Laser Welding Machine 200W

SuperbMelt 200w Laser Welding Machine - China Leading Jewelry Welding Equipment

Laser Welding Machine 200W plays a crucial role in repairing and welding various types of jewelry, including precious materials such as gold, silver, platinum, and even diamond-studded pieces.

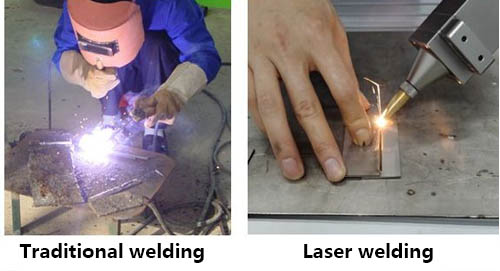

This machine is highly regarded in the jewelry industry. Compared to traditional welding methods, laser welding offers higher efficiency, reduces costs, and minimizes material waste. It significantly aids in jewelry production, repair, and customization processes.

Moreover, this jewelry welding machine provides the advantage of permanent welding, enabling manufacturers and designers to meet client demands and create unique, custom-designed pieces.

| Model | SPB-200WB |

| Wavelength | 1064nm |

| Maximum output power | 200W |

| Maximum pulse energy | 80J |

| Pump source | Single lamp |

| Pulse width | 0.1-20ms |

| Pulse frequency | ≤50Hz |

| Aiming and positioning | Microscope + camera system |

| Application | Welding and repairing various precious metal trinkets |

| Host power consumption | ≤7KW |

| Electricity demand | AC220V±5%/50Hz |

| Cooling system | Water cooling |

| Host size | L: 1050mm, W: 620mm, H: 1250mm |

| Chiller size | L: 620mm, W: 480mm, H: 710mm |

| Total weight | 193kg |

- High accuracy: Suitable for gold, silver, platinum, diamond, and other jewelry materials, this skill allows for high precision welding and repair operations.

- Lower costs: This process is more cost-effective and less wasteful of material than standard welding techniques.

- Permanent welding: Because laser-welded areas are stronger and more resilient, designers have more creative freedom.

- Customization capabilities: Able to adjust and change in response to client demands, satisfying a variety of design specifications.

- Decreased material loss: Laser welding’s directionality and accuracy help to reduce material loss.

- Simple to use and simple to learn how to use after a brief training.

- Time-saving: Quick welding speeds significantly cut down on welding time.

- Compact and light-weight: Lightweight and small-sized equipment allows for simple storage and transportation.

- Robust safeguarding – Incorporated safety mechanisms increase operational security.

- Eco-friendly: No toxic gasses are released, making it safer for both the environment and operators.

Laser welding devices have revolutionized the jewelry industry’s approach to creating and mending fine jewelry. Jewelers can deal with a variety of valuable materials, such as gold, silver, platinum, and even fragile diamonds, with more accuracy and grace, guaranteeing perfect repairs and adaptations. The capacity to produce permanent welding, a crucial component for guaranteeing the durability and integrity of the jewelry, is what distinguishes SuperbMelt’s 200W Jewelry Welding Machine from others. With the use of this technology, jewelry designers and manufacturers can satisfy customer requests while expressing their creativity and creating one-of-a-kind creations, all while cutting costs and wastage of materials. Modern jewelers cannot function without their laser welding devices, which allow them to create everlasting gems in the jewelry industry.

Why SuperbMelt Laser Welding Machine 200W

Any Question About SuperbMelt Laser Welding Machine 200W

A Jewelry Industry-Specific Guide to Laser Welding Machine 200W

Introduction of Laser Welding Machine 200W in Jewelry Industry

In the jewelry industry, where precision, material preservation, and aesthetic perfection are paramount, Laser Welding Machine 200W has become an indispensable tool. Unlike traditional welding methods that often damage delicate precious metals or ruin intricate designs, this machine caters to the unique needs of jewelry making, repair, and customization. To understand its significance, we’ll explore its development in jewelry applications, modern techniques tailored for (jewelry), its role in the industry’s evolution, and how it outperforms traditional tools for jewelry work.

1.1 Early Development of Laser Welding Machines for Jewelry

1.2 Modern Application Techniques of Laser Welding Machine 200W for Jewelry

- When welding thin gold chains (0.3-0.5mm thick), jewelers use short pulses (0.1-0.5ms) and low frequency (5-10Hz) to avoid melting the delicate links.

- For thicker platinum rings (2-3mm), longer pulses (2-5ms) and higher frequency (15-20Hz) create deep, permanent welds that match platinum’s durability.

1.3 History of Laser Welding Machine 200W in Jewelry Production & Repair

- Customization at scale: Jewelers could weld personalized engravings onto rings or attach unique gemstone settings without compromising design integrity.

- Efficient repairs: Fixing a broken gold bracelet that once took 2-3 hours with soldering now took 15-20 minutes with laser welding, as there’s no need to disassemble the piece.

1.4 Laser Welding Machine 200W Outperforms Traditional Jewelry Welding Tools

- No discoloration: Traditional soldering uses high heat that turns gold pink or silver black, requiring polishing that removes tiny amounts of precious metal. Laser welding’s focused beam heats only the weld spot, leaving surrounding metal unaltered—critical for preserving the original finish of vintage or high-end jewelry.

- Gemstone safety: Diamonds, sapphires, and emeralds are sensitive to heat; soldering torches can crack or cloud them. Laser Welding Machine 200W’s low heat dispersion (the area around the weld stays below 100°C) lets jewelers weld near gemstones without removing them.

- Permanent, invisible welds: Soldered joints often weaken over time or leave visible lines. Laser welds merge metals at the molecular level, creating joints as strong as the original metal—ideal for engagement rings or heirloom pieces that need to last decades.

- Faster turnaround: A soldered repair for a silver pendant takes 1-2 hours (including cooling and polishing); laser welding completes the same task in 10-15 minutes, letting workshops handle more orders.

Types of Laser Welding Machine 200W for Jewelry Industry

The jewelry industry’s diverse needs—from small-scale repair shops to large production facilities—have led to three specialized types of Laser Welding Machine 200W. Each is designed for specific jewelry tasks, from fixing delicate earrings to mass-producing rings.

2.1 Bench-Top Laser Welding Machine 200W (Jewelry Repair Specialized)

- High-magnification microscope (up to 50x) with LED lighting to see tiny details, like the gap in a platinum prong.

- Lightweight welding head (1-2kg) that rotates 360°, letting jewelers reach hard-to-access areas (e.g., the inside of a ring band).

- Quick-change nozzles (0.2-0.5mm diameter) for different weld sizes—small nozzles for delicate prongs, larger ones for thicker chain links.

2.2 Production-Grade Laser Welding Machine 200W (Bulk Jewelry Making)

- Automated workpiece clamping that holds multiple pieces (e.g., 10 ring blanks) at once, reducing manual setup time.

- Programmable welding paths—jewelers can save parameters for standard pieces (e.g., “gold band weld”) and repeat them with one button, ensuring every ring has the same weld quality.

- Higher cooling capacity (water cooling system with 10L/min flow rate) to run continuously for 8+ hours, critical for batch production.

2.3 Mobile Laser Welding Machine 200W (On-Site Jewelry Services)

- Lightweight design (total weight under 50kg, compared to 193kg for standard models) with wheels for easy movement.

- Battery-powered cooling system that works for 4-6 hours without an outlet, ideal for locations without reliable electricity.

- Simplified control panel with presets for common repairs (e.g., “gold chain fix,” “platinum prong repair”)—no need for advanced training to operate.

Essential Supporting Equipment for Jewelry Laser Welding Machine 200W

In jewelry work, Laser Welding Machine 200W can’t deliver optimal results alone—it needs supporting tools tailored to precious metals and delicate designs. These tools protect materials, ensure precision, and keep jewelers safe. We’ll cover why they matter, how they fit into jewelry workflows, and key choices like quartz crucibles for small-scale metal work.

3.1 History of Supporting Tools in Jewelry Laser Welding

3.2 Sources of Jewelry Materials for Laser Welding

- New Precious Metals: Gold (14K, 18K, 24K), silver (925 sterling), and platinum (950) ingots or sheets from refineries. These need cleaning tools to remove factory residues before welding.

- Recycled Jewelry: Scrap from old pieces (e.g., melted-down gold rings, broken silver chains) or customer-provided heirlooms. These require metal analyzers to check purity (e.g., ensuring recycled gold is 18K) and ultrasonic cleaners to remove dirt.

- Gemstone-Set Pieces: Diamond, sapphire, or emerald jewelry needing repair. These need specialized fixtures to hold the piece without pressing on the gemstone, and heat-resistant pads to protect delicate stones.

3.3 Must-Have Supporting Equipment for Jewelry Laser Welding

- Jewelry-Specific Fixtures & Clamps: Made of rubber or silicone (to avoid scratching), these hold pieces in place during welding. For example:

- Ring clamps: Adjustable to fit sizes 3-15, with soft pads to protect the band.

- Prong fixtures: Tiny, needle-like clamps that hold individual prongs (for diamond settings) without blocking the weld spot.

- Ultrasonic Cleaner (300-600W): Critical for pre-welding cleaning—removes oil, dirt, and oxides from metal surfaces. A 30-minute soak in an ultrasonic cleaner (using jewelry-safe detergent) ensures the weld bonds properly; without it, oil can cause porosity (bubbles) in the weld.

- Metal Analyzer (XRF or Fire Assay): Verifies the purity of metals (e.g., confirming a “platinum” piece is 950 platinum, not a cheaper alloy). Welding different purities (e.g., 14K gold to 18K gold) can cause weak joints, so this tool prevents costly mistakes.

- Laser Safety Glasses (1064nm Wavelength): The SPB-200WB uses a 1064nm laser—standard safety glasses won’t block it. Jewelry-specific glasses are lightweight (for all-day wear) and have anti-fog coating (critical when working close to the machine).

- Heat-Resistant Pads (Silicone or Ceramic): Place under gemstone-set pieces to absorb excess heat. For example, when welding near an emerald (which cracks at 300°C), a ceramic pad keeps the stone’s temperature below 100°C.

3.4 How to Choose a Quartz Crucible for Jewelry Laser Welding

- Size: Opt for small capacities (5-10ml) — jewelry work rarely needs more than 5g of molten metal. A 5ml crucible fits easily on the machine’s worktable and reduces metal waste.

- Purity: 99.9% SiO₂ purity is non-negotiable—impurities (like iron) can leach into molten gold, turning it a dull color. Look for “jewelry-grade” quartz (certified by suppliers like Corning).

- Thickness: 1-2mm walls are ideal—thicker crucibles take longer to heat (wasting time), while thinner ones risk cracking when holding molten platinum (which melts at 1772°C).

- Shape: Cylindrical with a narrow neck—prevents molten metal from splashing during pouring, critical when filling tiny gaps in a ring. Avoid wide-mouth crucibles (they increase spill risk).

FAQ Guide of Laser Welding Machine 200W

- 1. What is the purpose of a 200W laser welding machine in the jewelry industry?

- 2. How does laser welding with 200W improve the efficiency of jewelry manufacturing?

- 3. Is it suitable for welding various precious metals like gold, silver, and platinum?

- 4. Can the SuperbMelt 200W Laser Welding Machine repair delicate jewelry pieces effectively?

- 5. What are the advantages of using a laser welding machine over traditional welding methods in jewelry making?

- 6. Is the 200W laser welding machine capable of welding diamonds onto jewelry?

- 7. How does the permanent welding feature benefit jewelry manufacturers?

- 8. What materials are compatible with the SuperbMelt 200W Laser Welding Machine?

- 9. What precision and accuracy can be achieved with this machine in jewelry welding?

- 10. Does the machine support custom and fine jewelry design work?

- 11. How does the SuperbMelt 200W Laser Welding Machine contribute to cost savings and material efficiency?

- 12. Can this machine be used for both jewelry manufacturing and repair work?

- 13. What is the expected lifespan of the laser welding machine?

- 14. Is it user-friendly and suitable for both experienced jewelers and beginners?

1. What is the purpose of a 200W laser welding machine in the jewelry industry?

A 200W laser welding machine serves several key purposes in the jewelry industry, including:

Precise Repairs: It allows for detailed and intricate repair work on jewelry pieces, such as fixing cracks or joining small, delicate components.

Material Versatility: The machine can handle a variety of materials commonly used in jewelry, including gold, silver, platinum, and other precious metals, as well as work with materials like diamonds for repairs or adjustments.

Efficient Production: Compared to traditional welding methods, laser welding is faster and more accurate, increasing efficiency in jewelry production and reducing labor costs.

Cost and Material Savings: By focusing heat only where needed, it minimizes material waste and avoids damaging surrounding areas, especially important for valuable metals.

Permanent Welding: It provides strong, long-lasting joints, ensuring durability and high-quality craftsmanship.

Customization and Creativity: Designers can use laser welding to create unique, intricate designs, enabling them to meet customer demands for bespoke jewelry.

These advantages make the 200W laser welding machine an indispensable tool for jewelers aiming for precision, efficiency, and high-quality outcomes.

2. How does laser welding with 200W improve the efficiency of jewelry manufacturing?

Laser welding with a 200W machine significantly improves the efficiency of jewelry manufacturing through the following ways:

Fast and Precise Welding: Laser welding operates at high speeds with pinpoint accuracy, allowing jewelers to create or repair intricate designs faster than traditional methods.

Minimal Material Waste: The focused laser beam ensures heat is applied only where needed, reducing material loss and avoiding damage to surrounding areas of the jewelry piece.

Reduced Post-Processing: Laser welding produces clean and smooth joints that often require little to no additional polishing or finishing, saving time during production.

Enhanced Versatility: The machine can handle a variety of precious metals and alloys, accommodating different jewelry designs and repair requirements efficiently.

Cost-Effectiveness: By improving throughput and reducing material waste, laser welding minimizes manufacturing costs while maintaining high-quality results.

Consistency in Quality: Laser welding delivers uniform results, which is essential for batch production or mass manufacturing of jewelry.

These improvements make the 200W laser welding machine an indispensable tool for jewelers looking to enhance productivity and maintain superior craftsmanship.

3. Is it suitable for welding various precious metals like gold, silver, and platinum?

Indeed, a 200W laser welding equipment is ideal for joining different precious metals, such as platinum, silver, and gold, as well as other materials often used in jewelry making. This is the reason:

Versatility: Because of its exact control over heat and power, it can work with a variety of metals and alloys, which makes it perfect for high-value and sensitive materials.

Non-Contact Process: For delicate metals like gold and silver, the laser welding technique guarantees that the jewelry items will not be subjected to excessive physical stress, hence avoiding distortion or damage.

High Precision: The precise laser beam allows for the smooth welding of delicate features and complex patterns in precious metals while preserving their structural and visual integrity.

Low Thermal Impact: It reduces heat-affected areas, shielding the surrounding regions from deterioration or discoloration. This is especially crucial for heat-sensitive metals like platinum.

For jewelers looking to create or fix fine jewelry quickly while maintaining the integrity of the priceless materials utilized, this equipment is a popular option.

4. Can the SuperbMelt 200W Laser Welding Machine repair delicate jewelry pieces effectively?

Yes, fragile jewelry may be repaired with great success with the SuperbMelt 200W Laser Welding Machine. It is the perfect tool for managing delicate and complex jewelry work since it was made with efficiency and accuracy in mind. Important elements influencing its efficacy include:

High Precision: Repairing tiny or complex components without damaging nearby regions is made possible by the fine control provided by the concentrated laser beam.

Minimal Heat Damage: Jewelry items maintain their structural integrity and visual attractiveness because of its low thermal impact, which guards against damage to sensitive materials.

Versatility: By carefully changing the settings, this machine can repair a broad range of jewelry materials, including gold, silver, platinum, and even pieces containing gemstones.

Long-lasting repairs for delicate jewelry are ensured by laser welding, which produces strong, flawless joins.

Professional jewelers and repair professionals who want to efficiently fix complicated and precious jewelry items use the SuperbMelt 200W Laser Welding Machine because of these advantages.

5. What are the advantages of using a laser welding machine over traditional welding methods in jewelry making?

When manufacturing jewelry, there are a number of important benefits to using a laser welding equipment rather than conventional welding techniques.

Accuracy and Management:

Because laser welding offers very precise and concentrated control, jewelers may operate on small or complex regions without causing damage to nearby materials. For expensive objects with intricate intricacies, this accuracy is essential.

Minimal Damage from Heat:

Laser welding’s confined nature minimizes heat-affected zones, avoiding the deformation or discoloration of delicate metals and gemstones that conventional welding sometimes causes.

Strong and Smooth Joints:

Jewelry’s appearance and structural integrity are improved by laser welding, which produces strong, almost undetectable joins.

Adaptability:

ability to weld a variety of materials, such as alloys, titanium, platinum, silver, and gold. It may also be used to fix delicate or complicated items.

Speed and Efficiency:

Compared to conventional techniques, the procedure is quicker, saving time in both manufacturing and maintenance. This makes it particularly useful in settings with high demand or large manufacturing.

No Extra Materials Are Needed:

Solder and filler materials are often not used for laser welding, which lowers costs while maintaining the quality of the original material.

Increased Efficiency:

Modern laser welders with features like ergonomic designs, AI adjustments, and automatic settings enhance efficiency and lessen jewelers’ fatigue.

Eco-friendly:

It is a more sustainable choice since it produces less trash and uses fewer consumables.

Because of these benefits, laser welding machines are a necessary tool for contemporary jewelry manufacturing, repair, and personalization, taking the place of conventional techniques that often lack accuracy, effectiveness, and material preservation.

6. Is the 200W laser welding machine capable of welding diamonds onto jewelry?

The 200W laser welding machine is highly versatile and effective for welding various precious metals like gold, silver, and platinum. However, welding diamonds directly onto jewelry is not feasible using a laser welding machine or other conventional welding methods.

Diamonds are not metals and cannot be melted or fused in the same way metals are during welding. Instead, diamonds are typically set mechanically into jewelry using prongs, bezels, or adhesive methods rather than being welded.

The laser welding machine can, however, assist in creating or repairing the metal settings (like gold or platinum prongs) that securely hold the diamonds in place. This process ensures precision and avoids damage to the diamond or other gemstones due to the localized heat application.

7. How does the permanent welding feature benefit jewelry manufacturers?

Jewelry makers may profit from a 200W laser welding machine’s permanent welding function in a number of ways.

Increased Durability: Permanent welds guarantee that the jewelry keeps its structural integrity throughout time, giving consumers premium items that are resistant to deterioration.

Precision in Craftsmanship: Without sacrificing the jewelry’s appearance or design, producers may execute detailed welding and delicate repairs thanks to the concentrated laser beam.

Material Conservation: Laser welding’s accuracy reduces waste, which makes it more economical than other techniques that could result in material loss.

Streamlined Workflow: Permanent welding saves time and improves efficiency by doing away with the need for repeated welding or extra strengthening procedures.

Customer satisfaction: Manufacturers may satisfy customers’ demands for quality and durability by producing jewelry that is sturdy and long-lasting, which builds loyalty and confidence.

Because of these benefits, laser welding is a crucial technology in contemporary jewelry creation and repair, particularly for expensive or elaborate items.

8. What materials are compatible with the SuperbMelt 200W Laser Welding Machine?

The SuperbMelt 200W Laser Welding Machine is compatible with a wide range of materials commonly used in the jewelry industry. These include:

Precious Metals:

- Gold (Yellow, White, Rose)

- Silver

- Platinum

- Palladium

Alloys:

- K-Gold alloys

- Sterling Silver (925)

Other Metals:

- Titanium

- Stainless Steel

- Copper and Copper-based alloys

Gemstones and Materials:

- Can be used in processes that involve securely attaching diamonds and other gemstones to metal settings, although it does not weld the gemstones directly.

This versatility makes the 200W laser welding machine an excellent choice for manufacturing, repairing, and customizing jewelry pieces. Its precision ensures compatibility with delicate and high-value materials.

9. What precision and accuracy can be achieved with this machine in jewelry welding?

The SuperbMelt 200W Laser Welding Machine offers exceptional precision and accuracy in jewelry welding, thanks to its advanced laser technology. Here’s what you can expect:

Spot Size Control:

The laser allows for extremely fine spot sizes, typically as small as 0.2 mm, ensuring precise targeting of the welding area without affecting surrounding materials.High Accuracy:

The machine delivers highly accurate welding, ideal for intricate jewelry designs and repairs. It prevents deformation or damage to delicate pieces, maintaining the original structure and appearance of the jewelry.Heat Input Control:

Minimal and controlled heat input reduces thermal distortion, enabling clean and precise welds. This is particularly important for materials sensitive to heat, like gold and silver.Seam Quality:

The laser produces smooth, clean, and aesthetically pleasing weld seams without requiring extensive post-processing.Adjustable Parameters:

The ability to fine-tune parameters such as pulse frequency, energy, and beam focus ensures consistent and precise welds across various materials and thicknesses.

These features make the SuperbMelt 200W Laser Welding Machine indispensable for high-quality jewelry manufacturing and repair, offering artisans the capability to achieve flawless results with minimal effort.

10. Does the machine support custom and fine jewelry design work?

Yes, the SuperbMelt 200W Laser Welding Machine is well-suited for custom and fine jewelry design work. Its precise and controlled laser welding capability allows for intricate and delicate designs to be executed with ease. Here’s how it supports custom jewelry creation:

High Precision: The machine’s fine control over the laser allows for extremely detailed and accurate welds, which is essential in custom jewelry making where intricate designs and small parts are often involved.

Minimal Heat Impact: The low heat input reduces the risk of damage to delicate gemstones or metals, preserving the integrity of the design. This is particularly useful for fine jewelry that may have thinner sections or sensitive stones.

Flexibility: The machine can handle a variety of materials, including gold, silver, platinum, and diamonds, which are commonly used in custom and high-end jewelry. This versatility allows jewelers to work with different designs and materials without compromising on quality.

Custom Repairs: The laser welding machine’s ability to repair fine jewelry pieces, such as reattaching prongs or fixing broken links, makes it an ideal tool for custom design shops that offer repair services alongside design work.

Minimal Post-Processing: The high-quality welds produced by the laser reduce the need for extensive finishing work, allowing designers to achieve cleaner, more polished results in less time.

Overall, the SuperbMelt 200W Laser Welding Machine supports jewelers in creating complex, customized designs with precision, speed, and minimal risk of damage to the materials involved.

11. How does the SuperbMelt 200W Laser Welding Machine contribute to cost savings and material efficiency?

Due to a number of important benefits, the SuperbMelt 200W Laser Welding Machine provides considerable material efficiency and cost savings in the jewelry production process:

Minimal Material Waste: Because of their greater heat zones, traditional welding techniques often need excessive material input, which may result in waste and the requirement for post-weld cleaning. But with laser welding, less surplus material is utilized since the concentrated laser beam accurately transfers heat to the weld region. Higher material efficiency is the outcome, particularly when dealing with pricey metals like platinum, silver, and gold.

Minimized Post-Processing Requirement: The machine’s accurate control over the welding process results in smoother, cleaner welds, which lessens the requirement for intensive post-weld finishing techniques like polishing or grinding. In addition to saving labor expenses and time, this maintains the jewelry’s quality.

Reduced Energy Consumption: Laser welding simply targets particular locations, as opposed to conventional welding methods that may need lengthy, high-temperature operations. Over time, lower power prices are the consequence of this low energy use.

Minimal Heat-Affected Zones: Because laser welding can only heat a very small region, the remainder of the jewelry won’t be impacted by the heat. This keeps the jewelry’s strength and look intact, particularly for delicate designs, by preventing needless material deterioration in the surrounding regions.

Fewer Reworks and Repairs: The 200W Laser Welding Machine’s accuracy greatly lowers the quantity of mistakes or flaws that occur during the welding process. This results in further cost savings and increased production efficiency by reducing the need for reworks or repairs.

In conclusion, jewelry makers may save a lot of money by using the SuperbMelt 200W Laser Welding Machine since it avoids the need for post-processing, saves time during the production process, and uses less energy.

12. Can this machine be used for both jewelry manufacturing and repair work?

Indeed, the SuperbMelt 200W Laser Welding Machine is a multipurpose tool that can be used for both jewelry repair and manufacture. It helps both applications in the following ways:

Manufacturing of Jewelry: The machine is perfect for producing accurate and complex patterns. It enables producers to accurately weld tiny parts like settings, bezels, and clasps. It is crucial for creating personalized jewelry because of its accuracy and versatility in working with precious metals, such as gold, silver, and platinum. Furthermore, its small heat-affected zone guarantees that the surrounding materials won’t sustain any damage during the welding process—an essential feature for delicate designs.

Jewelry Repair: The laser welding equipment is excellent at restoring damaged or fractured jewelry without sacrificing the piece’s integrity. It is a great tool for repairing damaged objects since it can weld tiny connections or reconnect components with little material loss. The accuracy of the machine enables jewelers to deal with delicate stones without subjecting them to needless heat, which may otherwise harm them.

Because of its great efficiency, precision, and adaptability, the laser welding equipment is essential for both producing new jewelry and fixing or restoring damaged items. Additionally, the machine lessens the jewelry’s exposure to heat, which is advantageous when dealing with pricey or complicated items.

The SuperbMelt 200W Laser Welding Machine is thus designed to satisfy the requirements of both jewelry manufacture and repair, whether you are creating new designs or repairing broken ones.

13. What is the expected lifespan of the laser welding machine?

A SuperbMelt 200W Laser Welding Machine’s or comparable laser welding systems’ anticipated lifetime is often determined by a number of variables, such as the machine’s component quality and maintenance level. Usually:

Laser Source: Depending on the kind of laser (fiber lasers usually have longer lifespans compared to previous YAG lasers), the laser module or generator, a crucial component, may last 10,000 to 100,000 working hours. This may equate to five to ten years or more of service with frequent usage.

Maintenance: The lifetime may be greatly increased by performing routine cleaning, replacing consumables (such as lenses) on time, and following operating instructions.

Cooling System: To avoid overheating, the machine’s cooling system is essential. This component may function effectively over time with routine maintenance (such as cleaning the water tank and ensuring fluid levels are maintained).

Usage Intensity: Compared to machines operated sporadically, those used continually at high power may wear out more quickly.

Replacement components: The machine’s lifespan may also be impacted by the quality and availability of replacement components, such as protecting glass or mirrors.

In order to guarantee maximum performance throughout their operating lives, manufacturers such as SuperbMelt build their equipment with durability in mind and provide assistance. Following the manufacturer’s maintenance guidelines and running the equipment within the suggested limits are essential for extending its lifespan.

14. Is it user-friendly and suitable for both experienced jewelers and beginners?

Yes, the SuperbMelt 200W Laser Welding Machine is designed to be user-friendly and suitable for both experienced jewelers and beginners. Here are some reasons why:

Intuitive Interface: The machine often comes with a clear and easy-to-navigate interface, including features like an HD touchscreen and ergonomic controls, making it simple for users with varying levels of expertise to operate.

Precision and Automation: With built-in automatic settings and highly precise laser focus, it reduces the learning curve for beginners while providing experienced jewelers with the tools to perform complex tasks.

Safety Features: Equipped with safety mechanisms like protective covers and real-time monitoring, it minimizes risks, ensuring that even new users can operate it with confidence.

Versatility: The machine’s ability to handle various precious metals, including gold, silver, and platinum, makes it adaptable for diverse jewelry tasks, whether for small repairs or intricate designs.

Training and Support: Manufacturers like SuperbMelt often provide detailed manuals, training materials, and responsive customer support, which further enhances usability for all skill levels.

This combination of accessibility and advanced capabilities makes it an excellent choice for jewelers at any experience level.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited