Copper Granulator Machine

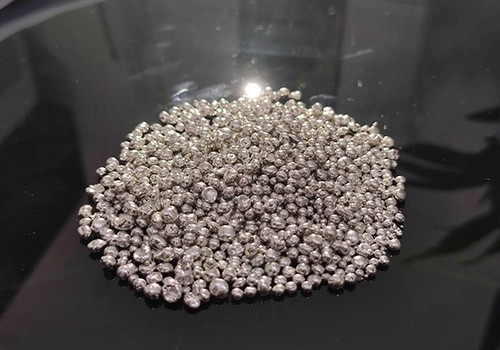

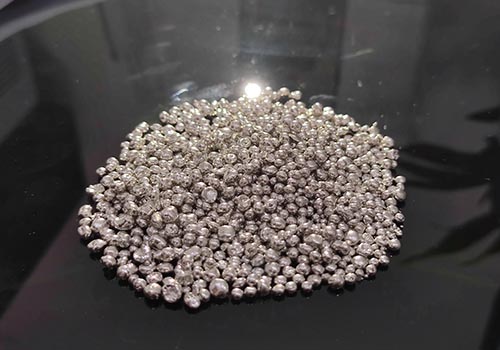

SuperbMelt Gold, Silver, Copper, Platinum, Palladium 2600°C Particle Manufacturing Machine

SuperbMelt Copper Pellet Machine is capable of casting metal pellets using either quartz or graphite crucibles. This feature enables the machine to cast metal pellets with a melting point of 2600°C, such as platinum and rhodium, using a quartz crucible. The machine can cast 30-200 kg of gold, silver, platinum and copper pellets in one operation, making it ideal for jewelry processing plants, the aerospace industry and the medical industry!

The Copper Pellet Machine uses a self-granulation method to form pellets, ensuring fast and continuous feeding. It can complete the casting of 30-200 kg of metal raw material pellets in one operation within 8 minutes.

If you would like to know more about the granulator, please contact us today for a customized solution!

| Model number | SPB- |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 25-160 kw/Adjustable |

| Applicable metal | Gold, Silver, Copper,Platinum, Palladium, and their alloys |

| Melting time | 8 minutes |

| Max capacity | 30-200kg |

| Max temperature | 2600℃ |

| Cooling method | Water cooling |

| Granulation method | Graining by self-weight |

| Crucible type | Common to quartz and graphite |

- Fast granulation speed with continuous feeding capability.

- Separate water tank for granulation forming, convenient for material retrieval.

- Utilizes an efficient and energy-saving heating system with water-electric separation, ensuring a lifespan of over 10 years.

- Easy operation with one-key start, suitable for operation by ordinary workers.

- Core components use international brands, such as Schneider switches and German Infineon IGBT, ensuring stable equipment operation.

- Metal Recycling: To treat and recycle metal scrap, recycling plants make considerable use of metal granulators. Larger metal objects can be effectively broken down into tiny grains by them, enabling further processing.

- Scrap Yards: To make handling and shipping of metal scraps easier, scrap yards frequently use metal granulators to decrease the size of the pieces. In order to prepare materials for recycling, this technique is essential.

- Foundries: Metal granulators are used in foundries to treat waste metal and produce granules that may be melted down and utilized in molding and casting procedures.

- industrial: When metal wastes or damaged metal products need to be broken down into smaller bits for recycling or reuse, metal granulators are used in a variety of industrial industries.

- Metal Fabrication: By dissolving surplus or unused metal resources into granules that may be recycled or used again, granulators in metal fabrication companies help control waste.

- automobile Industry: To help recycle precious metals, metal granulators are used in the automobile industry to treat metal scraps, end-of-life cars, and metal components.

- Electronics Recycling: Metal granulators are used in the recycling of electronic waste, or “e-waste,” which is the process of disassembling metal parts from old electronic equipment into granules that may be processed further.

- Building and Demolition: Metal granulators help in the recycling of metals from various sources by processing metal components from trash generated during construction and demolition.Energy Sector: Metal granulators are used in the energy sector to

- process metal components, guaranteeing effective management of metal waste produced during the manufacture and upkeep of equipment connected to energy.

- Environmental Remediation: Metal granulators can be used to process and decrease the size of metal-laden materials in circumstances where metal-contaminated locations need to be remedied.

Why SuperbMelt Copper Granulator Machine

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Any Question About SuperbMelt Copper Granulator Machine

FAQ Guide of Copper Granulator Machine

- 1. What is a copper granulator machine?

- 2. What is the purpose of a granulator machine?

- 3. How does a metal pellet casting machine work?

- 4. What is the difference between crusher and granulator?

- 5. What is a gold/silver/platinum granulator?

- 6. What types of materials can be processed by a gold/silver/platinum granulator?

- 7. How does a gold/silver/platinum granulator work?

- 8. What are the advantages of using a gold/silver/platinum granulator?

- 9. Can a granulator handle various forms of gold, silver, and platinum, such as jewelry, electronic components, or industrial scrap?

- 10. What sizes of granules can be produced by these machines?

- 11. Are gold/silver/platinum granulators suitable for small-scale operations?

- 12. Do these machines require special maintenance for processing precious metals?

- 13. Are safety features incorporated into gold/silver/platinum granulators to prevent accidents during operation?

- 14. Can these machines handle other non-precious metals or materials?

- 15. Is it possible to customize a gold/silver/platinum granulator to suit specific processing needs?

- 16. What is the lifespan of a typical gold/silver/platinum granulator, and is there a warranty offered?

1. What is a copper granulator machine?

A Copper Granulator Machine is an industrial device designed for recycling copper-containing scrap materials, particularly copper wires and cables. Its primary function is to process copper scrap into smaller granules, separating the metal from insulation and other impurities. This process facilitates the efficient recycling of copper, which can then be reused in the production of new materials.

2. What is the purpose of a granulator machine?

The purpose of a granulator machine is to reduce the size of various materials into smaller particles or granules. Granulation is a process commonly used in recycling, manufacturing, and other industries to transform large or bulky materials into more manageable forms. The specific purposes of a granulator machine include:

- Size Reduction: Granulator machines are employed to break down larger materials into smaller particles. This is particularly important in recycling, where materials like plastics, metals, and rubber are often processed into granules for reuse.

- Material Recycling: Granulators play a crucial role in recycling operations. For example, plastic granulators shred plastic waste into small granules, making it easier to melt and mold into new products.

- Resource Recovery: Granulators help recover valuable materials from waste streams. In the case of metal granulators, they can extract metal particles from electronic waste or scrap materials.

3. How does a metal pellet casting machine work?

A metal pellet casting machine works by melting metal and then shaping it into small, typically spherical, pellets. The process involves several steps:

Melting: The first step is to melt the metal. This is often done using induction heating or resistance heating. The metal is heated to its melting point, turning it into a liquid form.

Casting: Once the metal is molten, it is poured or injected into a mold. The mold is designed to shape the molten metal into small pellets. The pellets can have various shapes, but they are often spherical.

Cooling: After casting, the molten metal in the mold is allowed to cool and solidify. This solidification process helps the metal take on the shape of the mold and form into pellets.

Ejection: Once the metal has solidified, the pellets are ejected from the mold. This can be done mechanically, using ejector pins or other mechanisms, or the pellets may simply fall out of the mold.

Collection: The ejected pellets are collected for further processing or use. They may undergo additional treatments, such as cooling, cleaning, or sizing, depending on the specific requirements of the application.

Repetition: The process is often repeated in a continuous or batch mode to produce a large quantity of metal pellets.

The choice of metal, the design of the mold, and the specific parameters of the casting process can all influence the characteristics of the resulting pellets. Metal pellet casting machines are used in various industries for manufacturing small metal components, alloys, or materials in pellet form for further processing or use in different applications.

4. What is the difference between crusher and granulator?

Granulators and crushers are two types of size reduction machinery used in many sectors, although they have distinct uses and work on different theories. The following are the main distinctions between a granulator and a crusher:

- Goal and Method of Action:

The purpose of a crusher is to break up big rocks, minerals, or other heavy materials into smaller fragments. Using mechanical force to split the material into smaller pieces is how crushers work.

Granulator: A granulator is a device that is intended especially to reduce materials into tiny grains. Granulators produce particles with precise shapes by using cutting or shearing movements to create a more consistent and controlled size reduction.

- Size and Shape of the Output:

Crusher: Particles of various sizes can be produced by crushers, and the final product may have a combination of fine and coarse particles. The crushed material might have different sizes and shapes.

Granulator: Granulators generate granules or particles that are comparatively well-defined and uniform. When compared to crushers, the output’s size and form are usually better regulated.

- Uses

Crusher: Often used to reduce huge rocks or minerals into workable sizes in the mining, quarrying, and building sectors. In recycling, crushers are also used to break up different materials like asphalt and concrete.

Granulator: Often utilized in the recycling, pharmaceutical, and plastics sectors. Granulators are used to break down materials into smaller pieces so they may be handled and transported more easily or processed further.

- Mechanism of Cutting:

Crusher: Works by attrition, impact, or compression. Gyratory crushers, impact crushers, and jaw crushers are a few examples.

Granulator: This device reduces the size of the material by cutting or shearing it. Knife and rotary granulators are two common kinds.

- Content Feed:

Crusher: This device typically takes bigger feed sizes and reduces them into tiny bits.

Granulator: This device accepts smaller feed sizes to make granules and is frequently used for finer materials and processes.

In conclusion, while both granulators and crushers are used in size reduction processes, granulators are made for more precise size reduction, resulting in uniform granules with particular properties, whereas crushers concentrate on reducing larger materials into smaller pieces with less control over the size and shape.

5. What is a gold/silver/platinum granulator?

A granulator is a machine designed to break down scrap or raw materials into small, uniform-sized granules. In the context of precious metals, these granulators are specifically tailored for processing gold, silver, or platinum materials.

6. What types of materials can be processed by a gold/silver/platinum granulator?

Gold, silver, and platinum granulators are primarily designed for processing precious metal scrap, electronic waste containing these metals, or raw materials in granular form.

7. How does a gold/silver/platinum granulator work?

These granulators typically use cutting or shearing mechanisms to reduce the size of materials. They may include additional processes such as shredding, grinding, or refining to achieve the desired granule size.

8. What are the advantages of using a gold/silver/platinum granulator?

Granulators offer efficient and cost-effective means of processing precious metals, allowing for recycling and reclamation of valuable materials. They help in reducing waste and environmental impact.

9. Can a granulator handle various forms of gold, silver, and platinum, such as jewelry, electronic components, or industrial scrap?

Yes, modern granulators are versatile and can handle a variety of forms, including jewelry, electronic components, industrial scraps, and other forms of precious metal materials.

10. What sizes of granules can be produced by these machines?

The granule size produced by these machines can vary based on the specific model and settings. Typically, they can produce granules ranging from fine powders to larger, uniform sizes.

11. Are gold/silver/platinum granulators suitable for small-scale operations?

Yes, there are granulator models designed for small-scale operations, making them suitable for jewelers, small refining facilities, or businesses with lower processing volumes.

12. Do these machines require special maintenance for processing precious metals?

Maintenance requirements depend on the specific granulator model, but generally, regular cleaning, lubrication, and inspection are recommended to ensure optimal performance when processing precious metals.

13. Are safety features incorporated into gold/silver/platinum granulators to prevent accidents during operation?

Yes, reputable granulator manufacturers prioritize safety features such as emergency stops, safety guards, and proper labeling to minimize the risk of accidents during operation.

14. Can these machines handle other non-precious metals or materials?

Some granulators may be designed to handle a range of materials, including non-precious metals. It’s essential to check the specifications of the specific model to determine its capabilities.

15. Is it possible to customize a gold/silver/platinum granulator to suit specific processing needs?

Many manufacturers offer customization options to tailor granulators to specific processing requirements, ensuring optimal performance for different applications.

16. What is the lifespan of a typical gold/silver/platinum granulator, and is there a warranty offered?

The lifespan varies based on usage and maintenance, but reputable manufacturers often provide warranties for their machines. It’s advisable to inquire about warranty terms and conditions when purchasing a granulator.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited