Automatic Wax Injector Machine

Professional jewelry manufacturing equipment supplier in China

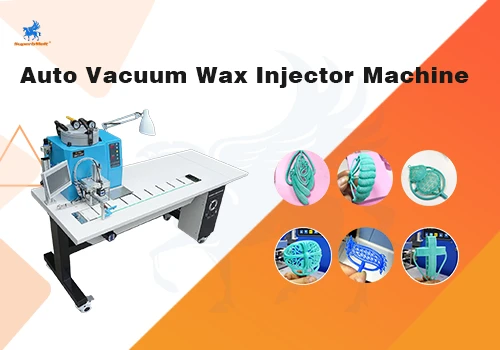

The automatic wax injector machine is used to make various types of jewelry wax molds, such as bracelets, rings, pendants, earrings, etc., also the mold of clocks and watches can be made.

It can be directly used to cast gold, silver, copper, platinum and other materials. As well as be made into a style that can be set with diamonds, and can be used with a wax setting machine to achieve rapid mass production.

SuperbMelt automatic jewellery wax injector machine adopts a fully automatic intelligent chip induction wax injection system to achieve a high level of automation and greatly improve production efficiency. The wax tank has a large capacity and can work continuously, saving time and human resources. Made in a vacuum environment, it is safe and environmentally friendly while also ensuring the quality of the finished wax mold.

| Machine Name | SPB-AW1900 |

| Model | SuperbMelt-886M |

| Power | 1100W |

| Power Supply | AC220V 50/60HzZ |

| Air Pressure | 0.45-0.65 Mpa |

| Vacuum | ±0.06-0.07 |

| Tamaño del molde(L*W*H) | 116*116*96mm |

| Waxtank Capacity | 9kg |

| Temperature Accuracy | ±0.2℃ |

| Temperature Range | 40-90℃ |

| Vacuum Time Rang | 0.5-8s |

| Mould Pressure Range | 0.5-2.5kg |

| Wax Pressure Range | 0.3-2.5kg |

| Wax Precision | 1% |

| Wax Time Range | 0.5-10s |

| Dimension Size(L*W*H) | L1470+260*W690*H790+510mm |

High Quality Workbench

The workbench of is made of high-quality environmentally friendly wood boards, which makes the work more stable, with a large desktop space and can put enough molds.

Vacuum Melting Wax

The wax tank adopts vacuum technology, which can melt the wax particles more fully and avoid the generation of air bubbles, thus ensuring the integrity and precision of the finished product.

Multi-size Molds

The suitable size range of the fixture is 116*116*96cm. Within this range, molds of various sizes can be used. Whether it is rings, bracelets or small and medium-sized handicrafts, it can meet the needs of wax injection. Realize multiple usages of one automatic wax molding machine.

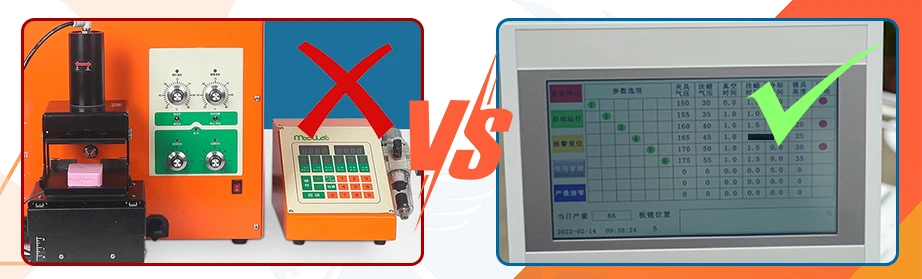

PLC Touch Screen Operation

Equipped with PLC touch screen, various parameters of machine operation including temperature, pressure, wax melting time, wax injection speed, etc. can be easily adjusted through the control system.

Temperature Control System

The components of the automatic wax injector machine are all imported brands, equipped with a three-level digital wax temperature control system, and the temperature control accuracy can reach ±0.2 degrees.

Automatic Cooling

The wax-injected mold will be sent to the cooling device to achieve rapid cooling, higher work efficiency and more perfect finished products.

Large Capacity

The wax tank has a capacity of 9kg, twice that of traditional wax injection. Therefore, frequent opening of the cover and waxing can be avoided, and wax models of different sizes and styles can be mass-produced at one time. The work efficiency is high and labor costs are also saved.

Wax Tank Design

The switching device of the wax tank is simple and user-friendly, which can realize fast open in 2 seconds. And the use of polymer non-stick coating can reduce the generation of residual wax, and the high-temperature spraying process is adopted inside and outside the cylinder to ensure the safety of workers.

High Level of Automation

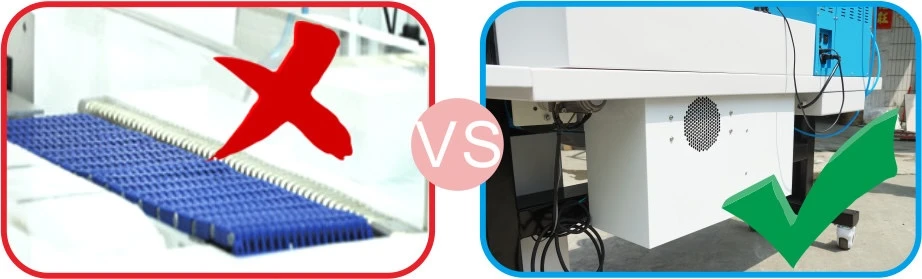

The use of fully intelligent chips can automatically identify mold parameters. Equipped with a wax mold conveyor belt, automatic transmission and discharge. After wax injection finished,the molds will also be automatically pushed out, a auto clamp wax injector only needs to be equipped with one worker to take the material, the work is simple, and the level of automation is high.

Energy Saving

SuperbMelt automatic wax injector machine is in a sealed state from wax melting to wax injection, which minimizes the outflow of odors and meets the environmental friendly standard. The constant temperature system can maintain the temperature of the wax liquid, which is more energy-saving.

Continuously Working

Equipped with an integrated air-cooling system to dissipate heat in time to ensure that the jewellery wax injector machine can work continuously for 24 hours, with longer service life and high stability.

SuperbMelt automatic wax injector machine is a device that is commonly used in jewelry making to inject wax into molds to create wax patterns and designs before casting them in metal.Such as the gold silver copper and platinum rings, bracelets, pendants and earrings.

Jewelry wax injector can produce intricate and detailed wax patterns that can be cast into complex jewelry designs.

Wax Injection

An automatic wax injector machine is used to inject wax into a mold. This process creates a wax model of the jewelry design that can then be used to create a metal castingof the jewelry piece.

Consistency

An automatic wax injector machine ensures that the wax is injected into the mold at a consistent rate, which results in consistent wax models that are accurate to the

design.

Customization

An automatic wax injector machine allows for the creation of custom designs that are unique to the jeweler and customer’s specifications.

Precision

It can produce wax models with high precision, allowing for intricate details to be accurately captured in the wax model.

Vacuum Melting

It can avoid air bubbles and form a high-precision and high-quality wax molds.

Large Capacity

The wax tank has a large capacity, reducing the number of openings, saving time and labor

Intelligent Chip Identification

Fully intelligent chip identification and the use of automatic conveyor belt, high degree of automation.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Automatic Wax Injector Machine

Any Question About SuperbMelt Automatic Wax Injector Machine

FAQ Guide of SuperbMelt Automatic Wax Injector Machine

1. What Types of Wax Raw Materials are Suitable?

The temperature of most waxes on the market is more than 70 degrees, except for white wax, which is more than 100 degrees, and the maximum temperature of our automatic wax injector machine is 90 degrees, so most of the wax raw materials can be realized.

2. How to Control the Temperature and Pressure of Wax Injection?

The temperature is set according to the melting point of the wax raw material, and the pressure depends on the product design and precision requirements. For complex and detailed products, the pressure needs to be increased to achieve high quality requirements.

3. How to Clean Up the Residual Wax?

The small cylinder in the middle of the wax tank will recover the residual wax on the nozzle by vacuum, and then discharge it uniformly.

4. What Size Wax Pattern is Suitable?

The mold suitable for the machine is between 116*116*96cm, as long as the jewelry design does not exceed the maximum range of the film, it can be realized.

5. How many Wax Molds of Rings can be Injected into a 9kg Tank?

Judging by the size and weight of the ring, taking a 1g ring as an example, you can inject about 8000-9000 pieces in a tank.

6. Can it Work Continuously?

The equipment is equipped with an air cooling system to ensure the continuous operation of the wax molding machine.

Guide of SuperbMelt Automatic Wax Injector Machine

Comparison Between Automatic Wax Injection and Traditional Wax Injection

Precision

Automatic wax injection is generally considered to be more precise than traditional wax injection because the machine can control the wax flow rate and injection pressure more accurately.Speed

Wax injection machine for jewelry is generally faster than traditional wax injection because the machine can adjust wax melting and wax injection speed, can inject wax into the mold more quickly and consistently.Production Volume

Labor Intensity

Traditional wax injection requires skilled labor to operate the injector gun and ensure consistent injection, while automatic wax injection requires less labor because using full intelligent chip identification, automatic conveyor belt and other devices.Cost

The cost of automatic wax injector machines is generally higher than the cost of traditional wax molding machine. However, the savings in labor and increased production efficiency can make up for the higher initial investment in the long run.Process Steps

The traditional wax injection process needs to be completed manually, such as mold clamping, wax injection, pressure holding, mold opening, core pulling and top mold, etc. However, using the automatic wax injector machine only needs to set the parameters through the plc control system to automatically complete all the processes, which is simpler and more convenient.How to Use SuperbMelt Automatic Wax Injector Machine?

Early Preparation

- When Unifying the Mold:

- When the Mold is Different:

Wax Injection Process

Step 1: Open the lid of the wax tank, pour in the wax pellets or blocks that need to be melted, and then lock the lid.Step 2: Turn on the temperature control system, adjust the temperature of the wax cylinder to 80-85 degrees Celsius and melt it for 1-2 hours.

Step 3: Adjust filter’s pressure: 0.4-0.5Mpa.

Step 4: Open temperature control system to adjust wax cylinder/ wax mouth/ runner at 72-75 degrees Celsius.

Step 5: Press the power buttom, then click ‘Orgin’ key.

Step 6: Check if the lights in three areas are lit: depressed cylinder/feeding cylinder/pisher cylinder area.

Step 7: Choose ‘IC Mode’ or ‘No IC Mode’.

Step 8: Measure the size of the rubber mold and adjust the distance between the front and back of the clamp / the up and down position of the wax nozzle( Clamp JOG/ Nozzle JOG).

Step 9: Input Injection pressure/ Fixture pressure/Injection time/Vacuum time. For small items, the cooling time is not needed to be set.

Step 10: Set the rubber mold on the sensing area, and click ‘Write’, then the data is saved on chip.(If choose ‘No IC Mode’, don’t click it).

Step 11: Click on the screen to inject wax.

What Technologies Are by Automatic Wax Injector Machines?

Fully Automatic Intelligent Identification Chip

For each mold, parameters need to be entered manually when the wax is injected for the first time. After that, the machine can automatically identify the chip of the mold, and after reading the parameters of each chip, it will automatically complete the wax injection; if there is the same mold, you can directly read and copy the chip parameters directly on the machine.

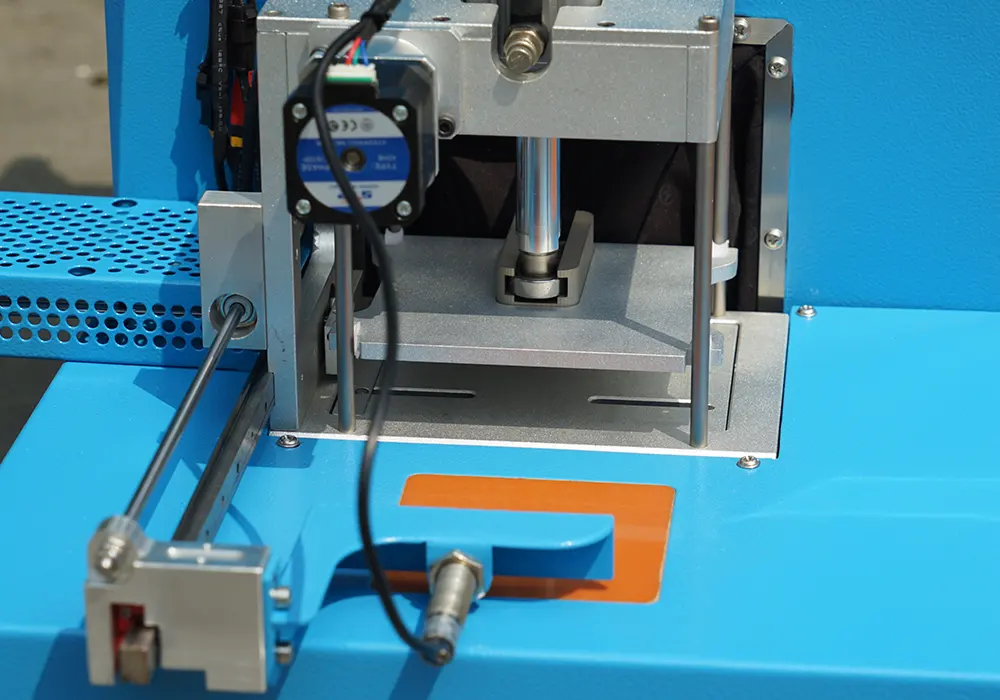

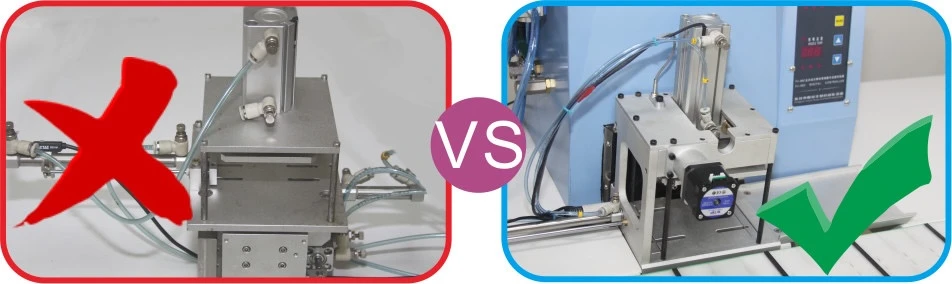

Automatic Transfer and Clamping Device

The machine has a high level of automation, and the installed conveyor belts can be directly and uniformly transported without manual placement, which greatly saves time and ensures the safety of workers.

Within the applicable mold range, different sizes can be automatically identified and centered by the fixture, and then aligned with the nozzle, which is simple and quick.

PLC Control System

All parameters required by the product can be controlled through the PLC screen, such as process temperature, pressure holding time, number of injection molds, etc. can be set directly, the operation is more convenient, and no complicated equipment training is required.

Vacuum Technology

Not all wax mold products need vacuuming, such as trinkets, rings, earrings, etc., and the vacuuming technology of the machine can meet some high-precision products or medium and large handicrafts. Vacuuming can make the wax model more complete and delicate, and the details will be better.

Automatic Cooling System

After the mold is injected with wax, it will be released from the fixture and then pushed out to enter a cooling area. The mold will be cooled quickly by air cooling, which can ensure that the wax mold will not be damaged when the film is removed, and the finished product will be more perfect.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited