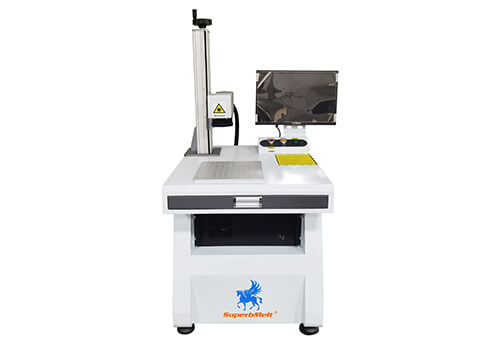

Laser Engraving Machine For Silver

Laser Engraving Machine for Silver revolutionizes the way silver is engraved, making it a must-have for jewelers, engravers, and manufacturers looking for quality and efficiency.

SuperbMelt Laser Engraving Machine for Silver is specifically designed for engraving or printing on silver and gold jewelry. This device can engrave at a speed of 10,000mm per second, significantly enhancing production efficiency for jewelry or craft shops.

A Laser Engraving Machine for Silver is a high-precision device that etches intricate designs, patterns, text, or logos onto silver surfaces. Utilizing laser technology, it delivers unmatched precision and efficiency for engraving on delicate materials like silver, making it an essential tool for jewelry manufacturing, customization, and branding.

Using traditional methods for jewelry engraving can be time-consuming, expensive, and challenging to replicate complex patterns consistently. However, modern laser engraving machines, with their rapid, efficient, and precise technology, have revolutionized the jewelry industry by greatly improving production efficiency and allowing for greater design freedom.

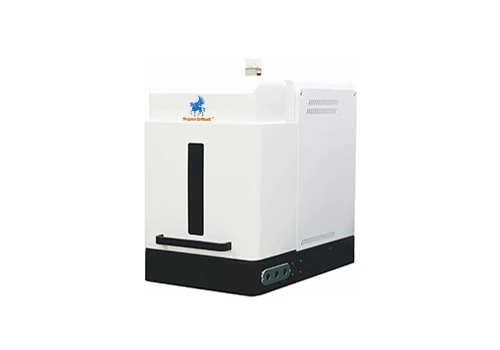

| Type: | Fiber laser marking machine |  |

| Model number: | FLMM-series | |

| Laser power: | 20W/30W/50W | |

| Marking range: | 110x110mm | |

| Marking speed: | ≤7000mm/s or ≤13000mm/s | |

| Power supply: | AC220V/50HZ | |

| Cooling method: | Circulating air cooling | |

| Positioning method: | Red ray positioning | |

| Accessibility: | 3 red ray assisted focus | |

| Lifting stroke: | 550mm |

- Features

High-Precision Fiber Laser:

Developed using imported fiber laser technology, ensuring exceptional precision for detailed engraving and marking tasks.

Market-Leading Speed:

The fastest laser marking system available, significantly enhancing processing efficiency for large-scale production.

Superior Stability:

Outstanding stability for long-term, fault-free operation, ensuring seamless production workflows.

Wide Software Compatibility:

The marking software is compatible with major design programs such as AutoCAD, CorelDRAW, and Photoshop, supporting various file formats like PLT, PCW, DXF, and BMP.

Bilingual Interface:

Offers both Chinese and English user interfaces, providing intuitive operation for global customers with minimal learning curve.

Extensive Font Support:

Supports SHX and TTF font libraries, enabling diverse font designs ideal for branding, personalization, and more.

- Advantages

Enhanced Production Efficiency:

High-speed marking capabilities dramatically reduce processing times, meeting the demands of rapid production schedules.

Versatile Applications:

Suitable for marking both metallic and non-metallic materials, covering industries such as electronics, jewelry, and automotive parts.

Cost-Effective Operation:

Fiber lasers feature low power consumption and long service life, minimizing material and maintenance costs.

High-Quality Marking Results:

Delivers clear, permanent, and wear-resistant marks that don’t fade, perfect for premium branding and precision processing.

Flexible Workflow:

Supports multiple file formats and design software, allowing for seamless imports without conversion, streamlining designers’ workflow.

User-Friendly and Globally Accessible:

The bilingual interface simplifies operation and ensures accessibility for users from different countries, enabling quick adoption.

Eco-Friendly and Sustainable:

Operates without consumables or pollutants, aligning with modern green manufacturing standards.

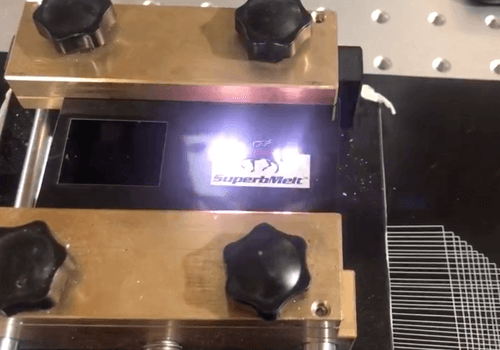

Jewelry Engraving:

- High-precision engraving for intricate designs on gold, silver, platinum, and other precious metals.

- Customization of jewelry with names, dates, or logos.

Electronic Components:

- Marking serial numbers, barcodes, and QR codes on circuit boards, chips, and connectors.

- Ensuring traceability and compliance in electronic manufacturing.

Medical Equipment:

- Engraving permanent markings on surgical instruments, implants, and medical devices.

- Markings are sterile and wear-resistant.

Automotive Industry:

- Etching VIN numbers, part codes, and brand logos on automotive parts.

- Ensures product identification and anti-counterfeiting measures.

Tool and Mold Making:

- High-durability markings on industrial tools and molds for identification or branding.

Luxury Goo

- Personalizing watches, pens, and other high-end accessories with intricate designs.

Promotional and Branding Items:

- Customizing corporate gifts, awards, and promotional merchandise with logos and text.

Aerospace and Defense:

- Marking precision components with unique identifiers for traceability and compliance.

Packaging:

- High-speed marking of expiry dates, batch numbers, and barcodes on packaging materials.

Why SuperbMelt Laser Engraving Machine For Silver

Any Question About SuperbMelt Laser Engraving Machine For Silver

FAQ Guide of Laser Engraving Machine For Silver

- 1. Can a laser engrave silver?

- 2. What to use to engrave silver?

- 3. What is the best engraver for jewelry?

- 4. Is it hard to engrave silver?

- 5. What metals can be laser engraved?

- 6. What is the difference between etching and engraving?

- 7. Does laser engraving on metal wear off?

- 8. What is the best engraver for jewelry?

- 9.What are the disadvantages of laser engraving?

- 10. How long do laser engravers last?

1. Can a laser engrave silver?

Yes, laser engraving machines can engrave silver effectively. Silver, being a reflective and highly conductive material, requires specialized laser equipment to achieve precise and high-quality results. Here’s how it works:

Laser Engraving on Silver

Fiber Lasers:

- Fiber laser machines are ideal for engraving silver due to their ability to focus a high-intensity laser beam on reflective surfaces.

- They can create detailed designs, text, and patterns without damaging the surrounding material.

CO2 Lasers:

- While not as commonly used for silver, CO2 lasers can mark coated or treated silver surfaces.

Marking Techniques:

- Deep Engraving: Creates a lasting impression by removing material.

- Surface Marking: Adds patterns, logos, or text without material removal.

- Polished Finish: Laser engraving on silver leaves a smooth, polished finish suitable for luxury items.

Applications of Laser Engraving on Silver

- Jewelry: Rings, necklaces, bracelets, and pendants.

- Custom Gifts: Watches, keychains, and silverware.

- Industrial: Labels, logos, and QR codes for traceability.

Laser engraving is precise, permanent, and allows for intricate designs that traditional methods cannot achieve, making it an excellent choice for silver engraving.

2. What to use to engrave silver?

What to Use to Engrave Silver

Engraving silver requires specialized tools or machines to ensure precision and avoid damaging the delicate material. Below are the tools and methods commonly used for engraving silver:

1. Laser Engraving Machines

- Best for: High-precision designs, logos, text, or intricate patterns.

- Equipment Used: Fiber laser engraving machines (ideal for silver due to its reflectivity and conductivity).

- Advantages:

- Non-contact process that preserves material integrity.

- High-speed and accurate engraving with customizable designs.

- No need for consumables like engraving bits.

2. Rotary Engraving Tools

- Best for: Deep engraving or traditional manual techniques.

- Equipment Used: Dremel or other handheld rotary tools equipped with fine diamond or carbide bits.

- Advantages:

- Affordable and versatile for small projects.

- Suitable for hand-engraving personalized items.

3. Hand Engraving Tools

- Best for: Custom, artistic, or detailed manual engravings.

- Equipment Used: Burins,

3. What is the best engraver for jewelry?

The Best Engraver for Jewelry

Selecting the best engraver for jewelry depends on the type of material, the complexity of the design, and the production scale. Below are some of the top options:

1. Fiber Laser Engraving Machine

- Best for: Precision, speed, and professional engraving on metals like gold, silver, platinum, and stainless steel.

- Advantages:

- High precision for intricate designs, logos, and text.

- Non-contact engraving ensures no material damage.

- Efficient for both large-scale production and custom pieces.

- Suitable for engraving on curved or irregular surfaces.

Recommended Example: SuperbMelt Laser Engraving Machine for Silver

2. CO₂ Laser Engraving Machine

- Best for: Engraving non-metal materials like wood, acrylic, and certain stones used in jewelry making.

- Advantages:

- Versatile for non-metals, ideal for mixed-material jewelry.

- Clean and smooth engraving on organic materials.

3. Rotary Engraving Machine

- Best for: Deep engraving or traditional patterns on metals and gemstones.

- Advantages:

- Durable engraving with depth for a classic look.

- Can handle a variety of shapes, including rings and bracelets.

4. Handheld Engraving Tools (Dremel)

- Best for: Small-scale or hobbyist engraving projects.

- Advantages:

- Affordable and portable.

- Ideal for personalizing jewelry with simple patterns.

Key Considerations:

- Material: Fiber lasers are the best for metals; CO₂ lasers are better for non-metals.

- Precision: For detailed and intricate designs, fiber lasers excel.

- Volume: For mass production, automated laser machines are highly efficient.

For professional and efficient jewelry engraving, fiber laser engraving machines are the top choice due to their precision, speed, and versatility.

4.Is it hard to engrave silver?

Engraving silver can be challenging depending on the method and tools used, but modern technology has made the process much more manageable. Here’s what you should know:

Factors Affecting the Difficulty of Engraving Silver

1. Material Properties

- Softness of Silver: Silver is a relatively soft metal, making it easier to engrave manually compared to harder metals like steel. However, its softness can also make it prone to scratches or deformation if not handled carefully.

- Alloys: Sterling silver (92.5% silver and 7.5% other metals) is harder than pure silver, which can make engraving slightly more consistent.

2. Method of Engraving

- Manual Engraving: Requires skill and steady hands to achieve clean lines and consistent depth. It is time-consuming and not ideal for intricate or repetitive patterns.

- Laser Engraving: Highly precise and efficient. It’s the easiest method for engraving silver, allowing for complex designs with minimal effort and no risk of material damage.

- Rotary Engraving: Suitable for deeper cuts and traditional designs but requires more effort and care compared to laser engraving.

3. Tools Used

- Using the right tools significantly reduces the difficulty. Fiber laser engraving machines, for example, are specifically designed to engrave metals like silver with speed and precision. Hand tools, on the other hand, require expertise and patience.

Conclusion

Engraving silver isn’t inherently hard but depends on the engraving method and tools used. For professionals and jewelers, laser engraving offers the easiest and most precise solution, while manual engraving is more challenging and time-intensive.

5. What metals can be laser engraved?

1. Stainless Steel

- One of the most commonly engraved metals. Laser engraving produces high contrast marks, making it ideal for industrial applications, tools, and jewelry.

2. Aluminum

- Both anodized and non-anodized aluminum can be engraved with a laser. Anodized aluminum produces vibrant marks with a high contrast, while untreated aluminum produces a dark, subtle engraving.

3. Brass

- Brass can be engraved to create high-quality, detailed designs. The engraving process often leaves a rich, contrasting mark, especially on polished brass.

4. Copper

- Copper can be engraved, but it can be more challenging due to its high reflectivity. However, with the right settings, laser engravers can produce crisp, detailed markings on copper surfaces.

5. Titanium

- Titanium engraves easily with a laser and produces a striking, durable mark. It’s often used for high-end jewelry, watches, and medical tools.

6. Gold and Silver

- Both metals can be laser engraved with great precision, making them ideal for personalizing jewelry. Laser engraving on precious metals produces high-quality, fine details without damaging the surface.

7. Platinum

- Platinum, a precious and durable metal, can also be engraved with a laser, although it requires higher-powered lasers due to its toughness.

8. Nickel

- Laser engraving on nickel results in a precise, permanent marking. It is commonly used for industrial applications, including identification tags and parts labeling.

9. Zinc

- Zinc and its alloys can be laser engraved, though the surface can be sensitive to heat, requiring specific laser settings to avoid damaging the material.

10. Carbon Steel

- Carbon steel can be engraved with a laser, especially for industrial or custom applications, with excellent precision and durability.

11. Cast Iron

- Laser engraving is effective on cast iron, typically used for industrial purposes, and offers good contrast for identification or decorative designs.

12. Magnesium

- Magnesium can be engraved with a laser but requires careful handling due to its flammability when exposed to heat, often needing lower power settings.

Other Materials

- Bronze, Nickel Alloys, and Steel Alloys are also suitable for laser engraving.

6. What is the difference between etching and engraving?

The terms etching and engraving both refer to processes used to create designs or markings on a surface, but they differ significantly in their techniques, appearance, and applications. Here’s a breakdown of the key differences:

1. Technique

- Engraving:

- Engraving involves physically cutting or carving into the surface of a material using a sharp tool or a laser. In traditional engraving, a tool like a burin or graver is used to cut the design into the material.

- Laser engraving uses a laser beam to remove material from the surface, creating a permanent mark by burning or vaporizing the surface layer.

- Etching:

- Etching is a chemical process where a surface is coated with an acid-resistant material (such as wax), and then the design is created by exposing the material to acid or a laser. The acid reacts with the surface, creating grooves or markings in the exposed areas.

- Laser etching uses a laser to burn or vaporize the surface layer without actually cutting into the material, leaving a mark on the surface.

2. Depth of the Mark

- Engraving:

- Engraving creates a deeper mark or groove in the material. The result is usually a 3D effect with a tactile, raised or sunken surface.

- The depth of the engraving is usually visible and can be felt by touch.

- Etching:

- Etching typically creates a shallower, more surface-level mark compared to engraving. The etched mark is often a slight discoloration or texture on the material, rather than a deep incision.

- Etching is often used for creating designs that are more subtle or delicate.

3. Appearance

- Engraving:

- The marks from engraving are typically sharp, well-defined, and often create a high contrast between the design and the background.

- Laser engraving can provide high-precision marks with crisp edges.

- Etching:

- Etched marks usually have a softer appearance, often showing a more subtle or faded texture, and may be less defined than engraved marks.

- Etching can create more intricate and delicate details, but the mark tends to be less permanent and prominent than engraving.

4. Materials

- Engraving:

- Engraving can be done on a wide range of materials, including metals, glass, wood, plastic, and stone. It’s commonly used on jewelry, tools, plaques, and trophies.

- Etching:

- Etching is typically used on materials like glass, metal, and ceramics, especially for decorative purposes. It’s common in art, jewelry, and the creation of intricate patterns on metal surfaces.

- Etching is especially popular in creating detailed artwork or logos on glass or intricate designs on jewelry pieces.

5. Application Process

Engraving:

- The engraving process can be done manually (using tools like a graver or burin) or mechanically (using a rotary tool or laser).

- It is more precise for creating fine, permanent designs that need to withstand wear and tear.

Etching:

- Etching can be done chemically (using acid or other chemicals) or with a laser, where the laser causes a surface change rather than physically cutting the material.

- The process is often used for larger or more intricate designs but doesn’t have the same longevity as engraving.

6. Durability

- Engraving:

- Engraved marks are permanent, and the design typically lasts longer due to the depth of the cut into the material.

- Etching:

- Etched marks, while relatively durable, may wear away over time, especially on softer materials or in environments with heavy abrasion.

Summary Table

| Feature | Engraving | Etching |

|---|---|---|

| Process | Physical cutting or laser removal of material | Chemical or laser-based surface treatment |

| Depth | Deeper, permanent mark | Shallow, surface-level mark |

| Appearance | Sharp, well-defined marks | Softer, faded marks |

| Materials | Metal, glass, plastic, wood, stone | Metal, glass, ceramics, some plastics |

| Applications | Jewelry, tools, awards, plaques | Artwork, jewelry designs, glassware |

| Durability | Highly durable, withstands wear | Less durable, may wear over time |

Conclusion

- Engraving is best for creating deep, high-contrast, permanent designs on a variety of materials.

- Etching is typically used for surface-level, more intricate, or artistic designs, often on metal or glass, but it may not be as durable as engraving.

7. Does laser engraving on metal wear off?

Laser engraving on metal is highly durable and typically does not wear off under normal conditions. Since the process involves using a laser to remove the surface layer of the metal, the engraving is permanent and resistant to fading. However, the longevity of the engraving can be influenced by factors such as the type of metal, the depth of the engraving, and the conditions to which the engraved item is exposed. For example, items exposed to harsh chemicals or excessive abrasion might show signs of wear over time, but in general, laser engraving provides a long-lasting mark on metal surfaces.

8.What is the difference between laser etcher and engraver?

The best engraver for jewelry depends on the type of engraving you need and the materials you’re working with. Here are some of the top options for jewelry engraving:

1. Laser Engraving Machines

- Best For: Detailed, precise, and intricate designs on jewelry, including rings, bracelets, necklaces, and other small items.

- Why: Laser engraving machines, especially fiber laser engravers, are perfect for engraving on delicate metals like gold, silver, platinum, and even diamonds. They offer high precision and can handle fine details, such as logos, text, and patterns. The process is quick, doesn’t require contact with the metal, and the results are permanent.

- Top Picks:

- Gravotech Laser Engraving Machines: Known for their precision and versatility, they are highly regarded in the jewelry industry.

- Trotec Laser Machines: High-quality laser engravers with exceptional speed and precision, ideal for intricate jewelry engraving.

- SuperbMelt Fiber Laser Engraving Machine: Known for offering excellent precision for engraving on jewelry materials like silver, gold, and platinum.

2. Rotary Engraving Machines

- Best For: Engraving simple designs, logos, or text on jewelry surfaces.

- Why: Rotary engraving machines use a rotating tool to carve or etch designs into the surface of jewelry. These machines are ideal for engraving larger or deeper designs that need more tactile contact with the surface.

- Top Picks:

- JewelCraft Rotary Engraving Machine: A reliable choice for high-precision engraving, especially for small jewelry items.

- CNC Engravers: For larger-scale engraving tasks or those requiring more complex shapes, CNC (Computer Numerical Control) rotary engravers can provide exceptional accuracy and detail.

3. Handheld Engraving Tools

- Best For: Small-scale or custom engraving jobs, such as adding initials or personal touches.

- Why: If you’re looking for manual control, handheld engravers are great for personalizing small jewelry items. They’re affordable and portable but require more skill and time for precision.

- Top Picks:

- Dremel Engravers: Well-known for versatility, these tools are ideal for small-scale, precise engraving jobs.

- Gravograph Hand Engravers: Known for their easy-to-use handheld tools that can be used for engraving intricate designs on jewelry.

4. Diamond-Tipped Engraving Tools

- Best For: Deep engraving on harder materials like platinum or tungsten.

- Why: These tools are perfect for creating permanent marks on hard metals, making them ideal for high-end jewelry engraving. The diamond tip ensures sharp, clear engravings even on the toughest materials.

- Top Picks:

- Gesswein Diamond Engraving Tools: These are highly regarded in the jewelry industry for fine, deep engravings on precious metals.

5. CNC Milling Machines (for Jewelry Design)

- Best For: Creating 3D engravings or detailed designs on metal jewelry.

- Why: CNC milling machines can carve 3D designs and intricate textures into jewelry pieces, making them perfect for designers who want to create complex and personalized jewelry.

- Top Picks:

- Roland JWX Series CNC Milling Machines: These are excellent for creating 3D models or engraving detailed designs on metal and wax for jewelry casting.

Conclusion:

- If you’re looking for precision, high-speed, and intricate engraving on metals like silver or gold, a laser engraving machine like the SuperbMelt Fiber Laser Engraving Machine is likely your best option.

- For more hands-on or custom engravings, rotary engravers or handheld tools like Dremel might be ideal for simpler tasks.

- For more complex designs or 3D engravings, CNC milling machines are suitable.

Ultimately, the best engraver depends on your specific needs and the materials you’re working with, but laser engraving offers the most advanced technology for jewelry engraving.

9. What are the disadvantages of laser engraving?

While laser engraving offers numerous advantages, such as precision, speed, and versatility, it also has a few disadvantages:

1. Initial Cost

- High Initial Investment: Laser engraving machines, especially high-quality ones like fiber lasers, can be expensive to purchase upfront. The cost can be prohibitive for small businesses or hobbyists who are just starting.

2. Limited Material Thickness

- Shallow Engraving Depth: Laser engraving is usually limited to surface-level engraving. For deep engraving, or creating raised patterns, additional processes (like rotary engraving) might be required. This limits its use for projects requiring deeper cuts.

3. Material Restrictions

- Not Suitable for All Materials: While lasers are effective on metals like gold, silver, aluminum, and stainless steel, they may not work as well on certain materials like ceramics, plastics, or reflective surfaces. Some materials might even produce toxic fumes when laser-engraved.

- Reflectivity Issues: Highly reflective metals, like mirror-finish gold or aluminum, can cause issues with the laser beam’s focus and efficiency.

4. Heat Affected Zone (HAZ)

- Surface Discoloration: The heat from laser engraving can cause a heat-affected zone (HAZ) around the engraving area. This can sometimes lead to slight discoloration or oxidation on certain materials, especially metals, requiring post-processing to clean up.

- Potential for Warping: In cases where the material is thin or highly sensitive to heat, there’s a risk of warping or distortion due to the localized heat from the laser.

5. Size Limitations

- Size of the Work Area: The engraving area is often limited by the size of the machine’s working bed. While some laser engraving machines offer large work areas, others may be restricted to smaller projects, making them less suitable for large-scale productions or bigger items.

6. Maintenance

- Regular Maintenance: Laser engravers require regular maintenance, such as cleaning the lenses and ensuring the laser beam is properly aligned. Failing to do so can reduce the machine’s effectiveness, quality of engravings, and overall lifespan.

7. Learning Curve

- Complex Setup: Laser engraving machines can be complex to operate, especially for beginners. Proper training is often required to ensure the correct settings, such as power, speed, and focus, are applied to achieve the desired results.

8. Speed vs. Quality

- Trade-Off Between Speed and Precision: While laser engraving is fast, achieving the highest precision may require slower speeds, which can increase production time. This trade-off can be an issue for businesses with high production demands.

9. Post-Processing Requirement

- Cleaning After Engraving: Some materials, especially metals, can have residue or smoke marks left after engraving. Post-processing may be required to remove these residues and clean the engraved surface, adding extra steps to the production process.

Conclusion:

While laser engraving offers excellent precision and versatility, the high initial cost, material limitations, and potential heat-related issues are important considerations. For businesses or individuals looking to do small-scale engraving with intricate designs on metals, laser engraving is still one of the best choices. However, it’s essential to weigh these disadvantages against its capabilities before deciding if it’s the right tool for your needs.

10.How long do laser engravers last?

The laser has a lifespan of 100,000 hours and requires no maintenance for its entire lifetime. Based on the development trend of laser marking machines, this device is currently the mainstream product in the marking industry for the next five years.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited