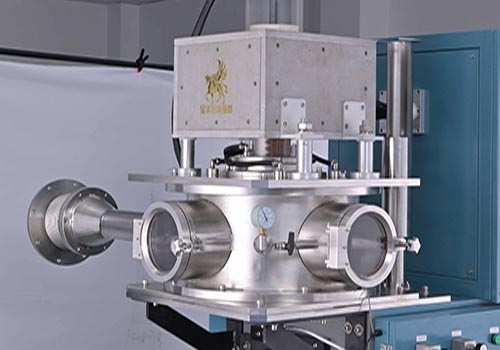

Vacuum Continuous Casting Machine

SuperbMelt vacuum continuous casting machine assists customers in casting high-quality jewelry plates or tubes.

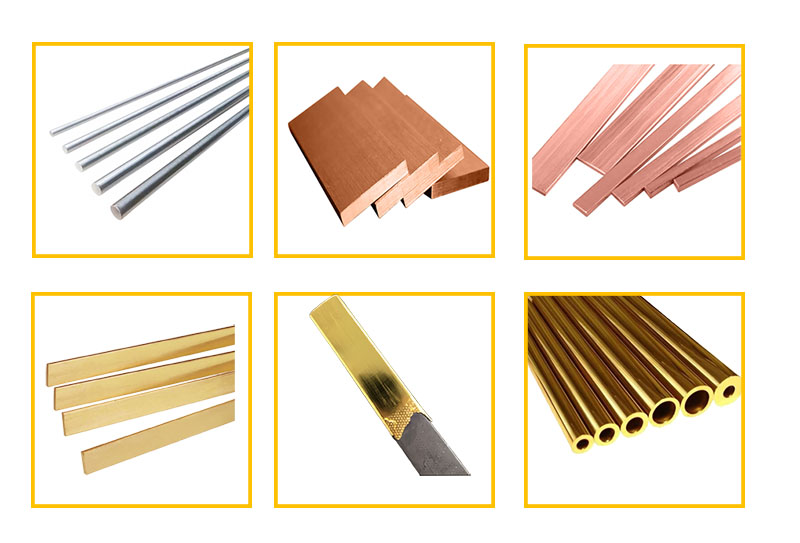

SuperbMelt Vacuum Continuous Casting Machine utilizes its high vacuum pressure to cast high-quality, smooth, and pore-free raw materials for gold, silver, copper, K gold, and other metal jewelry, including sheets, tubes, and rods.

The Vacuum Continuous Casting Machine comes with stirring function, inert gas protection, and vacuum secondary feeding capabilities to prevent metal oxidation, ensuring uniform color in the finished products. This machine can cast 2kg of metal raw material in a single operation and is suitable for jewelry production, semiconductor manufacturing, solder production, and other industries.

- Industry: Jewelry Casting, Precious Metal Processing, University Laboratories, and related fields.

- Metals: Gold, K Gold, Silver, Copper, and their alloys.

| Model number | SPB-HVLS | SPB-HLS |

| Power source | 380V | Single phase 220V, 50/60Hz |

| Power | 15 kw | 15kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 5minutes | 5minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 2100*1250*1950mm | 900*1150*2000mm |

| Weight | 680kg | 220 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

- High vacuum (6.67×10-4pa), high vacuum melting, high product density, low oxygen content, no pores, suitable for the production of high-quality bonding wire.

- Anti-oxidation, inert gas protection during refining to solve the problem of alloy oxidation.

- Uniform fineness, electromagnetic and physical stirring methods make the alloy more uniformly colored.

- Smooth surface of the finished product, using a bottom-pulling design, the traction wheel undergoes special treatment, resulting in a flat and undamaged finished product with a smooth surface.

- Precise temperature control ±1℃, using imported temperature control meters, intelligent PID temperature control system, temperature difference ±1℃.

- 7-inch full-color touch screen, more convenient for observation/touch, new system, concise UI interface, easy operation with a single touch.

- Multiple protections, multiple safety protections, worry-free use.

Why SuperbMelt Vacuum Continuous Casting Machine

Any Question About SuperbMelt Vacuum Continuous Casting Machine

Any Question About SuperbMelt Vacuum Continuous Casting Machine

FAQ Guide of Vacuum Continuous Casting Machine

- 1. What is the continuous casting technique?

- What is a Vacuum Continuous Casting Machine?

- 3. Which metals can be cast using the Vacuum Continuous Casting Machine?

- 4. How does the high vacuum feature benefit the casting process?

- 5. What role does inert gas play in the casting process?

- 6. How is the alloy's fineness ensured in the casting process?

- 7. What is the significance of the bottom-pulling design in surface quality?

- 8. How precise is the temperature control of the Vacuum Continuous Casting Machine?

- 9. What is the role of the 7-inch full-color touch screen in operation?

- 10. In which industries is the Vacuum Continuous Casting Machine commonly used?

- 11. What safety features does the Vacuum Continuous Casting Machine offer?

1. What is the continuous casting technique?

Continuous casting is a manufacturing process used in the metal industry to produce long, continuous lengths of metal with a consistent cross-section. This technique is commonly employed for metals such as steel, aluminum, copper, and other alloys. Here’s an overview of the continuous casting technique:

Mold Filling:

The process begins with the molten metal being poured into a water-cooled mold. The mold is typically made of copper and has the desired cross-sectional shape of the final product.

Solidification:

As the molten metal passes through the mold, it begins to solidify and take the shape of the mold. The outer layer of the metal comes into contact with the cooled mold, forming a solid skin.

Withdrawal from Mold:

The partially solidified metal is continuously withdrawn from the mold. The withdrawal speed is carefully controlled to allow for proper solidification and prevent defects.

Secondary Cooling:

After leaving the mold, the metal continues to cool through a secondary cooling process. This is often achieved using water sprays or other cooling methods to control the temperature gradient and ensure uniform solidification.

Cutting and Coiling:

Once the metal has solidified sufficiently, it is cut into desired lengths or coiled for further processing. Continuous casting can produce long lengths of metal, minimizing the need for subsequent joining processes.

Continuous casting offers several advantages, including:

Cost Efficiency: It eliminates the need for multiple casting and rolling processes, reducing labor and energy costs.

Improved Quality: The continuous process leads to a more uniform and refined microstructure, resulting in improved mechanical properties of the final product.

Reduced Waste: Continuous casting minimizes material waste compared to traditional casting methods, where excess material is often discarded.

Versatility: It is suitable for various metals and alloys, making it a versatile technique in the production of a wide range of products.

Continuous casting is widely used in the production of various metal products, including billets, slabs, blooms, and other semi-finished goods, which can then be further processed into finished products.

2. What is a Vacuum Continuous Casting Machine?

A Vacuum Continuous Casting Machine is a specialized equipment used for casting metals in a continuous process under high vacuum conditions.

3. Which metals can be cast using the Vacuum Continuous Casting Machine?

The machine is designed to cast a variety of metals, including gold, silver, copper, and their alloys like K gold.

4. How does the high vacuum feature benefit the casting process?

The high vacuum (6.67×10-4pa) helps achieve high product density, low oxygen content, and pore-free castings, ideal for producing high-quality bonded wire.

5. What role does inert gas play in the casting process?

Inert gas protection during refining prevents oxidation issues commonly associated with alloy processing.

6. How is the alloy's fineness ensured in the casting process?

The machine employs electromagnetic and physical stirring methods, ensuring a uniform fineness throughout the cast alloy.

7. What is the significance of the bottom-pulling design in surface quality?

The bottom-pulling design, along with specially treated traction wheels, results in a smooth surface on the finished product with no damage.

8. How precise is the temperature control of the Vacuum Continuous Casting Machine?

The machine maintains precise temperature control with an accuracy of ±1℃, using an imported temperature control meter and an intelligent PID temperature control system.

9. What is the role of the 7-inch full-color touch screen in operation?

The 7-inch full-color touch screen provides a convenient interface for observation and operation, featuring a new system and a user-friendly UI.

10. In which industries is the Vacuum Continuous Casting Machine commonly used?

This machine finds application in industries such as jewelry casting, precious metal processing, and university laboratories.

11. What safety features does the Vacuum Continuous Casting Machine offer?

The machine incorporates multiple safety protections, ensuring worry-free and secure operation in various casting processes.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited