Coin Die

As a top coin die manufacturer, Superbmelt provides one stop solution for coin die customization

As a coin die maker, we design your own coins with highly automated equipment to help you achieve fast and accurate die customization.

Coin dies are important stamping tools in the production of gold, silver, copper, zinc or other types of metal coins. Various customized logos, texts and shapes are embossed on coin dies which will in turn appear on both sides of the metal coins.

A coin die is a steel rod with a face that is the same size as the coins that it will be striking and for custom coin engraving. Two of these coin dies are needed to strike metal coins; one has the obverse (front) design while the other has the reverse (back) design.

The coin dies are set up in the Superbmelt hydraulic logo stamping machine for effective and efficient stamping on coins. Lubricants are not used in coining as they are incompressible.

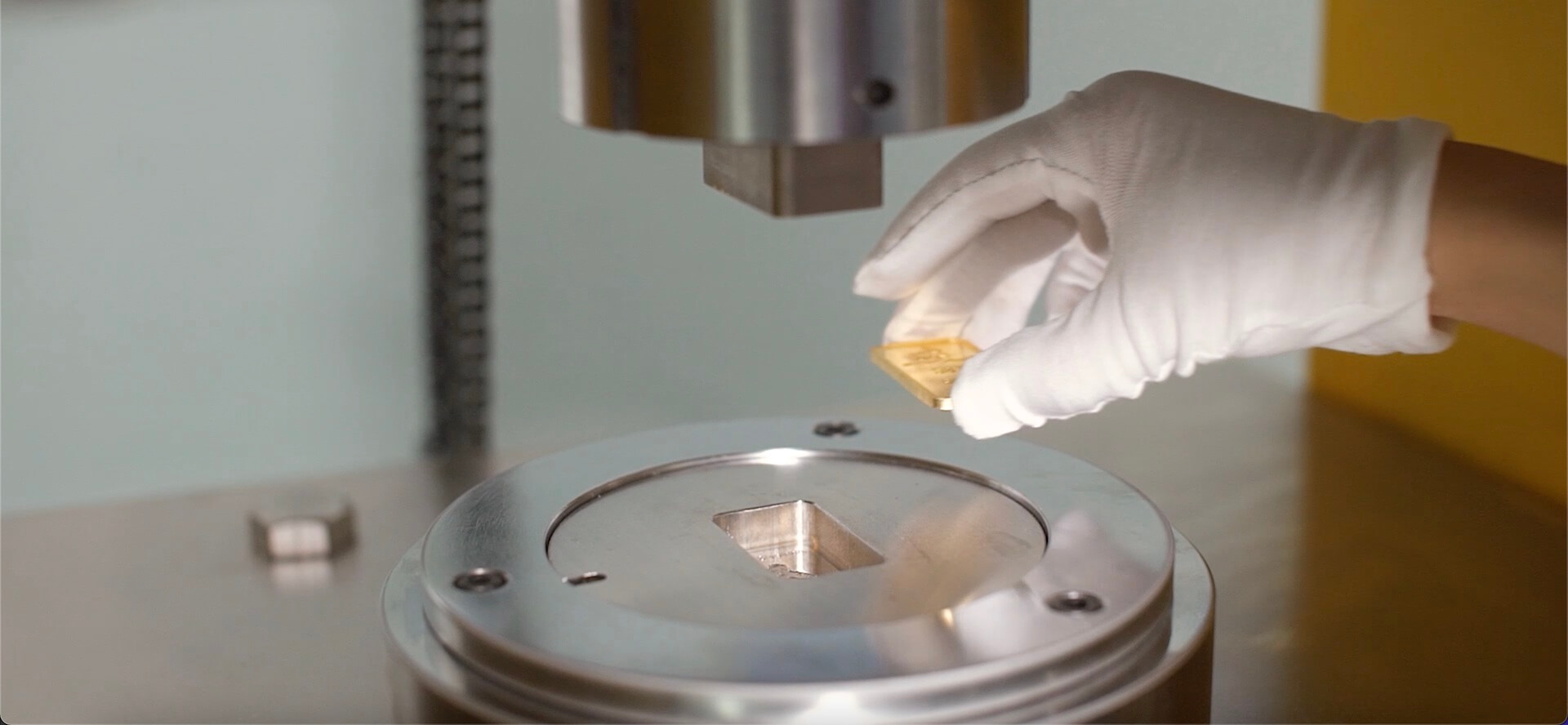

We manufacture coin dies as well as samples on gold coins for our customers before they are shipped.

We at Superbmelt provide our clients with all coin minting equipment for every gold and silver coin making process, training and guidance to our clients.

Our molds can be customized with various metal materials such as gold, silver, copper, etc. We can make any shape that can be seen on the market, such as round coins, square block coins, irregular coins, etc., which can be used for souvenirs, decorations, Appreciation items, sale of gold coins and bullion, etc.

Therefore, weight information on gold nuggets, animal and plant patterns on souvenirs, text and portrait patterns on gold coins, etc., can all be easily realized.

- Coin dies are a faster, easier and less complicated approach to stamping coins when compared to the old process of beating, screw pressing and true gas press.

- Coin dies produce finer, lasting and detailed surface patterns on gold or silver coins.

- Coin stamping dies eliminates the needs for complex finishing processes and does not require expensive machinery.

- The work hardened surface of coins can resist impact and abrasion when stamped with coin dies.

- DIY coin dies allow coin manufacturers to produce unique and uniform patterns on coins which signifies authenticity. An ununiformed pattern on the same coin from the same manufacturer will be unacceptable to customers.

- Coin press dies are capable of stamping many hundreds to thousands of coins before they are retired and defaced.

- The coin die stamping does not impact the mirror-like appearance of gold coins. Therefore, the coin quality is highly maintained.

- No loss of metal is recorded during the process of stamping with the coin die.

When you already have design drawings or computer files, you can send them directly to the sales. Or if you have pictures, we can also ask the designer to make a computer document for you to confirm.

Then we will arrange proofing, and the middle 5-10 days is the production period.

After the mold is done, we will use it to press the finished product and send it to you for confirmation. Whether you want to see the real thing or a picture, we can provide it.

Finally, we will arrange express delivery as soon as possible to ensure that the mold can be delivered to your factory more fast to help you start production quickly.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Coin Die

As a professional coin minting solution supplier, it is our responsibility to provide you with the highest quality coin die

High Quality

Any Question About SuperbMelt Coin Minting Solution

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

How to Custom Coin Die for Coin Making?

Are you looking for a custom coin dies maker to help you establish a coin minting line?

The most important key to custom coin die is saving time and cost. There are many ways to make coin dies, and there are complex processes such as engraving, sandblasting, grinding, etc. Therefore, a professional coin die maker must be able to produce customized dies on time and help you go into production quickly.

Secondly, the most common process of minting coins is always achieved by hydraulic presses. In order to better cooperate with the operation of such machines, it is also very important to have long-lasting and high-quality coin stamping dies.

If you are new to the minting industry, SuperbMelt will better help you understand and choose the appropriate custom coin die.

From design to die making and imprinting of samples, we have professional equipment such as 3D scanners, cnc engraving machines, and hydraulic presses with a high level of automation to complete.

How SuperbMelt Custom Coin Dies

The making of a custom mold involves multiple layers of workmanship, the basic process being able to cast gold coins into shape in one time. The post-processing will also involve metal inlays, partial gold plating, etc. These processes are all to achieve high-quality and high-precision gold coin products. Therefore, the quality of a finished gold coin depends on the fineness of the mold process.

In addition to fine craftsmanship, a professional customization process is also required. Superb team can help you understand and provide a variety of solutions for a complete production line from design to gold coin casting.

You don’t have to worry about whether the quality and effect of the finished product can’t meet expectations, because we will carry out a coin-pressing test after the completion of each mold sample and send pictures to our customer for confirmation.

1.1, Coin Die Making Process

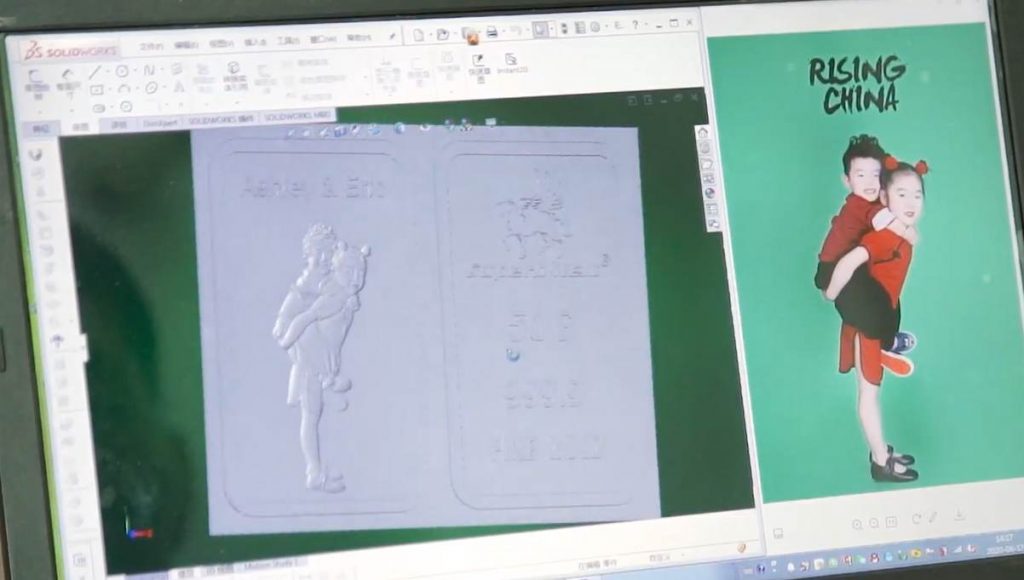

- Step 1: Draw the Design

With the development of computers, computer sketches are basically used to replace the previous manual sketches, usually using graphic or 3D design software, such as Adobe Photoshop, Corel Draw and 3D max. Use the color system software Pantone Solid coated to better match the color, thereby reducing the color difference.

If it is an existing design, a 3D scanner can be used to quickly reproduce it.

- Step 2: CNC Engraving

Profile engraving is the most commonly used method of mold engraving, and today, digital engraving technology has replaced traditional profiling engraving,

Digital engraving files are generated by computer, and the design of some reliefs can be simple and fast with the use of digital engraving technology, while making the reliefs as agile as traditional crafts. This approach greatly reduces the time for pattern adjustment and modification.

- Step 3: EDM Sandblasting

The method of eroding the size of the material through spark discharge is called EDM, and the design of the mold is made into a 3D shape by using electrodes, which is also called ‘copper work’.

Thanks to the development of CNC control technology, the use of electrodes to process molds with complex shapes can be easily realized.

- Step 4: Mold Surface Plating

After the engraving of the mold is completed, it is necessary to do a layer of electroplating treatment on the surface of the mold. There are two electroplating methods: chemical and physical. Nowadays, the quality requirements of products are gradually increasing, and physical coating technology is more popular. It can increase the printing durability by nearly 10 times.

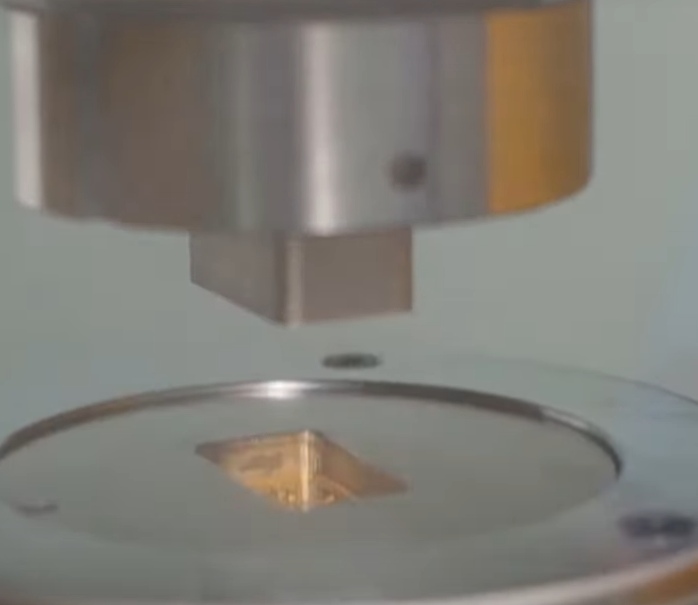

- Step 5: Make Coins by The Hydraulic Press

Use a hydraulic press to mint coins. A thin strip of metal is annealed to obtain the correct stamping hardness before coin pressing.

The hydraulic press is then equipped with coin stamping dies, set to specific diameters based on coin size. Two dies are pressed together to stamp the coin. Once complete, the coin is inspected and then a second impression is made.

After the minting process begins. The coin is placed on the bottom mold and pressed down. It comes into contact with other coins and dies with such force that the coin is imprinted.

It’s a relatively simple process that’s been used for hundreds of years. As one of the leading professional precious metal minting solution providers, we have multiple minting lines around the world. People can rely on SuperbMelt for their coin minting equipment and on-site minting instructions.

1.2, The Quality of The Finished

To make quality and beautiful coins, it is crucial to make sure that the coin dies are highest in quality. The dies need to be engraved and appropriately polished. A little bump on the die’s surface will severely affect the coin’s look.

Sandblasting and polishing are a big factor affecting the quality of finished products. The sandblasting process includes: traditional mirror sandblasting, the sandblasting of the bottom surface and the embossed text are different processes, the bottom surface is a mirror surface but the pattern looks like frosted. Therefore, there is a contrast with the mirror effect of the bottom surface, which looks more layered and thick. At the same time, the pattern also has a metallic aesthetic in contrast.

A process similar to this effect is reverse sandblasting. In addition to the effect of traditional mirror sandblasting, local light is added to the sandblasting part of the pattern and text. This process is often used in manual mold polishing and chemical mold polishing. This process highlights the beauty of the embossed pattern and enriches the face of the coin.

These processes will also be combined with chrome plating, which not only makes the surface of the mold smooth and beautiful, but also protects the pattern during the stamping process, and when hydraulic press finished, it will easier to separate from the mold.

Why Choose SuperbMelt Coin Dies?

It is clear that without a fair quality coin minting die, it will be very difficult to make coins with stunning designs and patterns. However, you also have to choose the right coin dies and punches to get the best result. So, from where you can get top-quality and high-grade coin dies for coin manufacturing? Well, this is where you can get in touch with SuperbMelt now.

They are the well-known manufacturer of high-quality coin dies that can stamp hundreds of thousands of coins. SuperbMelt has emerged as a leading coin die manufacturer in this industry, serving this industry for years. If you still think about why to choose SuperbMelt, then here are some factors that you can consider.

2.1, We are The Manufacturer of The Coin Die

All know that SuperbMelt is a leading electro-machinery enterprise that manufactures, sales and distributes melting, forming and casting machines for different materials. But along with this, it also manufactures top-quality, and long-lasting coin dies, or you can say coin stamping dies.

We can be your perfect solution provider for precious metal coin minting. With years of experience, we have established multiple coin manufacturing lines across the globe. As one of the most trusted coin die makers, SuperbMelt specializes in coin die engraving, having a strong reputation for solution expertise, quick delivery schedules, and details.

We can provide you fully-developed dies that are ready to be used for production. We also offer various die services. Don’t wait for a long to produce coins, use our dies a start your manufacturing work now.

It’s time to kick start your business’s delivery schedule with SuperbMelt coin dies solution. We offer faster delivery of products, and the reasons behind this are our master’s and trained engravers, expertise, and advanced equipment. Visit our site now to know about the coin die options that we offer.

2.2, Make Gold Coin Sample by Custom Coin Die

Started the journey in the year 2001, SuperbMelt has emerged as a leading and reputed solution provider in this industry. We have established a robust identity around the customers’ experience, as well as expectations. If you are looking for a reliable custom coin striking dies manufacturer, you can trust SuperbMelt for that. No matter your requirements related to custom coin dies, we will get the right solutions with us.

When you place your order, analyze and understand the demands and give our best to develop the products without affecting the core quality. After the development, we carry out stringent quality checks through our excellent and highly experienced inspectors to come over the whole range and ensure that the coin minting die is free from any defects. What’s more? We always ensure that the dies are dispatched to you within the given period to create maximum customer satisfaction.

With time, the technical details also have started to evolve. We also keep ourselves updated about the latest technologies used for producing coin dies, including hammered coin dies. Starting from computer-generated graphics to die, we always ensure that custom coin dies all to the given specifications. When you look at the finished products, you can know our quality workmanship.

This is something that we are famous for more. We understand that you need something different to make your coin unique and help you. We, at SuperbMelt, use machines that are approved by ISO CE SGS professional certification bodies. Join us and enjoy one-stop service for your coin die requirements. When you are with us, you will always get the best custom coin dies.

2.3, We Provide Technical Solutions for Gold Coin Minting

Ensure that the life-span of the coin die is good and that you will have to choose the right metal for the coin die. It may be noted that planchet composition and size can be a significant determinant here, but striking pressure can also create a massive difference. It has been seen that many coins die face catastrophic failure developed by improper annealing, extreme stress, and low steel quality.

You need to consider some significant factors: press type (hydraulic or mechanical), planchet hardness, die hardness, die alloy, die alignment, irregular strikes, and more. As per a well-known Benchmark Committee, Peter Huber, a coin die’s average lifespan can range from 67,5000 to 1,929,927 coins. Modern coin dies made of hardened steel can be used to produce many hundreds of thousands of coins.

SuperbMelt has an experienced and skilled R&D team inside, so we have a one-stop service to solve various coin die problems, including die customization, hammered coin dies, Masonic coin dies, etc., and what everyone cares about the most die service life and timely customer service issues.

Our die making technology and equipment are constantly optimized, moving towards the era of digital engraving, and we customize reasonable and scientific gold coin production plans for customers in the minting field. Under our step-by-step guidance, your gold coin production will be able to run without any pressure.

2.4, Our Delivery Time is Fast

One of the major reasons behind choosing us for your customer coin die requirements is our speedier delivery process. We understand your emergency and always try our best to ensure that you are getting your products on time. We use the latest coin die machines to create dies within the stipulated period.

Besides, we keep sufficient stock of materials, including different metals used for die making, so you start the making process as soon as you place your order. There is no need to worry about the delay in your die delivery when you are with us. You can expect your delivery within 7 to 15 working days based on your location.

2.5, You can Get Coin Die at The Right Price

Some people think that buying high-quality coin dies and punches is very costly. However, with SuperbMelt, you can always get quality products at the best price. You will find the price of our dies is comparatively low.

When you buy dies from SuperbMelt, you are guaranteed international standard quality at a price you can easily afford. This is something that makes a popular among small and medium-sized businesses. We are a government Audited Superb as AAA credit company, so you can always trust us for the best quality.

Are you planning to establish your coin minting line? Need professional advice and technical support for this? We will love to help you with this. SuperbMelt can be your ideal partner in this industry. Get in touch with us now.

Conclusion

Those in this field, i.e., coin minting lines, face challenges as they don’t have many ideas. Before starting your unit, you need to know everything about coin minting, starting from the coin stamping dies, pressing machines to the coin minting process.

This article will help you in getting a clear idea about this. If you still have some doubts, please feel free to contact us anytime you want. As a leading precious metal coin minting solution provider, we have established many coin minting lines worldwide.

SuperbMelt now and get a one-stop-solution for your coin minting line. You will offer you a comprehensive manufacturing package that will come included with coin mining equipment, a process to make custom coin striking dies, guidance about how to choose the best coin die making machine, on-site guidance, and professional engineers to enhance your process.

We always aim at solving your coin minting issues and have years of experience in offering easy-to-understand instruction about different precious metals. Choose us now as your technical support partner and keep your coin minting line running smoothly. Want to know how we can help you in building and managing a perfect coin minting line? Call us now. For more information, you can go through our FAQs section.

FAQ Guide

How do you make a coin die?

All the coins struck through the minting process are struck by a pair of durable dies. Speaking about a coin die, a steel rod has a face that will be the same size as the coins you want to produce. The steel rod will carry the design for just one side of the coin. So, to strike a coin, two such streel rods will be used. One steel rod will carry the obverse design, and another rod will have the reverse design.

Before making dies, the artistic representations are accurately digitized in 3D and then sent to an advanced CNC- Computer, Numeric Control milling machine, replicating the design on the steel rod's end. This is called the Master Hub. This is the first step of the die making process.

The master hub will be then put into a powerful hydraulic press to press it against another steel rod to create the second piece. This will carry the negative or reverse image of the coin design, and this is called the Master Die and the second step of this process.

Now, master dies are placed under hydraulic presses and then forced on more steel pieces to produce the Working Hubs. After getting Working Hubs, these are processed once again to make Working Dies. Generally, working dies are used to manufacture coins. One pair of dies can be utilized to create thousands of coins.

What does a coin die look like?

Speaking about a coin die's physical appearance, a steel rod has a face of the same size as the coins. One die will carry the coin's front design, and another die will have the reverse design.

What does minting coins mean?

In simple words, minting is the process of coin manufacturing. This process includes pressing pieces of metal with designs. These are the designs that you will show the coin's denomination. The image or design may also have some security features and about the country minting the coins. The process is generally carried out by mint, producer of coins, and handling the coins' distribution.

Can I mint my own coins?

Yes, you can. If you want to make your own coins, then you can always take the help of SuperbMelt. We can offer your all types of assistance for dies and coin manufacturing. We will provide different options to make your coins look distinctive and original. You can create your own custom coin striking dies and produce coins using our coin die making machine. So, go on and start your own coin minting line now.

How coins are made step by step?

Here are the steps following which you can create fine gold coins.

Use a powerful casting machine or use a gold ingot machine to create a sheet or bullion. After getting the sheet, you need to put that into a rolling machine. To obtain the desired thickness, roll the sheet multiple times. While doing this, make sure that the metal is soft.

Now, using a powerful tonnage hydraulic press, punch the sheet to get the coin shape. You can go for a round or square shape.

Put the blank coins into your annealing furnace and then re-annealed it. After that, you can put the coin into the acid to remove the dirt. Remove the blank coins from the acid and keep them in a tumbler. Then add soapy water and white glass particles to clean them.

Now, press the coins with a hydraulic coin pressing machines carrying the logo. That's it; now you have your own gold coins.

How do you draw a gold coin?

To draw a gold coin, you can use graphics software to create designs that you want to engrave on your gold coins.

What are coin dies made of?

Coin die is the most crucial part of the coin making process. This is the thing that will be pressed on the blank, and it carries the design of the coin. So, it needs to be very durable. For this, most of the coin manufacturers prefer to produce coin striking dies from hardened steel. Dies made of this material can produce thousands of coins before they are defaced.

How were ancient coin dies made?

There is still no accurate answer about how the ancient made a coin die to struck the coins. You will not find any written record about the process. To give you an idea about this, we have tried our best to reconstruct the process of ancient coin dies making from the pieces of evidence and surviving artifacts that we have.

As per the available pieces of evidence, old coin dies were made of hard iron or bronze. If you consider a bronze coin die, you will find them easy to engrave, and they don't rust. However, the only demerit of this die is it will lose its ability to sustain pressure faster. It is expected that iron dies were used for striking large silver coins, decadrachm, tetradrachms, and more they have traces of die rust. Besides, these ideas had also to be used for large bronze coins.

However, there is no accurate information about how the coin dies were sunk. Based on some archaeological evidence and ancient coins, it is expected that a coining team could manufacturer around 20,000 strikes before wearing out a set of dies.

If you look at the Ancient roman coins, you will see standardized portraits on all the coins. The interesting question here is how the portraits can be so uniform as the coin dies were engraved individually by different artisans. So, here we can consider two replication processes. These are; Hubbing and Casting die. It is a fact that to cast bronze dies for coins, the Greeks used lead or bronze die patterns. They used the lost wax process.

However, as they used the hand-held technique for die and coin making, it often led to off-center and weak strikes. Some ancient coins also have misaligned strikes. So, you will find all the ancient coins will be a little different from each other.

What is a die break on a coin?

Speaking about a die break, it is a form of failure when the coin die falls out or breaks off. Most of the mint workers or coin manufacturers called this a piece-out. A marginal die break happens when the coins are struck from a die that misses a piece adjacent to the rim. When not adequately connected to the rim, the tiny die breaks, called die chips.

The majority of die breaks happens at the margin of the die. There will be a sharp junction between the die face and die neck that is prone to failure. The die breaks that involve the rim and a little portion of the field is called the cuds.

As per the experts, the longer the coin striking dies are in use, the larger the die breaks occur. So, after a specific time, you should replace the dies with new pieces.

The coins' value having a die crack or break will depend on the fracture's severity and size.

How coin dies are made?

Coins dies are made through four critical processes as mentioned above, i.e., creating a master hub, making master die, preparing working hubs, and making working dies from working hubs.

What is a die mark on a coin?

Die marks are like tiny marks and letters that appear on the coins to know about the die used to create the coins.

How gold coins are made?

As discussed above, all the coins are made through the mint. The entire coin manufacturing process is called minting. Silver and gold coins are a small part of a range of different coins a professional mint produces. Nowadays, precious metal coins, for example, Canadian Maple, South African Krugerrand, and American Eagle, are produced as bullion coins that are generally used for investment. In some countries, gold coins are manufactured under license from mints and central banks. National banks and governments usually control such coins. Well, here are the processes of gold coin making.

The first step in gold coin making is to melt the required precious metals in a furnace using a high-quality crucible that you can buy from SuperbMelt. We will suggest you go for graphite crucible for this. Gold metal generally melts at 1064-degree Celsius, and silver melts at 961-degree Celsius. The excess heat then channeled to heat the water utilized in the process.

Coils around 40 to 50 meters long, weighing one tonne, are made from the melted metal. Once done, the coils are then rolled up, applying heavy pressure of around 200 to 300 tonnes. Then, they are cut down into blanks.

Now, it's time to create the design that you need to print on the gold coin. Many companies take the help of professional artists to craft a draft design before developing a plaster model. This is a process that can take around one year to get completed. The model is scanned through digital technology to create coin dies and punches. Powerful and computer-controlled engraving machines will then cut it with maximum accuracy to 0.001mm.

After the completion of coin blanks and dies, the striking process takes place. Under heavy pressure, the coin stamping dies are pressed into gold blanks. Once done, you will get finished gold coins.

The gold coin striking dies are replaced after a specific time when they become worn. So, to keep your gold coin making process running smoothly, make sure that you have a sufficient number of identical hubs to replace the dies.

After this, coins are minted, and before making them available to use, gold coins are meticulously inspected. If they pass the inspection round, they will be sent for circulation. So, this is the detailed process of gold coin making. When producing gold or other precious coins, purity and precision take topmost priority. For this, blanks are manually placed in the coin press and checked individually for quality.

How are The Reeded Edge of Gold Coins Made?

The production of a coin needs 3 parts to complete, the upper mold, the lower mold and the collar. The collar mainly plays a positioning role. When the coin is squeezed, the material will be fixed within the diameter range of the collar, making the coin regular and full.

Therefore, if you want the edge of the coin to have a reeded edge, you need to make milled edge on the inner collar, and the stamped coin needs to be about 0.2-0.4mm smaller than the diameter of the collar, and it will be expanded by extrusion to press the reeded on it edge.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited