Jewelry 3D Printer

China High Quality and Professional Jewelry 3D Printer Supplier

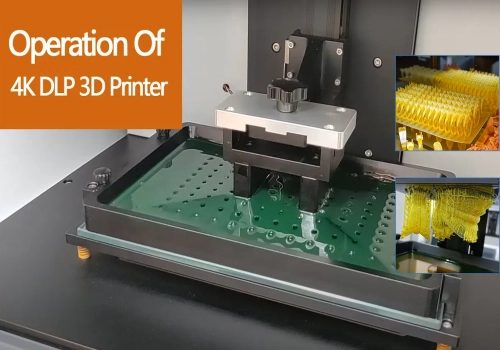

SuperbMelt Jewelry 3D Printer enables jewelry designers to transform complex jewelry designs into physical products, shortening the product development cycle.

The printer uses UV printing technology and resin materials to create finished products that can be directly used for making jewelry molds, significantly reducing mold time and cost, thereby aiding in the rapid production of jewelry products.

- Saving:By minimizing material waste and reducing the need for labor-intensive processes, jewelry 3D printers can significantly lower production costs. This makes it more economical to produce small batches or one-off custom pieces.

- Precision:The precision and accuracy of jewelry 3D printers ensure that the final product closely matches the original design. This level of detail is crucial for creating high-quality jewelry pieces that meet exacting standards.

| Model number | SPB-4K200 | SPB-4K250 | SPB-4K200W | SPB-4K250W |

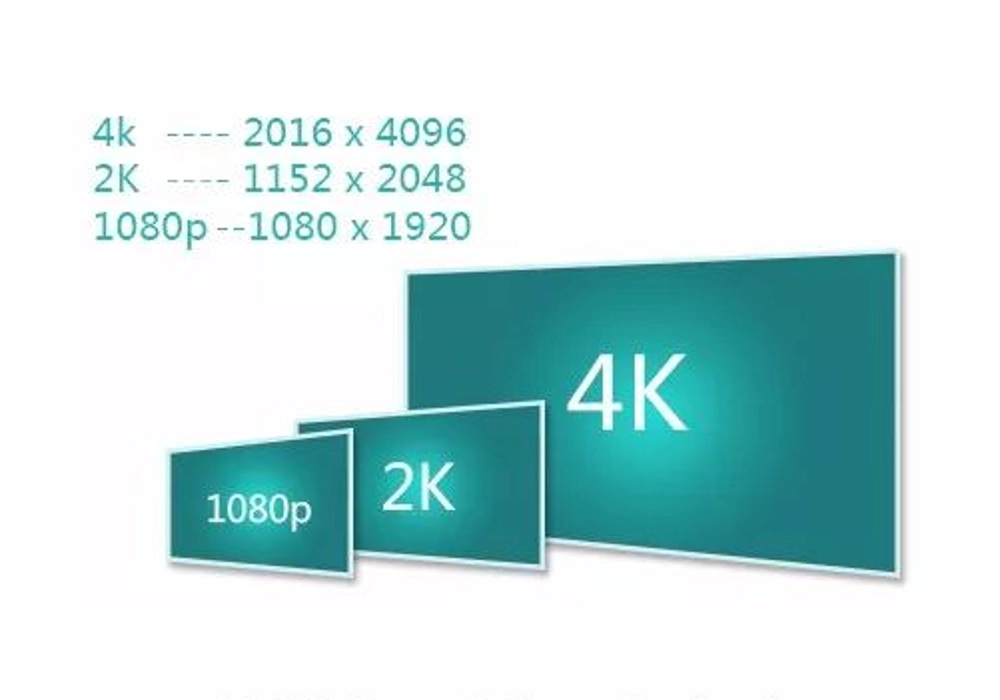

| DLP resolution | 3840*2160 | 3840*2160 | 3840*2160 (4K) | 3840*2160 (4K) |

| Pixel | 50um | 65um | 50µm | 65µm |

| Power | 800W | 800W | 1phase 220V,50Hz, 350W | 1phase 220V,50Hz, 350W |

| Machine size | 620mm*620mm*1600mm | 620mm*620mm*1600mm | – | – |

| Layer thickness | 0.025-0.1mm | 0.025-0.1mm | 0.025-0.1mm | 0.025-0.1mm |

| Forming size | 192*108*150mm | 250*140*150mm | 192*108*150mm | 250*140*150mm |

| Printing speed | 15-28mm/h | 15-28mm/h | 15-28mm/h | 15-28mm/h |

| File formate | STL/SLC | STL/SLC | STL/SLC | STL/SLC |

| Light Source | UV LED 405nm Texas Instruments DMD chip | UV LED 405nm Texas Instruments DMD chip | UV LED 405nm Texas Instruments DMD chip | UV LED 405nm Texas Instruments DMD chip |

| Materials | Pewter Castable Materials | Pewter Castable Materials | Pewter Castable Materials | Pewter Castable Materials |

High Resolution

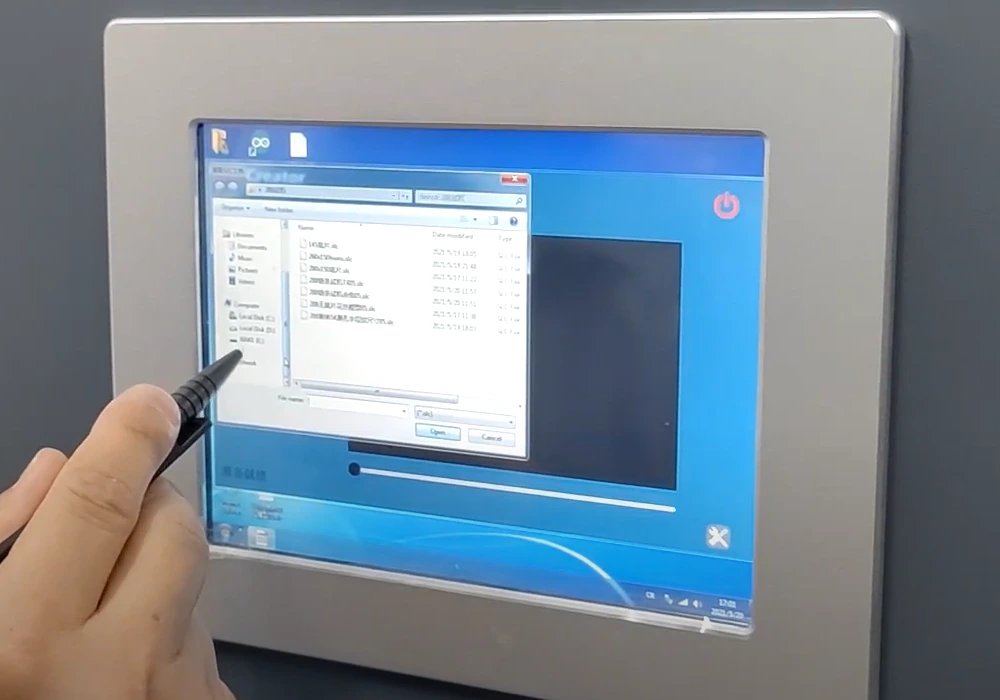

The use of 4K industrial-grade ultra-high-resolution projection optical engine makes the projected image clearer. Its resolution is 3840×2160, so the printing accuracy is also higher. It can easily solve the printing of some difficult jewelry styles, and the printed texture of the finished product will be more clear and detailed. In this way, it is easier to obtain perfect and exquisite jewelry products in the later casting process.

Large Format Print Size

The printing layout reaches 192mm*108mm*120mm, and 30-50 models can be formed at a time. Realized mass production, making production more efficient, suitable for medium and large jewelry factories. The molding space is also large, suitable for large-scale model production such as animation figures, metal crafts, etc.

Swing Trough

Every time it is completed, when it rises, the trough will also swing at the same time to assist in the separation of photosensitive resin, which can buffer the stripping process, improve stability, and ensure the quality of the finished product.

Remote Monitoring

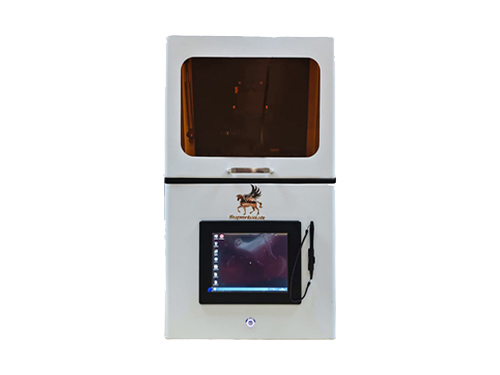

Equipped with a remote monitoring system, you can clearly understand the printing process and status without standing next to the machine during printing. When an abnormality occurs, you can control it in time, so as to avoid wasting time and cost due to printing failure.

Various Printing Materials

Most of the castable resins, ceramic resins and dental molding resins on the market can be used, and no fixed model brand is required. This means more choices for you, the ability to buy the qualities you need individually, and more finished products that are achievable.

Strong Compatibility

The machine can adjust the temperature and humidity, so there is no need to worry about receiving interference in a too cold or too hot environment, which will affect the operation of the machine. This feature prolongs the service life of the machine and ensures the printing quality.

High Stability Light Source

Whether each layer of mold can be stably molded depends on whether the light is uniform. Our 4k printer uses LED UV light source, which is characterized by high stability and high uniformity. The service life of this light source can reach more than 20,000 hours, which effectively guarantees the stability of the printing process and makes the molding more reliable.

Jewelry 3D printers are crucial for the jewelry industry as they focus on jewelry industry applications. They are primarily utilized for creating molds before jewelry casting. With the use of castable materials, such as gold, silver, platinum, or other metals, the jewelry pieces can be successfully cast later on.

In addition, these printers also offer the possibility of working with non-castable materials. The process involves initially creating a resin mold, followed by mass production utilizing a wax injection machine. Subsequently, the jewelry can be cast. It is worth noting that this method is particularly well-suited for producing animation dolls and original models for large-scale handicrafts.

Why SuperbMelt 4K Resin 3D Printer

Any Question About SuperbMelt Jewelry Resin 3D Printer

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Here's What Our Satisfied Customers Have to Say

More SuperbMelt 3D Jewelry Printers For You To Choose

3D Jewelry Printer FAQ Guide

Similar to SLA (Stereolithography) printers, DLP (Digital Light Processing) resin 3D printers employ the same technique. DLP printers, on the other hand, project an image of the item onto the resin using a digital projector rather than a laser to cure the resin. When the resin is exposed to ultraviolet (UV) light from the projector, it solidifies and builds up the object layer by layer.

The cross-section of the item is projected digitally onto the resin, and UV light causes the resin to solidify where the light strikes it. A fresh resin coating is applied to the surface as the construction platform is gently lowered. Up till the complete item is printed, the procedure is repeated.

DLP resin 3D printers are distinguished from other types of resin 3D printers by their excellent resolution and quicker production rates.

If you need to process precious metals for jewelry or other purposes, are you looking to invest in a high-quality 3D resin printer? Just visit the official SuperbMelt website. Because of their unmatched accuracy and precision, our 3D resin printers are ideal for any industrial jewelry or metalworking enterprise. You may locate the ideal 3D printer for your unique demands and budget by selecting from a variety of models and parameters. It’s never been simpler to purchase the high-quality 3D resin printers you need to grow your business with our simple online buying procedure and quick, dependable shipment. To find out more and to place an order right away, visit our website!

A UV light source is used in resin 3D printing to layer-by-layer cure liquid photopolymer resin until a solid 3D item is created. A 3D model serves as the foundation of the procedure and is divided into tiny layers using specialist software. The 3D printer, which has a vat of liquid resin, is then given the sliced model. A build platform is employed by the printer to progressively descend into the resin vat. The resin is then cured using a UV light source in accordance with the slice pattern. The platform is raised and the procedure is repeated for the following layer once each layer has dried. The 3D item may be taken from the printer once all the layers have dried and cleaned with isopropyl alcohol to get rid of any uncured resin. To guarantee that the piece is completely hardened, it can then be further cured in a UV curing chamber.

- Even though maintaining the performance and durability of a 3D printer can be a dirty and time-consuming task, it is vital. The steps to cleaning resin from a 3D printer are as follows:

- Remove the build plate and resin vat from the printer while wearing safety gloves.

- Any extra resin should be poured back into the bottle or into a different container for future use.

- Any resin that has set should be scraped off the build plate and vat with a plastic scraper or spatula.

- Remove any residual liquid resin from the vat and build plate using a paper towel or other cloth.

- Isopropyl alcohol (IPA) or a cleaning solution made especially for resin should be put in a cleaning container.

- the cleaning container with the vat and building plate inside, and then

- The cleaning container should include the vat and the building plate. Let them soak for ten to fifteen minutes.

- Scrub the vat and build plate with a soft-bristled brush to get rid of any residual resin.

- Clean IPA or water should be used to properly rinse the vat and construct plate.

- The construction plate and vat can be dried using compressed air or a lint-free towel.

- Any spent cleaning solution should be disposed of in accordance with local laws.

- You may properly remove resin from your 3D printer and maintain it in good operating order for your subsequent project by following these instructions.

100% lost wax casting/ 100% ashless combustion. The final product surface will be smooth. Subsequent polishing is easier, and the finished product is more convenient to handle.

Fast printing speed: equipped with an oxygen supply system, aerobic printing is 3 times faster than traditional printing.So it can achieve mass production.

Yes, photosensitive resin can be printed

15-28mm/hour. It depends on your material, different materials, printing time will be slightly different.

Wax 3D Printer: This type of printer uses wax-based materials and is highly suitable for creating complex jewelry designs. They offer high precision and a smooth surface finish, making them ideal for producing highly detailed casting models.

Resin 3D Printer: Resin printers use light-curable polymer resin materials that solidify when exposed to ultraviolet light. They are capable of producing high-resolution models with fine details. Resin printers are commonly used for creating prototypes, intricate patterns, and master models for jewelry casting.

- Step 1: Design and print the jewelry model using 3D modeling software.

- Step 2: Create the jewelry mold using a jewelry manufacturing machine to transform the 3D printed model into a casting mold.

- Step 3: Pour the molten casting material into the mold and wait for it to cool and solidify.

- Step 4: Perform post-processing on the cooled jewelry mold, such as polishing, grinding, and plating, to enhance the appearance of the jewelry.

Photosensitive resin, a type of printing substance used in 3D printing, has features that make it waterproof and high-temperature resistant. Solvents, photoinitiators, and oligomers make up the bulk of it. It includes low-toxicity elements, which are typically safe for use when in brief contact. However, hazardous chemicals including benzoin and benzophenone are present in the photosensitive resin used in 3D printing.

SuperbMelt 3D Resin Printing Guide

Jewelry 3D Printer

1.1, The application of 3D printers in the jewelry industry

The application of 3D printers in the jewelry industry has been widely recognized and utilized, providing important support and assurance for jewelry production and research and development. Its main applications in jewelry include jewelry design and creative development, mold making, customized jewelry production, jewelry manufacturing, and jewelry restoration.

1.2, What materials are good for 3D printing jewelry?

These materials are suitable for 3D printing jewelry: resin, castable wax, PLA (polylactic acid), and metal. Among them, resin is one of the most commonly used materials. Jewelry printed with resin can capture intricate details and have a smooth surface. Resin is available in various colors and can be post-processed to achieve a polished effect.

1.3, The Process of Making 3D Printed Jewelry

The rapid development of 3D printing technology has achieved breakthroughs in innovative applications in professional fields such as gold and jewelry, creating favorable opportunities for the personalization, digitization, and intelligentization of the gold and jewelry industry.

The process of 3D printing jewelry with a jewelry 3D printer usually involves designing the jewelry model, importing the designed jewelry model file into the 3D printer software, setting the parameters for printing, removing the model from the printing platform after printing, and performing post-processing according to requirements, such as vacuuming, high-temperature dewaxing, and casting.

Working Principle of a Jewelry 3D Printer

working principle of a jewelry 3D printer involves importing the digital design file into the printer. Inside the printer, layers of plastic, metal, or other materials are deposited using lasers or nozzles, resulting in the creation of a three-dimensional piece of jewelry. This process is rapid and can be completed within a few hours, enabling the production of the entire piece of jewelry.

2.1, Maintenance Tips for Jewelry 3D Printers

- To Clean

Clean the printer after each use: Use a soft cloth or tissue to remove any excess resin from the resin tank, build plate, and other areas of the printer.

- 3D Printer Resin Tank

Change the resin tank regularly: Over time, the resin tank may develop scratches or other damage that can negatively affect print quality. Change the resin tank every few prints or whenever you notice any damage.

- 3D Printer Base Plate

Check and clean the build plate: Before each print, make sure the build plate is clean and free of any debris or residue. Use isopropyl alcohol and a soft cloth to clean the build plate if necessary.

How to Choose the Right Jewelry 3D Printer

Choosing the right jewelry 3D printer depends on your specific needs and intentions. In the jewelry industry, 3D printers are available at different price points, and the choice of materials also varies accordingly. Before purchasing a 3D printer, it is important to have a clear understanding of your intended use.

If you only need the printer for design reference and visualizing the end result, a 3D printer that uses resin materials would be sufficient. However, if you want to directly obtain finished products through 3D printing and design, you will need a printer that can work with metal materials, which tends to be more expensive.

In addition to considering the price, it is crucial to ensure the quality of the 3D printer. With numerous brands available in the current market, it can be overwhelming to make a choice. However, it is important to select a jewelry 3D printer of good quality. SuperbMelt offers both resin printers and lost wax printers, providing jewelry 3D printers that meet the needs of the jewelry industry.

3.1, Best 3D Printer for Jewelry

The greatest resin 3D printers for manufacturing jewelry are available from SuperbMelt.The 4K resolution and superb precision of SuperbMelt resin 3D printers make them perfect for printing jewelry.The 3D printer offers an intuitive user interface that makes it simple to use.It also boasts a solid and dependable printing mechanism.You can simply make complicated and extremely detailed jewelry replicas with this 3D printer.For jewelry designers trying to execute ideas in the most precise and effective manner possible, this is a must-have tool.The jewelry resin 3D printers from SuperbMelt are revolutionizing the sector by providing jewelry producers of all skill levels with unmatched accuracy and efficiency.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited