Continuous Casting Machine Manufacturers

Introduction of Continuous Casting Machine Manufacturers

Continuous casting machine manufacturers have developed innovative equipment for casting precious metals in jewelry. These devices mold raw precious metals like gold, silver, and platinum into high-quality plates, bars, and rods.

Automatic continuous casting machines provide accurate temperature control and a regulated environment to cast metal with remarkable purity and uniformity. High-quality raw materials are needed to make elegant, lasting jewelry, thus consistency is crucial.

Continuous casting process reduces material waste and boosts productivity, making it perfect for small-scale and industrial jewelry manufacturing. These equipment match the high standards of the current jewelry business, whether you’re refining metals for high-end jewelry or preparing them for rolling or forging.

Continuous Casting Machine Features

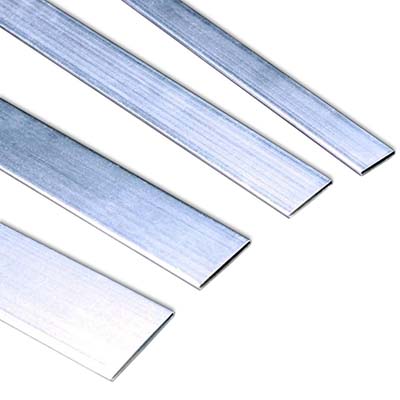

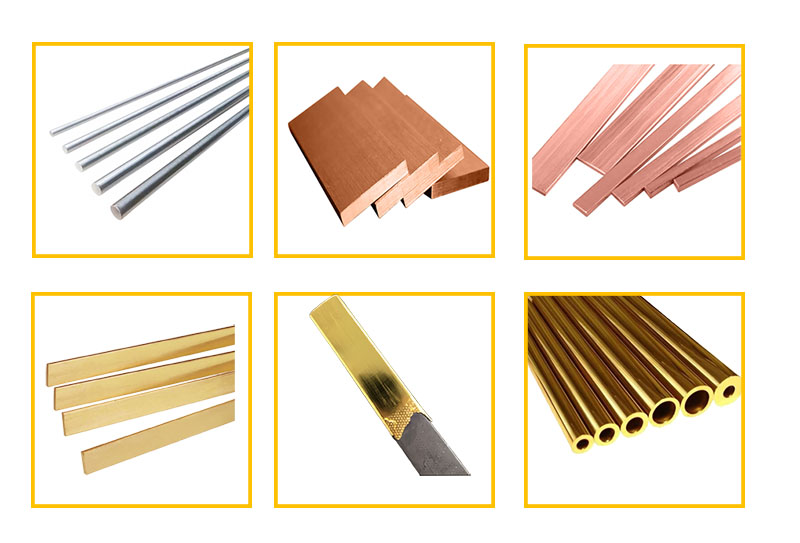

Capable of casting 50kg gold, silver and copper tubes, sheets, plates and bars.

The device is also able to automatically stir any molten metal. This feature helps you improve your production efficiency as well as the quality of your final product.

It can cast alloys and semi-alloys into different sizes and shapes in the shortest time. This feature not only saves your time, but also saves a lot of money.

Details of Continuous Casting Machine Manufacturers

- Industry: Jewelry Casting, Precious Metal Processing, University Laboratories, and related fields.

- Metals: Gold, K Gold, Silver, Copper, and their alloys.

| Model number | SPB-HVLS | SPB-HLS |

| Power source | 380V | Single phase 220V, 50/60Hz |

| Power | 15 kw | 15kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 5minutes | 5minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 2100*1250*1950mm | 900*1150*2000mm |

| Weight | 680kg | 220 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

- High vacuum (6.67×10-4pa), high vacuum melting, high product density, low oxygen content, no pores, suitable for the production of high-quality bonding wire.

- Anti-oxidation, inert gas protection during refining to solve the problem of alloy oxidation.

- Uniform fineness, electromagnetic and physical stirring methods make the alloy more uniformly colored.

- Smooth surface of the finished product, using a bottom-pulling design, the traction wheel undergoes special treatment, resulting in a flat and undamaged finished product with a smooth surface.

- Precise temperature control ±1℃, using imported temperature control meters, intelligent PID temperature control system, temperature difference ±1℃.

- 7-inch full-color touch screen, more convenient for observation/touch, new system, concise UI interface, easy operation with a single touch.

- Multiple protections, multiple safety protections, worry-free use.

Any Question About SuperbMelt Continuous Casting Machine Manufacturers

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited