Jewelry Chain Making Machine

As a precious metal equipment expert, we provide a one-stop service to solve any problems with your jewelry chain manufacturing line

How to Make Jewelry Chain

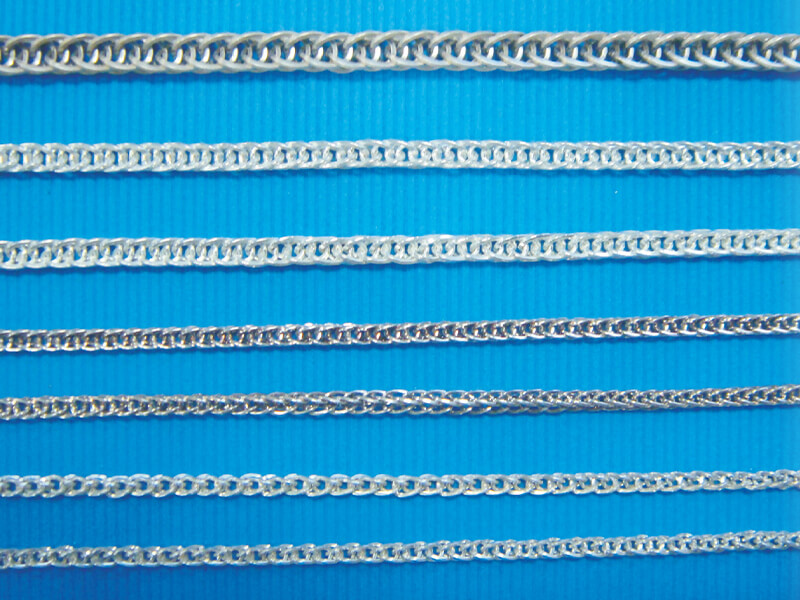

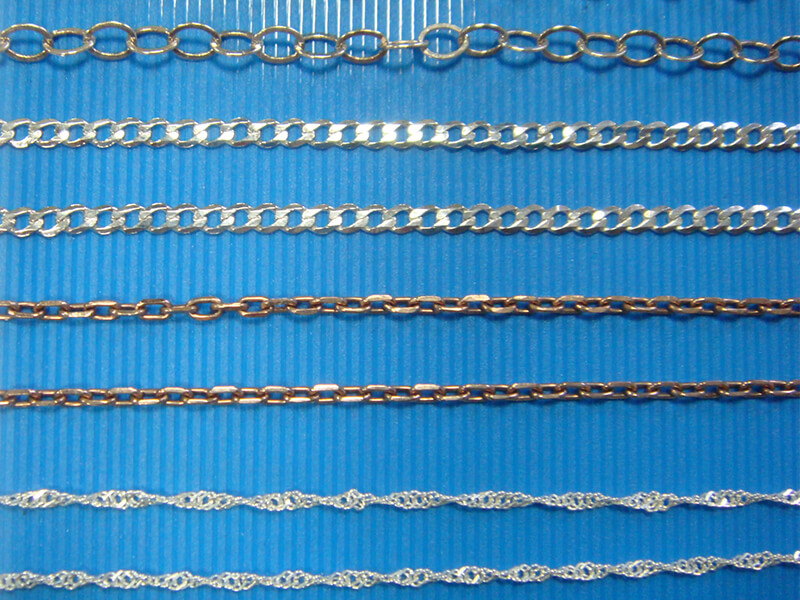

As a professional precious metal jewelry chain production solution provider, SuperbMelt has more than 10 years of experience. The types of jewelry chains we can make include trace chain, belcher chain, curb chain, hayseed chain, snake chain, bead chain, rope chain, Figaro chain, etc.

Superbmelt provides you with a one-stop solution for gold jewelry chain manufacturing lines. Including on-site guidance, jewelry chain production equipment, and engineers to help you expand throughout the process. Our engineers have participated in the research of various styles of jewelry chains and have served as technical consultants for major jewellery chain manufacturers.

We at SuperbMelt are committed to offering top-notch machines to make your jewelry chain making process faster and better. We are here to help the industries to keep up with the ongoing innovative drive. We have perfect solutions for you.

Jewelry Chain Production Line

1st Continuous casting machine

3rd Wire drawing machine

5th Jewelry hammering machine

Cast a gold rod

Roll the gold rod into thin wires

Drawing the gold filament

Making jewelry chain

Hammer the jewelry chain

Faceting jewelry chain surface

2nd Jewelry roll mill

4th Jewelry chain making machine

6th Jewelry chain faceting machine

1st Continuous casting machine

2nd Jewelry roll mill

3rd Wire drawing machine

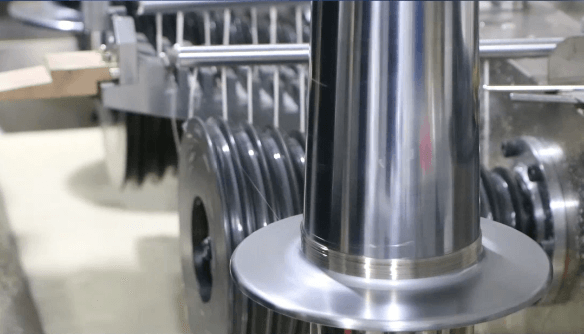

4th Jewelry chain making machine

5th Jewelry hammering machine

6th Jewelry chain faceting machine

Looking at the current demand trend for jewellery of gold, silver, copper, stainless steel etc, manufacturers across the world are looking for advanced machines to make jewelry chains. For this, SuperbMelt has introduced its new gold chain making machine that has greatly simplified the chain making process. The modern process of the chain making process is:

- Obtain pure gold by melting gold ore using an induction furnace. Using the machine, you can smelt the gold ore faster.

- Now use a contentious casting machine, make gold rods. The machine can be used to attain circular, rectangular, cylinder shapes based on your desired design.

- Once done, you can use a jewelry rolling machine to convert those rods into thin wires with super smooth and fine surfaces.

- After that, use a wire drawing machine to cover the thick wire into the thin wire as per your requirement. That wire will be used to make chains.

- Now, make jewelry chains using our jewelry chain making machine. The machine can make different types of chains, such as snake chain, double curb chain, and more.

- For perfectly binding the parts and to attain a perfect shape, use a jewelry hammering machine. The machine is automatic.

- In the last, use a jewelry faceting machine to facet the surface of the chain and get the shininess.

With more than 15 years of experience in this field, SuperbMelt has become a reliable name in this industry and quite famous for the machines it offers. So, when it comes to attaining better performance and faster operation, you can always trust SuperbMelt.

We are focused on offering our clients the highest-quality machines that can offer a wide range of solutions. Choose SuperbMelt and enjoy an all-in-one solution under your budget.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

How to make jewelry chain: Jewelry chain making process and making line configuration solution

With time, the demand and popularity of jewelry chains are increasing. After all, they play a crucial role in creating articles jewelry. If you look at the commercially made jewelry chains, you will find them easily recognizable template designs.

If you go for silver or gold jewelry, you will find them very expensive. Some pre-made chains also come with different types of protected films, for example, rhodium, which makes them challenging to repair, lengthen or shorten.

Therefore, if you need a chain in your jewelry designs, whether it be for making a neckless or for other purposes, in the long run, it will be better for you to produce your own. If you think this is not an easy task, then it’s time to buy a high-quality jewellery chain-making machine, and you can easily make chains within a few hours.

By producing your own jewelry chain, you can make sure that you are enhancing your jewelry piece, and each of them will look unique. When you have the best gold chain-making machine, you can go for different types of chain combinations, for example, ovals, squares, rounds, and more of different sizes combined with solid sections or square sections of wire and more.

However, for the best result, you need to choose a good quality machine, and this can be a challenging task for you. So, to help you out in this, we have created this article where you will find all the essential information to make the buying process comfortable. So, let’s get started with this.

Introduction of Jewelry Chains on the Market

Speaking about chains, these are a series of metal rings or links that are connected to one another and can be used for a different purpose. These modern-day accessories are becoming regular daywear to some people.

They use them just as they are wearing clothes. Most of people love to wear chains, and they wear them with pride. Chains have adorned people’s wrists, necks, and ears for more than 5000 years. Keep reading to know when it all started.

Exploring the history of chain

As per the historical data, jewelry chains date back around back to 2500 BC. The credit can be given to the ancient Egyptians who used to thread links of silver and gold. During that time, gold was plentiful in Greece, and the Greeks crafted 3-dimensional pendants to use on their chains.

It was during the 8th century BC when the strap chain was created. Strap chains came with a unique design connected to lie side by side. As a result, it looked like a flexible band.

During 300 BC, the elite upper-class people were used to wear chains made with gemstones. During a period called Renaissance, a period when personal ornamentation became very popular, Leonardo da Vinci improved the chain design. During medieval times, the brooch was the most famous piece of jewelry. But in the Renaissance period, that shifted to a pendant attached to a gold chain.

Speaking about the upper-class people, those lavish pendants generally illustrated the Biblical scene or some emblems that represented the names of loved ones or saints. In fact, more functional jewelry chain pendants were also found. Some even have toothpicks.

For a few years, the usage of the chain remained the shame, with a little bit of newly added tasks, for example, the muff chain.

The chains are generally made of different precious metals, for example, silver and gold. You can also see jewelry chains made of palladium or platinum.

The major reasons behind using such metals are these are not reactive, and while making a chain using a chain making machine, the metals don’t lose their original strength. Therefore, you can use them for creating intricate designs. On the other hand, to keep their shine, minimal maintenance is required.

However, with time, the chain making process became standardize and automate, all thanks to the advanced, fully automated gold chain making machine. Now, you can find chains with unique designs to take the overall beauty of the users to a whole new level.

1.1, Why are jewelry chains popular in the market?

Jewelry chains made using a gold chain making machine are a super classic jewelry piece. One of their impressive components is flexibility.

For many years necklaces and jewelry chains have appeared in different forms, newly invented or reinvented and made from different materials; the chains have served different purposes. But there is one element that always remains constant.

The chains satisfy the need to convey or display a message. In some cases, these jewelry pieces are used to show off their status.

You can find different types of chains for jewelry making. But it all depends on your personal choice and the design that you have in your mind. Looking at the increasing popularity of chains, chain manufacturers have introduced different types of chains with beautiful styles.

The fantastic beauty of the jewelry chains is that they can instantly add a new dimension and look to your hand-made jewelry designs. Perhaps you want a simple chain for the pendant, or you want a unique chain for adding extra sparkle. All types of designs are there.

Now you can create your own jewelry chain to come up with some unique designs. For this, all you need to get a high-quality gold chain making machine.

These machines are easy to use and designed to offer you can automate chain making process. Now, let’s talk about some popular types of jewelry chains that are quite popular across the world.

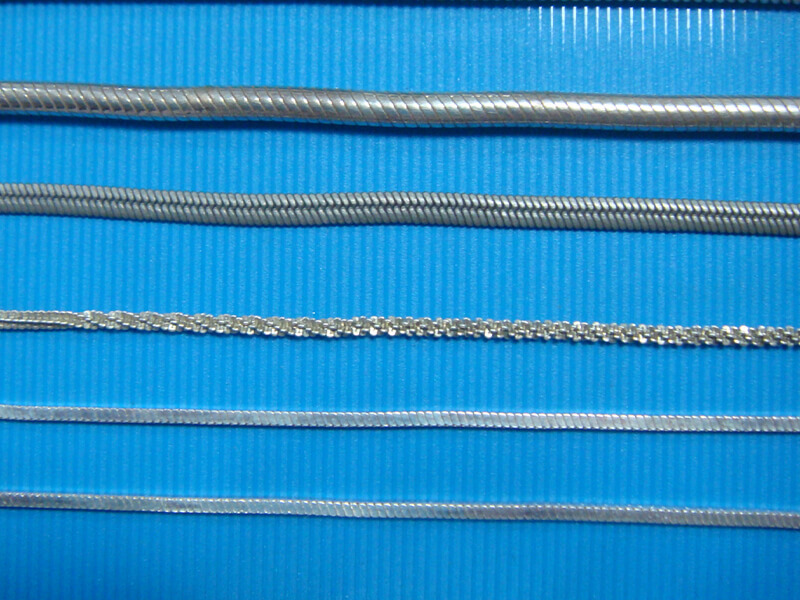

Trace chain

This is one of the widely used chains used for jewelry making and can be a perfect all-rounder for your jewelry design. Speaking more about it, such a chain comes with different oval-shaped links, producing a super fine chain with a minimalistic look.

Moreover, using an automatic chain making machine, you can produce different types of trace chains based on a different levels of thickness and lengths. For example, 14ct gold, 9ct gold, sterling silver plate trace chains.

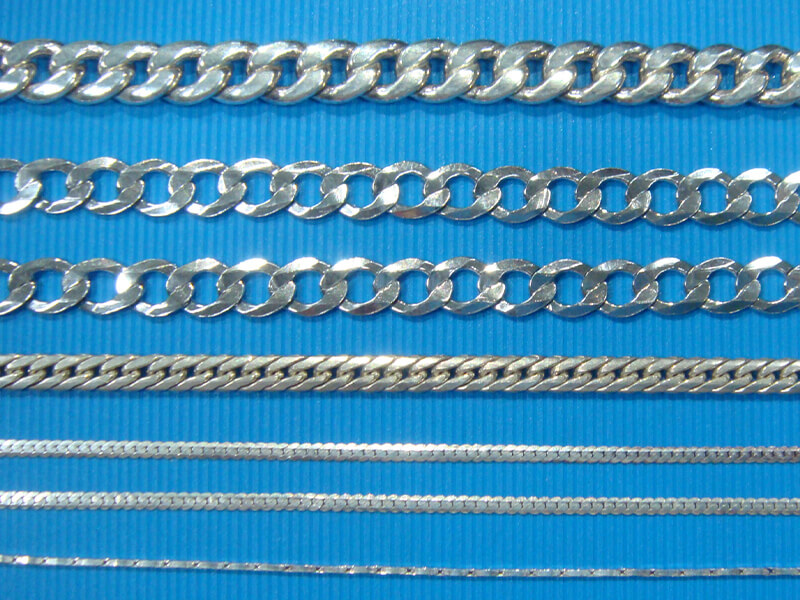

Belcher chain

It is also famous as Rolo chain. In terms of look, it may look like a trace chain, but in the belcher chain, you will find the links are a little wider than the thickness. The chains are quite sturdy in nature and very popular among men.

You can create maxi or mini belcher chains along with a 9ct gold oval belcher chain for your jewelry designs.

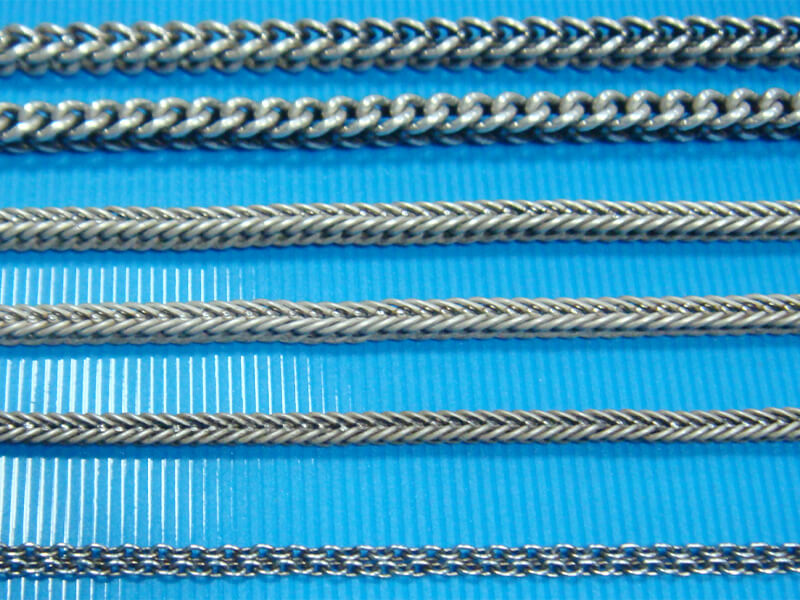

Curb chain

Curb chain looks little heavier than other types of chains. Here the links are a little flattened and twisted very tightly together, creating an interlocking design.

Well, for some people, curb chain is a perfect statement neckless and quite popular among both women and men jewelry category. Buy an advanced gold chain manufacturing machine, and you can quickly produce good-quality chains.

Hayseed chain

If you are looking for a lightweight and beautiful chain with a fantastic look, you can always go for a hayseed chain. The chain is intricately linked together and comes with highly delicate detailing that will never fail to produce a lovely sparkle. Your chain will shine.

Snake chain

These types of chains are also known as Brazilian chains and quite different from other chains. You might be wondering how? Well, these chains are not made up of links.

Comes with a unique design; a snake chain consists of smooth metal plates that are tightly woven to produce a durable and flexible chain. You can create such chains easily using a chain maker machine and give a sophisticated look to your designs. What are you waiting for? Get the machine now.

Bead chain

These chains are also known as pelline or ball chains. This can be a fantastic choice for your jewelry design. The chains come with small metal spheres of tiny balls running throughout the chain, and there will be no open links.

The parts are fixed at a specific interval with the connector bars. If you love the design of a bead chain, then you may also love a satellite chain that is a dainty chain with silver beads.

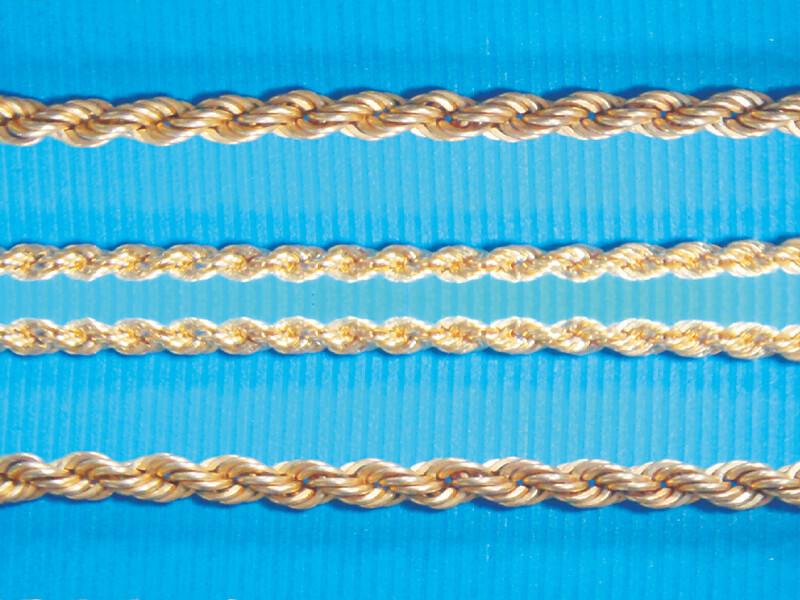

Rope chain

Rope chains are pretty famous for their interesting look. They come with links appropriately woven to create a unique twisted effect and look like a rope. This can be a great option if you are after a chain to attract all. You can go for the sterling silver or 9ct gold rope chain option.

Figaro chain

With this chain, you can add details to your jewelry design. Such chains come with flattened links and generally feature three to four shorter links that are separated with a longer link. With the alternating sizes of links design, these chains look amazing.

1.2, The purpose of jewelry chain

Marriage

You all know that wedding is excitement and matter of joy for the wedding couples. After the wedding, they can spend their life together, sharing their sorrows, happiness, and more. As this is a big day in their life, it is essential to look beautiful.

Right before the ceremony, they become busy thinking and deciding about their dresses, engagement ceremony, bridal jewelry selection, and more. And when it comes to bridal jewelry, no one can forget the jewelry chains.

If you want to look beautiful, a perfect jewelry chain can make a huge difference. These chains are designed both for bride and groom and have become an essential part of marriage. In fact, you can go for different types of jewelry chains based on your outfit, and you will look stunningly beautiful.

What’s more? After the introduction of the automatic Chain making machine, you can now easily get customized or tailored-made jewelry chains.

Hipster decoration

It can be said that much of modern hipster fashion in women takes cues from various eras, for example, styles of grunge of the 90s and hippie styles of the 1960s. If you consider the outfit, a perfect place to start is with stylish denim.

Why? The types of denim come with chains that complement the hippie look. Whether you go for a bootcut, short, skinny, or a boyfriend pair of jeans, with a different types of chains made of different materials, they look fantastic. Such jeans can be combined with graphic tees, leather jackets, flannel shirts, cardigans, or oversized sweaters.

What’s more? You can complete your look by adding wide-brim fedoras, oversized glasses, or slouchy beanies. The chain-attached denim looks beautiful with sneakers, scarves, booties, or compact boots. Well, it can be said that your hipster look will remain incomplete without a jewelry chain.

Social dress decoration

When it comes to looking unique with your social dress without affecting the culture, you can decorate your social dress with different types of jewelry chains. Now, let’s talk about how to decorate a dress with chains.

You may have a nice dress with great color, but after some time, it will become boring. But when you have some jewelry chains, you can easily redesign the dress. For this, understand how low you need your back and draw lines using tailor chalk.

Then cut that portion. Once done, you need to pin the seam and sew it properly. Now, put your dress on a mannequin and make sure the result is good. Now, understand where you want to add the first chain.

Sew the chains on your dress by sewing on the chain on the dress’s one side and then attach the clasp. Make sure the string is short enough to keep the dress’s sides together. You can add as many jewelry chains as you want. For a fantastic look? Try to add some chains around your neck.

Some other usage of chains

Chains have also been used to make pocket watches retrievable, make different connected jewelry pieces, and attach them to reading glasses. Besides, some women also use belts made of chains over their outfits. On the other hand, different jewelry pieces are also used for religious purposes.

Chains around wrists, around necks, and waists on boots dangling from hip pockets, they all have become an essential part of the fashion industry. From fashion models, musclemen to bikers, all love them.

Introduction to the Production Process of Jewelry Chains

2.1, The production history of the jewelry chain

It is a fact that chain-making is not an easy task. It involves different stages, processed through which the raw material is converted into a finished product. The introduction of wire helped the goldsmiths to created chains from different precious metals.

Neolithic people found that gold was very soft, supple, and pliant as per the historical data. So, they pounded and hammered the gold to give that different shaper and form. Besides, they stretched the length by hammering the gold. This was the birth of chain-making.

It may be noted that during the 18th century, jewelry chains were handcrafted. The process was very time-consuming and laborious. They developed chains by twisting and turning the wire into various shapes were formed and linking one link with another to create a chain.

2.2, The traditional way of making jewelry chains – purely hand-made

The traditional jewelry chains were made using hands. What they all had in common, though, was that a jewelry artist makes each piece using only their hands and some simple tools. First, they used to hammer the metal, silver, or gold to turn them into flat strips.

After that, they would pull the strips through different dies to create wires. After that, the wire was then wound around a structure to create loops. For example, a mandrel. This was used to shape metal into the desired size or shape.

After that, it was cut through the looped wire and interlocked. Finally, they used heat to join the parts. As you can see, the entire process is very time-consuming.cv

2.3, The invention and development of chain the making machine

It can be said that till the 18th century, the chain-making process was laborious, time-consuming, and handcrafted. As demand for jewelry chains increased, the manufacturers started looking for a different way to mass production.

As a result, in 1750, a French man, Jacques de Vaucanson, invented the machine which created U shaped wire for a mesh chain. This further led to a good chain making machine in the year 1782. By the 1800s, various types of chain making machines were developed, and all based on the basic model. During the 1870s, the method caught the eyes of Americans and Europeans.

It was 1893 when Americans introduced their first model of chain making machine in the Chicago World Exposition. The machine was based on better technology and offered better speed.

With time, other types of machines were introduced. For example, casting machines, rolling mill, wire drawing machine, advanced chain making machines, and more.

Introduction and Application of Chain Making Machine

3.1, The types of chain making machine

Speaking about the Jewelry chain making machine, it is a set of machinery used in manufacturing gold, silver chain, or other jewelry chains. First, let’s know about different types of chain making machines. In general, there are two major types of machines. These are the curb chain and cable chain making.

Cable machine process

Under this process, wire is feed into a set of rollers. The wire then passes into a guide section. This particular section guides it into a build chamber named stop. Here the wire length is measured. Besides, the desired size of the link was established.

This will be the first link of the gold chain. After that, the next piece of wire is carefully measured and then passed through the first ink to create a part of a chain. The process is followed to create an interlock the links.

Next, there will be a cutter that will cut the wire from the feed stock and push the wire into a U shape. After the formation of shape, a set of clamps holds the wire, and the link is closed to finish the shape.

Curb making machine

Under this machine, the wire is introduced into a tool that looks like a lop. Then, the wire is twisted and then coiled into a spiral form. When the loop revolves, the spiral-designed wire is then moved through the previous loop.

Once done, the loop is closed. Using a scissor, the spiral is cut down, and this link is rotated to make the next spiral. This process will continue till the desired length is obtained.

Snake chain making machine

This machine is generally used to make a chain from flat stock. They work quite faster while forming a different pattern.

Ball chain making machine

If you want to make ball chains from flat stock as well as wire, then this machine will be an ideal option for you.

Firago chain machine

Such machines come with two heads and can easily make two sizes of ink at the same time.

Platinum chain making was not an easy task. The reason is platinum is a hard metal and not easy to work with. As a result, for many years, different pliant metals, such as copper, silver, and gold, were used to make chains.

However, with time, jewelry chain machines were introduced. Today’s machines are so powerful that you can now easily create chains from different metals. Even though some chains are hand-made, as some love to wear hand-made chains, there is also a great demand for machine-made chains.

3.2, The working principle of the chain making machine

Silver and gold are two primary metals used to make jewelry chains. With their lustrous and shiny aura, the chains will look amazing. But to quickly made such a beautiful chain, you need something advanced, like a gold chain making machine.

These machines are designed to create different chains, like curb chain, box chain, snake chain, Figaro chain, and more. Speaking about the working principle of the machine, the process is easy to understand.

A thin wire is attached to the machine to create the chain. The wire is produced by processing the gold rod through a wire drawing machine. Once done, the chain manufacturing machine will create the chain.

Owing to their ease of maintenance, simplicity in design, longer functional life, affordability, and some fantastic silent features, these machines are best for producing new-age jewelry chains. In addition, you can use them to produce different styles and sizes of silver chains for both women and men.

Besides, you can create an exquisite assortment of silver chains based on modern and old-style minimalistic styles. The machine will definitely impress you.

SuperbMelt is a reliable name in the field of producing and supplying the best quality jewelry chain making machines across the global ground. They are a perfect combination of cutting-edge technology and pricing.

Do you want to start your own jewellery making business and want to buy a reliable chain making machine? Please feel to get in touch with us. We offer customized solutions at the best price possible. As a leading supplier, we are growing at a faster rate, offering outstanding solutions.

3.3, The invention of the chain making machine has changed the entire jewelry industry

The best jewellery chain making machine has brought a great revolution in the process of jewelry chain making. Forget about those time-consuming and manual processes; it’s time to witness the simplicity of the chain-making process by utilizing these machines.

The design, performance, maximum level of perfection, and more have made these machines an essential part of the global jewelry-making industry.

These advanced machines come with a robust metal body, and they are very easy to install. But prefer to buy from the best gold chain making machine manufacturers.

They are perfect to resist extreme working conditions. Produced from high-grade components, the machines can be customized based on your chain production requirements.

Nowadays, buying jewelry is more about just an experience. Chains have become a status symbol. Clients love to leave their personal mark.

Using a gold chain making machine, this can be easily done. As a jeweler, you can easily customize your own specifications. It is removing all physical frontiers from the chain-making process.

Exploring some benefits of chain making machines

- Using this, the chain can be massed produced. Different designs can be made.

- You can make lightweight and thin hollo chains.

- Jewelry chains can be made in different karats of gold and sterling silver.

- You will save time as the chain can be made accurately and quickly.

- In updated modern machines, which are quite expensive, links can be automatically welded by a laser welding torch.

- You can use wires of different shapes, such as square, oval, and round.

Introduce Step by Step How to Produce the Jewelry Chain Nowadays

Step 1, Get pure gold

If you want to produce a gold chain, then first, you need to get pure gold. Fur this; you can use an induction furnace to get gold from the ore through the smelting process. Once done, the liquid gold is turned into bars that can be used for making products.

Step 2, Make a gold rod

The next step after getting pure gold is to make a gold rod. For this, you can use contentious casting equipment. Such machines are designed to cast different precious metals into the desired shape. For example, you can make a rod, circular, cylindrical, or rectangular shapes based on your chain design.

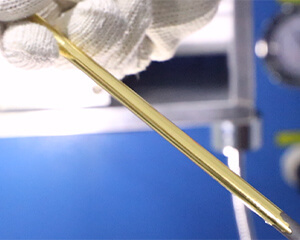

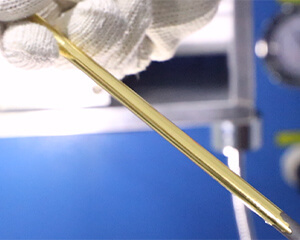

Step 3, Roll the gold rod into thin wires

After that, the gold rod is processed through the jewelry rolling mill to convert the rod into thin wires. These machines can effectively roll various precious metals faster and accurately. In addition, the pressure created by the rolling wheel created wires with a smooth surface, and the surface will have a mirror effect.

Step 4, Further reduce the diameter of the gold wire

For this, a wire drawing machine is used. The machine can convert the thick wire into thin wire through the drawing process. The obtained gold wire with reduced diameter can now be used to make gold jewelry chains.

Step 5, Making jewelry chain

Now, it’s time to use a chain maker machine to create a chain. The machine can be used to create a box chain, rope chain, snake chain, and more such complex-structured jewelry chain. Besides, you can also make a double curb chain, disco chain, and anchor chain by modifying the machine parts.

Step 6 (optional), Hammer the jewelry chain to obtain the desired shape

Well, this is an optional step, where a jewelry hammering machine is used to binding the parts and give the chain a perfect shape. The machine can automatically hammer the chain based on the configuration.

Step 7 (optional), Faceting jewelry chain surface

To bring extra shininess, you can facet the chain surface, and for this, you can use a jewelry faceting machine. Using this, you can polish facets onto a particular mineral specimen.

As you can see, compared to the traditional jewelry chain making process, the modern chain making process is relatively easy and can be done within a few hours. All you need to buy a good quality jewellery chain making machine, and you are ready to go.

Introduction to the Equipment of the Jewelry Chain Production Line Provided by Superbmelt

5.1, Gold continuous casting machine

SuperbMelt gold continuous casting machine is designed and developed for casting different precious metals, for example, silver and gold. You can cast metals into your desired shape.

Using our machine, you can cast the metal into circular, rod, rectangular, and cylindrical shapes. Comes equipped with the modern gas melting protection technology, you will enjoy an accurate as well as automate temperature control process. Our machine is cost-effective and fast.

5.2, Jewelry rolling mill

The jewelry rolling mill machine comes with two smooth, hardened as well as highly polished steel rollers. Instead of using the manual rolling machine, you can use the electric mills, which are best for large quantity production.

However, while buying one, you need to consider your budget and how frequently you use the machine. Our machines are designed to meet various thickness and width jewelry rolling requirements.

These machines are ideal for semi-finished gold artworks and jewelry. The metal sheet will be extremely flat, and all the sheets will have a uniform thickness. Get in touch with us to know more about your rolling mill machines and place your order.

5.3, Wire drawing machine

As the name suggests, a wire drawing machine can draw a thick wire into the thin wire. As a result, you can achieve the desired surface roughness, wire diameter, roundness, straightening degree, and internal microstructure to make the chain.

Remember that the wire drawing machine can significantly influence the wire pretreatment quality and is a crucial machine in the jewelry industry.

With impressive working efficiency, the machine can make imported materials, and, on the other hand, the wheel has carburization that effectively enhances the abrasive resistance. What’s more? The moto technology used in the machine has a step-less speed modulation design.

Besides, it has an automatic rewinding machine. While using it, you don’t have to worry about the heating up issue as the SuperbMelt wire drawing machine comes with an automatic cooling system that automatically stops the machine when the work is done.

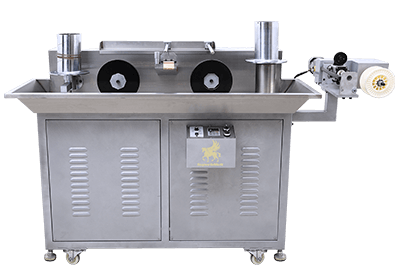

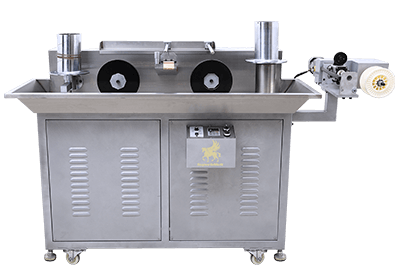

5.4, Chain making machine

This is an essential tool in the chain making process. Gold chain making machine is designed to produce chains with different types of links. During the chain making process, the metal wire is spiraled before being sectioned.

One machine can produce a variety of different styles. The machine is fully automatic and can produce 100 percent accurate results. This can easily handle copper, silver, and other soft metals. If you are looking for an advanced rope chain making machine, you can always trust SuperbMelt.

5.5, Chain hammer machine

SuperbMelt manufacturers and supplies high-performance chain hammering machines. The machine comes equipped with all the required accessories.

Advanced features, corrosion resistance, robust build quality, low maintenance, and sturdy material make the machine quite reliable. To make sure the machine can offer best-in-class performance, we have tested the machine by the artisans in the machine manufacturing field.

Use this machine, and you can easily give your jewelry chain the coveted shapes and plan. Explore more details about the machine at our official website now.

5.6, Chain faceting machine

Using our chain faceting machine, you can offer a fantastic decoration to your silver or gold chain. The attractive looks that your chain will have will impress customers from all age groups.

The machine manufacturing is conducted under expert guidance, and supreme quality components are used. To meet your quality requirements, our machines are verified through different quality control tests. Some of the impressive features of the machine are:

- High strength

- Reliable performance

- Produces impeccable design to the chain

- Longer service life

- Less maintenance

- Smooth finish

- Ensures precision designing of jewelry chains

Why Choose SuperbMelt’s Solution – Some Conditions of a Good Supplier

6.1, Do you have extensive experience in the industry?

With years of experience and expertise in this field, SuperbMelt has emerged as one of the leading box chain making manufacturers offering the best solutions to all. The company has more than 15 years of R&D experience and deploying which they manufacture quality gold necklace making machine.

6.2, Is there a team of engineers familiar with the production process?

At SuperbMelt, you can get jewelry making machines in different sizes, grades, and dimensions. The team of engineers understands everyone’s requirements and develops the machines accordingly. As a result, the machines come with different top-notch features, for example, low maintenance, easy operations, long life, and more. In addition, they have an extensive level of knowledge about the production process.

6.3, Can you provide technical support for the jewelry chain?

While choosing a company for chain-making solutions, make sure that they offer robust technical support. This is where you can trust SuperbMelt. More than 95 percent of issues related to installation, operation, and repairs can be solved remotely through real-time video instructions, illustrative images, and live chat. In addition, all the parts come with two years or a warranty, so you don’t have to worry about the repair cost.

6.4, Can we provide a complete set of production line equipment?

For faster operation and better performance, you need to choose a company that can offer a complete set of equipment to produce a jewelry chain. As a leading name in the industry, SuperbMelt manufacturers and supplies different chain-making machines to the client to produce chains from different precious metals.

6.5, Is the company in sustainable development?

SuperbMelt always gives importance to sustainable development procedures. So, when you buy machines from the company, you also become a part of the company’s journey to create a sustainable development environment. In fact, the machines are ISO, CE and SGS approved.

6.6, Check the brand reputation

Before choosing a company to buy a gold chain maker machine, check the reputation of the company. For that, you can check the reviews given by old clients. You can always trust SuperbMelt as the government audited SuperbMelt as an AAA credit company. Besides, with sufficient stock, the company ensures faster delivery of the machines.

6.7, Put safety first and Pay attention to details

Banking on the advanced manufacturing facilities, SuperbMelt is affianced in well-guaranteed jewelry chain making machine. High operations, long service life, utmost precision, 100 percent accurate perfection, rugged design, and noise-free operation make the machines an ideal choice for every business. The machines are made of solid metals and meet the required industrial quality standards.

Frequently Asked Questions of Jewelry Chain Making

What is a gold chain making machine?

As the name suggests, this machine is used to create jewelry chains, and the process is automatic. Made of durable materials, such machines can easily produce high-quality chains from different precious metals, for example, silver and gold. However, while buying a machine, don’t forget to check the machine’s features.

What machines are used to make jewellery chains?

In the process of making a jewellery chain, different types of machines are used for different purposes. In general, you will need a gold continuous casting machine, rolling mill, a wire drawing machine, a gold chain making machine, chain hammer, and faceting machine. For all these things, you can contact SuperbMelt. We offer machines to create different types of gold chains.

How is a jewelry chain made?

All the jewelry chains are made using a wire made of different precious metals. The wire is converted into the desired diameter, and the chain manufacturing machine will create the chain by thread the link with the previous links. Compared to the traditional methods, not a chain can be made within a few hours. If you are in search of the best gold neckless making machine, you can always trust SuperbMelt.

How are gold chains made?

The process of gold chain making is also called chain stitching, and using a gold chain making machine, the production process can be automated. A golden wire with a specific diameter is passed through the Chain making machine that creates beautiful patterns from its fragments and interconnective the finished parts of the gold chains. The machines are so powerful that they can make gold chains having about 600 links in 1 to 2 minutes.

Where do gold chains come from?

As per the data, chains date back to around 2500 BC. During that time, the ancient Egyptians began threading silver and gold together. Gold was bountiful during that time, and they gradually developed gold pendants to wear with the gold chains. During 300BC, the upper-class people wore luxurious gold chains with beautiful gemstones.

How much gold do you need to make a chain?

Well, it will completely depend on your requirements. Based on the weight and design, the gold quantity will vary. Gold chains are available from even 3 grams to 100 grams. You can also go for more. However, in general, around 10 to 50 grams of gold is enough to make men’s jewellery.

How are chain necklaces made?

The process begins with a wire. A good quality wire is annealed in a furnace. After that, the wire is processed through a dire to attain the required diameter. Next, the drawing process work-hardens the wire. Once done, the wire is processed through a necklace making machine that threads the wire to create a link on the chain. The machine can easily create a chain neckless automatically, and your finished product will look amazing.

How are silver chains made?

Earlier, jewelers would make cast loops and join them together to form a chain. However, as they use manual processes, it is a very time-consuming process. In fact, in one day, it is not possible to solder the loops in one piece. That’s why they started using the smelting process to create a silver rod. The modern process includes a chain-stitching process. Under this process, a silver wire is passed through a mechanical device that creates beautiful patterns from its fragments, interconnecting the finished parts of the chain. A good quality jewellery chain making machine can produce a silver chain with around 6000 links in just one minute. After the weaving process, the chain is coated with unique material to make it durable. Then it is polished using a chain faceting machine.

How do you make a silver chain smaller?

To shorten a silver chain, simply measure how many inches need to be removed from it. Then take out that portion, and after that, re-attach the clasp end to the rest of the chain. This process is straightforward and can be used for simply designed chains, for example, ball chains or cable chains. However, the process can vary when you go for a complex-designed silver chain.

Can a jeweler shorten a chain?

Yes, a professional jeweler can easily shorten a chain. However, shortening certain types of chains, for example, stone-studded curb chains, snake chains, rope chains, and more, are pretty challenging to shorten. The process can take time. But a jeweler can get it done for you as he/she has the best gold chain maker machine.

How do I make my chain longer?

Most of the chains are made of some standard jewelry materials, for example, gold or sterling silver, and the width can range from 1 to 2mm. To make the chain longer, the jeweler source a perfectly matching portion of the chain and then attaches it to the end of your chain, extending it to your desired length. However, using a fully automatic gold chain making machine, you can create the portion for your chain quickly and use them to add length to your existing chain.

How do you shorten a chain length?

Well, experts suggest that for the best result, you should take the help of a jeweler. Jewelers are the masters of their craft and know everything about the chains. Besides, they come equipped with the best automatic chain making machine that lets them shorten the chain faster. They will accurately cut the necessary parts out, attach the clasp ends back, and your chain will now fit you perfectly. If you have all the necessary tools, you can even shorten your chain at home.

How is a snake chain made?

Snake gold or silver chains are very popular for wearing with pendants. These chains are generally created from sheets instead of wire. These are tubular and sleek cords of metal. The snake chain is constructed from thin, cut sheet plates so that this chain can be a solid appearance. The plates band together to create a zig-zag effect. Most snake chains come finished, that is, with a clasp attached.

How do you shorten a link bracelet?

If you have a link bracelet and it is too long for you, then you can now easily shorten the bracelet to fit properly. All you need to some simple tools and a high-quality bracelet-making machine for this. First of all, you need to understand how many links you will need to remove. Now bend the clamps carefully while holding the clasp. Remove them from opposite ends of the piece. Cut these links using the wire snips. Now, you need to re-attach the jump rings to the new end links. For this, you can use a needle nose plier. To make sure the jump rings are fitted properly, you can use a jewelry hammering machine.

Do gold chains break easily?

Well, this will depend on the design of the gold chain. For example, hollow gold chains are lighter and less expensive, but such chains are weaker. As a result, they can break, dent and kink easily. If you want a durable gold chain, then going for a solid chain will be a good option for you. Some of the strongest styles of the gold chain are Figaro Chain, anchor or mariner chain, curb chain, wheat chain, cable chain, and more.

Conclusion

Looking at the growing demand for the stylish and durable chain, it can be said that a jewelry chain manufacturing unit can make a decent level of profit in the coming days. But for the best result, you need to buy a high-quality and super performance jewellery chain making machine. This is where SuperbMelt comes into play.

Popular as a well-known electro machinery enterprise, the company deals in the production, sales as well as distribution of different types of casting, forming, and melting machines, offering an easy-to-mold and smelt gold, bronze, copper, silver, lead, and more.

As one of the leading gold chain making machine manufacturers, SuperbMelt designs the machines to offers a fast, reliable, and smooth casting and forming experience. We deal with different industries, for example, aerospace, metal mining industry, automotive industry, artistic sculpture, jewelry, and more.

In order to make sure every industry is maintaining an innovative pace, we at SuperbMelt have a dedicated workforce that is highly focused on providing the customers with the best gold chain-making machine of high and stable quality. When you are with us, nothing can stop you from enjoying our wide range of solutions.

SuperbMelt manufacturers and supplies equipment for the jewelry chain production lines. We deal with continuous casting machines, rolling mills, wire drawing machines, chain-making machines, hammers, and faceting machines. So, we are your all-in-one solution for all your jewelry chain making requirements.

SuperbMelt- Jewelry machinery expert

- We help gold miners and goldsmiths in perfectly smelting the gold.

- We help the metal refineries in developing a robust melting and casting line.

- We offer solutions to melt collected gold into fine bars.

- SuperbMelt offers solutions to help jewelers in jewelry casting and making.

With more than 15 years of experience in this field, we continuously adopt the latest technology to enhance the performance of the machines.

When you are with us, you will also enjoy the best post-sale services. We offer the fastest solutions for your operational guidance, maintenance, and repair requirements.

So, what are you waiting for? Check our jewellery chain making machine price and place your order now. For more details about our machines, please feel free to get in touch with us anytime you want. You would love to offer our best solutions.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited