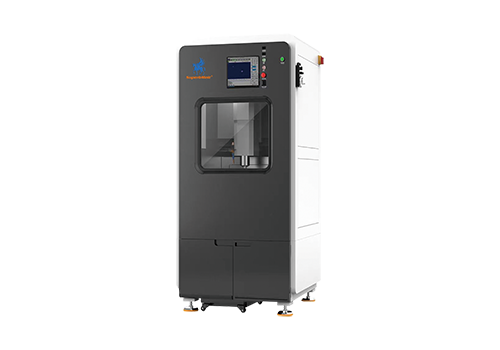

Jewelry CNC Machine

5-axis CNC machining equipment suitable for any shape of jewelry such as bangles, necklaces, rings, etc.

SuperbMelt jewelry CNC machine is suitable for processing jewelry made of metals such as gold, silver, copper, and platinum, and is capable of carving complex 3D shapes on jewelry.

The jewelry CNC machine is suitable for a wider range of materials, especially harder metals and thicker materials. This feature makes the machine ideal for large-scale production and jewelry processing factories that require high-precision cutting.

The 5-axis automatic tool change design enhances the efficiency, flexibility, and accuracy of the processing, reducing manual intervention, saving production time and costs, while ensuring product quality consistency and precision.

| Equipment nam | Jewelry 5 Axis CNC Machine |

| Model | SPB-CNC510 |

| X/Y/Z Axis Movement Accuracy | 0.05/0.05/0.05 mm |

| A/C Axis Movement Accuracy | 0.05° |

| X/Y/Z Axis Positioning Accuracy | 0.02/0.02/0.02 mm |

| A/C Axis Positioning Accuracy | 0.02° |

| X/Y/Z Axis Stroke | 350/250/200 mm |

| A/C Axis Rotation | 120°/360° |

| Max Workpiece Size/Height | Diameter 200 mm / Height 180 mm (Clamp: 120 mm) |

| Max Working Load | 20 kg |

| Main Spindle Speed | 4KW / 40,000 rpm |

| Tool Specification | ISO20 |

| Tool Storage Capacity | 6 (Horizontal Type) |

| Max Speed of X/Y/Z Axis | 6 m/min |

| Max Spindle Speed | 15/20 rpm |

| Power Supply | 380V/50Hz |

| Compressed Air | > 0.55 MPa |

| Machine Weight | 850 kg |

| Power Consumption | 5KW |

| Cooling System | Gold Five Axis Control System (RTCP functionality) |

| Dimensions | 1000 * 1100 * 1900 mm |

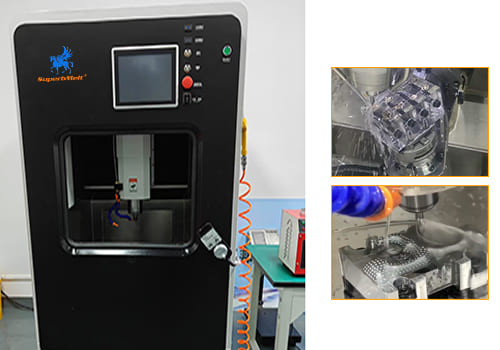

- SPB-CNC510is a compact five-axis CNC engraving machine with an automatic tool change system.Its A- axis swivel + C-axis rotary design structure offers greater flexibility, enabling complex 3Dcurved surface engraving with a single clamping.

- A utomatic Tool Change: No manual intervention required. The fully sealed internal linear tool magazineaccommodates 6 tools, significantly improving machining efficiency.

- SuperbMelt five-axis CNC system supports RTCP (Real-Time Tool Center Point) functionality.

- The main structure and swivel table adopt an integral cast iron design, ensuring long-term stability.

- high rigidity, and superior vibration resistance during machining.

- Compact fully enclosed noise-reducing design effectively minimizes noise for a quiet workingenvironment. With a footprint of only 0.94 square meters, it can fit into standard elevators, enablingmulti-floor operations and high space utilization.

- Widely used in craft processing factories, gold/silver jewelry workshops, metalworking factories,product R&D, school education, technical training institutions, DlY creators, and more. it is a highlypractical five-axis machining center.

- Jewelry Design and Customization:

CNC machines can carve intricate designs, allowing jewelers to create highly detailed and custom pieces like rings, bracelets, necklaces, and pendants.

- Engraving:

CNC machines can be used for precise engraving, adding intricate patterns, logos, or inscriptions on jewelry items.

- Prototyping:

Jewelry CNC machines can quickly produce prototypes of jewelry designs for customers to approve before mass production.

- 3D Carving:

Complex 3D shapes such as custom designs, detailed textures, or patterns can be carved into the jewelry, allowing for more elaborate designs than traditional handcrafting methods.

- Finishing:

CNC machines can be used for polishing, texturing, or other finishing touches to give jewelry the perfect look and feel.

- Casting:

CNC machines are sometimes used to create molds for the casting process, including lost wax casting.

- Jewelry Manufacturing:

CNC machines are heavily used in jewelry manufacturing for mass production and customization, offering precision and efficiency.

- Luxury Goods:

High-end and luxury brands utilize CNC machines to produce intricate and high-quality designs consistently.

- Fashion and Accessories:

In fashion and accessories, CNC machines are used to produce not only jewelry but also related items like brooches, pins, and belt buckles.

- Prototyping & R&D:

Jewelry designers and companies in the R&D sector use CNC machines to create prototypes, test designs, and experiment with new materials.

- Personalized Gifts and Souvenirs:

CNC technology allows businesses to create custom jewelry items such as personalized rings, bracelets, and necklaces for special events and gifts.

Why SuperbMelt Jewelry CNC Machine

Any Question About SuperbMelt Jewelry CNC Machine

Guide of SuperbMelt Jewelry CNC Machine

Key Features of Jewelry CNC Machines

When it comes to crafting fine jewelry, jewelry CNC machines are the ultimate tool for unparalleled precision and quality. Designed to meet the needs of modern jewelry businesses, the machines offer a range of features that streamline production and enhance creativity.

- High-precision engraving and cutting

Equipped with advanced laser or spindle technology, jewelry CNC machines deliver micron-level accuracy, ensuring perfect patterns and intricate designs are engraved on gold, silver, platinum, and other precious metals. - Material handling versatility

From delicate gemstones to durable alloys, these machines are designed to handle a wide range of materials, making them ideal for custom jewelry design and mass production. - User-friendly software integration

Compatible with industry-standard design software, jewelry CNC machines enable seamless 3D modeling and CAD/CAM integration, allowing you to easily turn your ideas into reality. - Efficient mass production

With automated workflows and high-speed processing, these machines enable jewelry businesses to meet tight deadlines and scale up production without compromising quality. - Compact and space-saving design

Designed for small workshops and large factories, jewelry CNC machines have a small footprint, making them ideal for businesses with limited space. - Durability and Low Maintenance

Built with high-quality components, these machines are built to last and require minimal maintenance, ensuring consistent performance and reducing downtime. - Customization and Personalization

Whether you’re creating personalized engravings or intricate patterns, jewelry CNC machines offer the flexibility to meet unique customer needs, helping you stand out in a competitive market.

How Jewelry CNC Machines Work

What is a Jewelry CNC Machine?

A Jewelry CNC Machine is a computer-controlled tool designed to carve, engrave, and shape precious metals and materials with exceptional precision. It uses advanced software and mechanical components to automate the jewelry-making process, ensuring consistent quality and intricate designs.

How a Jewelry CNC Machine Works:

- 1. Material Setup

The jeweler selects the material (such as gold, silver, platinum, or wax) and secures it to the CNC machine’s table. The correct setup is essential to ensure stability and precision during machining.

Why it’s important: A secure setup prevents errors and ensures consistent results.

- 2. Machine Calibration

Before it starts, the CNC machine is calibrated to match material and design specifications. This includes setting the cutting tool, spindle speed, and depth of cut.

Why it’s important: Calibration ensures the machine operates with optimal precision, reducing the risk of errors.

- 3. Machining Process

The CNC machine follows CAM instructions to cut, engrave, or shape the material. Depending on the design, this may involve:

Milling: Removing material to create a 3D shape.

Engraving: Adding intricate patterns or text.

Drilling: Creating holes or settings for gemstones.

The machine’s high-speed spindle and precision tooling ensure smooth and accurate results.

Why it matters: Automation allows complex designs to be executed with minimal human intervention, saving time and labor costs.

What is the difference between CNC engraving and laser engraving

CNC Engraving vs. Laser Engraving: What’s the Difference and Which is Best for Jewelry?

When it comes to engraving jewelry, two popular methods stand out: CNC engraving and laser engraving. Both techniques offer precision and versatility, but they work in fundamentally different ways. If you’re a jeweler trying to decide which method is best for your needs, this guide will break down the key differences, advantages, and applications of CNC engraving and laser engraving.

What is CNC Engraving?

CNC (Computer Numerical Control) engraving uses a mechanical cutting tool to carve designs into a material. The tool moves along multiple axes (typically 3 or 5) to remove material and create precise patterns, textures, or text.

Key Features of CNC Engraving:

Material Versatility: Works well with metals, wood, plastics, and wax.

Depth Control: Can create deep and tactile engravings.

Durability: Ideal for long-lasting, wear-resistant designs.

3D Capabilities: Can produce complex 3D engravings and textures.

Best For:

Jewelry with deep or tactile engravings.

Custom designs requiring 3D effects.

Materials like gold, silver, and platinum.

What is Laser Engraving?

Laser engraving uses a high-powered laser beam to vaporize material and create precise markings on the surface. It’s a non-contact process, meaning the laser doesn’t physically touch the material.

How It Works:

A design is created using graphic design software.

The laser beam follows the design path, heating and vaporizing the material to create the engraving.

The result is a clean, precise mark on the surface.

Key Features of Laser Engraving:

High Precision: Ideal for intricate and delicate designs.

Non-Contact Process: No risk of material deformation or tool wear.

Speed: Faster for surface-level engravings.

Material Flexibility: Works on metals, glass, ceramics, and more.

Best For:

Fine, detailed engravings like text, logos, or patterns.

Heat-sensitive materials or delicate jewelry pieces.

High-speed production of surface-level designs.

Key Differences Between CNC Engraving and Laser Engraving

| Aspect | CNC Engraving | Laser Engraving |

|---|---|---|

| Process | Mechanical cutting tool removes material. | Laser beam vaporizes material. |

| Precision | High, but limited by tool size. | Extremely high, ideal for fine details. |

| Depth | Can create deep engravings. | Surface-level engravings only. |

| Speed | Slower due to material removal. | Faster for surface engravings. |

| Material Compatibility | Metals, wood, plastics, wax. | Metals, glass, ceramics, plastics. |

| 3D Capabilities | Yes, can create 3D textures. | No, limited to 2D surface designs. |

| Durability | Highly durable, wear-resistant. | Durable but may fade over time on some materials. |

Which is Better for Jewelry?

The choice between CNC engraving and laser engraving depends on your specific needs:

Choose CNC Engraving If:

You need deep, tactile, or 3D engravings.

You’re working with hard metals like gold or platinum.

Durability and wear resistance are a priority.

Choose Laser Engraving If:

You require intricate, fine details or surface-level designs.

You’re working with delicate or heat-sensitive materials.

Speed and precision for small, detailed engravings are critical.

Conclusion

In the ever-evolving world of jewelry making, CNC technology has emerged as a game-changer, offering unparalleled precision, efficiency, and versatility. Whether you’re using a Jewelry CNC Machine for intricate engravings, a Jewelry CNC Milling Machine for detailed 3D designs, or a Jewelry Lathe Machine for perfectly symmetrical pieces, CNC tools empower jewelers to push the boundaries of creativity and craftsmanship.

By automating complex processes and ensuring consistent quality, CNC machines enable jewelers to:

Enhance Precision: Achieve micron-level accuracy for flawless designs.

Boost Efficiency: Streamline production and meet tight deadlines.

Expand Creativity: Experiment with intricate patterns, textures, and custom designs.

Scale Production: Meet growing demands without compromising on quality.

Whether you’re a small-scale artisan crafting bespoke pieces or a large manufacturer producing high-volume collections, investing in CNC technology is a step toward innovation and growth. By understanding the capabilities of CNC engraving, milling, and lathe machines, you can choose the right tools to elevate your jewelry business and stay ahead in a competitive industry.

Embrace the future of jewelry making with CNC technology, and unlock new possibilities for precision, creativity, and success.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited