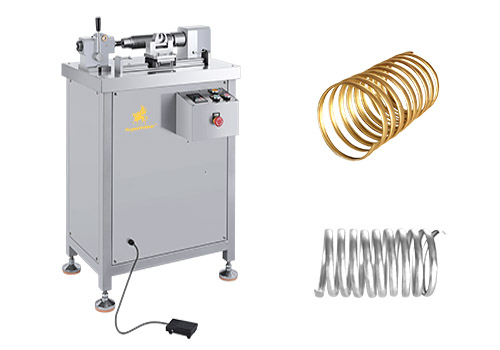

Tube Coiling Machine

SuperbMelt China Premier Supplier of Jewelry Bangle Manufacturing Machines

SuperbMelt tube coiling machine is a specialized equipment designed for coiling tubes, with a coiling diameter range from 15 to 80 millimeters. It is used to coil gold, silver, and alloy sheets into circular, spiral, or other shapes of coils.

This machine achieves the coiling operation by feeding the tubes into the coiling device at preset angles and speeds. With variable frequency speed control, it can coil 0-40 turns per minute, significantly improving the efficiency of bracelet manufacturing for jewelry makers.

In the jewelry manufacturing industry, the tube coiling machine can be used to create the basic structures of metal bracelets and rings, providing jewelry makers with customizable and innovative design options. By adjusting the machine settings, tubes of different diameters, lengths, and shapes can be produced to meet various jewelry styles and design requirements.

- High efficiency: 1 minute equals 40 coils.

- High precision: Finished product diameter tolerance of ±0.03mm.

- No loss: Shape changes without affecting weight.

- Variable frequency speed control: Speed adjustable from 0 to 50 rpm.

- Easy operation: Simple panel design for easy and convenient operation.

- Convenient mold change: Simple machine construction enables easy mold replacement.

| Model | SPA-PWM4 |

| Voltage | 220V |

| Power | 400W |

| Rotating speed | Adjustable speed 0~50r/min |

| Circle diameter | 15~80MM |

| Applicable metal | Gold, K gold, silver, etc. |

| Size | 700*600*1100MM |

| Weight | 71KG |

- Metal bracelets, rings, and other jewelry pieces are made using the jewelry manufacturing process.

- Crafts Manufacturing: Applies to the creation of metal sculptures, such as ornaments and decorations.

- The metal processing industry is used to make metal tubing for conduits and pipelines, among other uses.

- Electronics Manufacturing: Used to create metal casings and brackets for electrical gadgets.

- Automotive Industry: This sector produces metal parts for cars, such as brackets and exhaust pipes.

- The fundamental structures of metal decorations for furniture, lighting fixtures, and other decorative objects are crafted using this material in the home décor industry.

Why SuperbMelt Tube Coiling Machine

Any Question About SuperbMelt Tube Coiling Machine

SuperbMelt Tube Coiling Machine Guide

How to make a bracelet

1.1, Handmade Process

First, get all the supplies ready, such as the bracelet’s primary material and ornamental components. While beads, jewels, pendants, and other ornamental components can be used as accents, the main body material can be made of metal wire, leather, rope, etc.

Next, using the bracelet’s size and form as a guide, measure and mark the necessary length and breadth on the main body material. To shape and size the main body material, use equipment like pliers, scissors, and so on. If working with tougher materials like metal wire, use stronger cutting tools.

Next, use pliers or other hand tools to bend the main body material into the desired form for the bracelet, making sure to bend it smoothly and without sharp edges to follow the pattern. Add ornamental elements to the bracelet based on style and personal tastes. Some ideas are to tie beads on a cord, set gemstones in metal wire, or use engraving tools to engrave leather surfaces.

Join the bracelet’s two ends using metal clasps, jump rings, or other specialty connectors if it has holes or has to be fastened. Lastly, make sure the bracelet is securely fastened to every component and wipe the surface to remove any residue or contaminants.

1.2, Casting Bracelet Method

Metal Sheet Preparation: To begin, press metal (such as gold, silver, etc.) into thin sheets using SuperbMelt’s pressing machine. These sheets will be used as the bracelet’s raw material.

Bracelet Design: Create a design plan for the bracelet based on its dimensions, form, and design specifications.

Metal Sheet Cutting: To cut the metal sheet into coils that are the right size and shape, use the tube coiling machine. The bracelet’s primary structure will be composed of these coils.

Coil Shaping: To bend the cut metal coils into the appropriate shape for the bracelet, shape them in accordance with the design specifications. To accommodate a range of bracelet sizes, adjust the coils’ length and diameter as necessary.

Welding and Connection: To guarantee the bracelet’s integrity and stability, weld or join the ends together.

Surface Treatment: To make the bracelet’s surface more polished, smooth, and glossy, use surface treatment techniques like polishing and buffing.

Decoration and Inlay: Depending on the specifications of the design, add embellishments like diamonds or gemstones, or carry out engraving and carving.

Quality Inspection: Verify that the final bracelet satisfies design standards and specifications by conducting a quality inspection.

Packaging and Sales: Following the completion of all procedures, package the bracelet and get it ready for distribution to buyers.

To satisfy consumer and market needs, high-quality, aesthetically pleasing bracelets may be made quickly using SuperbMelt’s tube coiling and pressing machines.

1.3, How to 3D print a bracelet

Design: To begin, use computer-aided design (CAD) software to generate a digital model of the bracelet. As you design the bracelet, take into account details like its dimensions, form, texture, and embellishments, and make sure the model’s construction satisfies the specifications needed for manufacturing.

Preparation: Gather the materials required for the 3D printer based on the developed digital model. These materials are usually premium plastics that work well with the printer of choice, such polymer resin.

Printing: In accordance with the printing settings, load the digital model into the 3D printer and begin printing. To build the bracelet’s sturdy framework, the printer will stack materials one layer on top of the other. The printing procedure might take many hours or even days, depending on the bracelet’s complexity and size.

Post-processing: To enhance the bracelet’s surface quality and finish once printing is finished, post-processing may be necessary. This might entail sanding the surface, painting, providing a finish, or eliminating support components.

Inspection and Adjustment: Examine the bracelet’s quality and look during post-processing. Make any necessary alterations to guarantee the bracelet satisfies the required requirements.

Embellishments: To improve the bracelet’s appearance and allure, add embellishments like jewelry, jewels, or other ornamental components, depending on the design specifications.

SuperbMelt Tube Coiling Machine FAQ

- 1. What is a Tube Coiling Machine?

- 2. How does a Tube Coiling Machine work?

- 3. What types of tubes can be coiled using a Tube Coiling Machine?

- 4. What are the main components of a Tube Coiling Machine?

- 5. What industries commonly use Tube Coiling Machines?

- 6. Can a Tube Coiling Machine handle different tube diameters?

- 7. How precise is the coiling process with a Tube Coiling Machine?

- 8. What are the safety measures to consider when operating a Tube Coiling Machine?

- 9. Is training required to operate a Tube Coiling Machine?

- 10. Can a Tube Coiling Machine produce coils with different shapes?

1. What is a Tube Coiling Machine?

A Tube Coiling Machine is a specialized equipment used to coil metal tubes into various shapes, such as circular or spiral, for different applications.

2. How does a Tube Coiling Machine work?

A Tube Coiling Machine works by feeding a metal tube through a series of rollers or mandrels that shape the tube into the desired coil pattern while maintaining its structural integrity.

3. What types of tubes can be coiled using a Tube Coiling Machine?

Tube Coiling Machines can coil a wide range of metal tubes, including stainless steel, copper, aluminum, and various alloys.

4. What are the main components of a Tube Coiling Machine?

The main components of a Tube Coiling Machine typically include a feeding mechanism, rollers or mandrels for shaping the tube, a control panel for adjusting parameters, and safety features.

5. What industries commonly use Tube Coiling Machines?

Tube Coiling Machines are commonly used in industries such as HVAC (Heating, Ventilation, and Air Conditioning), automotive, aerospace, and manufacturing for applications like heat exchangers, refrigeration coils, and tubing assemblies.

6. Can a Tube Coiling Machine handle different tube diameters?

Yes, many Tube Coiling Machines are designed to accommodate a wide range of tube diameters by adjusting the settings or using interchangeable tooling.

7. How precise is the coiling process with a Tube Coiling Machine?

Tube Coiling Machines can achieve high precision in coiling, with some models capable of maintaining tolerances within a few millimeters or less.

8. What are the safety measures to consider when operating a Tube Coiling Machine?

Safety measures when operating a Tube Coiling Machine include wearing appropriate personal protective equipment, following proper machine operating procedures, and ensuring that guards and safety devices are in place and functioning correctly.

9. Is training required to operate a Tube Coiling Machine?

Yes, operators should receive training on how to safely and effectively operate a Tube Coiling Machine to prevent accidents and ensure optimal performance.

10. Can a Tube Coiling Machine produce coils with different shapes?

Yes, Tube Coiling Machines can be programmed to produce coils with various shapes and configurations to meet specific requirements.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited