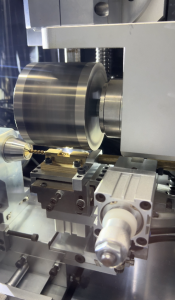

CNC Ball Chain Cutting Machine

CNC diamond cutting equipment suitable for spherical jewelry chains made of gold, silver, platinum, and K gold.

SuperbMelt CNC Ball Chain Cutting Machine is specially designed for high-precision decorative cutting of jewelry ball chains. It supports spherical beads made of gold, silver, platinum, and K gold. The machine can process 8–12 pieces per minute, bringing speed and efficiency to modern jewelry manufacturing.

It supports beads with diameters ranging from Ø2mm to Ø8mm and lengths from 15 to 20mm, making it suitable for various shapes such as round beads, olive-shaped beads, and bamboo-shaped beads. The CNC control system ensures consistent and customizable patterns, offering a wide range of decorative options for your jewelry designs.

This machine is widely used in jewelry workshops, chain factories, and ornament production lines, where speed, variety, and precision are essential.

| Model number | SPB-XC343 |

| Power source | 220V |

| Total power | 2.5kw |

| Main spindle speed | 24000r/min |

| Processing specification | Ø2-Ø8mm×15-20mm |

| Pneumatic pressure | 5-6kg |

| Working efficiency | 8-12pcs/min |

| Operation mode | Keypad screen |

| Dimensions | (L)800×(W)750×(H)1670mm |

| Net Weight | 400kg |

High Efficiency for Mass Production

- Capable of cutting 8–12 pieces per minute, suitable for gold, K gold, silver, and other precious metals

- Perfect for high-volume production lines, reducing labor costs and increasing productivity

Ultra-High Spindle Speed

- With a spindle speed of 24,000 rpm, the machine delivers sharp, clean, and brilliant cut patterns with a refined surface finish

- Supports Multiple Bead Specifications

- Processes bead sizes ranging from Ø2mm to Ø8mm in diameter and 15–20mm in length

- Compatible with round beads, olive-shaped beads, bamboo-style beads, and more

Precise Control & Easy Operation

- Equipped with an intuitive keypad screen for easy parameter adjustment

- CNC-controlled for consistent, repeatable patterns and customizable styles

Stable Operation with Reliable Power

- Powered by a 2.5kW system, ensuring strong and steady performance

- Air pressure of 5–6kg ensures smooth operation with efficient air consumption

- The machine’s robust build and 400kg net weight ensure long-term durability and vibration resistance

Compact Footprint for Flexible Placement

- Space-saving design with dimensions 800×750×1670mm, ideal for workshops and production facilities with limited space

- Jewelry Manufacturing Workshops

Ideal for producing decorative patterns on gold, silver, platinum, and K gold hollow beads used in necklaces, bracelets, and earrings.

- Ball Chain Production Lines

Designed for high-speed decorative cutting of hollow beads in mass production environments, improving both efficiency and output consistency.

- Custom Jewelry Design Studios

Enables small-to-medium studios to offer unique, CNC-patterned hollow ball chains for premium jewelry customization.

- Chain Ornament Factories

Suitable for creating decorative finishes on beads for chain-style jewelry, such as bamboo beads and olive-shaped beads.

- Jewelry Repair & Refurbishing Services

Used to re-cut or enhance worn-out bead patterns, restoring their shine and decorative detail.

- Luxury Accessories Manufacturing

Applicable in the finishing process for premium fashion accessories that incorporate decorative metal beads.

Why SuperbMelt CNC Ball Chain Cutting Machine

Any Question About SuperbMelt CNC Ball Chain Cutting Machine

SuperbMelt CNC Ball Chain Cutting Machine Guide

With the rapid development of the jewelry, fashion, home décor, and industrial signage industries, the demand for high-precision and customized ball chains has significantly increased, driving the growth of the automated cutting equipment market.

Traditional manual or semi-automatic machines are gradually being replaced by CNC technology, in pursuit of higher efficiency (such as SuperbMelt’s capacity of 3,000 pieces per hour) and lower defect rates (less than 0.1%).

Industry demands for energy-saving features (like SuperbMelt’s power-efficient design) and reduced metal waste are also accelerating the adoption of precision cutting machines.

Production Techniques for Various Ball Chain Jewelry Designs

Revolutionizing Ball Chain Jewelry Manufacturing: From Manual Craftsmanship to Intelligent Automation

The manufacturing of metal ball chains has undergone a groundbreaking transformation—from traditional manual processes to intelligent automated production. This revolution centers on three core breakthroughs: precision (±0.01mm, jewelry-grade standards), efficiency (fully automated output of up to 3,000 beads/hour), and flexibility (digital programming with one-click style change).

Modern production integrates CNC precision cutting and advanced laser technology, reducing precious metal loss by over 30%, and eliminating the 5–10% material waste commonly associated with traditional stamping techniques.

Each type of metal is processed using tailored, cutting-edge solutions:

Gold and platinum benefit from laser cutting combined with nano-welding, ensuring seamless, trace-free finishes.

Silver chains are treated with fully automated electrolytic polishing and rhodium plating to solve oxidation issues.

Stainless steel and titanium alloys are processed using fiber laser systems, overcoming the challenges of high-hardness materials.

The intelligent production ecosystem integrates precision forming, automated polishing, and digital twin control systems, supporting a wide range of needs from fine jewelry-grade craftsmanship to industrial-grade durability.

Looking ahead, the industry is evolving toward AI-generated design, blockchain traceability, and zero-carbon manufacturing, with a clear goal of achieving the “Three-Zero” vision:

- Zero defects (Six Sigma quality)

- Zero inventory (on-demand production)

- Zero limits (infinite design combinations)

This shift is reshaping the entire paradigm of ball chain manufacturing. For businesses looking to lead the high-end market, investing in CNC + laser hybrid machines is the strategic priority. These systems replace human uncertainty with machine precision, ensuring consistent quality and faster time-to-market.

1.1, The traditional methods of making ball chain jewelry

Metal Wire Processing Stages

- Manual Wire Drawing

Artisans use drawplates to gradually reduce the wire diameter to the target size (e.g., 1mm), requiring repeated annealing processes.

- Hammer Forging

Metal wire is shaped into spherical forms by hand hammering. Even skilled craftsmen can only produce around 200–300 pieces per day.

- Stamp Pressing

Foot-operated mechanical presses are used with molds for batch production, but each mold typically lasts only about 5,000 strikes before replacement is needed.

Surface Treatment Processes

- Tumbling Polishing

Ball chains are mixed with ceramic media and tumbled for 48–72 hours. However, this process results in approximately 10% deformation due to collisions.

- Mercury Gilding

Historically used for surface finishing with toxic mercury alloys, this method has now been replaced by modern electroplating techniques.

- Manual Engraving

Patterns are hand-engraved onto the ball surfaces using steel chisels, a task requiring 3–5 years of hands-on experience to master.

Assembly Technique Flaws

- Lead-Based Soldering

Traditional tin-lead solder compromises product safety and is now banned under EU RoHS regulations.

- Threading Loss

Manual chain threading often leads to a 15–20% loss of precious metal particles due to breakage or spillage.

- Dimensional Inconsistency

Finished chain segments typically exhibit a tolerance of ±0.3mm, which negatively affects comfort during wear.

Typical Quality Issues

- Visible Seams

Cold-pressed spheres often show parting lines (mold joint marks) on the surface.

- Oxidation and Tarnishing

Silver chains exhibit up to 60% oxidation within six months if not treated with modern anti-oxidation technologies.

- Insufficient Strength

Manually welded joints can only withstand loads of 200–300 grams, making them prone to breakage.

1.2, A comparison with modern methods of producing ball chain jewelry

Traditional vs. Modern Ball Chain Manufacturing Comparison

| Parameter | Traditional Craft Methods | Modern CNC Automation | Technical Advancement |

|---|---|---|---|

| Dimensional Accuracy | ±0.3mm (visible variance) | ±0.01mm (jewelry-grade) | 30x precision improvement |

| Production Speed | 200-500 units/day (manual) | 3,000 units/hour (continuous) | 60x output increase |

| Material Yield | 8-10% waste rate | <0.1% material loss | 35%+ precious metal savings |

| Surface Finishing | 48hr barrel polishing | 2hr automated electrolytic polish | 24x faster processing |

| Joint Strength | Lead-tin solder (300g capacity) | Mechanical clasp (2kg capacity) | 6x durability enhancement |

| Changeover Time | 2-3 days (mold replacement) | 5 minutes (digital reprogramming) | 100x faster configuration |

| Quality Consistency | 85% yield (artisan-dependent) | 99.9% yield (AI inspection) | 15x quality stability |

| Minimum Ball Size | Limited to 3mm | Capable of 1mm micro-chains | 200% size reduction capability |

| Environmental Compliance | Lead processes/high energy use | Full ROHS compliance | 90% pollution reduction |

1.3, The significance of ball chain jewelry in the jewelry industry

Foundational Importance

As one of the most widely used chain structures in the jewelry industry, the ball chain serves as a fundamental component.

It accounts for approximately 35% of the global metal jewelry accessories market (2023 data).

Over 90% of jewelry brands maintain at least 3 to 5 basic product lines featuring ball chains.

Functional Value

Core Connecting Component: Ball chains support pendants in 68% of pendant-style products.

Standard of Comfort: The smooth, rounded form makes it the preferred choice for children’s and sensitive-skin jewelry.

Industrial Applications: Standard fixture in medical ID bracelets, diving gear, and other specialized equipment.

Design Versatility

Style Range: Varying bead diameters (1–20mm) enables a design spectrum from minimalist to luxurious.

Material Innovation: Often the first to adopt new materials like 3D-printed precious metals and eco-friendly alloys.

A favorite element of contemporary designers, featured in 22% of innovative jewelry design patents.

Market Performance

Global CAGR of 8.7% (2020–2023), indicating steady demand.

High-end product premium: Precision ball chains can be priced 3–5 times higher than standard models.

Among the top three most searched terms on e-commerce platforms, with 2.4 million monthly searches for “ball chain jewelry.”

Craftsmanship Benchmark

Core curriculum in jewelry schools: A standard test of students’ metalworking skills.

Technical benchmark in the industry: New equipment and processes are often first tested on ball chain production.

Quality certification baseline: A standard model for EN 1811 nickel release testing compliance.

Current Development Trends

Smart Integration: Ball chains embedded with NFC chips for luxury product authentication.

Sustainability Transition: Eco-friendly ball chains made from 100% recycled gold and silver (now accounting for 18% of production).

Cultural Symbolism: The “gold bead” motif in Chinese trend designs sees a 40% annual increase in usage.

Conclusion

In the jewelry value chain, ball chains represent both a reliable profit driver (with gross margins of 45–60%) and a symbol of technical excellence. Its “simple but not basic” nature ensures that it will continue to hold a central role in the industry’s evolution.

Why Automated Equipment Is Needed for Ball Chain Diamond Cutting

2.1, Extremely low production efficiency, unable to meet market demand

Production Bottlenecks of Traditional and Semi-Automated Ball Chain Manufacturing

Manual Production:

Relies heavily on skilled artisans to individually polish and assemble each bead, with a daily output limited to 200–300 pieces per person. Consistency and precision are often poor.

Semi-Automated Stamping:

Although faster than manual methods, this process still suffers from long mold changeover times, limiting batch production speed to around 500–1,000 pieces per hour.

Surging Market Demand:

The rapid rise of fast-fashion jewelry and customized e-commerce orders has placed immense pressure on traditional methods, which can no longer meet tight delivery schedules.

Advantages of Automated Equipment

10x Increase in Output: Advanced CNC cutting machines can produce up to 3,000 pieces per hour.

24/7 Continuous Operation: No need for manual shift rotations, significantly reducing labor dependency.

Rapid Design Switching: Digital programming allows design and bead size changes in under 5 minutes.

2.2, Poor precision and high defect rate

Precision Limitations of Traditional Ball Chain Manufacturing

High Manual Error Margin:

Handcrafted processes result in bead size deviations of up to ±0.3mm, compromising wearing comfort and product consistency.

Stamping Mold Wear:

Leads to burrs and deformation, with defect rates reaching 5–10%, causing significant precious metal loss.

Welding Flaws:

Traditional lead-tin solder joints are prone to breakage, with rework rates exceeding 15%.

Advantages of Automated Equipment

Ultra-High Precision: Achieves ±0.01mm accuracy, meeting jewelry-grade standards.

<0.1% Defect Rate: Reduces precious metal waste by over 30%.

Laser Spot Welding & Precision Clasping: Enhances connection strength by up to 5x.

How to Choose a Ball Chain Diamond Cutting Machine

Parameter Comparison & Model Selection Guide for Ball Chain Cutting Machines

| Parameter | Basic Model Requirement | High-End Model Recommendation | Industry Application Advice |

|---|---|---|---|

| Cutting Precision | ±0.05mm | ±0.01mm (Jewelry-grade) | High-end jewelry: within ±0.02mm |

| Production Speed | 800–1500 beads/hour | 3000+ beads/hour | Mass production: ≥2000 beads/hour |

| Material Compatibility | Gold/Silver/Copper | Titanium/Stainless Steel/Platinum | Industrial chains: support high-hardness metals |

| Ball Diameter Range | 2–10mm | 1–20mm | Micro chains: 1–3mm cutting capability |

| Automation Level | Manual feeding | Automatic feeding + sorting | 24/7 production: fully automatic model recommended |

| Tool Life | 100,000 cycles (standard alloy) | 500,000 cycles (diamond-coated) | High-load operations: choose wear-resistant tools |

2. Model Selection Based on Production Needs

① Small-Batch Customization (Designers/Studios)

Recommended Model: Desktop CNC type

Features:

Compact footprint (<1㎡)

Supports USB file import

Quick mold changes within 15 minutes

② Mid-Volume Production (Jewelry Workshops)

Recommended Model: CNC model with automatic feeding

Features:

Equipped with vibratory feeder

Stores over 50 preset cutting patterns

③ Large-Scale Manufacturing (Jewelry Supply Chain)

Recommended Model: Intelligent production line

Features:

Integrated cutting, polishing, and inspection

IoT-based remote monitoring

3. Key Component Quality Standards

Spindle System: Use Swiss/Japanese bearings (lifespan >20,000 hours)

Drive Motor: Servo motor preferred over stepper motor (30% faster response)

Control System: Prioritize industrial-grade CNC systems (e.g., Syntec, FANUC)

Safety Certification: Must comply with CE standards; laser models require FDA laser safety rating

4. Value-Added Features to Consider

Intelligent Compensation: Auto-corrects for tool wear-related precision loss

Multi-Axis Linkage: Supports 3D engraving on spherical surfaces

Energy Saving Mode: Standby power consumption <100W (compliant with EU ERP standards)

Data Traceability: QR code marking for production batch tracking (ISO quality compliance)

Conclusion

The transformation of ball chain jewelry manufacturing—from labor-intensive manual methods to intelligent, automated CNC and laser-based systems—marks a pivotal leap forward for the jewelry, fashion, and industrial accessory sectors. As global demand continues to rise for high-precision, customizable designs, traditional techniques have proven inadequate in meeting efficiency, consistency, and sustainability requirements.

Modern ball chain production is now defined by ±0.01mm cutting precision, up to 3,000 beads per hour output, and defect rates under 0.1%. These advancements not only improve productivity but also dramatically reduce precious metal waste and energy consumption. As regulatory and market pressures push for eco-friendly and zero-defect manufacturing, fully automated solutions with AI design, blockchain traceability, and digital twin systems are setting new industry benchmarks.

For enterprises aiming to remain competitive in this evolving landscape, investing in next-generation ball chain diamond cutting equipment is no longer optional—it is a strategic necessity. Whether catering to small-batch custom designers or large-scale supply chains, the right equipment choice—paired with advanced automation features—can deliver consistent quality, faster turnaround, and future-proof adaptability.

Ultimately, ball chain manufacturing is not just a production process—it is becoming a symbol of technological innovation, craftsmanship excellence, and sustainable progress in the modern jewelry industry.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited