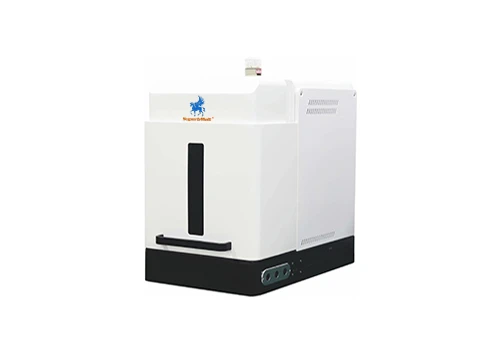

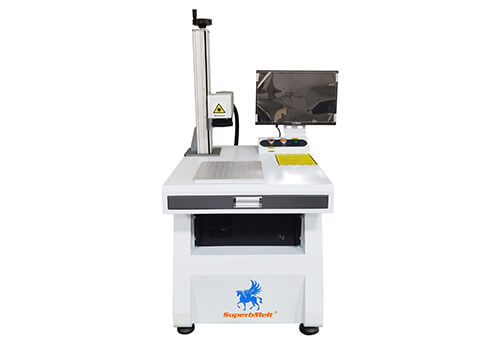

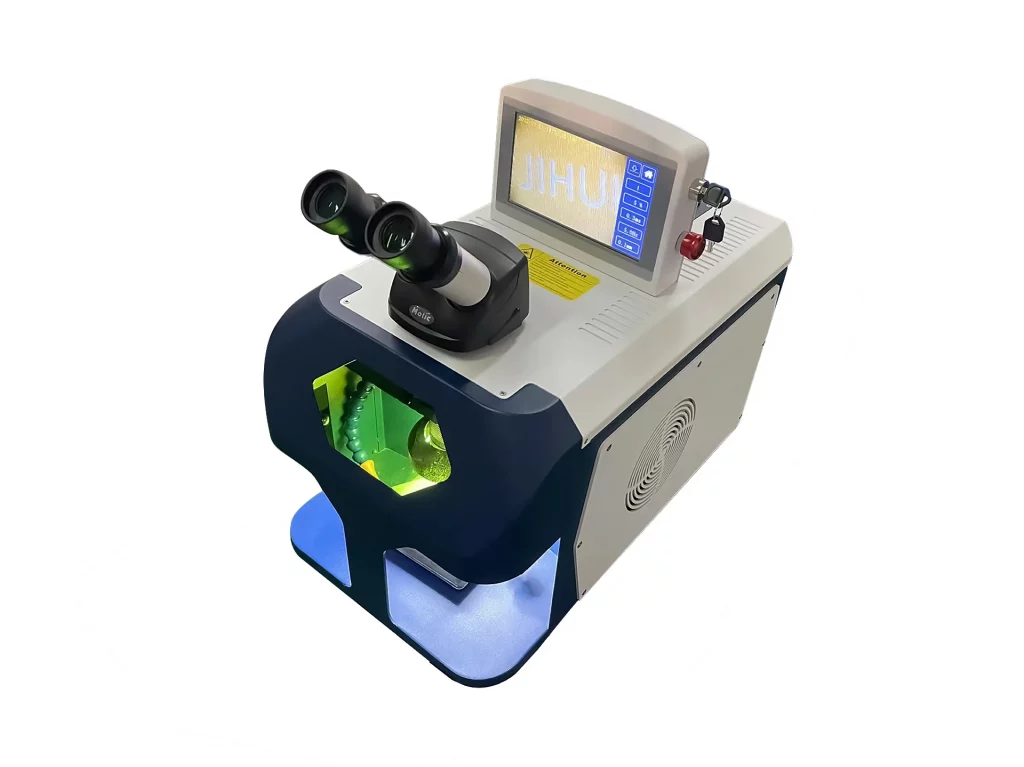

20W Fiber Laser Engraver

SuperbMelt 20w fiber laser marker is suitable for engraving metal jewelry of any material

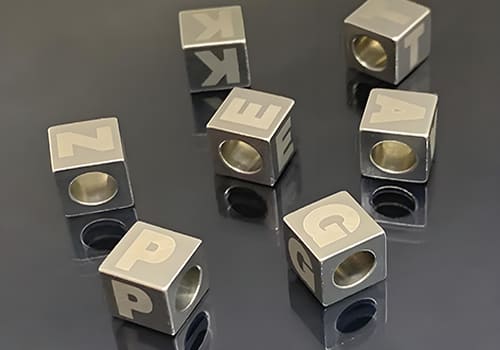

SuperbMelt 20W fiber laser engraver is a laser engraving machine tailored for the intricate world of precious metal jewelry. It’s capable of engraving jewelry of any shape, from bracelets and necklaces to rings and more, making it an essential tool for achieving large-scale production and streamlining manufacturing processes.

The 20W laser engraving machine delivers lasting marks and engravings, ensuring the enduring quality of the products. Thanks to its exceptional precision, it’s perfect for crafting intricate details and complex designs, making it the go-to choice for the jewelry industry.

Moreover, it finds extensive application in the crafts, giftware, and manufacturing sectors, allowing for the engraving of various materials, including metals, wood, plastic, leather, stone, and beyond.

| Model Number | SPB-MFLM |

| Average Output Power | 20W/30W/50W |

| Beam Quality | M²:1.5(TEMOO mode) |

| Repeatability | 0.01mm |

| Max Line Speed | 12000mm/s |

| Min Line Width | 0.017mm |

| Power Adjustment Range | 1%-100% |

| Laser Wavelength | 1064nm |

| Total Power | ≤500W |

| Marking Range | 110mm*110mm/175mm*175mm |

| Cooling System | Air Cooled |

| Laser Repetition Rate | 20KHz-80KHz(Adjustable) |

| Equipment Working Environment | Clean or Less Dusty |

| Min Character | 0.2mm*0.2mm |

| Equipment Operating Temperature | 13℃-28℃ |

| Marking Depth | 0.01mm-1mm(Determined by material) |

| Power Requirements | AC220V/50Hz/2A |

The features and advantages of the SuperbMelt 20W fiber laser marker are as follows:

- Versatility: This machine is highly versatile and can engrave a wide range of materials, including various metals (e.g., gold, silver), wood, plastic, leather, and stone. It’s perfect for jewelry but also suitable for other applications.

- High Precision: The 20W laser ensures extremely high precision, making it capable of engraving intricate details and complex patterns with exceptional accuracy. This is crucial for jewelry engraving and other fine work.

- Durable Engravings: The marks and engravings created with this machine are long-lasting and resistant to fading or wear over time. This durability ensures the quality of the products remains high.

- Large-Scale Production: SuperbMelt’s laser marker facilitates large-scale production. Its efficiency and automation features streamline the manufacturing process, saving time and labor costs.

- Ideal for Jewelry: Specifically designed for jewelry, this machine is an excellent choice for engraving a wide range of jewelry items, including bracelets, necklaces, rings, and more.

- Wide Application: While perfect for the jewelry industry, it also serves other sectors like crafting, giftware, and manufacturing. It can handle various materials, expanding its utility.

- Ease of Use: SuperbMelt’s laser marker is user-friendly and can be operated with relative ease. This makes it accessible to both experienced jewelers and those new to the craft.

These features and advantages make the SuperbMelt 20W fiber laser marker an indispensable tool for those seeking precision and efficiency in engraving and marking various materials, particularly in the jewelry and related industries.

1. Jewelry Manufacturing

The SuperbMelt 20W fiber laser engraver is a cornerstone for the jewelry industry. It excels in engraving on precious metals, including gold, silver, and platinum, ensuring intricate designs and fine details. Whether it’s marking rings, bracelets, necklaces, or other jewelry pieces, the machine delivers precision and durability. Its capacity to handle high production volumes streamlines the manufacturing process, making it ideal for large-scale jewelry production.

2. Crafts and Giftware

In the crafts and gift industry, the engraver allows for the personalization of items like trophies, awards, and custom gifts. It works seamlessly on a variety of materials, including metals, wood, leather, and stone, enabling the creation of bespoke items with lasting engravings.

3. Industrial Applications

The 20W fiber laser engraver is also suitable for industrial use, where permanent and precise markings are essential. Applications include engraving serial numbers, logos, and other identifiers on tools, machinery parts, and equipment components.

4. Artistic Design and Prototyping

For artists and designers, this engraver supports the realization of complex and creative designs on multiple surfaces. Its precision makes it a favorite for prototyping and producing high-quality samples.

5. Multi-Material Versatility

Beyond jewelry and metals, the machine engraves effectively on materials like plastics, wood, leather, and even some types of stones, broadening its usability across industries such as furniture manufacturing, fashion, and automotive parts.

Benefits in Application

- Durable and High-Quality Markings: Ensures permanent, clear engravings.

- Enhanced Production Efficiency: Saves time and resources during manufacturing.

- Versatile Material Compatibility: Works on diverse surfaces, making it an all-purpose tool.

- User-Friendly: Offers ease of use, even for beginners.

- Eco-Friendly Process: Requires no additional consumables, reducing waste.

By leveraging the SuperbMelt 20W fiber laser engraver, industries can achieve unparalleled precision, improve workflow efficiency, and cater to customized demands effortlessly.

Why SuperbMelt 20W fiber laser engraver

Any Question About SuperbMelt 20W fiber laser engraver

About SuperbMelt 20W Fiber Laser Engraving Machine and Related Products

FAQ Guide of 20W Fiber Laser Engraver

- 1. What materials can the 20W fiber laser marker engrave on?

- 2. What can you do with a 20W fiber laser?

- 3. What is the difference between a 20W and 30w laser engraver?

- 4. What is the best wattage for laser engraving?

- 5. Can it engrave intricate designs and fine details?

- 6. Is it suitable for large-scale production?

- 7. What safety features are in place to protect users?

- 8. What kind of technical support and warranty does SuperbMelt provide?

- 9. What file formats are compatible with the 20W fiber laser marker?

- 10. How fast is the engraving process with this machine?

- 11. Is this machine suitable for permanent marking on jewelry and other products?

- 12. What maintenance is required for the 20W fiber laser marker?

- 13. Can the machine be customized for specific production needs?

- 14. Does SuperbMelt offer training for operating the machine?

- 15. Is the 20W fiber laser marker energy-efficient?

- 16. What makes SuperbMelt's 20W fiber laser marker stand out from the competition?

1. Is 20W fiber laser enough?

Whether a 20W fiber laser is sufficient depends on the specific application and materials you plan to work with. Here are some factors to consider when evaluating if 20W is enough for your needs:

1. Material Type

- Metals: For engraving precious metals like gold, silver, platinum, and even stainless steel, a 20W fiber laser is typically sufficient. Fiber lasers are particularly efficient for metal engraving due to their high absorption rate and precision. However, for very hard metals or thick materials, a higher power laser (such as 30W or 50W) might be more appropriate for faster results.

- Non-Metals: For engraving on materials like wood, plastic, leather, and acrylic, 20W is more than enough. The laser power required for these materials is generally lower than metals, so a 20W fiber laser can easily handle these applications with great precision.

2. Engraving Detail and Precision

- A 20W fiber laser provides excellent precision, making it ideal for intricate designs, detailed logos, text engraving, and fine lines. If your goal is to create small, detailed engravings on jewelry or similar items, a 20W laser will provide the high-quality results you need.

3. Speed and Efficiency

- For high-throughput production, a 20W laser offers a good balance between power and speed. It is capable of engraving at a reasonable speed while maintaining the detail needed for high-end applications. However, if you are working with large-scale projects that require rapid processing, you might want to consider a more powerful system to reduce engraving time.

4. Application Type

- Jewelry Engraving: A 20W fiber laser is ideal for engraving jewelry, as it can deliver fine details and precise markings on delicate items like rings, bracelets, and necklaces. It’s especially effective for creating personalized engravings, patterns, and logos on small pieces.

- Industrial Applications: For industrial marking, a 20W laser will generally suffice for engraving serial numbers, barcodes, or logos on components and tools. However, for larger or thicker parts that require deeper engraving, higher-powered lasers may be more appropriate.

5. Material Thickness

- While a 20W laser works well for engraving on thin to medium thickness materials, it might not be sufficient for deep engraving on thick metal parts. For deeper marks or faster processing, you may need a higher-power laser, such as 30W or 50W.

Conclusion:

For most jewelry engraving applications, personalization tasks, and medium-thickness metals, a 20W fiber laser is generally sufficient. It strikes a good balance between power and precision, offering excellent engraving quality, speed, and versatility. However, for high-speed industrial marking, or for working with thicker and tougher materials, you may want to consider a higher-powered laser to improve performance and reduce processing time.

In summary, 20W fiber lasers are ideal for high-precision, small to medium scale applications like jewelry engraving, with the capability to handle a wide variety of materials, including metals and non-metals. If your needs extend to high-volume, industrial-scale marking, or deep engraving on thick materials, you may want to explore lasers with higher power options.

2. What can you do with a 20W fiber laser?

A 20W fiber laser is a versatile tool that can be used for a wide range of applications, particularly in engraving, marking, and cutting materials with high precision. Below are some of the key things you can do with a 20W fiber laser:

1. Engraving Precious Metals

- Jewelry Engraving: You can engrave intricate designs, names, logos, and personalization on precious metals such as gold, silver, platinum, and titanium. The high precision of a 20W fiber laser makes it ideal for creating fine details on jewelry items like rings, bracelets, necklaces, and pendants.

- Monograms and Custom Text: You can engrave text or logos on jewelry or small metal objects with excellent clarity and detail.

2. Marking Metals and Industrial Parts

- Metal Marking: A 20W fiber laser is commonly used in marking applications for industrial parts and tools. You can mark serial numbers, barcodes, logos, and QR codes on metals like stainless steel, aluminum, brass, and copper.

- Permanent Marking: The markings are permanent and resistant to wear, making fiber lasers ideal for products that require long-lasting identification or tracking.

3. Cutting Thin Metals

- While cutting thick metals requires higher power lasers, a 20W fiber laser can still be used to cut thin metals (usually up to 1-2mm thick) with high precision. Common metals cut include stainless steel, aluminum, and brass.

4. Engraving Non-Metals

- Wood Engraving: You can create intricate designs, logos, or text on wood. This is perfect for personalizing gifts, awards, or decor.

- Plastic and Acrylic Engraving: Fiber lasers work well for engraving on various plastics and acrylics, offering fine detail for signage, labels, and custom designs.

- Leather and Fabric Engraving: A 20W fiber laser can be used to etch logos, patterns, or text onto leather, fabric, or synthetic materials for custom accessories, wallets, belts, and more.

- Stone Engraving: Fiber lasers can engrave on stones, including granite, marble, and ceramics, making it suitable for creating custom tombstones, plaques, or decorative stones.

5. Cutting and Engraving Glass

- Glass Engraving: You can engrave intricate designs or text onto glass, including items like wine glasses, trophies, or awards. The laser creates precise, deep engravings without damaging the surface.

6. Customizing Gifts and Awards

- Personalized Gifts: A 20W fiber laser is perfect for customizing gifts such as glassware, watches, pens, or other small accessories with logos, names, and designs.

- Trophies and Awards: You can engrave high-precision logos, text, and designs on trophies, medals, and plaques.

7. Cutting and Engraving Electronics

- PCB Marking: For the electronics industry, 20W fiber lasers are used for marking printed circuit boards (PCBs), components, and semiconductors, helping with traceability and identification.

- Battery and Component Marking: Smaller electronic components, including batteries and connectors, can be engraved with part numbers, logos, or identification codes.

8. Creating Prototypes and Samples

- Rapid Prototyping: A 20W fiber laser is ideal for creating prototypes of designs and products in small runs. It’s particularly useful for designers, engineers, or makers who need to quickly test or visualize ideas.

9. Laser Etching on Coated or Painted Surfaces

- Surface Etching: You can use a 20W fiber laser to etch on coated, anodized, or painted metal surfaces without damaging the underlying material. This is useful for adding decorative or functional markings to parts or products.

10. Cosmetic and Artistic Engraving

- Artistic Work: Fiber lasers can be used to engrave artistic designs and images on a variety of materials, adding depth and precision to artwork. This is often used in the creation of custom artworks, fashion accessories, and decorative items.

Why a 20W Fiber Laser is Popular:

- High Precision: The 20W fiber laser can achieve extremely fine details, which is especially important in applications like jewelry engraving and intricate marking.

- Durable and Long-Lasting Marks: The laser creates permanent marks that are resistant to wear and corrosion, making it ideal for industrial applications.

- Low Operating Costs: Fiber lasers are energy-efficient, and their low maintenance requirements make them a cost-effective solution in the long term.

- Versatile Application: It can be used on a variety of materials, both metals and non-metals, making it suitable for multiple industries and applications.

Conclusion:

A 20W fiber laser is a highly versatile, precise, and cost-effective tool that can be used for a wide range of engraving, marking, and cutting applications. It is ideal for small to medium-sized businesses and industries, particularly in jewelry making, personalization, metal marking, and customized production.

3.What is the difference between a 20W and 30w laser engraver?

The main difference between a 20W and 30W laser engraver lies in their power output, which significantly impacts their engraving and cutting capabilities. Here’s a breakdown of the key differences:

1. Power Output

- 20W Laser Engraver: This machine has a 20-watt laser which is suitable for engraving on softer materials like wood, acrylic, plastics, and light metals (e.g., aluminum, brass, and copper). It’s ideal for fine details and delicate designs, but its cutting ability is limited to thinner materials.

- 30W Laser Engraver: With a 30-watt laser, this machine has more power, allowing it to engrave and cut materials at a faster rate and with greater depth. It can handle thicker materials, including thicker metals (up to 3mm), and can work with harder surfaces. The higher wattage enables better engraving quality on harder metals like stainless steel and also allows for deeper etching or cutting in some materials.

2. Engraving Speed

- 20W Laser Engraver: Typically, a 20W laser is slower in engraving compared to a higher-power machine. This means for intricate designs, it will take longer to complete the engraving.

- 30W Laser Engraver: The 30W laser can engrave at a faster speed, especially for larger designs or thicker materials. This makes it more efficient for higher-volume production.

3. Cutting Capability

- 20W Laser Engraver: A 20W laser is good for cutting thin materials (up to 1mm-2mm thickness), but it will struggle with cutting through thicker materials or metals.

- 30W Laser Engraver: The 30W laser has enough power to cut thicker materials (up to 3mm-5mm) like acrylic, MDF, and some metals (e.g., stainless steel). It can also create deeper cuts or engravings on harder materials.

4. Material Compatibility

- 20W Laser Engraver: Suitable for softer materials like wood, leather, plastic, rubber, and thin metal sheets (aluminum, brass). It’s also widely used for engraving on glass, stone, and ceramics.

- 30W Laser Engraver: With its higher power, the 30W laser can handle thicker and harder materials. It’s more suitable for engraving and cutting on stainless steel, anodized aluminum, and stone. It can also engrave and cut acrylics and wood at faster rates.

5. Depth of Engraving

- 20W Laser Engraver: The depth of engraving with a 20W machine is relatively shallow compared to a 30W machine. This is perfect for intricate designs and details but may not work well for creating deeper engravings on harder materials.

- 30W Laser Engraver: With a 30W laser, the machine can engrave deeper into materials, especially metals, creating more pronounced marks and detailed engravings. This is beneficial for industrial applications and creating more durable engravings.

6. Cost and Efficiency

- 20W Laser Engraver: Lower wattage means a more affordable price point. It’s ideal for small businesses or hobbyists who don’t need to cut through thick materials but require precise and high-quality engravings.

- 30W Laser Engraver: The higher wattage means greater efficiency for large-scale production, especially when engraving and cutting thicker materials. It is more expensive but offers better versatility for a wide range of materials and thicker items.

7. Energy Consumption

- 20W Laser Engraver: Lower power consumption compared to a 30W laser. This results in lower operating costs for smaller, more precise engraving projects.

- 30W Laser Engraver: Higher energy consumption due to the increased wattage, which means it can perform more demanding tasks but also results in higher operating costs for the user.

Summary Table

| Feature | 20W Laser Engraver | 30W Laser Engraver |

|---|---|---|

| Power Output | 20 watts | 30 watts |

| Engraving Speed | Slower for detailed work | Faster, suitable for larger production |

| Cutting Capability | Can cut thin materials (up to 2mm) | Can cut thicker materials (up to 3-5mm) |

| Material Compatibility | Wood, acrylic, plastics, thin metals | Thicker metals, harder materials, acrylic, wood |

| Depth of Engraving | Shallow engraving depth | Deeper engraving depth, especially on metals |

| Cost | More affordable | More expensive |

| Energy Consumption | Lower energy consumption | Higher energy consumption |

| Ideal For | Small-scale production, intricate designs, hobbyists | Industrial applications, larger production, thicker materials |

Which One Should You Choose?

- Choose a 20W Laser Engraver if you are working with smaller, intricate projects and primarily engraving softer materials or small batches of work. It’s also better if you’re on a budget and need something energy-efficient for detailed engraving.

- Choose a 30W Laser Engraver if you plan to work with thicker materials, need faster engraving for high-volume work, or require deeper engravings. It’s ideal for industrial use and businesses that need versatile engraving and cutting capabilities.

4. What is the best wattage for laser engraving?

The best wattage for laser engraving depends on several factors, including the materials you plan to engrave, the level of detail required, and the size of the projects you’re working on. Here’s a general guideline to help you choose the best wattage for your needs:

1. Low Wattage (5W to 20W)

Best For:

- Intricate and detailed engravings on softer materials like wood, leather, acrylic, and certain plastics.

- Small-scale projects and hobbyist work.

- Personalized gifts, engraving on jewelry, and craft items.

Advantages:

- Lower power consumption, resulting in lower operating costs.

- Ideal for fine details and delicate designs.

- Affordable, making it a great choice for small businesses and hobbyists.

- Produces shallow engravings, making it perfect for fine, detailed work.

Limitations:

- Limited cutting ability, especially on thicker or harder materials.

- Not suitable for large-scale production or high-volume tasks.

Example Uses:

- Engraving on wood, leather, and thin metals.

- Personalization of jewelry, awards, and trophies.

- Small and intricate designs like logos and text.

2. Mid Wattage (30W to 50W)

Best For:

- Versatile use on a wide range of materials including wood, plastics, acrylic, leather, and metals.

- Medium to large projects, as well as cutting and engraving thicker materials.

- Commercial and semi-industrial applications where speed and versatility are important.

Advantages:

- Can cut thicker materials (up to 3mm-5mm for metals like stainless steel, brass, and copper).

- Faster engraving speed compared to low wattage lasers, improving efficiency.

- Can handle a wider variety of materials, including ceramics and glass.

- Produces medium-depth engravings, perfect for engraving metals like stainless steel and anodized aluminum.

Limitations:

- More expensive than low wattage options.

- Higher energy consumption.

Example Uses:

- Engraving and cutting thicker acrylics, MDF, or plywood.

- Cutting leather and rubber.

- Industrial applications such as creating signage, custom gifts, and larger engravings on jewelry or metal products.

3. High Wattage (60W to 150W+)

Best For:

- Industrial and large-scale commercial production.

- Cutting and engraving on very thick materials, such as metal, stone, and thick wood.

- Heavy-duty tasks like large signs, metal parts, and batch engraving in factories.

Advantages:

- Can cut through thick metals, such as stainless steel (up to 5mm-10mm or more).

- Capable of engraving and cutting harder materials like stone, ceramics, and thick glass.

- Ideal for mass production and high-throughput engraving.

- Faster cutting speeds and deeper engraving capabilities.

Limitations:

- High initial cost and operating expenses.

- Requires cooling systems due to the high power.

- May produce rougher finishes compared to lower wattage lasers on delicate materials.

Example Uses:

- Large-scale metal fabrication, cutting and engraving thick metals like stainless steel and brass.

- Industrial applications in automotive, aerospace, and construction.

- Large signage and custom artwork for businesses and commercial applications.

Choosing the Best Wattage for Your Needs

Hobbyists and Small Businesses: A 20W or 30W laser engraver is ideal for engraving and cutting smaller items like jewelry, gifts, and craft pieces. This wattage provides enough power to work with most materials without excessive power consumption.

Medium to Large-Scale Production: A 50W laser engraver offers a balance between speed and versatility. It can handle a wide range of materials, including metals, and is well-suited for engraving, cutting, and industrial applications.

Industrial Applications: If you’re cutting through thick materials (e.g., metal fabrication or large signage), a 60W to 150W+ laser will give you the cutting power and speed needed for high-volume production.

Summary of Recommended Wattage Based on Application

| Wattage | Best For | Material Compatibility | Use Case |

|---|---|---|---|

| 5W-20W | Small-scale, intricate designs, engraving | Wood, acrylic, leather, soft metals, plastics | Jewelry engraving, gifts, crafts, personal items |

| 30W-50W | Versatile, cutting and engraving on thicker materials | Wood, acrylic, plastic, leather, metals | Signage, medium-volume production, custom engraving |

| 60W-150W | Industrial production, cutting thick materials | Metals, stone, thick plastics, glass | Metal fabrication, industrial applications, large signage |

Ultimately, the best wattage for your laser engraving needs depends on the types of materials you work with and the scale of your production. Higher wattage lasers offer more versatility but come at a higher cost, so it’s essential to balance power, precision, and budget when making a decision.

5. Can it engrave intricate designs and fine details?

Absolutely. The 20W laser provides high precision, allowing it to engrave even the most intricate designs and fine details, making it perfect for jewelry work.

6. Is it suitable for large-scale production?

Yes, the machine is designed for efficient and large-scale production, making it an excellent choice for businesses needing high output.

7. What safety features are in place to protect users?

SuperbMelt ensures that its laser marker complies with safety standards, and it typically includes features like protective enclosures and safety interlocks.

8. What kind of technical support and warranty does SuperbMelt provide?

SuperbMelt offers technical support and a warranty to ensure that customers have assistance and peace of mind regarding the performance of their machine.

9. What file formats are compatible with the 20W fiber laser marker?

Typically, the machine supports a variety of file formats, including vector formats like DXF, PLT, and AI, making it versatile for design input.

10. How fast is the engraving process with this machine?

The engraving speed can vary based on the material and design complexity, but the 20W laser is known for its efficiency and can provide relatively fast results.

11. Is this machine suitable for permanent marking on jewelry and other products?

Yes, the 20W fiber laser marker offers permanent and highly durable marking, making it an ideal choice for jewelry and other items that require lasting identification.

12. What maintenance is required for the 20W fiber laser marker?

Regular maintenance includes cleaning the lens and ensuring the machine’s ventilation system is clear to maintain optimal performance.

13. Can the machine be customized for specific production needs?

SuperbMelt often provides customization options, such as double-head configurations, to meet specific production requirements.

14. Does SuperbMelt offer training for operating the machine?

Yes, SuperbMelt typically provides training and user manuals to help customers become proficient in using their laser marker.

15. Is the 20W fiber laser marker energy-efficient?

Yes, this laser marker is designed to be energy-efficient, which helps reduce operational costs.

16. What makes SuperbMelt's 20W fiber laser marker stand out from the competition?

The machine’s high precision, durability, and versatility for multiple materials set it apart, making it a top choice for various industries.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited