Gold Smelting Equipment

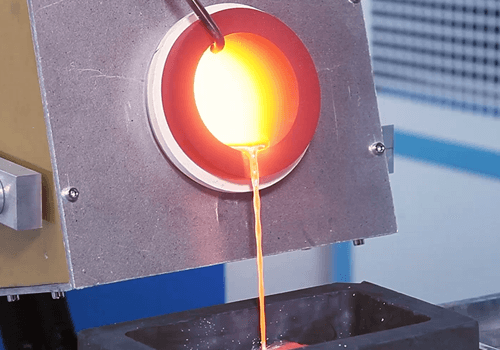

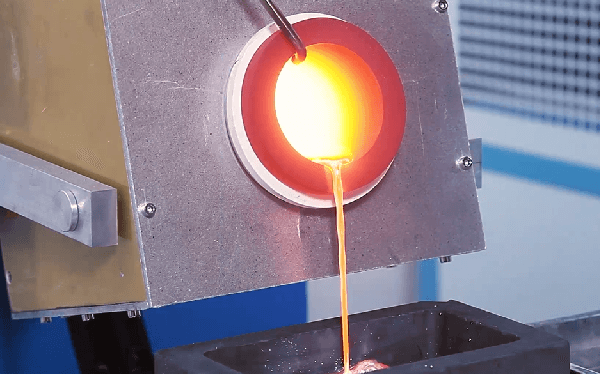

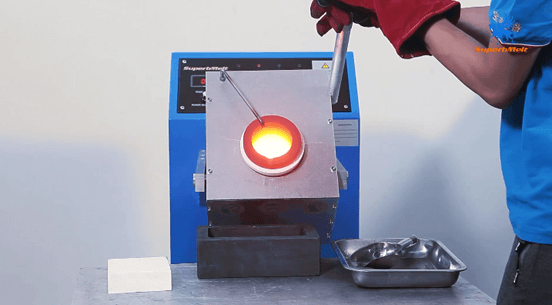

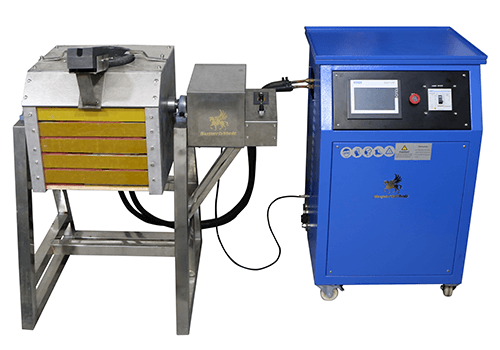

The Most Popular SuperbMelt 12kg gold (Pt, Ag, Cu, Al etc) smelting equipment on the market

SuperbMelt gold melting equipment (SPB-TB) can reach a maximum temperature of 1800℃ (the max temperature of tilting platinum smelter is 2600℃) with a power rating of 15kw. This provides an ultra-high heating effect capable of melting either 4kg of platinum or 12kg of gold or 6kg of silver (and similarly commensurate weights of other metals) within a period of 2-5 minutes.

SuperbMelt platinum and gold smelting equipment can heat your raw metals very fast. It speeds up your operations with the ultimate effect of increasing the profit margin. The gold melting machine is suitable for jewelry foundry and old jewelry refining plants.

Clere here to see more gold melting furnaces with different capacity

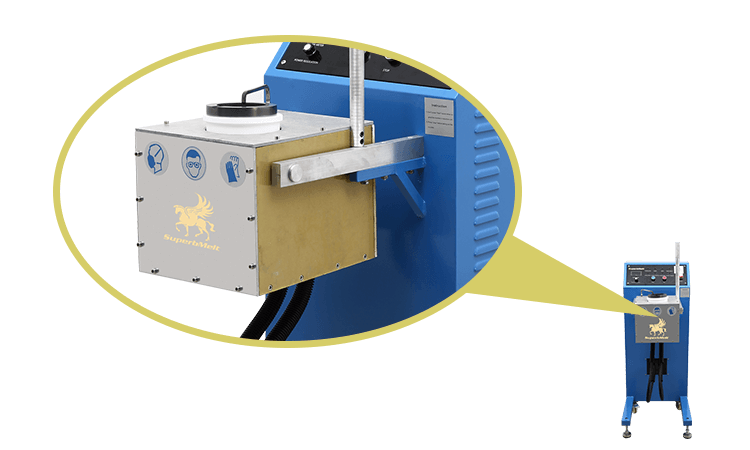

- Designed with convenience and efficiency as the core targets.

- The tilting furnace design ensures that melted metals can easily be poured into the mold. This prevents spillage or splashing which reduces the risk of operator injuries from hot liquid metal splashes.

- Another proof of the commitment to operator convenience is the use of a replaceable crucible for easy maintenance.

- Also, a strong electromagnetic stirring system ensures homogeneity of the liquefied metal. This comes handy especially for alloys.

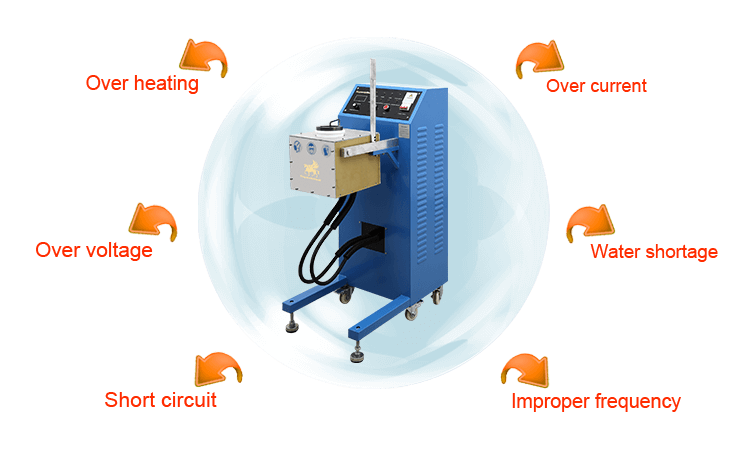

- The gold smelting furnace is also equipped with an omni-directional warning system. This alerts the operator when potentially harmful operating conditions are being approached.

- Induction gold smelting kit is manufactured with the capability of operating at full capacity for 24 hours. This considerably lowers downtime except for scheduled maintenance.

- The use of induction technology presents an advantage. Owing to the absence of electrodes and electric arcs which can form deposits of impurities.

| Model number | SPB-TB2 | SPB-TB4 | SPB-TB5 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 15 kw | 15 kw |

| Applicable metal | Platinum, palladium, gold, silver, steel, copper and their alloys | Platinum, palladium, gold, silver, steel, copper and their alloys | Gold, silver, steel, copper and their alloys |

| Max capacity | 2kg platinum | 4kg platinum | 12kg gold / 6kg silver |

| Melting time | 2 minutes | 3 minutes | 5 minutes |

| Max temperature | 2800℃ | 2800℃ | 1800℃ |

| Dimension | 740*500*1360mm | 740*500*1360mm | 740*500*1360mm |

| Weight | 95 kg | 100 kg | 95 kg |

| Heating technology | IGBT Induction heating | IGBT Induction heating | IGBT Induction heating |

| Water pump | Equipped | Equipped | Equipped |

| Cooling way | Water cooling | Water cooling | Water cooling |

Graphite crucible for gold/Silver melting Furnace

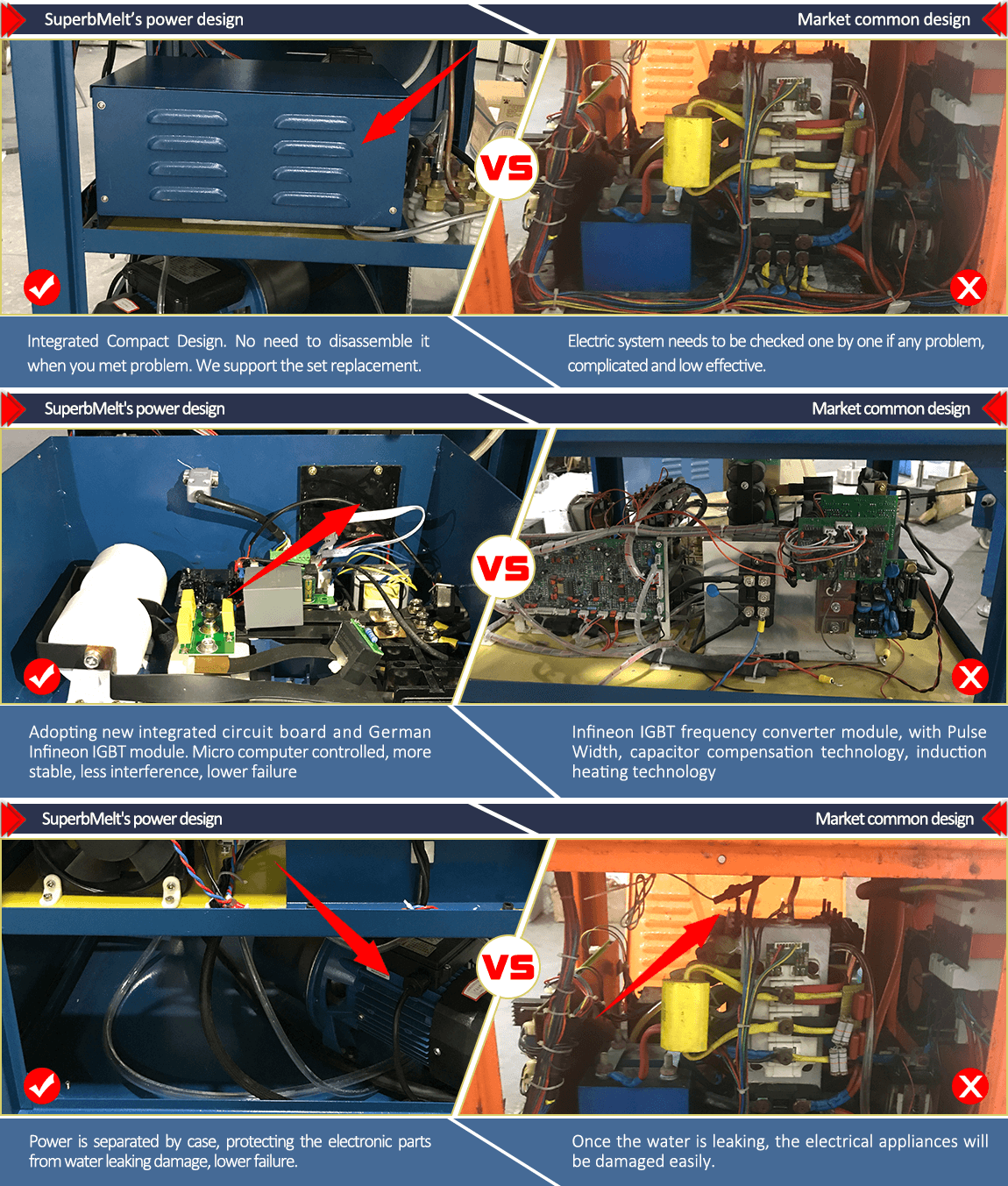

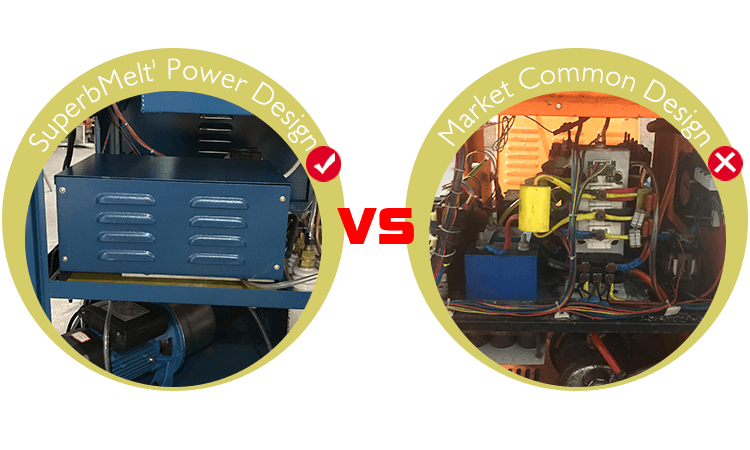

Compared with the common type, Our Superbmelt latest design power:

1,Save time and power

2,More Stable

3,Less Interference

4,Speedy melting, High efficient

5,Lower failure

6,Convenient repairing

Why SuperbMelt Gold Smelting Equipment

Helpful Resource For Your Reference ( An expert about induction gold melting equipment )

More SuperbMelt Gold Melting and Casting Equipment For Your Choice

Any Question About Induction Gold Melting Furnace

FAQ Guide of Gold Smelting Equipment

- Could I get 9999 Gold from Your Melting Furnace?

- What Is The Heating Principle for Gold Melting?

- Could We Use This Furnace to Melt Most Metals Like Iron, Gold, Silver, Copper and Aluminum?

- Does this machine Need Water Chiller?

- How to Solve the Gold Lost in Your Furnace?

- How Many Ways Does Gold Smelt?

- Can you melt 9 carats and 18-carat gold together?

- Can You Melt Silver in a Kiln?

- How Can I get Gold from Ore?

- How to Melt and Purify Gold?

- How to Melt Gold Dust?

- Could we Remove Copper from Gold In the Furnace?

- How to Remove Impurities from Gold?

- How to Separate Gold from Other Metals By Melting?

- How To Smelt Gold Jewelry?

- How many Degrees of Heat is Needed to Melt gold?

- Why is Borax Needed in Melting Gold?

- Can You Melt Old Gold Rings to Make New Ones?

- How Much Gold is There in Gold Ore?

- Can You Smelt Gold off Electronics?

- What is a Gold Smelter?

- What is the Best Way to Melt Gold?

- Can you Melt Gold without Flux?

- How do I Purify Gold at Home?

- How do you Know if It is Real Gold?

- Where can I Get My Gold Melted Down?

- Can I Melt My Own Gold at Home?

- What is the Difference between an Electric Arc Furnace and Induction Furnace?

- What Flux do You Use to Smelt Gold?

- How does an Induction Melting Furnace Work?

Could I get 9999 Gold from Your Melting Furnace?

Our gold smelting equipment is designed to smelt gold and other non-ferrous metals Therefore, our induction melting furnace cannot purify gold. It could smelt gold ore or sand to remove non-metal impurities to extract gold and other metals. Some customers used it for melt old gold to make gold bars For purifying purpose, it needs refining system.

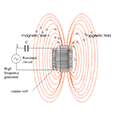

What Is The Heating Principle for Gold Melting?

The working principle of the induction heating process is a combined recipe of Electromagnetic induction and Joule heating. Planning to use a gold induction furnace? You will need to have the gold placed in a crucible since that is where the heating will be done.

The furnace is made using a non-conductive refractory material. The metal placed right inside the crucible will melt into a molten form. Ideally, the procedure used to generate high-quality non-ferrous alloys or steel for casting purposes. This should not be a complicated process to learn, but somehow, we can be of help if you feel that some skills are worth studying.

Could We Use This Furnace to Melt Most Metals Like Iron, Gold, Silver, Copper and Aluminum?

Yes, our machine is designed to melt most metals. But just before you melt ferrous metals, and non-ferrous metals, it needs to be fitted with different types of coils and crucible so that it performs optimally. For instance, silica crucible is best for both iron and steel melting.

The aluminum crucible is the best choice for melting copper, silver and gold. These things are important to understand, especially when you are looking to join the smelting and melting industry.

Does this machine Need Water Chiller?

Our machine can do very little if it does not rely on water chiller. Therefore, the most accurate answer to this question is yes. Note that gold smelting involves the generation of heat that could escalate to extremely high temperatures. If the water chiller is not used, the machine might encounter various complications.

A water chiller is a device that ensures successful heat exchange between the water and the refrigerant in a closed-loop system. As you can see, it is a necessary device that you might need, especially when you intend to engage in heavy-duty applications.

How to Solve the Gold Lost in Your Furnace?

Temperature control will set the melting point of gold alloy to avoid overheating to bring loss. Gold allow needs to be melted at a given temperature to ensure that there is no loss. Unless you are using the wrong Gold Smelting Machine, you will be able to take control of whatever is happening in the gold melting furnace. Before you begin melting, you need to ensure that you set temperatures to the correct levels. There is not supposed to be any gold lost in the furnace as long as you are using recommended procedures.

How Many Ways Does Gold Smelt?

The propane burner, resistance furnace, induction furnace, and microwave oven, are some of the primary ways in which you can smelt gold. It is important to know that all these methods work differently, which means you the same quality, and they also work at different speeds.

Out of the methods mentioned above, we tend to believe that induction furnace is the best method. It delivers the right amount of temperature to ensure that your gold is perfectly smelted within a shorter duration compared to when other techniques are used.

Can you melt 9 carats and 18-carat gold together?

Yes, you can melt the two metals together, but there are things you need to take note of. In case you melt together equal weights of 9 & 18-carat gold, you will end up with 13.5 carats.

Not so much use to anybody but the refiner. In order to have 9 carats from the mixture, you might need to add some silver and copper to a combined weight that is equal to the weight of the 18-carat gold. 40/60 fine silver to copper is the best starting point with the assumption that it is yellow gold we have in our case. To sum it up, it mainly depends on how much of each metal you are working on.

Can You Melt Silver in a Kiln?

Yes, this is a process that can be done. Kiln can generate enough temperature to melt silver successfully so that you cast it into different patterns and shapes as you please.

How Can I get Gold from Ore?

Smelting, which results in nearly pure gold, involves melting the negative terminals in our furnace at about 2,100 degrees F (1,149 degrees C). Our workers will add a chemical mixture known as flux to the molten material, so that the gold separates from the metals that are used to make the terminals. We will then pour off the flux and then the gold. Molds are used to transform the liquid gold into solid bars called doré bars. These low-purity bars are then sent to refineries all over the world for further processing.

How to Melt and Purify Gold?

Gold might be one of the hardest metals to purify, but there is always a solution. For instance, seasoned miners advice that you can refine gold using a mixture of nitric acid and hydrochloric acids. Using this method, you will get to dissolve the ore and also separate gold from available impurities. When you are through with the process, you will be left with gold and water.

Your gold will have an excellent purity level of up to 99.99%. That was just one of the many ways to refine gold once it has been separated from its ore.

How to Melt Gold Dust?

Melting gold is a critical process. If you cannot melt properly or fast enough, your end product will be affected. We would love to show you how easily you can melt gold dust. There is a wide range of methods that you can use; you can use a gas torch, an electric furnace, a gas furnace, and a coal furnace. The gas torch can also be used for gold melting, but gild dust can waste easily using a gas torch. Therefore, you might consider using a gas furnace, which is a good, affordable method. To complete the process using a gas furnace:

- Place some borax inside the crucible before you add the gold dust

- Use a flux, which is a mixture of borax and sodium carbonate. Try to mix this with gold dust right before you begin melting.

- Oil the mould hold and must be preheated

- Aluminium chloride can be used on the gold dust after pouring it on the crucible

- The last step involves selecting any portion of gold and then gold melting and then fixing it for melting.

Could we Remove Copper from Gold In the Furnace?

If you are using a crucible, it is very easy to remove some copper from gold. It would be a great idea to do this before you start to melt gold in the furnace. This is because once gold is in the furnace, the process might be really complicated.

Once you have added some copper in the crucible, remove the crucible and allow some time for the metallic mixture to cool down, Pour some nitric acid over the metallic mixture. Once you have done that, the acid will get the silver to dissolve the silver and any other base material. You will be left with pure gold.

How to Remove Impurities from Gold?

Gold might be one of the hardest metals to purify, but there is always a solution. For instance, seasoned miners advice that you can refine gold during amid smelting and melting using a mixture of nitric acid and hydrochloric acids. Using this method, you will get to dissolve the ore and also separate gold from available impurities. When you are through with the process, you will be left with gold and water. Your gold will have an excellent purity level. That was just one of the many ways to refine gold once it has been separated from its ore.

How to Separate Gold from Other Metals By Melting?

Gold might be one of the hardest metals to purify, but there is always a solution. For instance, seasoned miners advice that you can refine gold during amid smelting and melting using a mixture of nitric acid and hydrochloric acids. Using this method, you will get to dissolve the ore and also separate gold from available impurities. When you are through with the process, you will be left with gold and water. Your gold will have an excellent purity level. That was just one of the many ways to refine gold once it has been separated from its ore.

How To Smelt Gold Jewelry?

This is a possible process that you can do at home. You melt down your current gold jewellery and use it to make another item. This is a great process, especially when your current jewellery has some sentimental value. You will need a large baking potato and create some hole into it. Now you want to place some borax into the potato because it will help to get rid of any impurity available. Now you are free to add your gold to the hole and begin smelting.

How many Degrees of Heat is Needed to Melt gold?

You will need around 1,948 Fahrenheit to melt gold. This is the temperature that is needed to end up with stronger gold, because naturally, gold is way too soft to be used. Normally, it is advisable to use other alloy metals such as zinc, copper, silver during the melting process. Gold will always boil at a temperature of 5, 173 degrees Fahrenheit.

Why is Borax Needed in Melting Gold?

At SuperbMelt, what comes to our mind when we hear the word Borax is gold refining. This is very accurate since this mineral does way more than just clean clothes. It is a vital flux in metallurgy for separating slag from gold. You might have realized that lots of borax in the detergent aisle, but this product has a wide range of uses in a plethora of industries. In metal refining, borax is used as a cleaning agent that helps to get rid of impurities from precious metals such as gold.

Once you have borax, heat, and some knowledge here and there, you will not spend a lot of time trying to get rid of impurities from your gold. By using borax, you will greatly reduce the melting point of all the elements in the piece of a given ore, with gold included. While out there in the field, a gold prospector can grind and clean a piece of ore before mixing it with borax in a plastic bag. This bag will then be put in a crucible or gold and then heated at highly escalated temperatures. It is the heating action that makes borax to do what it is supposed to.

Can You Melt Old Gold Rings to Make New Ones?

Reusing precious metals is not an easy task compared to reusing gemstones. But it is a possible process. If you like, you can melt old gold and use the same product to make a new item. If you want, you can talk to some of our designers, and they will do the job for you. Gold can be melted down and redesigned on a ring by ring basis, and there are no special skills needed. However, if you decided to do this on your own, you want to ensure that no bubbles are formed as this might reduce the overall quality of the item you are making. It is not also possible to change the alloy. Therefore, for instance, you won’t be able to change yellow gold into white gold using this process. There are only three reasons why you might need to do this:

- For ethical reasons, which means newer mining has to take place You can also do this for financial reasons for instance if there are high levels of a carat in the gold If the metal itself has some sentimental value, for example, if it is a grandparent’s ring

Now we can tell you that this is a possible process, but you might need to talk to an expert beforehand, even if you wish to do it yourself.

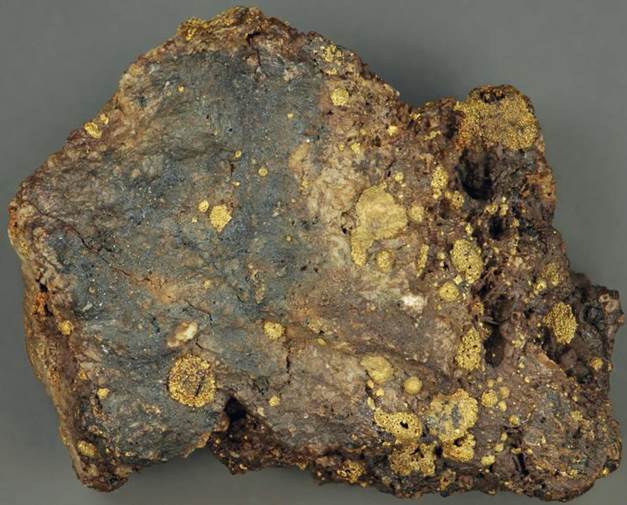

How Much Gold is There in Gold Ore?

Gold has a relatively high density (19.3 per cubic centimeter) and has made it amenable to recovery by placer mining and gravity concentration techniques. With a face-centred cubic structure, it is characterized by a softness and malleability that lends itself to being shaped into intricate structures without sophisticated metal working equipment. This in turn has led to its application from earliest times to the fabrication of jewelry and decorative items.

Gold mines and gold deposit are often categorized by the average proportion of gold contained in the ore at site. This is known as the ore grade.

All precious metals are graded by the proportion of metal in the ore. Grams per tonne of milled ore or g/t, is the most common metric used to represent grade of ore. The value of precious metal mines is determined by its total estimated weight, the grade of the ore and how difficult it is to extract and distribute.

The World Gold Council defines a high quality underground mine as having a gold ore density between 8 to 10 g/t, while a low-quality underground mine has a gold ore density of 1 to 4 g/t.

Can You Smelt Gold off Electronics?

Gold can be smelted off electronics for instance circuit boards of phones and laptops and the process of doing so involves the following:

Collect the straps from phones, most of the gold is in sim cards, the main board and the smaller components on the back of the LCD screen. Use a magnet to separate all gold plated steel parts as you need a different process to extract it.

Strip out the boards by placing your circuit boards in a glass vessel (a plastic container may get burned by the acid). In another container, mix two parts hydrochloric acid and one part weak hydrogen peroxide. Pour this mixture over the circuit boards so they are completely submerged. Wait for a week, giving the vessel a stir everyday with a glass or plastic rod. Over time, the acid will darken and gold flakes will come off the scraps.

Collect the flakes by filtering. The gold flakes are left behind. Pour the remaining circuit board bits into a deep plastic tray filled with water. Save any pieces with remaining gold for re-dipping. Pour the water through the filter to collect any gold dust and flush the flakes with water. Wash with methanol afterwards, wash with water to remove any residue.

Melt the gold by mixing with some borax. This enables the gold to be melted at 1064 degree celsius. When borax begins to soften add the gold flakes. Heat until the flakes are melted.

What is a Gold Smelter?

Gold smelting is the ability to extract gold from the ore it is combined with. Metal ores need to be heated to very high temperatures to produce pure metals, far higher than open fires can produce.

The result of smelting gold ore produces gold nuggets or gold bars.

There are types of furnaces used by gold producers to smelt gold. They are; propane burners, blast furnaces, induction furnaces, etc. The jewelry furnace is the most preferable since it has a high speed of melting. It is also the cleanest furnace to operate and the one with the smallest volume of flue gas and minimum metal loses. The efficiency, simplicity and high speed of operation achieved by the jewelry furnace justifies its capital cost. Jewelry furnaces tend to give a well mixed melt due to the stirring action of the electromagnetic field.

What is the Best Way to Melt Gold?

Melting gold requires a great amount of heat. There are several methods of melting gold; using a 1200 watt microwave, kiln, propane burner, electric arc furnace, resistance furnace or a gold melting machine.

The best method of melting gold is the use of a gold melting machine. It is important to have the right materials for melting gold in a gold melting machine. The following are what is required for melting in a gold melting machine; a gold melting machine, a crucible, protective gears, tongs, casting mold, flux (for smelting), etc.

Can you Melt Gold without Flux?

Flux is used to remove impurities from gold during smelting. Not using flux when smelting can be consequential, which will include issues like; loss of precious metals, difficulty in separation and impurities in gold.

Here are the ways in which the use of flux is beneficial:

Gold smelting will require a lower energy for melting as the flux speeds up the smelting and oxidation process.

Without the use of flux, gold cannot be easily separated from impurities, therefore, the use of flux contributes to getting a pure ingot or jewelry. Therefore, we can say that you need flux for smelting.

However, you do not need flux when melting gold because your gold is already pure.

How do I Purify Gold at Home?

Purifying gold involves dissolving impure gold in acid such that all impurities fall out. It is possible to refine gold without the use of large-scale, expensive chemical procedures. The process involves first adding nitric acid to gold (30 minutes), then adding hydrochloric or muriatic acid. After allowing this mixture to sit, it is filtered to remove contaminants, then treated to neutralize the acids in the solution. The result will be what looks like mud at the bottom of the container; this “mud” is actually gold. Rinse the muddy chunks three or four times with water, then treat with aqueous ammonia. After white vapors form, rinse the gold again with water and allow it to dry.

How do you Know if It is Real Gold?

There are several ways of identifying real gold. They are;

Magnet test- Holding a magnet close to the gold can determine the authenticity of gold. When a magnet is held close to the gold, if the magnet attracts the gold then it is fake and vice versa.

Visual inspection- The marking or hallmark tells you what percentage of gold items it consists of. The jewelry hallmark is usually printed on jewelry clasps or inner bands of rings.

Performing a density test by weighing the gold on a scale. Most of the time the hallmark may be false.

Using a nitric acid test- A little amount of nitric acid is dropped on the gold item, if there is no reaction, this means the gold is original; if there is a green or milky colouration, the gold is fake.

The magnifying glass test- This is a straightforward method of testing originality of gold. The magnifying glass helps to discover any signs of discolouration, colour, shinines and the hallmark purity.

The float test- The jewelry piece is placed in a bowl of water. If the gold sinks to the base of the bowl, it is original; if the gold floats, the gold is fake. This is not 100% accurate.

The scratch test- You can perform this test by rubbing the jewelry across any material of your choice (black jeweler stone, unglazed ceramic plate or unglazed porcelain tile). Analyze the colour of the produced streak, if the gold is real, it shows a golden, yellow colour. However if the streak is black, the gold item is fake.

Skin test- Hold the gold item in your hand for a couple of minutes. If it is fake, the sweat on your skin will cause a chemical reaction with the metal.

Handheld XRF analyzer- You can perform the most accurate gold test with the handheld XRF analyzer. This simply works by pointing the analyzer directly at your gold and it will display all elements present in the gold item along with the percentage on each element. With this, you can determine the authenticity of your gold without destroying your gold compared to other methods of testing.

Where can I Get My Gold Melted Down?

Melting old jewelry is possible but might be a challenge if the karat is less. A lesser karat gold item may be difficult because it has different metals with different melting points. You can however melt down your gold on your own depending on your level of expertise or a jeweler can do that for you. New jewelry can be created with the melted gold, if the material is insufficient for the new design, a new metal can be added.

Can I Melt My Own Gold at Home?

Melting gold requires a certain degree of heat source because it melts at 1064 degree celsius. Yes, gold can be melted at home using different techniques. You can use a propane torch, a 1200 watt microwave or a mini gold melting furnace. We recommend you use a mini gold melting furnace. There is a portable gold melting furnace for small melting production or hobbyists. With the mini gold melting machine, you can melt very fast in an accurate way. Just ensure your work area is well ventilated and you have protective equipment.

More and more people are learning to melt gold on their own because of how much they can save and how easy the process is to master.

What is the Difference between an Electric Arc Furnace and Induction Furnace?

Electric arc furnace uses its arc to generate heat to melt metals, while the induction furnace uses electromagnetic induction to generate heat to melt metals.

In the electric arc furnace, the heat of the arc after the material is cleared must be transferred to the molten metal through the slag, which is indirect heating. Thermal efficiency is poor. The furnace is in the shape of a basin, and plenty of the heat of the arc is lost through the furnace cover and the furnace wall. While the induction furnace is heated faster and has higher thermal efficiency. The heat is generated in the furnace, so the heating speed is high.

The oxidative burning loss of elements in an induction furnace is less. Because there is no ultra-high temperature of the arc in the induction furnace.

What Flux do You Use to Smelt Gold?

The following types of fluxes can be used to smelt gold: Borax, silica, hydrochloric acid, ammonium chloride, sodium nitrate, sodium carbonate, zinc chloride etc.

The use of flux for gold smelting has its benefits which includes; lower energy cost, higher profit margin, removal of mercury that can be harmful to health, and a pure separation process.

How does an Induction Melting Furnace Work?

Induction melting furnaces operate on a radically different principle to the cupola version. The induction furnace uses coil heating elements embedded within a crucible or integrated into the walls of the heating chamber itself and produces a magnetic field. These convert electrical energy into heat which is radiated through the material with an outstanding degree of thermal uniformity. The magnetic field can change directions depending on the direction of the current flow. An alternating current that passes through the coil causes a magnetic field that changes in the same direction at the same speed as the current. For instance, a magnetic field switches directions 60 times a second if the current is 60Hz AC.

Ultimate Gold Melting Furnace Buying Guide

At SuperbMelt, we have the best gold smelting equipment that comes with excellent features to make it stand out from the competition. This product can smelt non-ferrous metals such as gold, aluminium, copper, and silver. It can perform high-quality functionality even on metals of 250kg. Our Gold Smelting Equipment can work on metals and smelt at a temperature of 1800 degrees Celsius.

Application Fields of Gold Smelting Equipment

Our Gold Smelting Equipment can be used in a wide range of fields, some of which are mentioned below.

1.1, Smelting the Gold Ores

High pressure is usually involved in smelting gold. Heat and chemicals are also needed to ensure that the ore is broken down with the aim of separating it from available impurities. To smelt gold, it needs to be heated to a temperature of around 2,150 degrees Fahrenheit or 1046 degrees Celsius. Gold smelting equipment can be used to smelt gold ores, gold dust and gold mines to get rid of none-metal impurities so that pure gold is extracted.

1.2, For Recycling old gold

If you have some old outdated jewelry in your house, it makes sense if you can come up with a way of using it to create something new. This can be done when you have a much more wearing design in mind. This can be best done at home, especially if you are deeply convinced against finding an expert who can do the work for you.

You need to use the right smelting equipment to melt your jewelry down so that you cast it into something new. The same thing can be done with semi-finished products such as plates, tubes, and rods. Maybe you have something with sentimental value, but it does not fit your current lifestyle.

1.3, For Jewelry Casting

Before you cast jewelry, you need to ensure that it is melted so that it is turned into aqueous state, or rather converted from solid to liquid. Thereafter, you can use the smelting process, to improve the purity of your gold. Jewelry casting involves the creation of mold. The mold is then filled with molten metal so that you get a piece of finished jewelry.

This process is generally referred to as lost wax casting, and we are here to tell you that you can do all that with our machine. The process has that name because the process involves the lost of wax. Gold casting is a process that can be applied on gold nuggets and scrap gold to make things such as gold bars or granule for stock and deal.

1.4, For Industrial Applications

We started by making it clear that our gold smelting equipment is created to ensure that you get the most pleasurable application experiences. Despite your preferred field of application, SuperbMlet’s Gold Smelting Equipment is there to ensure that what you want is what you get.

Our equipment can be used for industrial applications, and it will record an exclusive performance. We understand that you might be looking to smelt metal in the workplace to come up with various products, which is why we think you might need the benefits that our equipment comes with.

The fact that our equipment can smelt at extremely high temperatures makes it ideal for a vast range of industrial applications. It can be used to smelt non-ferrous metals so that you end up with pure products that would make your business stand out from the competition. They have limited emission, which makes environmental and user friendly.

How to Smelt Gold Nowadays

The world has really advanced, and there are newer ways to smelt gold. In case you haven’t known these methods, you better start feeling lucky because we are about to lift the lid for you. But before we get started, let us remind you that most of these things can be done using our gold smelting equipment.

2.1, How to Smelt Gold By Propane Kiln

Wondering how to smelt gold by propane kiln? Read on. To begin, get a crucible container to let you hold the gold as it melts. There are impurities in the gold, and you can use flux to remove them. While doing these things, you need to give your safety the best priority because accidents might occur. Remember you will need to use heating out to generate the heat needed to smelt gold.

A propane kiln can help you melt gold. Once that is done, go ahead and shape your gold. To do this, make sure that the gold is placed in a crucible. If you are handling a finely powdered gold, be careful and make sure that you provide your flame and see that it is done slowly and safely. Failure to do that might have you blow out the whole powder from the crucible.

You need to heat it thoroughly and do it slowly. You need to have the flame right above the powder and try to see that the heating is done while delivering equal amounts of heat to the entire gold metal.

2.2, How to Smelt Gold By Resistance Furnace

Resistance furnace is more of current passing through conductor joule heat that is generated by an electric furnace for the source of heat. In this process, furnace acts as the heat source. It uses electric heating elements to convert electrical energy into the final heat energy. The heat energy is then used to heat metal. Resistance furnace can be used to smelt high amounts of gold, but it still might not be the best method out there.

This method might not be great especially when you are looking to avoid paying huge electricity bills for starters. Again, resistance furnace might develop heat complications, thereby leading to unevenly smelted gold. Therefore, try to use other smelting methods that will ensure that impurities are removed from the gold metal you are working on.

2.3, How to Smelt Gold in Induction Furnace

An induction furnace is an electrical furnace that involves the application of heat through induction heating of metal. Induction furnace comes in a wide range of capacities, from less than a kilo to a hundred tones. These machines are used to melt iron and steel, aluminum, copper, and precious metals.

2.4, Why You Should Choose Induction Furnace

Whether you are a seasoned smelter of a novice, you can always do well with induction furnace. These machines are programmed to smelt gold and other non ferrous metals of any size. They also are great for applications that require accurate supply of heat energy for casting purposes.

Without spending a fortune to get these furnaces, you will be impressed by the fact that they come in compact design with features put in place for precision purposes. The heat is supplied evenly to the entire metal within a short duration and you already have your results. You can always get in touch with us for the best deal since we are some of the key players in the industry.

| Model | Propane Melting Kiln | Resistance Melting Furnace | Induction Melting Furnace |

| Heating Principle | Propane Gas Burning | Resistance Heating | Induction Heating |

| Power | Propane Consumption | 1.7kw | 3.8kw |

| Melting Time | Over 30 min to melt I kg | Melts 1 kg of gold within 20 minutes | Melts 2kg of gold within 5 minutes |

| Max Temp | 1200 degrees | 1200 degrees | 1500 degrees |

| Molten Metal Stirring | No stirring function | No stirring function available | There is a magnetic field that stirs the molten metal to ensure that the alloy is perfectly mixed |

| Power Consumption | No electronic consumption | The induction heating saves more than 10 times power consumption per kilogram compared to resistance melting furnace | |

| Protection alarm | No protection for the gas burning, could lead to risky explosion | You can easily get burned due to lack of protection | There is an over-heating protection, but there is no water alarming |

| Working Time | Depends on propane supply | Can only work for 40 minutes before being let to cool down | It can work 24 hours continuously based on good water cooling |

| Machine Life | After frequent use, you will need to replace the heating torch | At least 50% of these machines get broken down after 12 months | As long as the cooling is perfect, the machine can last more than five years |

An induction furnace features a nonconductive crucible that holds the charge of metals that need to be melted, and a coil of copper wire also surrounds it. There is an aggressive alternating current that is flowing through the wire. It is the coil that creates a rapidly reversing magnetic field which penetrates the metal.

The magnetic field ensures that eddy currents, and circular electric currents are induced inside the metal. It does this through electromagnetic induction. Once the metal has been melted, the vigorous stirring is caused by the eddy currents to ensure that uniform mixing is achieved.

The Kinds of Gold Smelting Furnaces that SuperbMelt Can Provide

If you have not accessed our products and services, take a look at types of gold smelting furnaces you can have from us.

3.1, Mini 1-2kg Gold Smelting Furnace

SuperbMelt mini gold melting furnace (SPB-DH) is suitable for any of your small-scale gold production. It is capable of melting any gold pieces whose weights fall in the range 1-2Kg.

This small gold smelting machine can in no time reach a maximum temperature of 1600℃. This features also make this machine for melting other metals such as silver, copper and aluminium, just to mention a few.

SuperbMelt mini gold melting furnace also finds application in jewellery recycling. It is also very suitable for gold diggers in deals in collecting gold and its alloys.

3.2, Integrated 3-10 kg Gold Melting Furnace

The gold melting furnace is designed for melting 3g – 10kg gold. It is also suitable to melt other precious metal like silver, copper, palladium.

Induction gold melting furnace is based on the latest and most advanced IGBT induction technology, the top speedy melting could be realized within 2-4 minutes. The crucible is extractable by means of matched tong.Superb gold melting furnace is the better choice for lab, jewelry shop , research institute and mining company comparing with gas melting device and resistance melting type.We will make testing videos for each machine to ensure quality. Superbmelt also provides warranty of full refund due to bad quality within one year.

Let us take a look at the key features of this particular gold smelting equipment.

- Energy saving, Environmental protection, Low pollution level

- Light weight, Economic Space Occupation, Easy installation

- Enhanced monitoring and diagnostics system of SPB-H series gold melting furnace, guarantee the machine of high stability, reliability and security.

- Strict Supplier Management System and ISO 9001:2015; CE Quality Management System guarantees high quality of each equipment.

- 100% duty cycle, 24hours continuous working ability at maximum power.

- Superb gold melting furnace takes Use of solid-state IGBT inverter and power regulation, soft switch three resonance and frequency automatic tracking technology.

- The top speedy melting rate can finish per batch within 3 mins nearly.

3.3, 20kg-30kg Manual Tilting Melting Furnace

SuperbMelt gold smelting furnace, unlike any other product on the market, comes with awesome specifications. It has the capability of melting 20-30kg of non-ferrous metals like gold, silver, copper, aluminium. It can melt any metal up to a temperature of about 1800℃ based on an induction power supply of 25-35kw. All within a short time frame of 6 to 8 minutes.

Induction gold smelting furnace split design enhances easy tilting. This feature which gives the room for the pouring of liquefied metal without splashing or spill.

3.4, 10-50kg Chain Tilting Gold Smelting Furnace

This Gold Smelting Equipment from SuperbMelt comes with superb features that will place you ahead of your competitors. It has unique features that let it smelt 10-50kg of non-ferrous metal such as silver, gold, copper, and aluminium. It has the potential to melt up to a temperature of 1800 degrees centigrade. With its awesome features, there is no learning curve linked with this affordable, high-end product. At SuperbMelt, most of our efforts are spent in ensuring that you have the best equipment that can be used for any type of application. It is an innovation that you will use for many years to come.

3.5, 10-100kg Motor Tilting Melting Furnace

Are you looking to smelt any type of non-ferrous metal and in large quantity? Then this furnace must be the solution you have been looking for. It leverages carefully selected smelting technology that can melt between 10 and 100kgs of metals. But that is not all. The 10-100kg Motor Tilting Melting Furnace is one of the best on the market since it melts up to the required temperatures to let you mould your final product with ease.

3.6, 50-250kg Hydraulic Tilting Melting Furnace

This is the best Gold Smelting Equipment that you can get at SuperbMelt. Unlike other products, it is highly aggressive and generates enough energy to smelt non-ferrous metals of between 50 and 250 kg. This hydraulic tilting melting machine does come with sophisticated parts that let it complete the work within the desired time.

Though easy to us, it does not have some parts that you need to handle professionally, but that does not take too much of your time to learn. You can always talk to use beforehand since we have everything required to have a fascinating experience using this highly innovative gold smelting equipment.

Conclusion: How to Choose the Right Smelting Furnace

Just like any other business, you need to have a good plan before starting to operate. At SuperbMlet, we have many clients looking to

start smelting and melting businesses, without doing the due diligence. Note that any mistakes in the starting stages might make your business sink before it starts to make money. Therefore, since we value our clients, and wish them the best, we would like to share important information on how to choose the right smelting furnace.

Here are some of the things you need to consider when looking for the right gold smelting equipment.

1.The Gold Capacity

This has something to do with the size of your business. For instance, there is no point in looking for a 1kg gold smelting furnace, when you need to produce in large quantities. Though you can always start small as you grow, large businesses require a huge investment to keep with the ever-growing competition. You must have seen up there that we

have any type of equipment that you might need. Before you put your money on any equipment, think about the type of production you would like to take part in and make the most informed decision. If you like, you can go for a furnace that can smelt precious metal of up to 500 kg, depending on what suits your business best.

2.Consider Your Business Model

We are back to the business plan. It is crucial for you to understand your business model before making an initial investment. In case you are looking for something portable, maybe you are a small dealer or small scale gold miner, then there is no reason for you to go for something really huge. This makes sense in that you will spend a lot of money on power and space that you won’t need.

Also, small scale producer tends to plough back a small profit margin, so it will take time for them to get ROI in case they opt for the larger equipment. Big miners can use motor tilting furnace or hydraulic tilting furnace. It has adequate features to make you compete fairly as you try to grow your business and dominate a larger portion of the market.

3.Consider the Price

At SuperbMelt, we have any type of furnace that you might be interested in. But as the buyer, you ought to know that price plays a major role. This is important, regardless of the nature of your business. Even large businesses might have to plan well financially so that they do not record losses at the end of a given financial period.

Therefore, instead of exploiting your financial wellbeing, it is advisable to see that you are spending the right amount of money that will not bring your company to its knees. Check out our website for various types of furnaces we have and their prices so that you get what is right for your business’s undertakings.

4.Think about applicability

The world has gone tech-savvy overall, and many types of products are introduced in the market each day. With that in mind, you need to only go for what will help your business to thrive. Applicability is one key aspect to consider when thinking of getting the tight Gold Smelting Equipment. This is true in the sense that some of the newest products come with fewer features that limit you from getting high-quality products.

Some of them also consume a lot of energy without reflecting the same on their productivity. If you are just looking to start a business, it is vital to ensure that you are putting your money on something that will not cripple the overall stability of your business. We at SuperbMelt, advice that you test the equipment and ensure that all parts are working fine before making a purchase.

5.The reputation of the Dealer

You are not going to buy from the first dealer you find on the internet or offline. Do your homework fast, and we wish there was a way to emphasize this enough. This is where most buyers go wrong. They want to buy from dealers they know very little about, and they end up with wrong products that cannot even last.

If possible, try to run background research on the reputation of various dealers you wish to buy from and confirm that they have been on the market for some time. Online platforms can be created to review various manufacturers, and you should use them to avoid buying from dealers who do not care about quality. Talk to their previous buyers or rather ask questions on social media about the reputation of various dealers, including SuperbMelt.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited