3D Printers for Jewelry Manufacturing

Top Manufacturer in China

- Used for Jewelry Direct Casting, Prototyping and Rubber Molds

- Designed for Jewelry Manufacturers, Designers and Retailers

- With Budget, Affordable, and Professional Price

- Materials with Castable Wax, Castable Resin, or Uncastable Wax According to Different Customer's Demand

- LCD or DLP Technology

Our 3D Printers for Jewelry Making and Casting

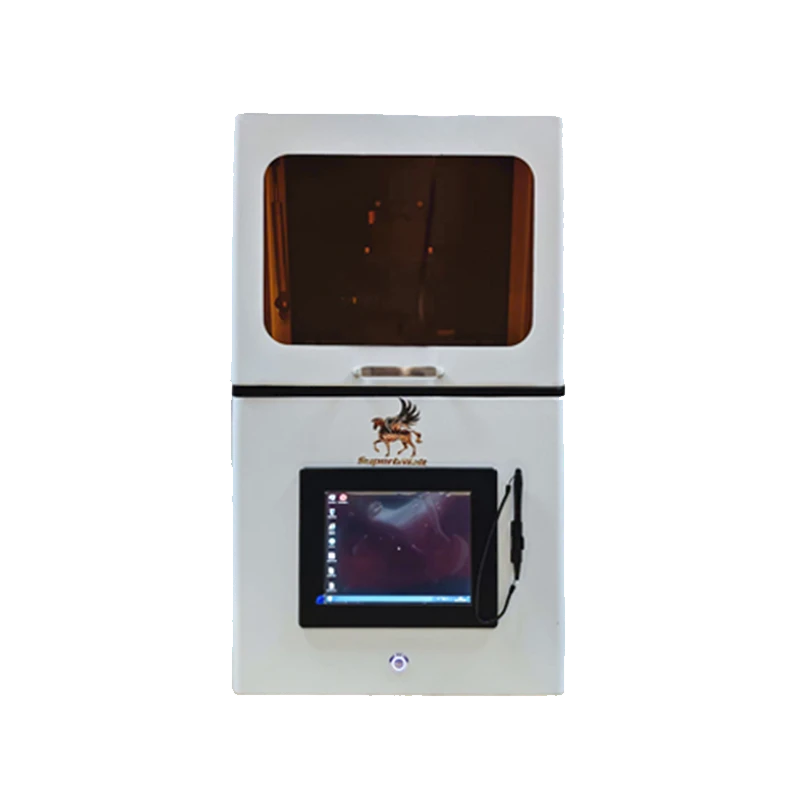

Jewelry Wax 3D Printer

50% white wax high performance and easy casting

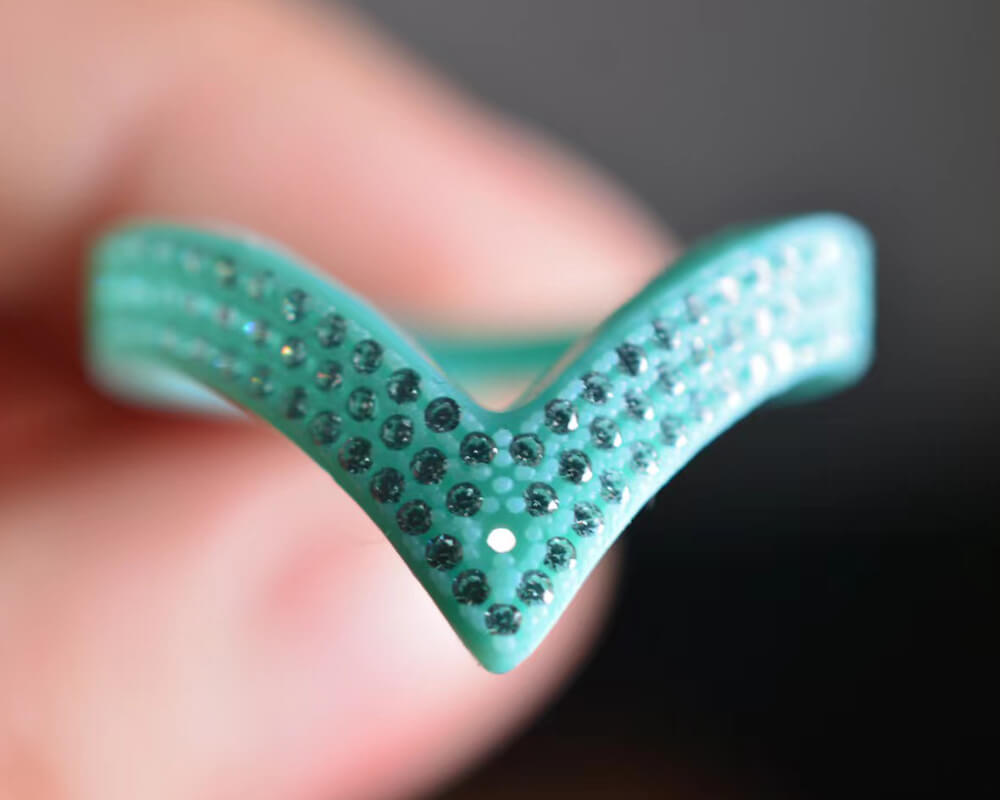

- High precision and ultra-precise, makes excellent casting performance.

- The wax 3D printer machine provides an independent oxygen supply system, and aerobic printing is more than 2 times faster than traditional printing.

- The propped up part of the printing mold is reduced by two-thirds, and the cost is greatly reduced due to the small loss.

- Can make complex wax models that are directly castable.

- High wax content so easy casting, clean burnout and superior surface finish.

Jewelry Resin 3D Printer

Cost-effective resin high precision for casting, prototyping and rubber molds

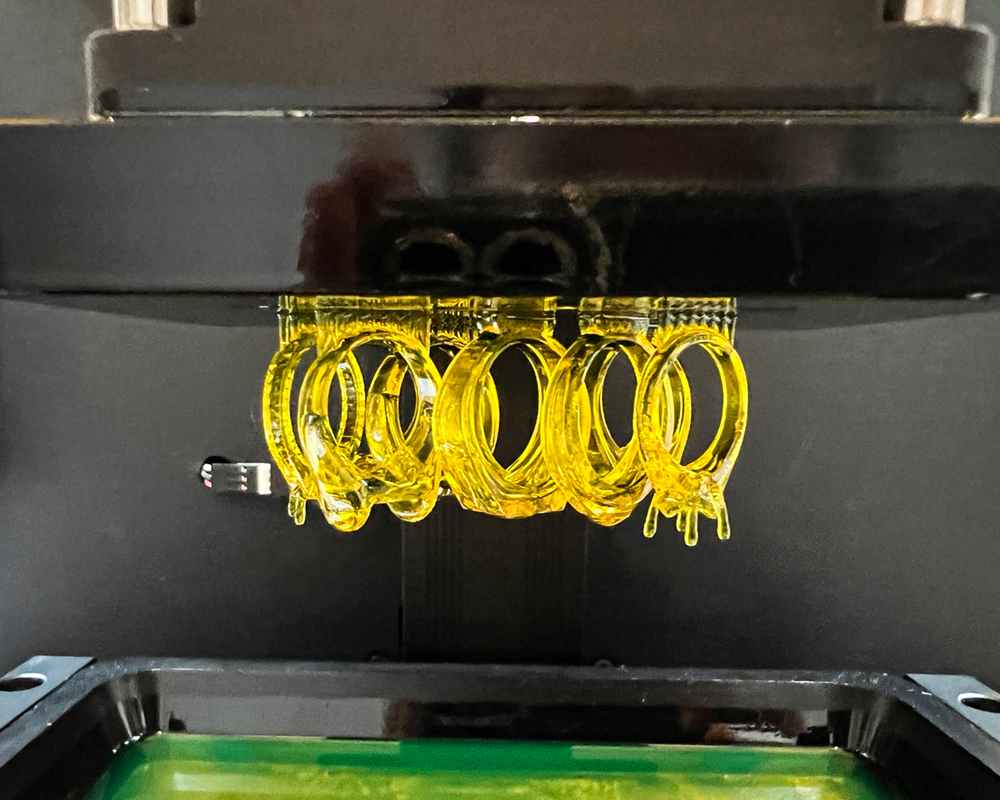

- Simplified Workflow, casting trees can be done faster and easier with a 3Dresin printer than with traditional manual assembly.

- Cut cost, High-automation printing reduces the output of human resources, thereby reducing labor costs.

- Intricate design. Photopolymers are loaded into printers in liquid form, so they are easier to shape into complex geometries than molten plastic.

- High speed and efficiency, compared to other prototyping methods, resin printing is much faster and can print more than ten designs at a time, thus speed up and improving production efficiency.

- Smooth finish, layer lines still exist in resin printing, but they are so small that are barely visible on some colors of resin. It has consistent prints with high surface quality, so it is more cost-effective.

Jewelry Resin 3D Printer

Cost-effective resin high precision for casting, prototyping and rubber molds

- Simplified Workflow, casting trees can be done faster and easier with a 3Dresin printer than with traditional manual assembly.

- Cut cost, High-automation printing reduces the output of human resources, thereby reducing labor costs.

- Intricate design. Photopolymers are loaded into printers in liquid form, so they are easier to shape into complex geometries than molten plastic.

- High speed and efficiency, compared to other prototyping methods, resin printing is much faster and can print more than ten designs at a time, thus speed up and improving production efficiency.

- Smooth finish, layer lines still exist in resin printing, but they are so small that are barely visible on some colors of resin. It has consistent prints with high surface quality, so it is more cost-effective.

8K Resin 3D Printer

A high-resolution 3D printer, which offers clearer output than a 4K printer, creates highly detailed and precise objects.

- High Resolution: Perfect for applications requiring high precision, such as jewelry making, dental models, and miniatures.

- Superior Print Quality:Produces sharp edges and fine details, reducing the need for post-processing.

- Advanced Technology: Utilizes LCD or DLP technology for curing resin, with the 8K resolution ensuring high fidelity to digital models.

- An 8K resin 3D printer is a high-resolution 3D printer that offers significantly greater clarity and detail compared to a 4K printer.

The Advantages of SuperbMelt Jewelry 3D Printers

High Resolution

3D printers based on DLP technology can image through millions or even tens of millions of tiny and high-precision pixels,so the printing resolution is high that can achieve extremely fine details.

You can refer to the following data: the pixel size of laser stereolithography equipment is close to 100μm, the width of our hair is 100μm, and the pixel size of DLP technology printer is 15μm.It can be seen that dlp can achieve very high accuracy.

Compared to other 3D printing methods, DLP printers print at a much higher resolution and have a smoother finished surface, resulting in a more satisfying overall print. In addition to the propped up part, there is almost no need for grinding, and the subsequent processing work is also less.

Fast Printing Speed

The working process of traditional 3D printers is from point to line, and then from line to surface, to complete the construction of specific shapes and images layer by layer.

Compared to DLP 3D printers, the printing speed is slow. The working process of DLP 3D printers is to project and polymerize a whole layer.

With the help of light shining on the material, the whole layer is formed at one time, which can significantly improve the printing speed in less production time.Can reach 15-28mm/hour so super fast.

Material Complexity

The wide use of 3D printer technology is inseparable from the materials it uses, including photosensitive resins, ceramic resins, castable wax materials, etc.

The development of these materials has made 3D printing technology more widely used in jewelry, dentistry and other industries.

Customization

The printed models will be archived in cad files, so it will be very flexible for post-processing, even if the wearer is not satisfied with the design, it can be easily changed and re-customized.

Mass Production

Highly automated printing and rapid prototyping can reduce time costs,also it can print more than 10 design models at one time then scaled-up jewelry production and provide more possibilities for mass production in the jewelry industry.

Reproduction

When used in conjunction with a 3D scanner, it can achieve rapid reproduction of existing jewellery pieces and saving design time and costs.

First use the 3D scanner to scan the existing work and save it as a cad file, and then use the 3D printer to print the document to achieve easy reproduction.

Cost-Efficiency

The printable materials for jewelry are relatively limited, and although the wax material is expensive, it has the best effect and the most cost-effective among the limited materials. It can reduce many processing steps in the later stage.

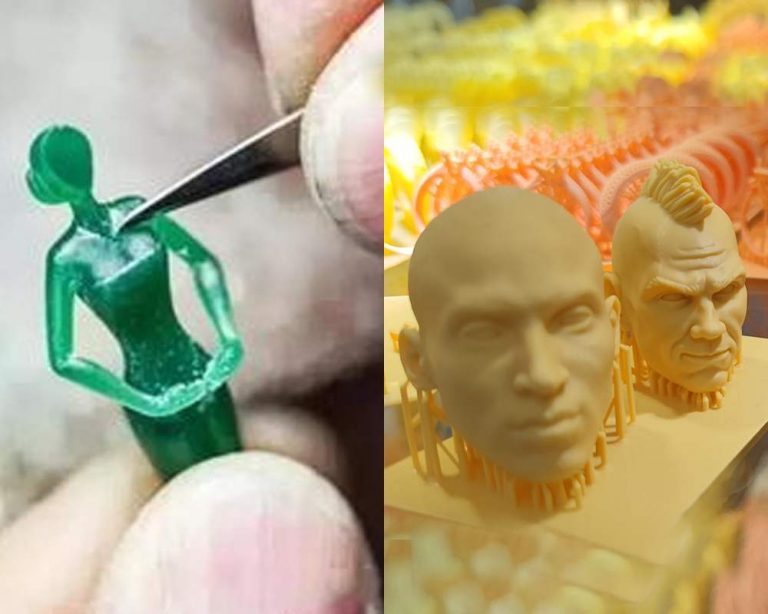

Quick Prototypes

When jewelry needs to be inlaid with gemstones, you can try it on the 3D printing model. The 3D model is clearer than the 2D image, which can ensure the perfect fit of the final cast product, thereby winning the recognition of customers.

Long Service Life

Compared to the other two SLA/LCD printers, the overall lifespan of DLP printers is very long. The service life mentioned here mainly refers to two aspects, one is the scrapping period of core optical devices, and the other refers to the near scrapping period that is basically difficult to use stably.

SuperbMelt DLP printers use custom optical machines, with an average stable working life of more than 20,000 hours, and support for long-term continuous use.

What Technologies Are Used in SuperbMelt Jewelry 3D Printers

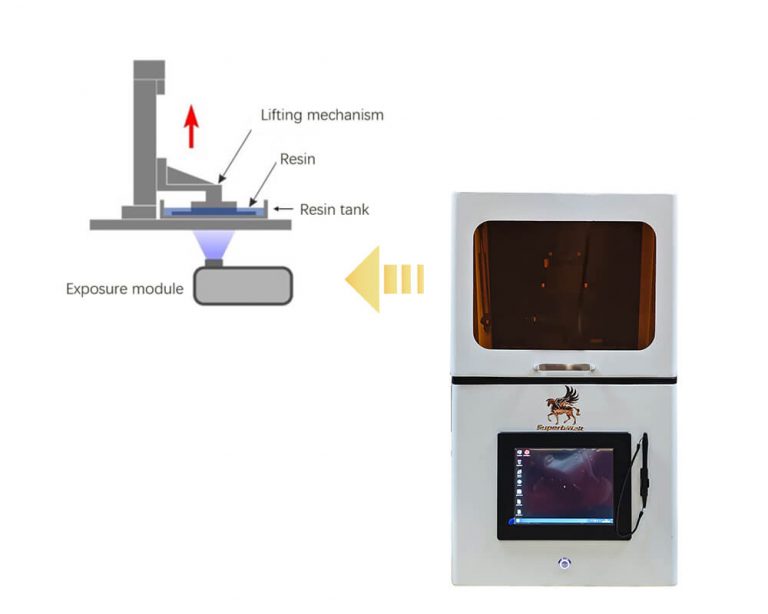

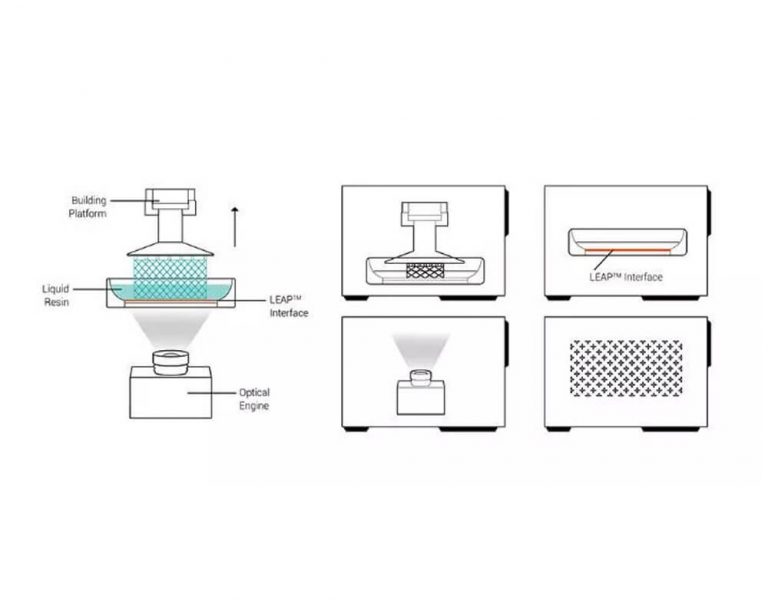

SLA & DLP

SLA technology is Stereo lithography Appearance, which uses a laser to focus on the surface of the light-cured material, so that it solidifies sequentially from point to line, from line to surface, and repeats itself, so that layers are superimposed to form a three-dimensional entity. is a technique of laser drawing layers.

DLP technology is Digital Light Processing, which mainly uses a projector to solidify photopolymer liquid layer by layer to create 3D printed objects. It is a projection drawing layer technology.

Due to the different technical principles, it is easy to understand the reason why DLP is much faster than SLA. SLA technology is formed from dots to lines, lines are formed into surfaces, and then the next layer of printing is performed, while DLP technology instantly forms surfaces, and then prints the next layer. Floor.

Under the same printing volume (DLP full-width printing) and the same quality printing state, after testing, DLP single printing is about 10 times faster than SLA.

Light Curing Technology

Light curing technology has gone through three stages of development SLA laser scanning and DLP digital projection, as well as new LCD light sources. The difference between the three is simply that the characteristics of light curing technology are different.

The core of each light curing technology is the solution to the problem of light source, from SLA of laser scanning, to DLP of digital projection, to the latest LCD printing technology.

Software

3D printing is a digital manufacturing method. In the 3D printing industry chain, 3D software is a very critical part. 3D software is inseparable from the acquisition of 3D data models, the processing of 3D data models, or the control of 3D printers.

ZBrush software is often used in digital sculpture, painting software, 3D design and other fields.

It revolutionized the entire 3D industry with its powerful features and intuitive workflow. In a clean interface, ZBrush provides the world’s most advanced tools for contemporary digital artists.

The combination of functions developed with practical ideas not only stimulates the creativity of artists, but at the same time, ZBrush produces a user experience that is very smooth when operating.

Rhino, as the most commonly used 3D modeling software, is a NUBRS surface modeling software. It has a wide range of usage, and there are many tutorials, and it is very convenient for self-study to get started.

Rhino’s modeling ideas are very free. It is a modeling software that has advantages in curve modeling and is easy to use. It has advantages in rapid expression.

Freefrom software is characterized by an intuitive human-computer interaction mode. It can perform engraving operations with force feedback on the model in the computer through human-computer interaction equipment.

It has an advantage in the manufacturing industry, mainly in the design of parting and high-precision operation. industries, such as the jewelry industry, and metal products that require mold opening, including the manufacturing of precious metal products.

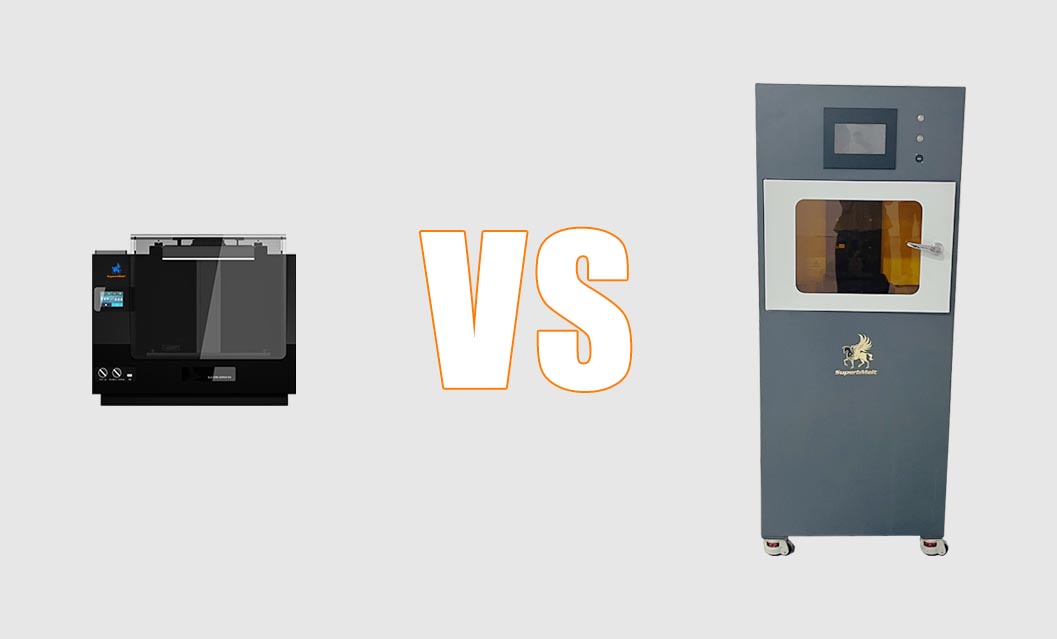

Jewelry Wax 3D Printer VS Jewelry Resin 3D Printer

The most direct difference between white wax and resin 3D printers is that the mechanical structure and working principle are different. The white wax 3D printer needs a special oxygen-permeable release film.

Accurate in Handling the Ttiniest and Sharpest Details

SuperbMelt jewelry 3D printing machine adopts high-precision imported UV light machine from Texas Instruments, and its precision can reach ultra-high printing accuracy of 20-50μm.

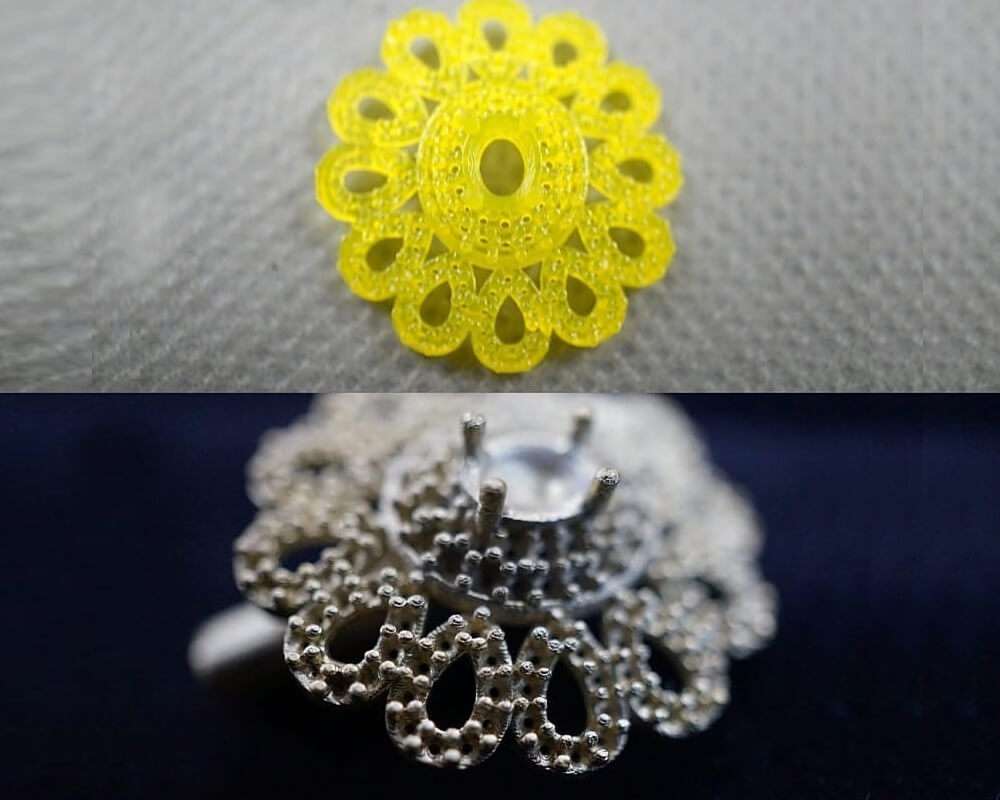

The Required Attributes for Lost Wax Casting

Lost wax casting is one of the most commonly used methods in the precious metal jewelry processing industry around the world. This method is now widely used in the casting process of gold, silver, platinum precious metals and non-ferrous alloys. It is characterized by many varieties, beautiful and exquisite appearance,mass production.

How Many Copies of Your Model Do You Plan to Print

The 3D jewelry Printer can save a lot of time and labor for jewelry customization. You only need to design the drawings and convert them into digital models. It only takes about ten minutes to print out the designed jewelry.And each time you can print at least 10 designs.After the later processing, a beautiful , One-of-a-kind jewelry was born.

8k 3D Printer VS 4K 3D Printer

An 8K printer has a much higher resolution than a 4K printer. It has about 7680 x 4320 pixels on the screen, which means it can create objects with finer details and smoother surfaces. This results in higher precision and more intricate designs.

Surface Finish

8K 3D Printer:Produces a smoother surface finish, reducing the need for post-processing work like sanding or polishing.

4K 3D Printer: Might require more post-processing to achieve a smooth surface finish, especially for highly detailed objects.

Cost and Application

8K 3D Printer: Generally more expensive and used in applications where ultra-high detail is essential.

4K 3D Printer: More affordable and suitable for a broader range of applications where extreme detail is less critical.

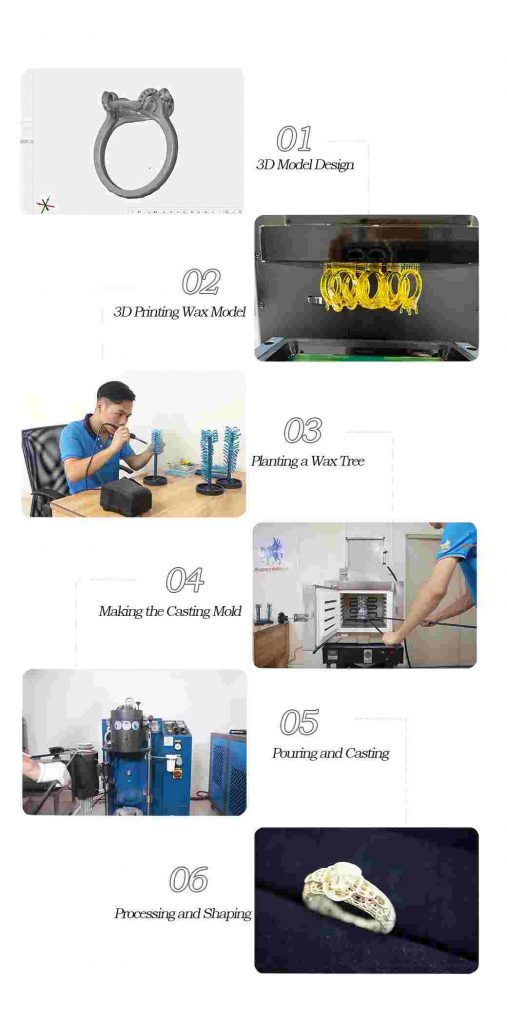

The Workflow of SuperbMelt Jewelry 3D Printer

Step 1: 3D Model Design

Users can design a unique and ideal creative jewelry patterns through 3D modeling software, and finally generate three-dimensional renderings.

If it is an existing design work, you can use a 3D scanner to make it a CAD digital effect and present it on the computer.

Step 2: 3D Printing Wax Mode

Jewelry is usually made of precious metal, and the lost wax casting process is still used at present, and the most critical wax model is made by 3D printing technology.

The jewelry industry usually uses DLP light-curing 3D printers. Light-curing is the most accurate 3D printing technology at present.

Using special liquid photosensitive resin wax consumables, a perfect wax model can be made with an accuracy of micron level, which can be perfectly restored and design.

Step 3: Planting a Wax Tree

The 3D printed wax model needs to cut off the excess support lines, and then use isopropyl alcohol to shake and clean it.

After removing the residual resin, the tree can be started. When planting trees, follow the principle of light and thin pieces on top and heavy pieces on the bottom.

Use a soldering iron to melt one end of the wax strip to stick to the ring, and the other end to melt and stick to the main wax strip.

Step 4: Making the Casting Mold

a.Preparation of Gypsum Slurry:

Jewelry manufacturing generally uses gypsum molds;

b. Grouting:

Place the wax tree in the center vertically into a special cup, and pour the prepared gypsum slurry into the mixer in a vacuum.

c. Dewaxing by Calcination:

The wax model can also be volatilized during casting, but due to the precise and complex texture of the jewelry, it is necessary to remove it before casting, and it also enhances the performance of the plaster model.

Step 5: Pouring and Casting

After melting and vacuuming the previously calculated amount of metal, use a medium frequency pouring machine to pressurize and inject it into the plaster mold, take it out and let it cool for 5 to 10 minutes, and then take out the casting after it is completely cooled in water.

Step 6: Processing and Shaping

Cut the ring from the trunk, and after grinding, polishing, and diamond setting, a ring designed by yourself is done.

Jewelry 3D Printers FAQ guide

- Why Are Your Price is Expensive? What Is the Difference?

- What Is the Smallest Wire Diameter a 3D Printer Can Print?

- Are All Resins Suitable for Casting?

- How Long Does it Take to Print?

- Can the Materials of Resin and Wax Printers be Universal?

- What Software is Available?

- How Long Is the Life of The Machine?Can it Work Continuously?

- How Many Design Can be Printed at One Time?

Why Are Your Price is Expensive? What Is the Difference?

Compared to other suppliers using LCD technology, our printers use DLP technology for better performance and greater accuracy.And we are using a UV light source.

DLP has high contrast, rich details, better text effect and longer service life.

Are All Resins Suitable for Casting?

There are two types of resins: directly castable and non-castable. If you need a finished resin to cast jewelry, you must choose a castable resin.

How Long Does it Take to Print?

15-28mm/hour, printing time will be different for different materials.

Can the Materials of Resin and Wax Printers be Universal?

In addition to the white wax 3D printer, other materials can be used in general, just need to match the corresponding parameters on the software.

However, the mechanical structure and working principle of wax printers are different from resin printers. resin printers must have a special oxygen-permeable release film to use wax materials.

What Software is Available?

General 3D software design files can be used, but some are for industrial use.

The most commonly used in the jewelry industry are these Rhino, ZBrush, Freeform, etc.

How Long Is the Life of The Machine?Can it Work Continuously?

The UV LED light source has a service life of 20,000 hours and can work continuously.

How Many Design Can be Printed at One Time?

Mainly determined by print size, up to 15-20 designs.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited