8K Resin 3D Printer

SuperbMelt Small LCD 8K Resin 3D Printer Supplier

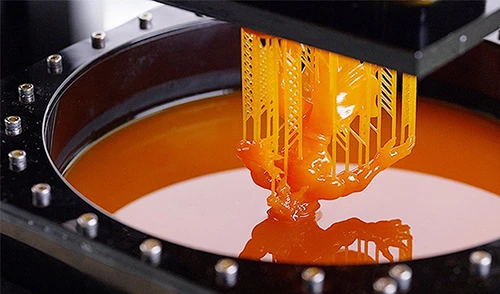

SuperbMelt 8K resin 3D printer offers higher resolution and precision, making it widely applicable in jewelry, artwork, medical devices, and model making industries. It can print extremely intricate and delicate structures, capturing even the smallest details and curves.

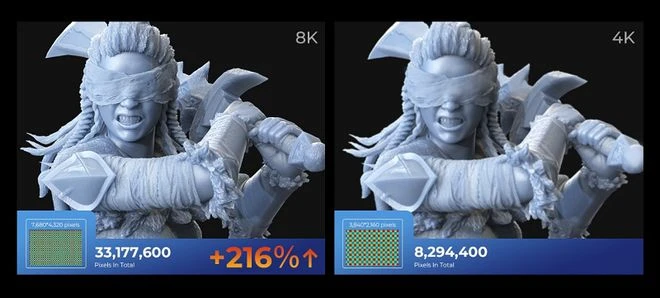

Compared to 4K 3D printers, the SuperbMelt 8K resin printer provides finer details, especially for jewelry applications. It allows jewelry designers and manufacturers to create highly precise and complex designs with exceptional accuracy.

For those seeking top-notch resolution and fine detail reproduction in 3D printing, the SuperbMelt 8K resin 3D printer is an excellent choice, particularly in the jewelry industry.

| Model | SPB-LCD228 |

| Supported | 405nm resin(8k) |

| X/Y/Z | X Y axis 0.075mm, Z axis 0.02mm |

| Printing speed | max 20mm/h (Z axis) |

| Machine size | L570*W355*H450mm |

| Format size | L228*W128*H230mm |

| Show | 8k LCD monochrome screen |

| Function | Automatic add resin function |

High Resolution

The 8K resin 3D printer can achieve a very high resolution, displaying fine, realistic details and curves.

Precision Printing

The printer possesses high-precision printing capabilities, allowing for the production of accurate models and parts.

Printing Complex Structures

The 8K resin 3D printer is suitable for printing complex structures, enabling the realization of more challenging design requirements.

Reproduction of Minute Details

The printer is capable of reproducing tiny details and curves, resulting in more realistic and lifelike prints.

Wide-ranging Applications

The 8K resin 3D printer finds extensive application across various fields, especially in jewelry, art, medical devices, and model making.

Specialization in Jewelry

This printer is focused on jewelry manufacturing and meets the jewelry industry’s requirements for model precision and quality.

High-Quality Printing

By using high-quality resin materials and light curing technology, the 8K resin 3D printer achieves excellent print quality.

Efficiency

Despite its high resolution, the printer can complete print tasks within relatively short timeframes.

SuperbMelt 8 resin 3D printer belongs to the desktop style category and is highly suitable for small-scale jewelry manufacturers. It is not only affordable in terms of price but also capable of producing jewelry molds with high precision and quality.

Why SuperbMelt 8K Resin Printer

Any Question About SuperbMelt Mini Gold Melting Furnace

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Here's What Our Satisfied Customers Have to Say

More SuperbMelt 3D Jewelry Printers For You To Choose

FAQ Guide of 8K Resin 3D Printer

No, 8K resin was created particularly for 8K printers. Due to the resolution and printing capabilities of the two printers being different, it is incompatible with 4K printers.

Usually, when people talk of 8K resin resolution, they’re talking about the vertical resolution, which is 7680 pixels. Depending on the particular setup and equipment, the horizontal resolution might change.

One kind of 3D printer that makes use of LCD (Liquid Crystal Display) technology is the LCD resin 3D printer. It controls the passage of light by using an LCD screen as a photomask, enabling the curing of resin material. This kind of printer is renowned for its low cost and quick printing capabilities. It is appropriate for printing models and components with a modest need for accuracy.

- Light source: LCD resin printers regulate light transmission by using a liquid crystal screen as a photomask. Typically, UV LEDs serve as the light source.

- Printing Speed: LCD resin printers typically print pages quickly.

- Resolution: The resolution of LCD resin printers is often lower.

- Cost: Compared to laser resin printers, LCD resin printers are often less expensive.

- LCD resin printers often have a wider print area, enabling for prints of greater sizes.

- Resin laser printers:

- Light source: Laser resin printers selectively cure the resin substance using a laser beam.

- Print speed: Laser resin printers often print pages more slowly.

- Laser resin printers often have a better resolution, enabling the production of prints with greater detail.

- Cost: Compared to LCD resin printers, laser resin printers are often more costly.

- Precision and accuracy: Laser resin printers are renowned for these qualities.

In general, it depends on the type of resin that is employed and the unique qualities of the PLA filament. Although resin 3D printing may produce extremely elaborate and detailed designs, it is not always more durable than PLA.PLA is renowned for its longevity and capacity to offer strong structural support. However, durable items can also be printed using resins that are intended for strength and impact resistance. In the end, the strength of the printed item will rely on elements including the qualities of the material, the print configuration, and design considerations.

The light-curing 3D printer, which employs light curing (SLA) and digital light processing (DLP), is one of the highest resolution 3D printers currently on the market. These printers can produce images with extremely fine details, frequently at the level of tens or even hundreds of micrometres (m).

A resin printer is a 3D printer that works with resin materials that cure under light. It employs layer-by-layer construction of structures by irradiating and solidifying liquid resin with a light source (often a UV LED or laser). By exposing the liquid resin to a light source that cures it into a solid state, resin printers construct the required 3D prints piece by piece. Resin printers are used in a variety of applications, including jewellery, artwork, medical equipment, and model construction. They may produce prints that are exceedingly precise and intricate.

SuperbMelt 8K Resin Printer Guide

4k vs 8k Resin Printe

The 8K resin printer offers a higher resolution, resulting in superior jewelry quality and finer details. It can showcase more intricate details and smoother curves compared to a 4K printer. The 4K printer, on the other hand, may exhibit fewer details and show some rougher features in comparison.

1.1, SuperbMelt 8k resin 3d printer

SuperbMelt 8K resin 3D printer is a compact desktop-style printer. Here are the features of the SuperbMelt printer

- LCD display

- Small,Mini

- 8K Resolution

- Stable and fast printing

- Efficient purification,Natural breathing,Purify odor Green

- No calibration neededIt can be printed directly

- Automatic feeding device Uninterrupted operation

1.2, The application areas of the 8K resin printer

Jewellery Manufacturing: The jewellery industry makes extensive use of 8K resin printers. It can print intricate, accurate jewellery designs and models that match the high standards set by jewellery producers.

Art Production: 8K resin printers have significant uses in the industry of art production. Its high resolution and detail presentation capabilities may be used by designers and artists to produce one-of-a-kind sculptures and works of art.

Medical gadgets: Medical models and gadgets may be produced with 8K resin printers in the healthcare sector. To assist physicians and medical researchers with surgical simulations, training, and teaching, it may print precise medical models.

Industrial Design and Manufacturing:8K resin printers are crucial tools in the fields of industrial design and production. It can create intricate, high-quality product prototypes and parts that assist designers and manufacturers in rapidly validating and iterating their designs.

Jewelry made by the 8K resin printer

Whether it is for producing jewelry or jewelry wax molds, the 8K resin printer delivers exceptionally high-quality results. It is capable of producing more intricate jewelry designs compared to a 4K resin printer.

2.1, What materials are used to make jewelry?

It uses a special resin material and creates objects by a layer-by-layer solidification process. It utilizes a light source, typically UV LED or laser, to irradiate and cure liquid resin material. During the printing process, the light source scans and solidifies the resin layer by layer, gradually building the entire structure of the object from the bottom up.

2.2, The advantages of an 8K 3D printer

The advantages of an 8K 3D printer over a 4K printer include higher resolution, accuracy, detail reproduction, printing of complex structures, and applications in various fields.

Why is it necessary to make jewelry:Small 8k Resin 3D Printer

great Level of Detail and accuracy Required: Making jewellery demands a great degree of detail and accuracy. Due to their increased resolution and precision, 8K 3D resin printers can produce finer, more lifelike jewellery models.

complicated Design Requirements: Some jewellery designs are extremely complicated and can only be realised with cutting-edge printing technology. In order to accommodate the demands of these intricate designs, 8K 3D resin printers can handle more complicated structures and features.

Rapid prototyping: 8K 3D resin printers are able to swiftly create jewellery prototypes, assisting designers in validating and modifying ideas more quickly, accelerating product development and time to market.

original and Personalised Designs: Jewellery makers may produce more original and individualised designs to create one-of-a-kind jewellery items by employing 8K 3D resin printers.

Conclusion

The 8K 3D resin printer plays a crucial role in the jewelry-making process, providing high precision, support for complex designs, rapid prototyping, and the ability for innovative and personalized designs.

SuperbMelt offers a variety of styles of jewelry 3D printers, including resin, wax, and options for both large and small sizes.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited