molten metal is quickly spun.

- Benefits: This casting method works well for a variety of metals, such as platinum, silver, and gold.Ideal for production on a small or large scale.reasonably easy and affordable.

Vacuum Casting Machines:

- Working principle: Before adding molten metal, a vacuum is used to eliminate air from the mold cavity. The lack of air bubbles in the mold produces a cast that is more accurate and detailed.

- Benefits: The castings’ exceptional quality and delicate detail.

- decreased porosity in the finished product.

- Perfect for detailed and sophisticated designs.

- enhanced command over the casting procedure.

- The type of jewelry being made, the required level of detail, and the particular needs of the production process are some of the variables that influence the decision between centrifugal and vacuum casting equipment. To fulfill varying casting demands, some manufacturers could combine the two types of machinery.

3. Which casting method is suitable for making jewellery?

Jewelry may be made using either vacuum casting or centrifugal casting technique; which one to use relies on a number of variables, such as the type of jewelry, the complexity of the design, and the needs for production. Here is a quick comparison to help you determine which approach could be more appropriate in various situations:

Casting via Centrifugation:

Suitability: Works well with many different kinds of jewelry, such as bracelets, rings, and basic forms.

Fit for both large- and small-scale manufacturing.

Benefits:

- rather easy and inexpensive procedure.

- rapid turnaround time for production.

- Ideal for producing simpler patterns in large quantities.

Principle of Vacuum Casting:

Vacuum casting machines work by drawing air out of the mold cavity prior to the addition of molten metal. A more accurate and detailed cast is produced when the mold is free of air bubbles.

Advantages:

- Extremely accurate castings with exquisite detail.

- decreased ultimate product porosity.

- Perfect for designs that are detailed and complicated.

- more command over the casting procedure.

- What kind of jewelry is being made, how much detail is wanted, and the particular needs of the manufacturing process all play a role in which centrifugal or vacuum casting equipment are used. To satisfy various casting requirements, some manufacturers could combine the two types of machinery.

4. What is an Automatic Casting Machine for Jewelry?

An Automatic Casting Machine for Jewelry is a specialized equipment designed for the efficient and precise casting of various metals, including gold, silver, copper, and brass, to create jewelry pieces.

5. How does a Ring Casting Machine work?

A Ring Casting Machine is designed to cast metal into ring shapes. It uses a specific casting process to ensure the accurate and detailed reproduction of ring designs.

6. What makes a Gold Jewellery Casting Machine different from other casting machines?

A Gold Jewellery Casting Machine is tailored for casting gold specifically. It is equipped with features and settings optimized for the unique properties of gold, ensuring high-quality jewelry production.

7. Can a Casting Machine for Gold Jewellery be used for other metals?

While primarily designed for gold, many Casting Machines for Gold Jewellery can be adjusted to cast other metals like silver, copper, and brass, offering versatility in jewelry manufacturing.

8. What is the significance of using a Copper Casting Machine?

A Copper Casting Machine is designed for the precise casting of copper, allowing jewelry manufacturers to create copper-based jewelry items with accuracy and efficiency.

9. How does a Brass Casting Machine contribute to jewelry production?

A Brass Casting Machine is specialized for casting brass, providing jewelry makers with the capability to craft jewelry pieces with unique designs and features using this particular metal.

10. Are Automatic Casting Machines suitable for small-scale jewelry production?

Yes, Automatic Casting Machines are suitable for both small-scale and large-scale jewelry production, offering efficiency and automation to enhance the manufacturing process.

11. What are the key features to consider when choosing an Automatic Casting Machine for Jewellery?

When selecting an Automatic Casting Machine for Jewellery, consider factors such as casting precision, material compatibility, ease of operation, and the ability to handle various jewelry designs.

12. Can a Gold Jewellery Casting Machine be used for casting intricate designs?

Yes, many Gold Jewellery Casting Machines are equipped to handle intricate and detailed jewelry designs, ensuring precision in the casting process.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited