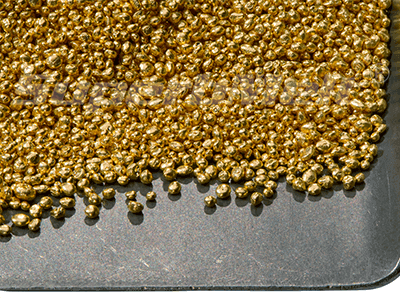

Metal Granulating Machine

Professional Precious Metal Casting Equipment Supplier in China

Metal granulating machine combines metal smelting and granulation to produce metal particles such as gold, silver, copper and the like, can realize the manufacture of 5 to 100 kg of metal particles, and is mainly used in metal recycling and processing plants. The liquid metal is produced by melting the metal material and then flowing the liquid metal into a mold with holes to create irregular metal particles.

SuperbMelt metal granulator has a simple structure, uses induction melting technology, and has a faster and more stable melting speed. And the cost performance is higher, is a good choice for many metal processing plants.

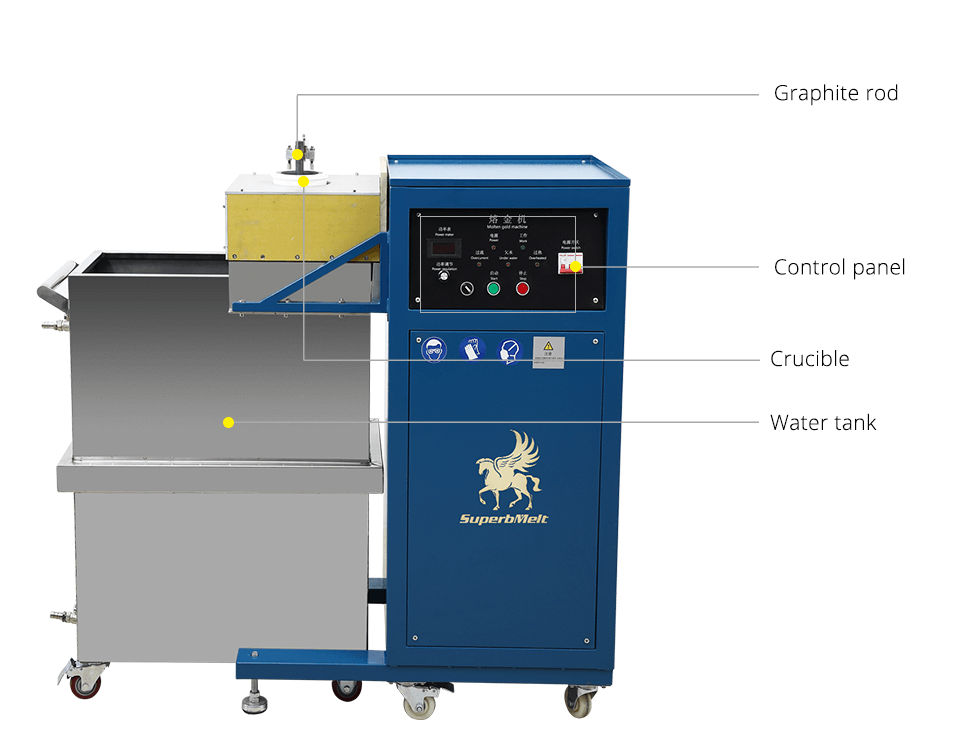

Granulating Machine

Parameter of Granulating Machine

| Model number | SPB-JL15 | SPB- JL25 | SPB- JL35 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 25 kw | 35kw |

| Applicable metal | Gold, K-Gold, Silver, Copper, Brass, Bronze | Gold, K-Gold, Silver, Copper, Brass, Bronze | Gold, K-Gold, Silver, Copper, Brass, Bronze |

| Casting method | Gravity granulation | Gravity granulation | Gravity granulation |

| The Max capacity | 24K Gold: 6.0 kg 925 Silver: 3 kg | 24K Gold: 15.0 kg 925 Silver: 8.0 kg | 24K Gold: 30.0 kg 925 Silver: 16.0 kg |

| Casting material | Particles | Particles | Particles |

| Dimension | 1200*530*1200mm | 1200*530*1200mm | 1200*530*1200mm |

| Weight | 150KG | 180KG | 220KG |

Automatic Tracking Frequency

Equipped with the function of automatically tracking frequency, and the melting process is more stable and safe. no noise during the working period, shorter granulation time and greatly improved production efficiency.

Solid-state Technology

The machine uses solid-state technology and uses the latest and most advanced IGBT module in the world. PID technology can achieve accurate temperature control and make the finished product quality better.

PLC Control System

Through the touch screen operation, the buttons are simple, the use is more convenient, and the parameter settings are clear.

Convenient Material Fetching

By adopting the separation arrangement of the material box and the water tank, the material can be easily collected and obtained when the granulation is completed.

Multi Holes Design

The mould is porous, and the granulation speed is faster.

Multiple Protection

The machine has a complete protection system. When overcurrent, overvoltage, excessive temperature and short circuit occur, fault lights will be turned on and alarm will be issued at the same time, so that employees can know more timely when working, so as to avoid operation risks.

Continuous Work

The feeding can be continuously carried out, and after the first batch of smelting is finished, the feeding can continue to be carried out in the smelting furnace without stopping the machine, thus achieving mass production and being more efficient.

The metal granulating machine can produce various metal particles which can be used for further processing or casting, and the shape of the metal particles can be more easily molded or processed into a final product. Therefore, it is widely used in the waste metal recovery and metal refining and casting industries.

Mining Industry

They are used for processing raw metal ores and concentrates to produce high-quality metal products.

Foundry Industry

The machines are used in the production of metal casting and forging, where they are used to melt down and granulate metal alloys for casting and forging processes.

Manufacturing Industry

The machines are used in the production of metal products, such as wire, rod, bar, and sheet metal, for various manufacturing applications.

Why SuperbMelt Metal Granulating Machine

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Any Question About SuperbMelt Metal Granulating Machine

Guide of SuperbMelt Metal Granulating Machine

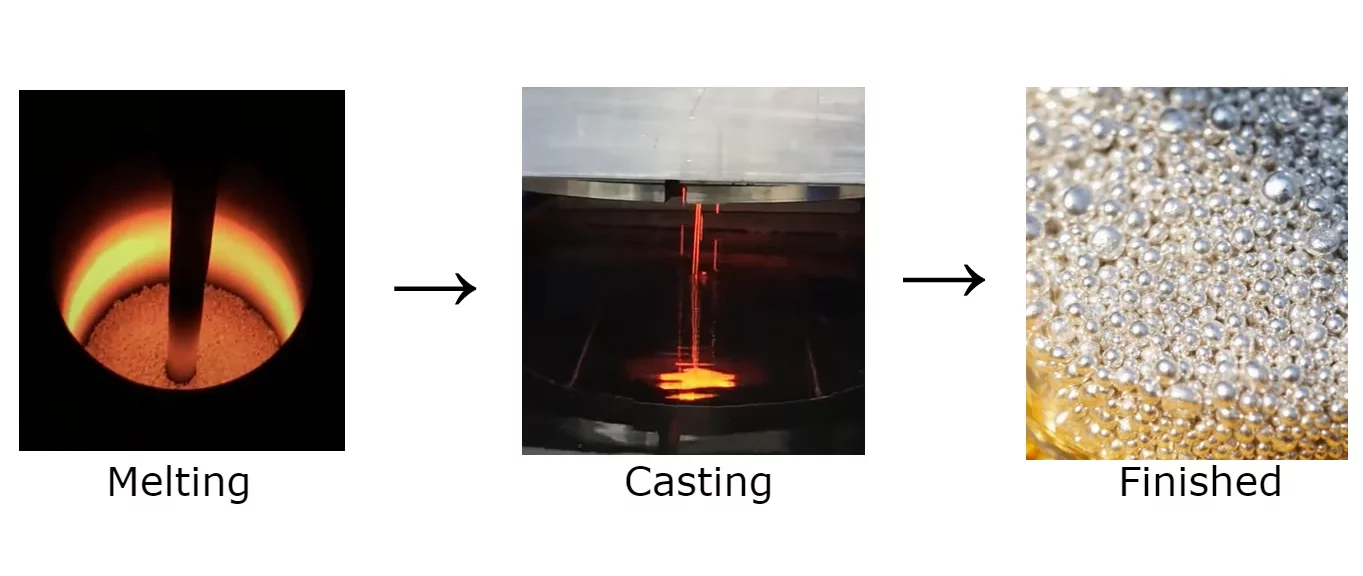

What is the Work Principle of Metal Granulating Machine?

The non-vacuum metal granulating machine is added with a water tank cooling device on the basis of smelting. When the metal is heated in the smelting furnace until its melting point reaches a liquid state, it will flow into a mold with holes, and finally flow into the cooling water tank to become metal particles.

What Final Products can Metal Grain Produce?

Metal Wires

The metal particles can be made into wire, the metal particles are made into a long rod by a continuous casting machine, then pressed to a specific thickness by a wire rolling machine, and finally the thin wire is made by a wire drawing machine.Metal Sheet

A continuous casting machine is also used to make the metal particles into long blocks, and then the metal blocks will pressed into sheets by a rolling mill.Tubes

Metal tubes can be produced by hollow tube welding machine shaping metal sheets around a mandrel and welding the seams together.Structural Components

Metal grains can be used to produce various structural components, such as beams, columns, and plates, for use in construction, bridges, and other infrastructure projects.Casting Jewelry

Metal particles can be used to make various jewelry, such as rings, bracelets, pendants, etc.Electronic Components

Metal grains can be used to produce various components for electronics, such as connectors, switches, and circuit boards.Why Necessary to Make the Metal to Particle?

Improving Reactivity

By reducing the size of metal particles, the surface area increases, leading to improved reactivity and making the metal more susceptible to chemical reactions.Improving Thermal and Electrical Conductivity

Metal particles have a high surface area-to-volume ratio, which leads to improved thermal and electrical conductivity, making them useful in various industrial applications such as electronics and energy storage.Increasing Strength

Fine metal particles can be dispersed in a matrix material to create a composite material that has improved strength and hardness compared to the individual components.Reducing Waste

By reducing metal waste into fine particles, it becomes easier to recycle the metal and reduce the environmental impact associated with traditional metal processing.FAQ Guide of SuperbMelt Metal Granulating Machine

1. How Many Capacity of Metal Granulation can it Achieve?

We have options from 5-100kg. According to your production demand, we will recommend the optimal model for you.

2. What is the Size of the Metal Particles?

The size of metal particles can be made into 2-5mm.

4. What Metals are Suitable for this Machine?

Gold, silver, copper, alloy steel can be made.

5. What Consumables do I need to Buy?

Stopper rods, graphite molds, graphite or quartz crucibles.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited