A utomatic Gold Coin Making Machine

China Professional Coin Embossing Equipment Supplier

Introducing the SuperbMelt Automatic Gold Coin Making Machine, the ultimate gold press machine for creating flawless and immaculate finished products. This high-quality stamping machine ensures a smooth, scratch-free embossing process, not only for gold coins but also for gold nuggets with personalized designs and more.

With its impressive speed of 10 stamps per minute, the SuperbMelt Gold Coin Press Machine significantly reduces labor costs and boosts production efficiency. It’s the perfect solution for the rapidly expanding minting industry. Thanks to its efficient hydraulic system, the stamping process guarantees consistent and reliable multi-blank coin stamping without any deformation of the coins or ingots.

The SuperbMelt Automatic Gold Coin Making Machine stands out as a newly developed, fully automatic solution dedicated to blank coin or gold nugget stamping. Its versatility allows it to handle various materials, including gold, silver, platinum, and others, ranging from 100 to 300 tons in a short period.

| Model | SPB-300ATS |

| Motor power | 20W |

| Pressure | 300 Tons |

| Maximum stroke of table | 200mm |

| Maximum enclosed height | 500mm |

| Minimum height of movable table from the | 800mm |

| Upward velocity of moving table | 220mm/s |

| Return speed of moving table | 210mm/s |

| Total Power | ≤500W |

| Effective area of worktable | 550*650mm |

| Dimension | 2300*1445*2600mm |

| Speed | 10 pcs/min |

| Machinery Weight | 5500kg |

| Touch Screen | Siemens PLC touch screen |

- The SuperbMelt Coining Press Machine produces high-quality finished products without any scratches.

- The automatic gold coin making machine significantly reduces labor costs and enhances production efficiency.

- It can emboss customizable models on both gold coins and gold nuggets.

- The machine is equipped with six loaders capable of holding up to 500 gold coins or gold bars at a time.

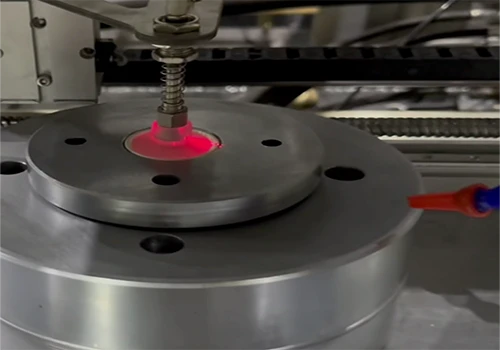

- It features an infrared sensor for precise coin punching and mold protection.

- The machine is equipped with a touch sensor for the automatic collection of coins or gold bars.

The SuperbMelt Automatic Coin Embossing Machine is primarily used to imprint desired patterns or logos on blank coins or gold bars.

This machine is specifically designed for customers who require high-quality coin production, as it ensures that no metal comes into contact with the coins during the manufacturing process, resulting in a scratch-free and exquisite finish.

Whether you want to produce high-quality coins or gold bars, this machine is capable of achieving it, thanks to its customizable and interchangeable mold feature.

Gold Coin Embossing Machine

SuperbMelt Automatic Coin Embossing Machine, easy operation, quick mold disassembly and assembly, and fast replacement.

Coin Hot Stamp Embossing Machine

Customizable molds, capable of logo embossing on both coin-shaped and bar-shaped items.

Automatic Metal Embossing Machine

There is no metal collision during the manufacturing process, ensuring a scratch-free finished product. The machine can produce and deliver 10 items per minute.

Why SuperbMelt Automatic Gold Coin Making Machine

Any Question About SuperbMelt Coining Press Machine

Helpful Resource For Your Reference ( Expertise in SuperbMelt Coin Embossing Machine )

Full-process infrared sensor protection for stamping

More options available for the Automatic Gold Coin Making Machine

SuperbMelt Automatic Gold Coin Making Machine Guide

SuperbMelt Professional Embossing Machine

- The SuperbMelt Automatic Gold Coin Making Machine utilizes sensor technology for precise punching and optimal machine protection.

- With a loading capacity of 500 coins or gold bars at a time, the machine operates without the need for manual intervention throughout the coin stamping process. It can produce 10 coins per minute.

- During the embossing process, the gold coins undergo collision-free handling, resulting in exquisite and flawless finished products without any scratches.

SuperbMelt Coin Stamping Equipment Features

Automatic embossing:

- The SuperbMelt coin stamping equipment offers fully automatic embossing capabilities, eliminating the need for human intervention.

Customizable models:

- The machine allows for custom model stamping, accommodating various coin or bar sizes as per requirements.

High-quality finished product:

- Through metal-free contact stamping throughout the entire process, the machine ensures the production of high-quality coins or gold bars without any scratches.

Efficiency:

- The equipment is capable of loading 500 coins or gold bars at a time, with a production rate of 10 items per minute.

How the SuperbMelt Automatic Gold Coin Making Machine Works

Loading:

Place up to 500 gold coins or gold bars into the designated container of the machine.

Parameter Setting:

Configure the machine parameters according to the desired specifications, such as the size, design, and other customized requirements.

Sensor:

Once the parameters are set, the machine initiates the imprinting process using its sensor technology. The sensor ensures precise positioning and alignment during the embossing or stamping process, resulting in accurate and high-quality gold coins.

Automatic Metal Embossing Machine

FAQ Guide of SuperbMelt Automatic Metal Embossing Machine

- 1. Where to buy a coin press machine?

- 2. What is minting machine?

- 3. What three metals would not be suitable for coinage?

- 4. How are coin dies made?

- 5. A machine mints coins at the rate?

- 6. What is a coin minting machine?

- 7. What is the quality of the finished product produced by a coin minting machine?

- 8. What materials can be embossed for coins or bars?

- 9. How much gold does it take to make a coin?

1. Where to buy a coin press machine?

You can find it on the official SuperbMelt website. The official website offers a range of gold coin logo embossing machines. Once you find the embossing machine that meets your needs, you can contact our sales staff for further assistance.

2. What is minting machine?

A coining press, commonly referred to as a minting machine or coin press, is a specialised piece of machinery used to make coins. The final coin result is created by applying great pressure and accuracy to stamp patterns into metal blanks. Typical minting equipment includes a press mechanism that applies pressure to the metal blanks and a set of dies with the required pattern. The artwork, themes, and text that will be imprinted on the blanks during minting are engraved or etched onto the dies. These devices are designed to produce coins that are consistently precise and fulfil the necessary requirements for weight, size, and quality.

3. What three metals would not be suitable for coinage?

- Lead: Lead lacks the durability and hardness needed for coinage since it is a soft, pliable metal. It is not suited for use in the manufacturing of coins because it is readily damaged, worn down, or deformed.

- Zinc: Although zinc is frequently used as an alloy in some coins, it should not be the main metal used in coins. Zinc is a rather soft metal that is susceptible to corrosion, which may reduce the durability and quality of the coins.

- Aluminium: Due to its low density and light weight, aluminium is an inappropriate metal for coinage. It doesn’t have the appropriate weight and feel that one would anticipate from a coin, and because of its poor durability, it is prone to dings, scratches, and other damage.

4. How are coin dies made?

- Coin dies are typically created by: Coin dies are used to stamp patterns into metal blanks during the minting process.

- Design Creation: The artwork, design, wording, and specs for the coin are all developed. A talented designer or engraver may do this using a variety of methods, including manual engraving, computer-aided design (CAD), or digital engraving.

- Prepare the master mould by creating it in accordance with the design. In order to do this, the design must be transferred to a metal workpiece, often composed of hardened steel or another robust material. Hand engraving or mechanical techniques like pantograph engraving or CNC machining can be used to create transfers.

- Production of the working mould: The master mould is used to make the working mould. Utilising the hub or reduction procedure, this is accomplished. Master patterns, which are typically composed of hardened steel, are used to stamp designs into softer metal workpieces. Through this procedure, the design is transferred onto the real coin manufacturing dies.

- Finishing and Hardening: To guarantee a precise and clear design, the working mould is then meticulously finished and polished. The strength and lifespan of the mould can be increased by applying heat treatment techniques like tempering or hardening.

- Mould inspection and repair: Completed moulds are carefully examined to make sure the design is accurately reproduced and to spot any flaws. A qualified engraver may carefully fix any minor flaws or mould flaws and make any necessary corrections.

Die maintenance is necessary to maintain the performance and lifespan of coin dies since they are prone to wear throughout the minting process. Regular cleaning, polishing, and, if required, re-engraving or redesigning the design are all included in this.

5. A machine mints coins at the rate?

The machine has a loading capacity of 500 coins or gold bars at once, and it is capable of stamping 10 coins or gold bars per minute.

6. What is a coin minting machine?

A specialised piece of machinery used to create coins is referred to as a coin minting machine, coin press, or coining press. It is made to quickly and precisely stamp patterns into metal blanks to produce finished coins that are ready for use or collecting.

Typical parts of a coin minting machine include the following:

The loading mechanism of the machine is in charge of maintaining a stock of metal blanks, frequently in the shape of round discs known as planchets or flans. The loading mechanism makes sure that blank coins are fed into the coin-stamping process consistently.

- Dies: A set of hardened steel tools called dies, which are etched with the desired coin design, are included with the machine. During the stamping operation, these dies are aligned to imprint the pattern into the metal blanks.

- Pressing Mechanism: To imprint the pattern on the metal blanks, pressure is applied by the pressing mechanism. To deliver the necessary force for the coin stamping process, hydraulic, pneumatic, or mechanical systems may be used.

- Modern coin minting equipment frequently have a control system that monitors the whole stamping procedure. This technology can control the amount of pressure used, keep an eye on the rate of production, and guarantee the precision and excellence of the coins produced.

- Finishing Components: Some coin minting machines have extra parts for post-mining procedures including cleaning, checking, and packing the coins after they have been struck.

Depending on the amount of technology and production demands, coin minting equipment can be fully automated or manually controlled. When creating coins for circulation, commemorative uses, or numismatic collections, authorised government mints and private minting facilities rely on these crucial technologies.

7. What is the quality of the finished product produced by a coin minting machine?

Throughout the coin manufacturing process, there is no metal contact, ensuring that each produced coin is of high quality and free from scratches.

8. What materials can be embossed for coins or bars?

When using the greatest coin minting press machine from SuperbMelt, you may easily mint platinum, copper, silver, gold, and various alloys without any problems, however with other stamping machines you would not have the option to pick different materials. Hardened materials may be easily processed by the machine’s strong hydraulic press.

9. How much gold does it take to make a coin?

According to your request gold coin or bullion size, solid gold or gold plated

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited