Gold Bar Maker

JD4 Vacuum Gold Bar Making Machine

More Details of Gold Bar Maker

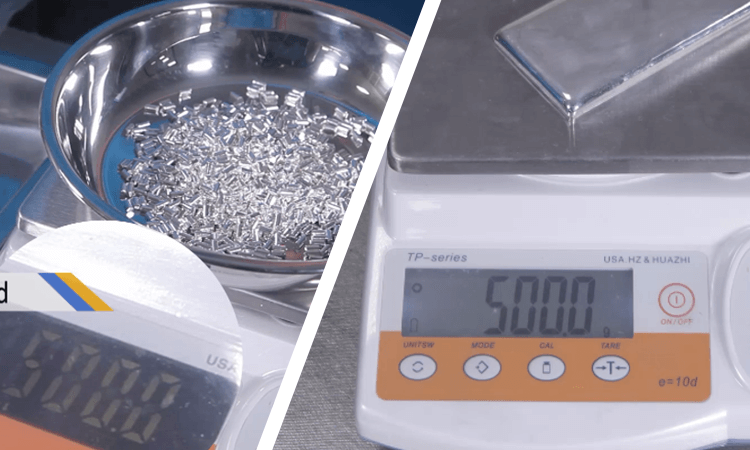

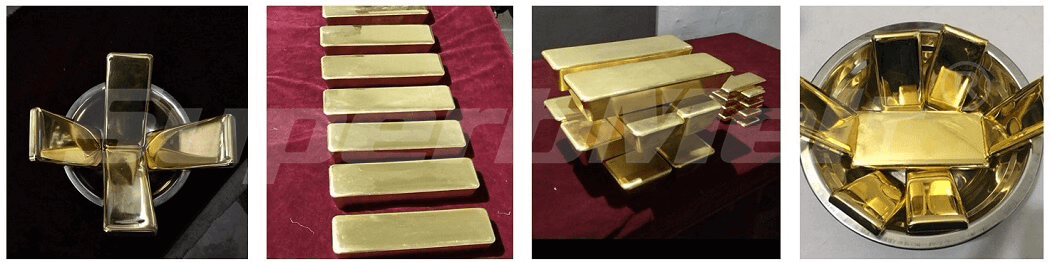

The Superbmelt gold bar maker is used to cast high quality ingots or gold bars. It allows users to measure and cast ingots of different sizes.

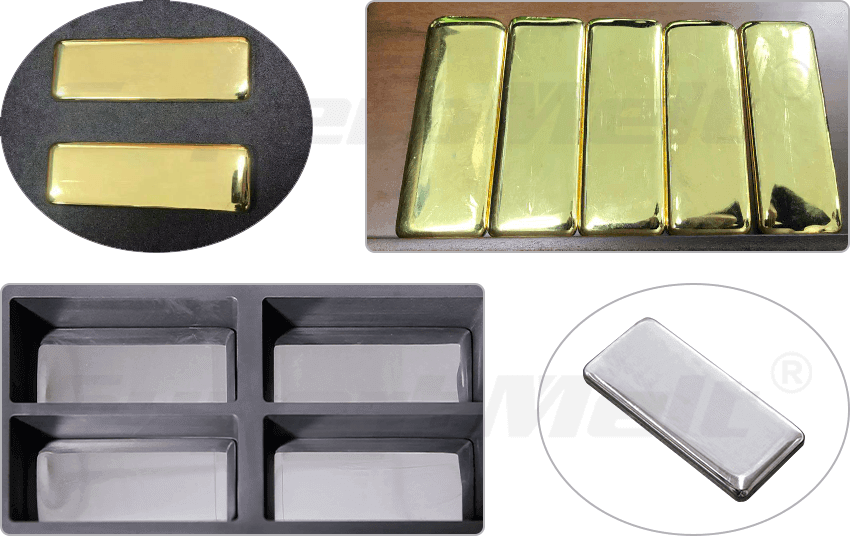

The use of the Superbmelt gold bar maker ensures fast production of gold bars because you can cast up to 4 pieces of gold bars at once or a single piece of 15kg gold bar. Superbmelt gold bar maker is widely used in foundries, financial institutions, jewelry industry, electronics industry, machinery repair shops, etc.

Metals that can be cast into bars with the gold bar making machine include; silver, gold, karat gold, etc. Making silver ingots with the Superbmelt gold bar maker is now easy because the casting process is automated.

Get Price of Gold Bar Maker

Features of Gold Bar Maker

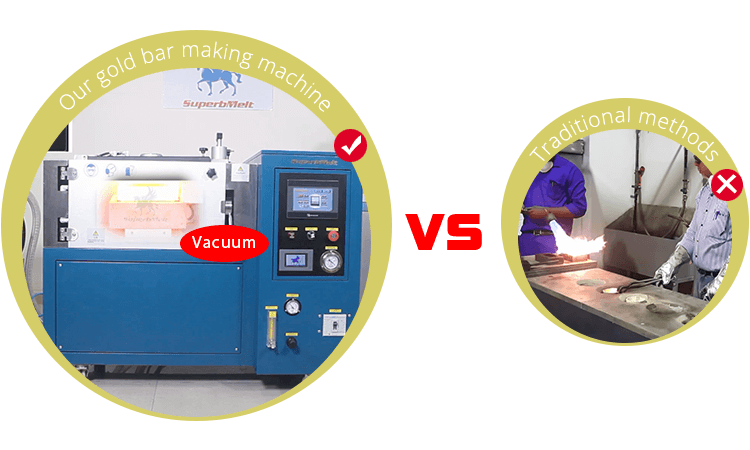

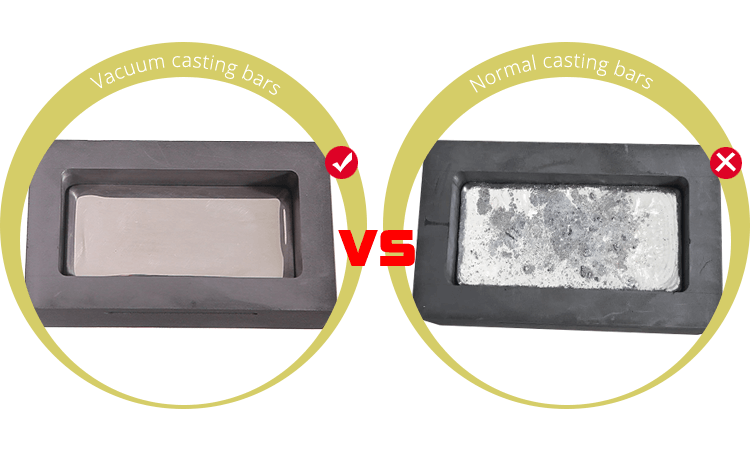

Without contact with air, the surface of gold bars are more smooth, no oxidation, no porosity.

The whole casting environment is closed, and no precious metal will be lost.

Comparing normal casting, vacuum casting bars are with flat and shiny surface and density.

Details of Gold Bar Maker

- Making gold ingots and gold ingots in the gold bar making machine takes place under vacuum. Under this process, no air or impurities get entrapped in the ingots. Therefore, you have high quality and pure ingots.

- The PLC control system of the Superbmelt gold bar maker automates the ingot casting process. A single operator can produce gold bars from start to finish. Thus, saving the need for numerous workers.

- A casting machine of this function requires about 45kw to 75kw of power to get gold bars casting started. You don’t have to spend extra charges on power usage when you include the ingot making machine in your production.

- The induction heating also contributes to energy saving. Induction heating ensures no energy is wasted and all energy generated is used within the machine, therefore, there is no unnecessary heat that can cause discomfort for users.

- Casting takes about 15 minutes. You can cast as much as 4 gold and silver ingots in one operation. This therefore speeds up production time.

- Making silver ingots with the Superbmelt gold bar maker is now easy, users can switch between automatic and manual mode.

- Superbmelt gold bar maker is noiseless and pollution free. The gold bar making machine is equipped with a green technology that ensures all forms of pollutants are trapped and do not escape into the atmosphere.

- The machine has alarm systems that detect errors such as system overvoltage, shortage of water supply, etc.

- Ingots cast with our gold making machine meets LMBA quality standards. All ingot produced with Superbmelt’s gold casting machine have a mirror reflective appearance, porosity free, oxidation free and shrinkage free.

| Model number | SPB-JD4 | SPB-JD10 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 45 kw | 75 kw |

| Control system | PLC | PLC |

| Applicable metal | Gold and silver | Gold and silver |

| Casting time | About 15 mins | About 12 mins for kliobar or 25mins for 400oz gold bar |

| The Max capacity | 4 pcs of 1kg bar or 15kg bar | 4 pcs of 1kg bar or 15kg bar |

| Dimension | 1450*620*1080 mm | 1510*750*1250 mm |

| Weight | 285 kg | 360 kg |

| Protective gas | Nitrogen or argon | Nitrogen or argon |

| Vacuum pump | 63 m³/hour | 63 m³/hour |

| Heating technology | Induction heating | Induction heating |

| Casting mode | Auto and manual mode switch | Auto and manual mode switch |

Graphite mold for gold/Silver bar casting machine

Choosing a right casting mold for gold/silver bar casting will improve the efficiency and quality of castings and save the cost of lost parts

Any Question About SuperbMelt Gold Bar Maker

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited