2kg Melting Furnace

The most popular SuperbMelt 1-2kg gold and silver melting furnace on the market

SuperbMelt 2kg melting furnace can melt up to 2kg of metals in a single operation. It is suitable for melting silver, gold, copper, aluminum, brass, bronze, and their alloys.

The furnace is available in two models: SPB-DH1 and SPB-DH2, designed to meet specific needs. Equipped with an induction heating system, the furnace not only saves time and costs but also enhances the efficiency of the production line.

This electric melting furnace is versatile and applicable in various fields, including jewelry making, scrap recycling, laboratory research, and personal use.

At SuperbMelt, our dedicated research team continuously develops innovative technologies to meet market demands and fulfill customer needs. We provide a wide range of machines to customers worldwide, catering to their unique melting and casting requirements.

For those looking for furnaces with larger capacities, please click here for more information.

If you wanna check metal melting furnaces with bigger capacity, Please click here.

- Superbmelt 2kg gold melting furnace is suitable for melting metals such as gold, silver, aluminium, copper, brass, bronze, and their alloys.

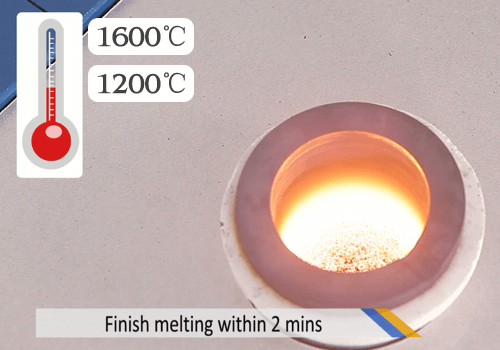

- You can melt up to 2kg of metal within 2 minutes, and 30kg of metal within 1 hour.

- The 2kg electric melting furnace allows you to melt continuously for 24 hours due to the presence of the water cooling unit. The water cooling unit prevents overheating of the metal melting furnace.

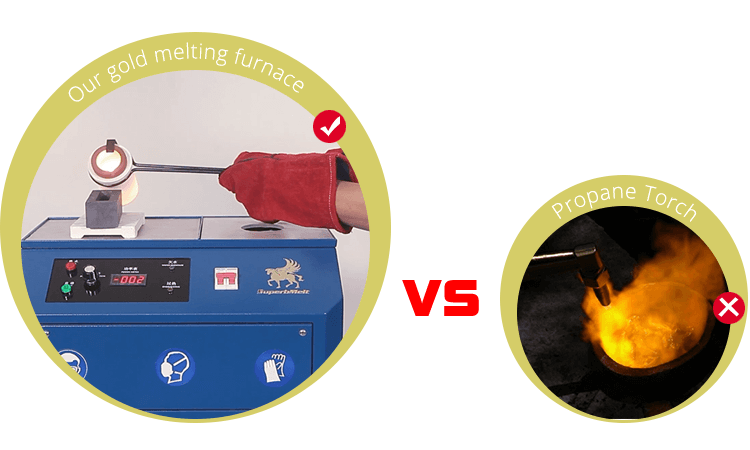

- Superbmelt metal melting furnace has an IGBT induction heating technology that ensures molten metal consistency, conserves energy use and saves melting time.

- Superbmelt home furnace for melting metals has a PLC control system which makes it easy to use.

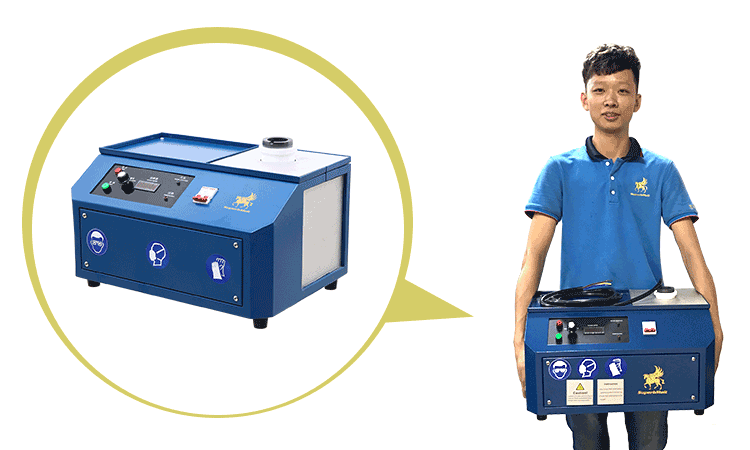

- Our 2kg gold melting furnace is a compact design with a dimension of 520*400*330mm and a total weight of 21kg to 22kg, this means you don’t require much space for your small melting furnace and it is easy to transport.

- Superbmelt electric melting furnace is suitable for use in jewellery industries, metal scrap recycling, gold mining, gold recovery plant, laboratory research, personal melting, etc.

- Superbmelt small metal melting furnace is safe for both the operator and the environment. The melting chamber of the 2kg gold melting furnace is enclosed to prevent molten metal spillage and escape of melting temperature.

- There is no release of toxic gases, smoke or noise when melting with Superbmelt electric melting furnace.

- You can use readily available crucibles such as graphite and silicon carbide crucibles to melt in your metal melting furnace. The graphite and silicon carbide crucibles are available at Superbmelt Electromachinery Co. Limited.

- Superbmelt small metal melting furnace is highly efficient for melting. Items cast are usually free of shrinkage, oxidation and porosity.

- Superbmelt 2kg electric melting furnace has a maximum temperature of 1600 degree celsius.

- The maximum power required for melting in the gold melting furnace is between 3.5kw and 3.8kw. Therefore, you don’t need to incur extra cost for melting and you can save up to 50% on energy.

- The 2kg melting furnace comes with an installation video and tutorial guide. This makes the operating process easy for you, even as a first time user.

- Superbmelt 2kg gold melting furnace prevents precious metal loss compared to the traditional melting process.

| Model number | SPB-DH1 | SPB-DH2 |

| Power source | Single phase 220V, 50/60Hz | Single phase 220V, 50/60Hz |

| Power | 3.5 kw | 3.8 kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 520*400*330mm | 520*400*330mm |

| Weight | 21 kg | 22 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

Graphite crucible for gold/Silver melting Furnace

Small 1-2kg gold and silver smelting pot is portable size design, light weight, easy to carry and fix.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Induction 2kg Melting Furnace

Any Question About SuperbMelt 2kg Melting Furnace

1. Can you melt gold with induction?

Yes, you can melt gold using induction heating. Induction melting is an efficient and precise method for heating and melting metals, including gold. It works by generating an electromagnetic field through an induction coil, which induces electrical currents (eddy currents) in the metal. These currents cause the metal to heat up due to its electrical resistance, ultimately leading to melting.

Key Advantages of Induction Melting for Gold:

- Efficiency: Induction melting heats the metal directly, reducing energy loss.

- Precision: It allows precise temperature control, ensuring optimal melting conditions for gold without overheating.

- Clean Process: Induction melting does not produce open flames, making it a cleaner and safer method.

- Speed: Gold can be melted in minutes, saving time in production or crafting processes.

This method is widely used in industries like jewelry making, metal recycling, and laboratory research due to its effectiveness and reliability.

2. How hot can a melting furnace get?

The maximum temperature a melting furnace can achieve depends on its type and the technology used. Here’s a general overview:

Induction Melting Furnaces: Typically, induction furnaces can reach temperatures of up to 2,800°C (5,072°F). These furnaces are ideal for melting high-temperature metals like steel, platinum, and titanium.

Electric Resistance Furnaces: These can generally achieve temperatures of about 1,200°C to 1,800°C (2,192°F to 3,272°F). They are suitable for metals like gold, silver, aluminum, and copper.

Gas-Fired Furnaces: Commonly used for melting metals like iron and bronze, these furnaces can reach temperatures of around 1,600°C to 2,000°C (2,912°F to 3,632°F).

Crucible Furnaces: Designed for melting non-ferrous metals, crucible furnaces often operate at a maximum temperature of 1,100°C to 1,500°C (2,012°F to 2,732°F).

Each type of furnace is optimized for specific applications and materials, and the choice depends on the melting point of the metal and the production requirements. For gold and silver, furnaces typically operate within a range of 1,000°C to 1,200°C (1,832°F to 2,192°F), which is sufficient for these metals.

3. What metals Cannot be heated by induction?

Induction heating relies on electromagnetic induction to generate heat within a conductive material. Therefore, metals that cannot be effectively heated by induction typically fall into these categories:

Non-Conductive Metals:

- Metals with very low electrical conductivity, such as lead or tin, are challenging to heat effectively because induction heating depends on creating eddy currents within the material.

Non-Magnetic Metals:

- Non-magnetic materials like copper and aluminum can still be heated by induction but require higher power and take longer compared to ferrous (magnetic) metals.

Non-Metallic Materials:

- Materials such as ceramics, plastics, and glass are entirely unsuitable for induction heating unless they are coated or embedded with a conductive material.

Metals with Low Permeability:

- Metals with low magnetic permeability, such as austenitic stainless steels, are harder to heat with standard induction methods, though specialized systems can overcome this limitation.

In summary, while induction heating is highly efficient for most conductive metals, those with poor conductivity, low magnetic permeability, or a low melting point may require alternative heating methods for optimal results.

4. Can I melt gold without flux?

Yes, you can melt gold without flux, but using flux is generally recommended for better results. Flux serves several purposes in the melting process:

Benefits of Using Flux:

- Removes Impurities: Flux helps to separate impurities from the gold, resulting in purer molten metal.

- Prevents Oxidation: It creates a protective layer over the gold, minimizing oxidation during melting.

- Improves Flow: Flux ensures smoother pouring by reducing viscosity and improving the flow of the molten gold.

Challenges Without Flux:

- Without flux, impurities may remain in the gold, affecting its quality.

- Oxidation can occur, leading to discoloration or imperfections in the final product.

- The melting process might be less efficient, particularly for scrap gold or gold with alloyed metals.

When Melting Without Flux:

If you choose to melt gold without flux:

- Use clean, pure gold to minimize impurities.

- Employ a controlled environment with minimal oxygen exposure to reduce oxidation.

- Use high-quality equipment like an induction melting furnace for precise temperature control.

While it’s possible to melt gold without flux, incorporating it can significantly enhance the process, especially when dealing with impure gold or refining tasks.

5. Is the 2kg melting furnace energy-efficient?

Yes, the induction heating system ensures high energy efficiency and lower operational costs.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited