Bangles Making Machine

As a precious metal equipment expert, we provide a one-stop service to solve any problems with your gold and silver bangles making line.

Gold and Silver Bangles Making Machine Solution Supplier

The actual craftsmanship of the seemingly simple gold and silver bangle is a progressive process. There are many types of precious metal bracelets on the market, such as inlays, including diamonds and jade; hollow and solid bangles, carved bangles, round and flat bangles and so on.

These styles require inlaying, casting, carving and sandblasting, etc. It is almost impossible to achieve mass production under the condition of hand-made, and many complex styles cannot be presented.

Therefore, SuperbMelt has developed a series of bangles production solutions to address these problems, satisfying most bangle styles and customer groups in the market. For simple casting bangles, complex hollow bangles, as well as pattern cutting and polishing processes, there are high-automatic equipment to support.

How Jewelry Bangles Are Manufactured?

Step 1: Casting into Strips

Using a continuous casting machine, the raw materials for the bracelet are cast into strips, making them easier to process into bracelets later. This machine can cast not only strips but also tubes, sheets, plates, and rods. It is widely used in the jewelry industry, with high production efficiency, cost savings, good casting quality, and excellent safety features.

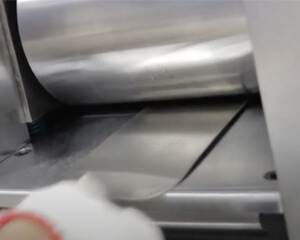

Step 2: Rolling and Shaping

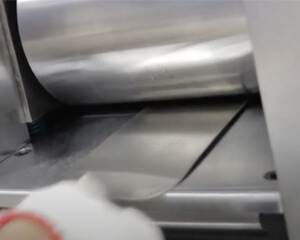

The cast strips are rolled using a rolling mill to achieve the desired thickness, then fed into a hollow tube making machine and tube drawing machine to form hollow tubes.

Step 3: Creating the Blank

The hollow tubes are then wound into a spring shape using a tube coiling machine to create a bracelet blank, after which a tube cutting machine is used to cut the coiled tubes.

Step 4: Jewelry Bracelet Casting

Finally, the cut ends are welded, and the rough bracelet is shaped into a finished product using a bracelet shaping machine.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Jewelry Hollow Bangles Making Line Process

1st Continuous Casting Machine

2nd Jewelry Rolling Mill

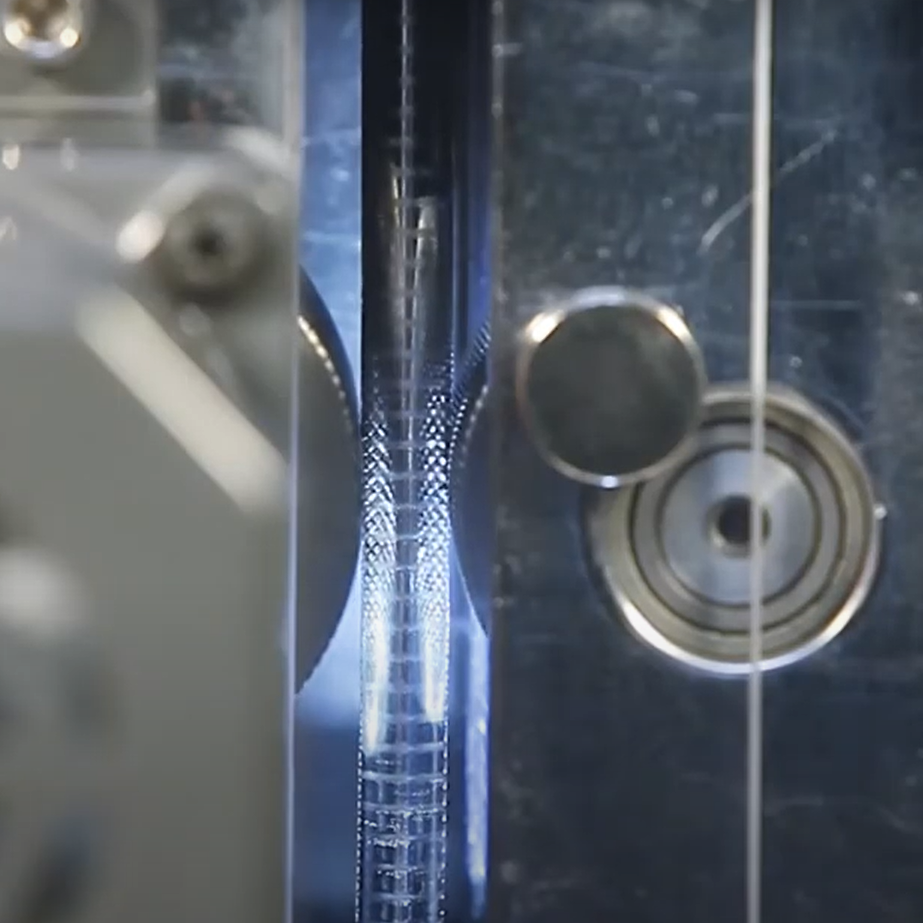

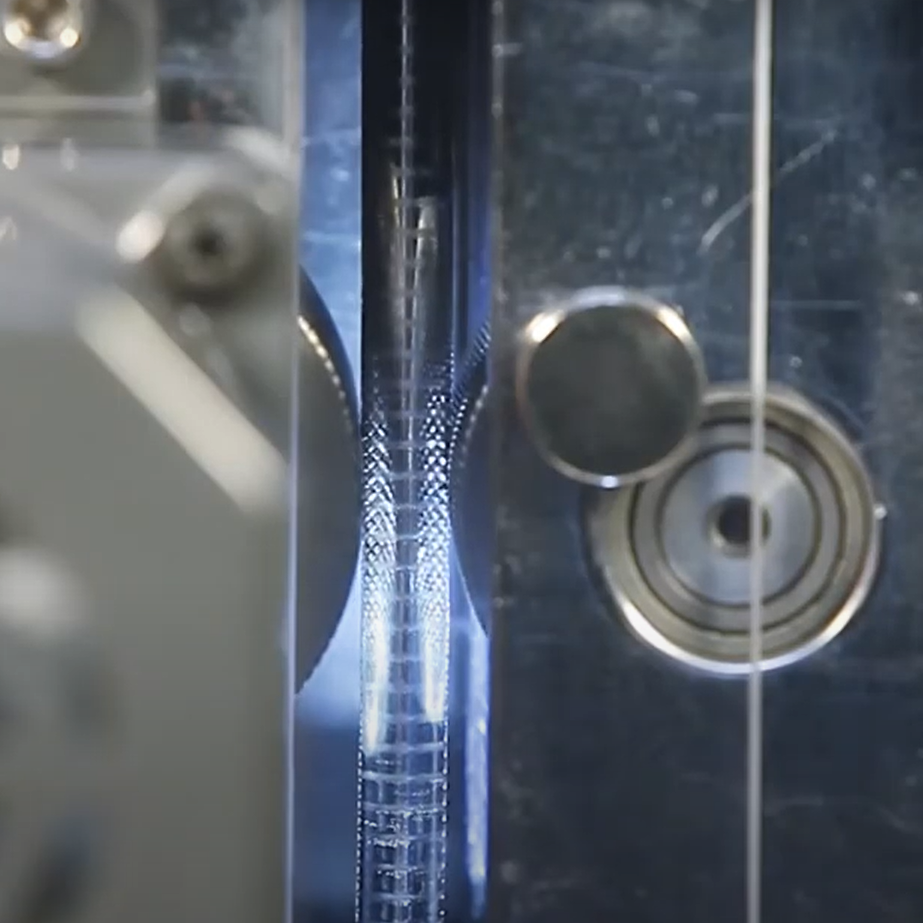

3rd Hollow Pipe Forming Machine

4th Pipe Drawing Machine

Casting metal into block

Roll block into sheets

Weld the sheet into a hollow tube

Tube drawing to required diameter

Coil the hollow tube

Shape the hollow tube into bangles

5th Jewelry Pipe Winding Machine

6th Roll Cutting Machine

8th Hollow Bangle Making Machine

Our bangles shaping machine can realize many styles of molding, such as inner and outer arc, round, inner arc and outer flat, chamfering, and so on. It is easy to change the mold, and it can also realize the shaping of gold and silver rings. [Learn More>>]

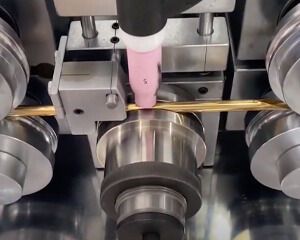

7thBracelet Welder

1st Continuous Casting Machine

2nd Jewelry Rolling Mill

3rd Hollow Tube Making Machine

4th Pipe Drawing Machine

5th Jewelry Pipe Winding Machine

6th Roll Cutting Machine

7thBracelet Welder

8th Hollow Bangle Making Machine

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited