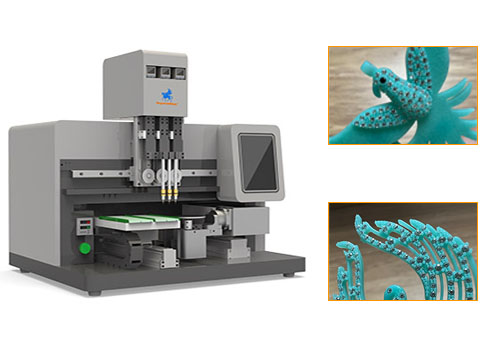

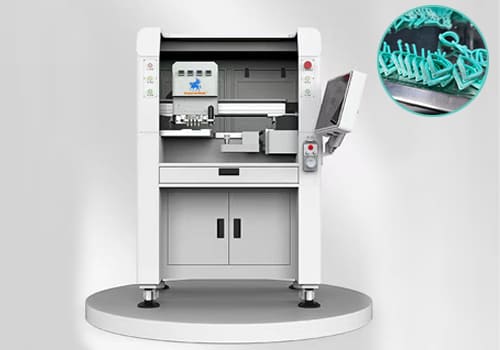

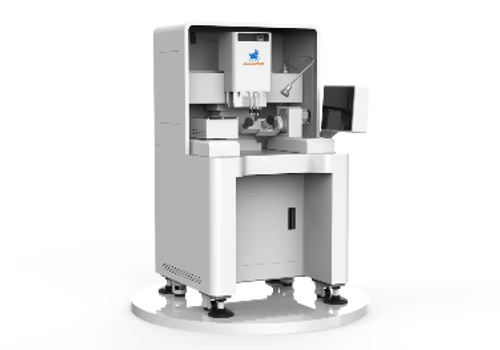

Desktop Automatic Wax Stone Setting Machine

Desktop Wax Stone Setting Machine suitable for small-scale jewelry manufacturers.

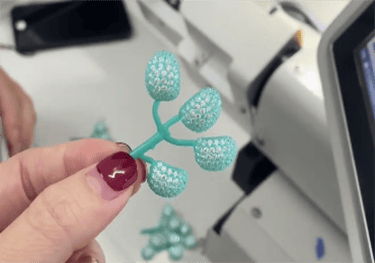

SuperbMelt Desktop Automatic Wax Stone Setting Machine is designed specifically for small jewelry businesses and DIY enthusiasts, featuring a compact footprint that fits seamlessly into any workspace. This machine can set 9,000-12,000 diamonds or gemstones per hour, significantly reducing wax setting time and boosting production efficiency—making it the ultimate tool for jewelry creation.

- Compact & Portable: Its space-saving design is perfect for small studios or home workbenches, requiring minimal space.

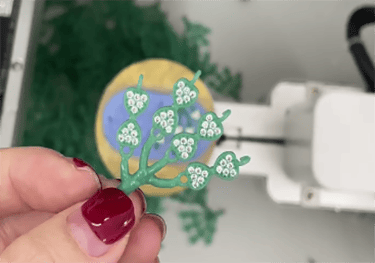

- Multi-Color Inlay: Supports inlaying up to 4 colors of diamonds in a single piece, enabling intricate and unique jewelry designs.

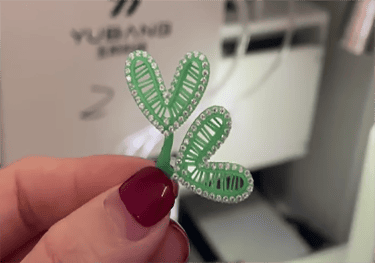

- High Efficiency & Precision: Automates the stone-setting process, eliminating labor-intensive manual work while ensuring high accuracy and consistent wax mold quality.

- Versatile Compatibility: Accommodates gemstones of various sizes and shapes, adapting to diverse design needs.

Whether you’re handling bulk orders or exploring creative jewelry designs, SuperbMelt empowers you to achieve exceptional quality with lower costs and greater efficiency. Simplify and elevate your jewelry-making process, and bring your creative visions to life with ease!

| Equipment Name | Desktop Automatic Wax Stone Setting Machine |

| Equipment Model | SPB-ASM1 |

| Workbench Structure | Five-axis linkage workbench |

| Running Speed | 9,000-12,000 diamonds per hour |

| Number of Suction Drill Bits | 3 suction nozzles |

| Drill Plate Fixing Method | Movable spring top screw on the upper side of the platform |

| Drilling Accuracy | ±0.02mm |

| Control System | Industrial-grade five-axis motion controller |

| Drive System | High-end servo |

| Transmission Method | High-precision screw guide |

| XYZ/A/C Effective Stroke | 200°95*150mm / +159°-5° / ±360° |

| Working Air Pressure | 80psi (0.4Mpa) |

| Equipment Appearance Size | Length 710 * width 600 * height 670mm |

| Equipment Weight | About 116KG |

- Five-Axis Linkage Worktable: Enables complex and precise stone setting with flexibility for diverse design requirements.

- High Drilling Speed: Capable of drilling 9,000–12,000 stones per hour, ensuring high production efficiency.

- Multi-Nozzle System: Equipped with 3 suction nozzles to enhance the setting process’s speed and accuracy.

- Adjustable Stone Plate Fixation: Features a movable spring-top screw on the platform, allowing secure and adaptable fixation.

- Exceptional Precision: Drilling accuracy of ±0.02mm ensures the perfect placement of stones for high-quality outputs.

- Advanced Control and Drive Systems: Industrial-grade five-axis motion controller and high-end servo drive system deliver superior performance and reliability.

- High-Precision Transmission: Uses advanced helical guide rails for smooth and precise operations.

- Ample Working Range: The XYZ/A/C effective travel dimensions of 28595100mm and rotational angles allow for versatile tasks.

- Energy Efficiency: Operates on AC220V/50Hz with a rated power of just 1.3kW, optimizing power consumption.

- Compact and Robust Design: Measuring 710600670mm and weighing approximately 116kg, it’s suitable for limited spaces yet sturdy enough for industrial use.

- Efficiency: Reduces production time significantly by automating the stone setting process, making it ideal for handling bulk orders and streamlining operations.

- Accuracy: High precision ensures perfect alignment and placement, reducing errors and waste.

- Versatility: Accommodates various stone sizes and shapes, catering to intricate jewelry designs.

- User-Friendly: Intuitive controls and flexible fixation mechanisms simplify operation and enhance productivity.

- Durability: Built with robust materials and components for long-term industrial usage.

- Cost-Effective: Minimizes manual labor and increases output, providing excellent value for jewelry manufacturers.

Desktop model occupies a small area, suitable for small jewelry merchants and jewelry DIY enthusiasts

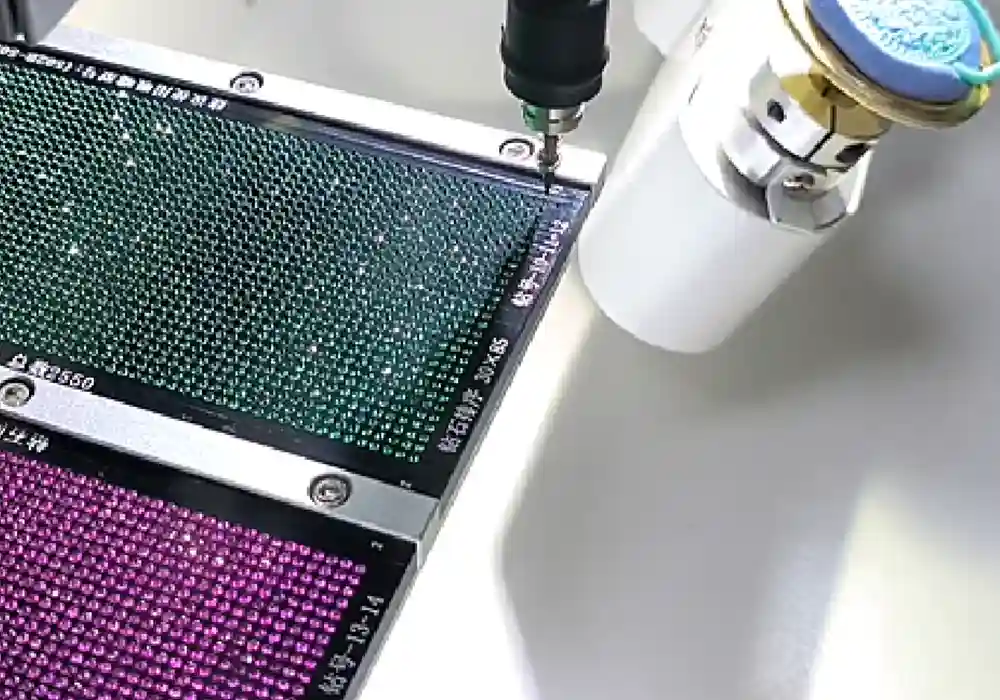

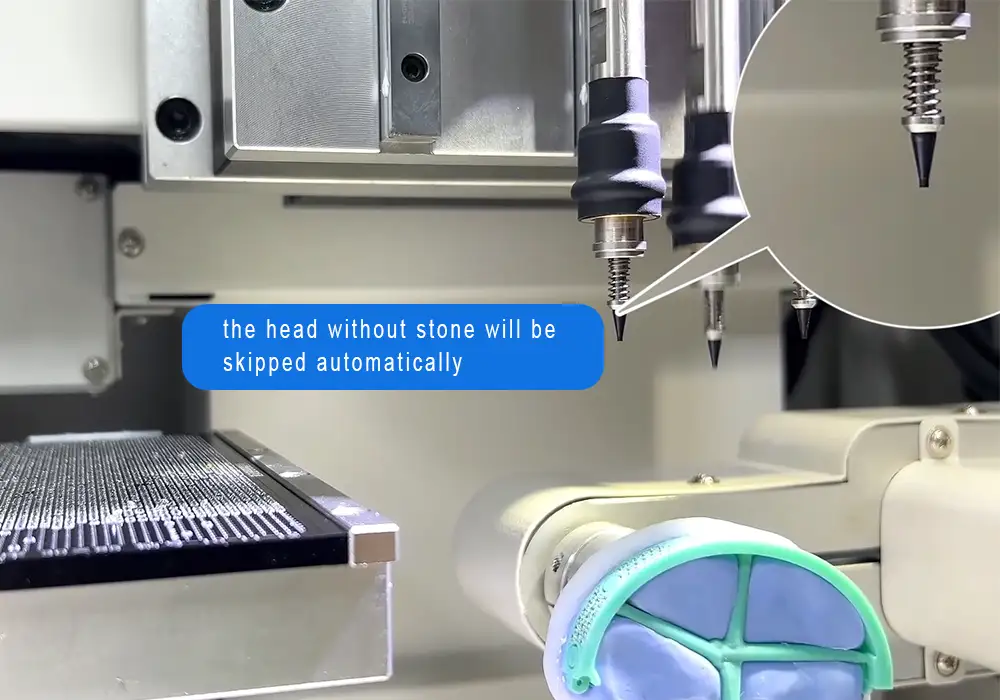

Intelligent identification of single or multi-color diamonds inlaid with up to 4 colors

Intelligent Identification System

The suction nozzle can automatically identify diamonds, which can prevent wrong drilling and missing drilling.

Why SuperbMelt Desktop Automatic Wax Stone Setting Machine

Any Question About SuperbMelt Desktop Automatic Wax Stone Setting Machine

FAQ Guide of Desktop Automatic Wax Stone Setting Machine

1. What is a Desktop Automatic Wax Stone Setting Machine?

A tabletop, compact device used to automatically embed diamonds or gemstones into wax models for use in jewelry production.

2. What is the production capacity of the machine?

With a capacity of 9,000-12,000 gemstones per hour, it is ideal for high-volume production.

3. What is the accuracy of gemstone placement?

The machine has a drilling accuracy of ±0.02mm, ensuring precise gemstone placement.

4. What kind of maintenance does the machine require?

Regular cleaning and calibration to maintain optimal performance.

5. Does the machine support wax models of different sizes?

Yes, it has a flexible design that works with wax patterns of various sizes and shapes.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited