Crucible for Melting Gold

As a top crucible supplier, Superbmelt provides various crucibles for gold smelting

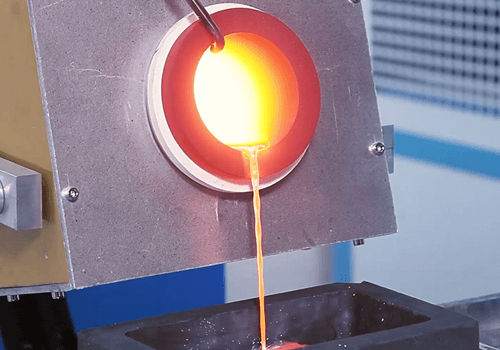

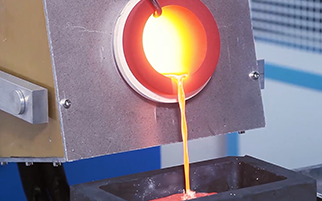

Crucibles for melting gold are usually made from superior garde graphite material and can be widely used in different kinds of furnaces . The gold melting crucible can be used to melt gold as well as silver and other metals such as aluminium, copper, brass, iron, zinc, lead, etc. Crucible for melting gold can be loaded with gold ingots and melting is done between 5 to 10 minutes. A crucible for melting gold can be properly maintained and can last a very long time without any form of crack.

The graphite crucible used for melting gold comes in different sizes from 1kg and more.

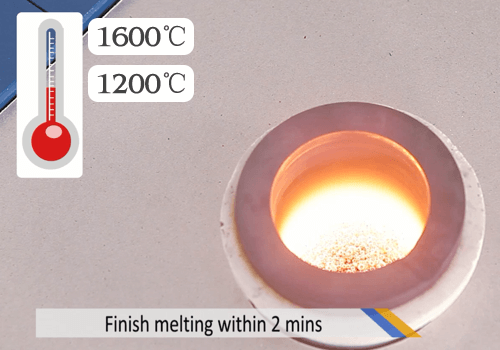

Crucible for melting gold has a thermal shock resistance, a high thermal stability and a high mechanical strength. The gold melting graphite crucible has a good oxidation resistance capability. The crucible for melting gold is also able to withstand a temperature reaching 2000 degree celsius. The melting temperature can be reached with a short length of time, hence, melting time is reduced to save energy.

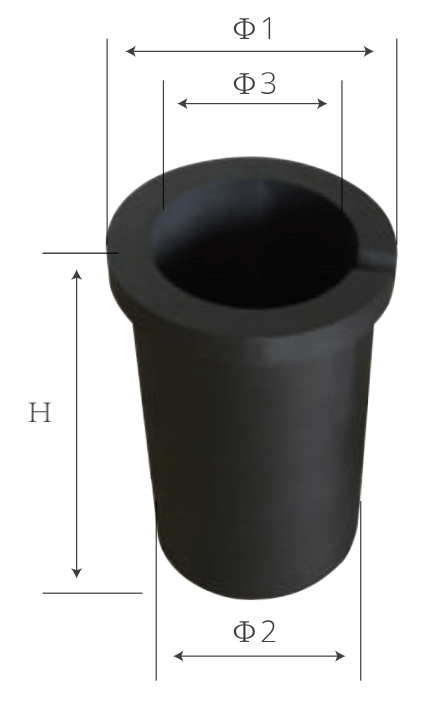

| Name | Φ1 (cm) | Φ2 (cm) | Φ3 (cm) | H (cm) | Weight (g) |  |

| 1KG Graphite Crucible | 58 | 46.5 | 35 | 88 | 170 | |

| 2KG Graphite Crucible | 68 | 57 | 43 | 108 | 280 | |

| 2.5KG Graphite Crucible | 68 | 58 | 43.5 | 120 | 310 | |

| 3KG Graphite Crucible | 72 | 66 | 51 | 110 | 390 | |

| 4KG Graphite Crucible | 85 | 77 | 60 | 130 | 380 | |

| 5KG Graphite Crucible | 100 | 88 | 69 | 132 | 680 | |

| 5.5KG Graphite Crucible | 104 | 92 | 69 | 155 | 860 | |

| 6KG Graphite Crucible | 112 | 100 | 79 | 178 | 1050 | |

| 8KG Graphite Crucible | 125 | 112 | 90 | 160 | 1000 | |

| 12KG Graphite Crucible | 150 | 134 | 100 | 210 | 1600 | |

| 16KG Graphite Crucible | 160 | 138 | 110 | 220 | 2000 | |

| 25KG Graphite Crucible | 165 | 165 | 135 | 220 | 1600 | |

| 30KG Graphite Crucible | 215 | 215 | 175 | 250 | 4700 |

- The crucible for melting gold in its process of high temperature use, the coefficient of thermal expansion is small and it has a certain strain resistance to quench and heat.

- The corrosion resistance of acid and alkaline solution is strong, it also has a high chemical stability and there is no chemical reaction during the melting process.

- The inner wall of the crucible for melting gold is smooth which makes all metals to have a smooth finishing after casting and adhere to the inner wall of the crucible, so that molten liquid has a good fluidity and is suitable for casting into various molds.

- Crucible for melting gold can also be used in smelting alloy tool steel and smelting nonferrous metals and alloys because of its superior properties.

- The high density of the crucible for melting gold has the best thermal conductivity and its thermal conductivity makes it superior to other imported crucibles.

- The crucible for melting gold has a special glaze layer and compact molding material that greatly improves the corrosion resistance and prolongs the lifespan of the crucible.

- All the graphite components in a crucible for melting gold are made of natural graphite which makes the thermal conductivity very good. Crucible users should bear in mind that graphite crucibles should not be placed on the cold metal table immediately after melting so as to prevent rupture due to rapid cooling.

- Other types of metals can go through the process of melting in a crucible for melting gold. Such metals are silver, copper, aluminium, lead, zinc, brass, and other nonferrous metals.

- The graphite crucible for melting gold can adapt to inert atmosphere furnaces, therefore making it suitable for high quality melting.

- Superbmelt crucibles for melting gold for sale come in various sizes that can meet all ranges of melting, from 1kg to 5kg and above. The various sizes can be used for different categories of users, from small jewelry melting business to a large industrial melting use.

- Gold melted in a Superbmelt crucible for melting gold is usually of high quality simply because the graphite crucible does not release any form of impurities despite its frequent use of melting.

Why SuperbMelt Graphite Crucible

High Quality

Any Question About SuperbMelt Graphite Crucible

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

How to Choose Crucible for Gold Melting: Graphite Crucible Buying Guide

What Material Can be Used in the Crucible for Gold Smelting

1.1, Development History of Gold Melting Crucible Material

From clay to brass and steel to graphite, the ferrous and non-ferrous metal smelting industry has enjoyed unique growth phases. To bring it home, let’s look at the two primary materials used in creating crucibles and how they have fared/faring with the continuous advancement in technology.

1.1.1, Graphite Crucible

The use of graphite in the creation of gold crucibles started in early 1900. Steel’s susceptibility to corrosion was becoming a significant problem. An alloy with a less corrosive nature was needed. A glance at the options available undoubtedly earned graphite the top spot.

Graphite melting crucibles comes first in our list not just because it’s the most used, but because its dimensional stability is comparable to no other. Graphite is an alloy suitable for designing and creating stove polish, pencils, lubricants, paints, crucibles, foundry facings, etc.

Graphite naturally exists in a less corrosive nature in comparison with other alloys. The melting crucible provides a smooth finish. It’s cost-effective and easy to maintain. Note that graphite is not as strong as steel. Graphite melting crucible’s ductility and wear resistance are subject to the heat applied. If you want your gold melting graphite crucible to last long, you must regulate the temperature you expose it to daily.

When using gold graphite crucibles, you don’t need to worry about efficiency/durability during the pouring or solidification phase—its stability helps guarantee continual smelting. You can keep the gold smelting furnace running all day long rest assured a smooth surface finish is guaranteed.

Note that while graphite crucibles are regarded as the most viable gold melting crucibles available, its can only withstand pressure lower than 1600 degree Celsius. Exposing a graphite crucible to temperature beyond 1600 degree Celsius can decompose the graphite to metal pollution.

1.1.2, Quartz Crucible

Quartz crucibles are end products of silicon and oxygen. Quartz is amongst the most prevalent mineral that can be found on the earth’s crust. The mineral is known for its presence in Russia, South Africa, Mexico, United States, etc. Unlike all other gold crucible making materials, quart has enjoyed a reputable presence in religion, tradition, and technology.

Quartz is a fine material for making crucibles. It ranks seven on Moh’s hardness scale. Fine-tuning quartz to suit your mining and bench jewelling needs would leave you with a glass-like crucible. These transparent crucibles are resistant to HF acid, possess excellent insulating behavior, and are environmentally friendly.

Using quartz gold melting crucibles to cater to your melting and smelting needs offers you a smooth and efficient finish. Unlike graphite crucibles, quartz crucibles are viable options for smelting metals beyond 1600 degrees Celsius.

Many jewellers and miners regard graphite crucibles as a more profound option due to its remarkable dimensional stability, low corrosion susceptibility and cost-effective nature—though foundry owners and metal melting companies hardly share the same viewpoint. Quartz is a more durable option for mass melting because it can melt beyond the 1600-degree Celsius benchmark graphite crucibles are known for.

Note that the price of quartz crucibles are higher than that of graphite.

1.2, Why Choose Graphite Crucible for Gold Melting

Guarantee Quality of Product

Everyone wants the best. Even with the lowest of budgets, we somehow manage to source out the best for everything we buy.

You want a crucible that can withstand the heat attached to smelting silver and still provide a smooth surface finish. You want a smelting crucible that can serve the diverse needs of your business. You want a crucible you can bank on to do the job.

Among the many crucibles smelting materials available, graphite is the most exceptional in quality in its finish product. It brings unpredictable ease of experience to the gold smelting process and still provides a finish your customers would love you for.

Suitable for All Metal Smelting Requirements

No miner or bench jeweler would fancy purchasing a new crucible for every smelting task. Operating with a crucible flexible enough to tackle dynamic smelting needs is the ideal in every ferrous and non-ferrous metal melting industry.

Crucible making materials such as copper, platinum, quartz, or porcelain are great choices but are quite picky. Their inability to operate with the same dimensional accuracy as graphite leaves them at a questionable spot.

Environmentally Friendly

How we treat the environment determines how our children would live in it. Building our smelting and melting operations around not eco-friendly materials unavoidably means more health problems and higher mortality rates.

Using gold melting graphite crucibles, you enjoy an eco-friendly smelting process optimized to give you the best possible finish.

Graphite Crucibles Help Save Cost

Cost is the defining factor in most business ventures. The price determines the class of people that patronizes a product and, sometimes, the product’s durability. Gold melting graphite crucibles are inexpensive. Its ability to self-lubricate earned it an edge amongst most other crucible making materials—it also helps you save cost on lubricants.

While companies might have to operate with a sizable budget if they want to rely on graphite crucibles for their daily operations, bench jewelers can enjoy the smooth and efficient smelting process graphite crucibles provide at a minimal cost.

Long-Lasting

Yeah, crucibles are inexpensive, but that doesn’t mean anyone would want to buy a pair every week. If you are into the gold smelting business and want something that can hold during dynamic or complex smelting operations, provide top-notch finish and last for a good deal of time—gold melting graphite crucibles should be a prioritized option.

1.3, The Role of Crucible in the Process of Gold Melting

Since we are clear in why graphite crucible is the best crucible for melting gold, its high time we talked about its role in the gold melting process and how it is used.

Graphite crucibles hold gold nuggets, jewelry, or any ferrous or non-ferrous metals in their molten state during the melting or smelting process. While graphite’s high tolerance for heat makes it’s a durable and highly efficient gold melting crucible, its reliability isn’t most times dependent on such renowned capabilities.

Certain factors determine the role graphite crucibles play in a gold melting operation.

1.3.1, The Temperature Change Rate the Crucible will Experience

If we are on the same page that graphite crucibles are the best for melting gold, then its high time we considered how temperature change affects your crucible in the gold smelting process.

How many kilos of gold are you planning to melt, and what sort of smelting furnace are you making use of? How long do you think your smelting operation would take? With an accurate answer, you can decipher the probable effect a smelting operation would have on your crucible and how to maneuver your way around.

The kilos of gold you want to melt determines the size of the graphite crucible you would need while the melting furnace helps point you to a specific category. The time the smelting operation would take gives you an edge as to how to regulate graphite melting crucible’s temperature during smelting operations.

1.3.2, How the Crucible is Charged

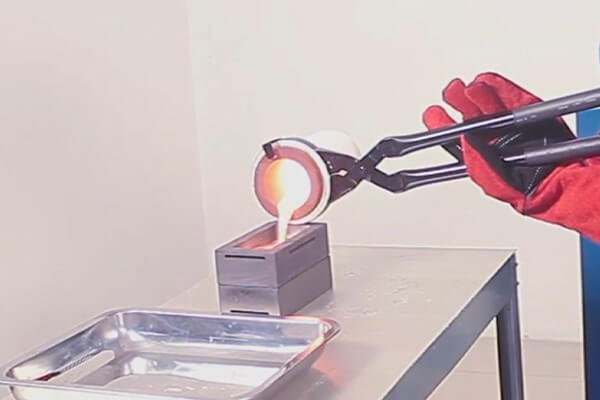

You can charge your gold melting crucible in different ways. Most bench jewelers use propane touch while foundries and metal casting industries rely on smelting furnace. Crucibles only remain essential in a gold smelting process for its ability to withstand high temperatures.

Graphite crucibles help eliminate surface finish issues. If you are not using a gold melting graphite crucible, you might run into problems during your gold smelting or melting process.

1.3.3, The Fluxes of Additions Used

The presence of impurities in metals dates as far as man’s first encounter with the raw materials. When smelting gold, some fluxes must be added to the metal before being placed in a furnace or added to the molten magma during the melting process.

Gold melting crucibles doesn’t just hold metals in their molten state; it also helps separate impurities. A crucible can help you differentiate between impurities and metals in smelting operations where a mixture of sodium carbonate and borax or other fluxes are used. Gold melting crucibles leave room for impurities to settle at the top of the molten magma while giving way for the actual metal to go under.

How to Choose a Graphite Crucible for Gold Melting

Graphite crucibles come in different shapes and sizes. With hundreds of companies offering different types of crucibles for sale, its best you know the kind of crucible that suits your gold melting needs before exploring the market for available options.

To help you better understand the processes involved in choosing a gold melting crucible, let’s look at the three primary factors that can influence your crucible choosing process.

2.1, The Type of Gold Melting Furnace

Like we stated earlier, the only reason graphite crucibles remain essential in the gold melting process is because it can withstand high temperatures and still provide a smooth and exceptional finish. A crucible that flutters under high temperature hinders efficiency in a gold smelting.

Wait a minute! Does that mean I can settle for any graphite gold melting crucible rest assured I would obtain the desired finish? Nope… you now know why graphite crucibles are regarded as the top choice, but that’s not all there is.

The type of gold melting furnace you are using determines the kind of crucible you would need. If you are using a hydraulic tilting melting furnace, you would need a graphite crucible while if you are using a hydraulic tilting melting furnace, you would require a quartz crucible.

Gold melting furnaces vary based on size and durability; the same applies to crucibles. So, first things first, check out the type of furnace you are making use of—if none is available, it’s best you explore our collection.

Crucibles for Different Furnaces

- Propane Touch

Propane touch serves as a renowned gold melting furnace for bench jewellers and hobbyist. The melting process Is not as environmentally friendly as that of an induction furnace but its durability is widely appreciated. When using propane touch to cater to your gold melting needs, its best you make use of graphite crucibles.

Propane touch are suitable for melting metals in small quantity, and the most cost-effective crucible making material you would find in the market for such operation is graphite.

- Resistance Furnace

While the usage of resistance furnace in foundries and laboratories has greatly diminished, a lot of jewellery casting companies still rely on its reliability when catering to their day to day melting task. Resistance furnace can be regulated to suit dynamic melting task.

If you are looking to melt metals in small quantity via a resistance furnace, its best you use gold melting graphite crucibles—otherwise, quartz crucibles are more durable options.

- Induction Furnace

Induction furnace demystified most of the myths attached to metal smelting. It made the gold melting process simple, cost efficient and time saving. And unlike most other gold melting furnaces available, it comes in different range and size.

Graphite gold melting crucibles are durable options for melting metals in a mini desktop melting furnace or manual tilting melting furnace—It helps save cost and provides a subtle finish. When using a hydraulic tilting melting furnace or vacuum induction melting furnace to melt large quantity of gold, its best you opt for a quartz crucible—it can withstand the high temperature required.

2.2, The Capacity and Dimension of the Furnace

Every foundry crucible supplier might provide you with crucibles of different ranges and sizes, but not all can provide customized gold melting graphite crucibles for multiple furnace types. To be on the safe side, make sure you are banking with a graphite crucible supplier providing customized graphite crucibles.

With a customized crucible supplier handy, it’s time to determine the graphite crucible capacity and dimension needed. The furnace’s material, capacity, and dimension tell the type of gold melting crucible you should make use of. When smelting large quantities of silver, its best you use silicon carbide graphite crucible, because the price is lower than pure graphite crucible.

Using a graphite crucible to smelt platinum in a motor tilting melting furnace is impossible because the temperature required would most time go above 1600 degrees—you have to rely on quartz. Note that the price of quartz crucible is relatively high, and it is generally used for small batches of platinum and palladium smelting.

To ease the stress attributed to understanding how to choose a gold melting crucible, place a call through to our support representative. With minimal info on the type of gold melting furnace you are making use of, our support representative would offer a wide selection of gold melting crucibles designed to meet your smelting needs.

2.3, The Melting and/or Holding Temperature You Maintain

If you have successfully navigated your way around the type of gold melting furnace you are using and the furnace’s capacity and dimension, it’s time to consider the melting and holding temperature you operate with on a regular.

Are you running a foundry or a bench jeweler who sometimes uses propane touch to meet dynamic melting needs? It’s time to consider how you operate. Crucibles serve as a melting and holding equipment. You can use it to smelt gold and still use it to hold the molten magma until an ingot is formed.

To fast track the process of choosing an efficient gold melting crucible for all your smelting needs, consider the following questions;

- How many kilos of gold do I melt a day?

- How many hours do I spend melting gold?

- Will my melting tasks require a temperature above 1600 degree Celsius?

- Do I want a gold melting crucible that maintains the same temperature, or would like to explore crucibles that can withstand more intense pressure?

- What sort of metal do I want to melt and which crucible melting material is regarded as a viable option?

With probable answers to the above-listed questions, you can determine the crucible design your foundry requires.

How SuperbMelt produces High-Quality Crucibles

Since we are arguably on the same page that graphite crucibles should be a prioritized pick, let’s look at some of the reasons our gold melting crucibles acquired a renowned reputation in the global market.

We provide machines and equipment optimized to suit the dynamic needs of jewelers, miners, foundry owners, and companies dealing in the smelting and melting of ferrous and non-ferrous metals.

Gold melting graphite crucibles are amongst our most prioritized merchandise. Ranging from customized crucibles used in smelting furnaces to crucibles for melting brass, gold, and silver, we provide it all. Let’s look at the primary factors that help us keep up with the dynamic customer expectation and needs our gold melting crucibles are designed to offer.

3.1, Control Raw Materials

The type of raw material used during production determines the efficiency you will get from the finished product.

What sort of graphite crucible making recipe is your preferred crucible supplier making use of? If you have no idea, its best you pick up the phone and start asking questions. Inside info on the type of raw material that goes into creating your gold melting crucible is paramount. This info doesn’t just help you avoid corrosion issues but also helps authenticate the type of surface finish to expect.

At SuperbMelt, our gold melting graphite crucibles are made from superior grade graphite material known for the 5 to 10-minute melting time it possesses—depending on the type of smelting furnace you are using. Our graphite crucibles can withstand furnace pressure of up to 1600 degrees Celsius for long hours.

Our gold melting crucibles are optimized to serve large and small businesses. Our graphite crucible reaches its maximum melting temperature within a short time frame: that’s, you can melt a ton of gold at maximum temperature without having to worry about corrosion or breakage.

3.2, Possess Levels that can Meet Different Standards

With different grades of graphite providing different qualities to the crucibles, the type of graphite your preferred gold melting crucible supplier operates with matters.

The smelting needs of foundry owners differ from that of a bench jeweller. A bench jeweller can make use of a graphite crucible made of low grade graphite and not attract as much loss as a metal casting company making use of the same. To be on a safe edge, its best you operate with a graphite crucible supplier providing crucibles made of high grade graphite that can meet dynamic melting needs.

SuperbMelt doesn’t just proffer solutions of superior quality but also ensures that every solution offered is in line with consumers’ needs.

Our gold melting graphite crucibles are designed with high grade graphite to suit dynamic melting needs. All our gold melting crucibles possess a strong resistance to alkaline and acid solutions with a small coefficient expansion. In simple terms, encountering burn-out issues or high exposure to heat when using our graphite crucible is impossible.

Many laboratories and jewelry mining companies dread using gold melting graphite crucibles for long hours, scared it might start adding impurities to well-refined metals—yeah, graphite crucibles not well-designed do at some point start adding impurities to gold and other metals during a melting process.

SuperbMelt possesses a collection of gold melting graphite crucibles designed to meet different standards. While we provide crucibles of varying range and size, all our crucibles are optimized to provide the highest quality solutions to various industries. Our design process revolves around creating the best quality regardless of size, budget, or industry.

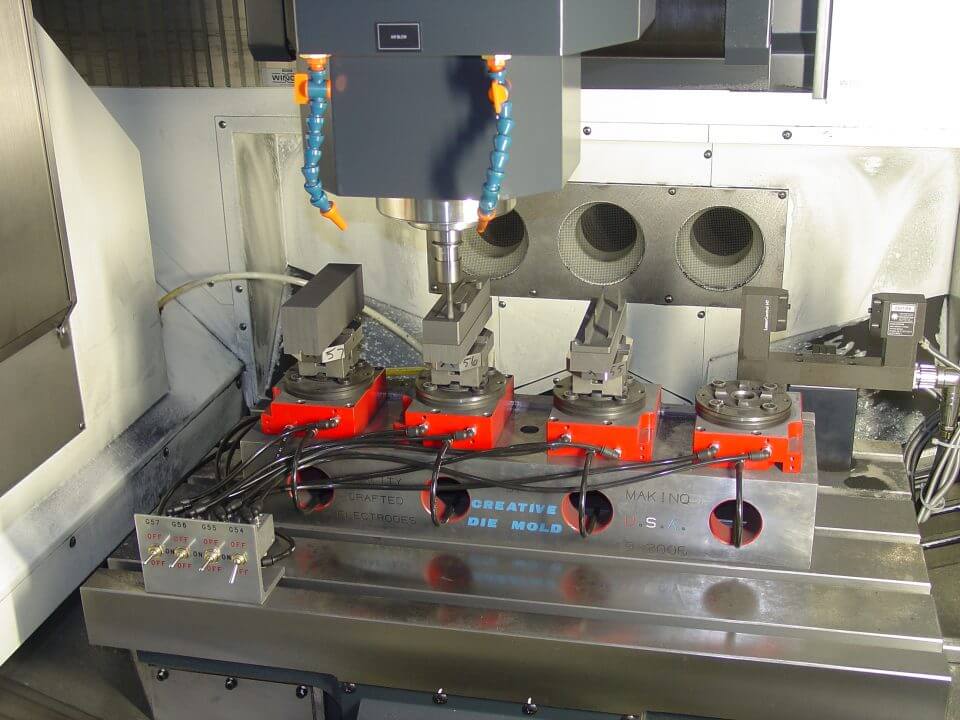

3.3, Precision CNC Machining

A subtle, smooth, and efficient finish is the ideal expectation in every metal smelting business. Opting for gold melting crucibles that doesn’t provide a smooth finish hinders opportunities in the global market. We made graphite our preferred crucible making material because they possess the ability to provide a smooth finish regardless of the temperature you expose them to.

Gold melting graphite crucibles exist naturally with the ability to eliminate rough edges when serving as a melting or smelting material. Though, the raw materials—graphite grade and quality—that go into the creative process and the type of material used to create the gold melting crucible can hinder efficiency.

While we use only high-grade graphite, we also rely on the efficiency of CNC machining to obtain a credible finish. The inner wall of our crucibles is machined till the smoothest surface finish possible is obtained. Note that without a smooth inner wall, the molten magma acquired after casting might not bring the fluidity required for a fine cast.

SuperbMelt relies on precision machining to provide the desired output to consumers. Using 3d CAD designs in line with your melting needs and furnace type, we machine high-grade natural graphite into a suitable shape.

3.4, Testing

Amongst all the steps involved in the crucible making process, the testing phase is the most important. Many gold melting crucible suppliers underestimate the rare opportunities the testing phase opens up due to the stressful process.

But without testing, it’s impossible to ascertain the credibility of a newly designed crucible. No crucibles for melting gold come out of SuperbMelt’s factory without being tested for efficiency, durability, and sustainability.

Some of the test we carryout include:

- Quality Test: all the crucibles contained in SuperbMelt’s store are made of high quality graphite. Though that does not in any way disrupt our quality test phase. All our crucibles are tested for impurities and graphite grade quality before being shipped out for sales.

- Durability Test; how long can our crucible last? What’s the estimated wait time attached to our gold melting crucibles? What’s the maximum melting point? We don’t wait for customer feedback to obtain this information. We carry our durability test as soon as our gold melting crucibles machining process is complete.

- Temperature Test: to ensure that our graphite crucibles can withstand the heating and cooling temperature its optimised to offer, we carry out pressure test before putting it out for sale.

What are the Advantages of Using SuperbMelt Crucibles

We have talked about the dominance of graphite crucibles in the industry, the development history of silver melting crucible materials, the processes involved in choosing a gold melting crucible, and our crucible creation process.

If you have read along thus far, you might be able to decipher one or two attributes as to why SuperbMelt crucibles are highly appreciated in numerous industries. If you have, that’s nice; we hope you are already exploring our collection. If you haven’t, don’t worry, we didn’t leave the advantages we offer to chance. Here are a few benefits you enjoy when banking with SuperbMelt.

- We are the factory

SuperbMelt is not a third-party influencer or consultant leading you to the wholesalers or retailers; we are the manufacturers. We design, structure, and machine gold melting crucibles into shape.

When we say we provide high quality, we are not saying it compared to other foundry crucible suppliers; we say it with reference to industry standard. SuperbMelt possesses a sales network that connects refiners, laboratories, foundries, and metal smelting companies across 30 different countries.

Our client base leaves little to no room for us to provide machines or equipment of low quality. In simple terms, SuperbMelt is amongst the few gold melting crucible suppliers regulating industrial trends. We are not just the factory catering to today’s dynamic crucible needs; we are also the factory behind the designs and innovations of the future.

- We Can Produce Graphite Products with Different Densities

SuperbMelt deals on only graphite crucibles. This is not because you can’t obtain a smooth surface finish from steel, porcelain, or quartz if the right lubricant is added, but because gold melting graphite crucible’s reliability is not just in the surface finish but also in its ability to retain the same cast quality when machined in varied densities.

We provide graphite melting crucibles for the induction furnace. These crucibles possess densities suitable for casting metals and other alloys. Our furnace crucibles are highly resistant to corrosion, require minimal energy, and are pollution-free. When using our induction furnace melting crucibles, you can rest assured you will obtain a molten magma free of impurities.

Our crucible for melting gold comes in different sizes. Its high density for thermal conductivity makes it a superior pick amongst other imported crucibles. SuperbMelt gold melting crucible is made of natural graphite and can be used for melting non-ferrous metals such as silver, aluminum, copper, zinc, etc.

The density of our crucible for smelting silver is the same as that of gold. The graphite crucible can withstand a temperature as high as 2000 degrees Celsius. Our silver melting crucibles are shock resistant, acid and alkaline resistant and can last for very long even with frequent usage. Our silver melting crucible can be used to melt ferrous and non-ferrous metals.

- Graphite Crucibles are Shipped Extremely Fast

Have you ever had to wait for weeks to get a product you have already paid for shipped to you? It’s frustrating, right?

Nobody likes banking with a company known for time-wasting. We are living in a fast-paced world, so regarding fast pace delivery as an ideal option when settling for a gold melting crucible supplier should be regarded as the norm.

We have been able to successfully streamline an extremely fast delivery process due to the large number of gold melting crucibles our factory manufactures daily. Superb Melt produces over 10,000 graphite crucibles every day.

Apart from our high output, fast delivery puts a priceless smile on customers’ faces. And since we work tirelessly to provide reliable solutions to see our consumers put on such a smile, you can purchase a gold melting graphite crucible from our store rest assured your goods would be shipped to you within the shortest possible time.

- ISO CE SGS Approved

Government certification is an essential aspect of our day to day business operations. We operate in over 30 different countries; without the right certificate, we won’t be able to proffer sustainable solutions to bench jewelers looking to explore our gold melting crucibles.

SuperbMelt is an ISO CE SGS approved company. This certification authenticates the fact that our graphite crucibles are of high quality. We also operate as an AAA credit audited enterprise.

- Strong Service Team With 24 Hours Support

Our communication models determine how often we relate with our customers. SuperbMelt is not a company that fancies leaving customers’ contributions and desires out of the manufacturing process.

To streamline efficient communication between our customers and us, we operate with a 24 hours service team. This team caters to the day to day sales, marketing, and communication endeavors between SuperbMelt and its customers.

With our round the clock team, you can authenticate orders, checkout buying specifications, track product, request refund, explore our gold melting graphite crucible collection, obtain customized solutions and learn more about our warranty policies anytime, anywhere.

Conclusion

Gold melting crucibles have become an essential part of our day to day lives. Almost every industry relies on the stress-free melting process it brings to metal casting.

If read along thus far, we are quite certain you already familiar with all the dos and don’ts behind the usage and buying process of graphite crucibles. There are hundreds of suppliers dealing in the importation and exportation of graphite crucibles for melting gold.

With each supplier bringing a unique flair to the industry, consumers are faced with a wide range of gold melting crucibles to choose from. If you wondered why we prioritized graphite crucibles for gold melting in this buying guide, it’s simple; SuperbMelt exists to serve individuals in the jewelry and metal casting industry.

Our gold melting graphite crucibles are optimized to radiate simplicity while taking out the tedious and tiring metal smelting aspect. Whether you are looking for a graphite crucible for a one-time smelting operation, gold melting crucibles for foundries or laboratories, or customized crucibles for a mini or heavy-duty smelting furnace—SuperbMelt got you covered.

Place a call today; we possess a support team ever ready to tend to your every need on around the cloud basis, 365 days a year.

FAQ

What needs to be checked before using a crucible?

Before using a gold melting crucible, you must check if the crucible is moist. You have to ensure that your crucible is free of water before use. Heating metals in a crucible that is wet can affect its reading. To be on the safer side, it’s essential you heat your empty crucible to a certain degree using a melting furnace or propane touch till it’s all dried up, then leave it to cool before using. It’s also essential to weigh the cubicle’s material compatibility with the metal you are about the melt, the melting furnace’s temperature, and the expected melting time before diving into the melting process.

What is the melting point of graphite?

Graphite is a stable alloy with no detailed specifications on what it’s melting or boiling point is. Graphite can withstand up to 5000 degrees Celsius of constant pressure. You can place your gold or silver into a graphite crucible, heat it in a furnace and obtain molten magma with no worries that the heat applied will leave a dent on your graphite crucible. Note that while graphite does not possess a specific melting point, graphite crucibles are prone to break when exposed to a temperature beyond 5000 degrees Celsius.

What does a crucible look like?

Most gold smelting crucibles possess an oval shape with round, smooth edges. Though, since numerous gold mining companies and laboratories fancy operating with customized crucibles, it’s impossible to allocate specific shape or size to the object. While gold melting crucibles vary based on shape and size, they all possess specific general features. Every crucible, weather made of graphite, steel, quartz, porcelain, and so on, possess smooth edges and are designed to withstand heat for an extended time. It’s important to note that a crucible efficiency is not dependent on its look—its reliability is based on what the crucible is made of.

Why is it called the Crucible?

Metal melting containers are called crucible because of their ability to endure extremely high temperatures without losing shape. Crucibles are available in ceramic and metal containers—each compatible with the smelting and melting requirements of specific metals. With hundreds of gold melting crucibles materials to choose from, there are certain factors and information that you must bear in mind when trying to select a crucible for melting gold, silver, or any other ferrous or non-ferrous metal. If you are a bit confused and would like a heads up on how to kickstart the process, get in touch.

Why is graphite use to make crucibles?

Graphite is used to make crucible because it’s a strong alloy possessing all the qualities a bench jeweler or miner requires from a crucible making material. The usage of graphite to make crucible dates back to the 1900s. Graphite’s widespread usage in the industry results from the exceptional features it possesses compared to other materials used for making gold melting crucibles. Gold melting graphite crucibles provides a dimensional accuracy like no other. Its viability is not dependent on lubricants—whether you are using a graphite crucible to melt gold or using it as a mold to create ingots, you can rest assured the desired output is guaranteed.

Which sort of metals can be melted in a crucible?

Ranging from gold to silver, platinum to zinc, crucibles can be used to melt all sorts of ferrous and non-ferrous metals. Crucibles are made with different materials. The best non-ferrous metal melting crucibles are made from graphite, while steel and porcelain crucibles are widely used to melt ferrous metals. Before settling for any metal melting crucible, it’s best you first weigh the type of metal you want to melt—not all metals are compatible with every crucible making material, the surface finish you would like to obtain, and the corrosive nature of the metal you want to melt must be in-line with your crucible’s material.

What are the different types of crucibles?

The different types of crucibles include porcelain crucibles, platinum crucibles, clay graphite crucibles, PTFE crucibles, stainless steel crucibles, Nickel crucibles, Carbon steel crucibles, quartz crucibles, Zirconium crucibles, Vitreous carbon crucibles, and crucible tongs. The different types of crucibles available can be designed and shaped to fit different industrial needs. Note that the efficiency of a crucible is dependent on the type of metal you want to melt. Before purchasing any gold melting crucible, it’s essential you familiarise yourself with its usage, corrosive nature, density, and durability.

What can be used as a crucible?

There are a handful of alloys that can be used for making crucibles. Amongst the many, let’s focus on the three widely used alloys. Graphite, Steel, and Quartz. Graphite crucibles rank top on the crucible making materials list. Graphite naturally exits with features in-line with the basic requirements most jewelers and melting experts require from a crucible. It provides a unique product finish, fast and efficient melting process, and high dimensional accuracy. Quartz minerals are the material behind the silica crucibles. Quartz is used to design transparent crucibles suitable for melting ferrous and non-ferrous metals. You can rely on quartz crucibles for a corrosion-free casting process. Steel became a widely appreciated crucible making material due to its long-lasting nature. When using steel crucibles, you enjoy a cost-efficient and environmentally friendly melting process.

How do you make a crucible melt gold?

You can make a crucible melt gold by inserting gold ingots into the crucible and relegating the crucible to high temperature. You can use a gold melting furnace or propane touch to apply the required heat to your crucible. Gold melting crucibles can be created with different materials, with different sizes, shapes, and designs. The time and temperature required to dissolve gold in a graphite crucible are not the same as that of a steel crucible. While graphite crucibles are regarded as the most cost-effective and durable crucible making material for gold melting crucibles, it’s best you carry out personal research before purchasing a crucible for your melting endeavors; you never can tell, steel crucible might be offering superior melting opportunities with reference to the melting task at hand.

What is melting crucible made of?

Melting crucibles are made from different alloys. The dominant crucible making alloys include graphite, quartz, steel, porcelain, cast iron, etc. The crucible making alloys available can melt different types of metals. Graphite crucibles are regarded as the best gold, silver, and other non-ferrous melting material; steel, a much more robust and long-lasting option, is compatible with melting ferrous metals. It’s important you weigh the corrosive compatibility of a crucible melting material before engaging in any melting activity. Bear in mind that all crucible making alloys’ efficiency is based on the type of material you want to melt.

How much gold do you lose when you melt it down?

When melting gold, you lose 1% to 2.5% of your gold. Most times, the exact amount of gold you lose is dependent on the melting process, the impurities contained in the gold, the type of graphite crucible melting material you use, and the temperature at which you heat the crucible. Melting gold in a crucible prone to impurities or with borax and charcoal can make you lose more than one percent of your gold. While you can minimize the amount of gold you lose during melting, you might want to bear in mind that it’s impossible to melt gold {weather refined or unrefined} without losing a certain percentage.

Why do you preheat a crucible?

You preheat a crucible to obtain a dry surface. Preheating a crucible helps remove moisture. Most metals are corrosive. Inserting a corrosive metal into a wet crucible affects expected readings. Before inserting metals into your gold melting graphite crucible, make sure you heat your crucible with a melting furnace or propane touch till its surface is entirely dry and free of water.

Why do we not allow the crucible to become red hot?

Heating a crucible till it becomes red hot can affect the metal casting process. Crucibles are made with alloys that can withstand hot temperatures for long hours—that doesn’t make them entirely resistant to heat. At specific temperatures, crucibles can break. Apart from the fear of breakage or spillage, heating a gold melting crucible till it becomes red hot can also make it increase in size—this can hinder the finished product in situations where your crucible is also used as a mold.

How do you heat a crucible?

To heat a crucible, you have to either place it in a gold melting furnace or use a propane touch. Propane touch serves as a durable heating option for bench jewelers and hobbyists looking to melt metals in small quantities. Factories, foundries, and laboratories using large graphite crucibles for gold melting are advised to smelt gold using melting machines. The comfortable and environmental friendly melting process melting furnace offers have earned it a million-dollar reputation in multiple industries. Note that before the creation of propane touch and induction melting furnace, jewelers and miners relied on the traditional method of using charcoal to heat a crucible. Charcoal is still used by bench jewelers and hobbyists to heat gold melting crucibles in different parts of the world.

What is a crucible for silver?

A crucible for silver is any metal melting container that can hold the silver in high temperature for an extended period without losing shape. Silver is amongst the few metals that melt easily under pressure. While crucibles for silver are required to possess a strong textile nature that can withstand high pressure, materials such as graphite with a less dense core than steel are regarded as a better silver melting material. Why is that? Graphite exists naturally with features that facilitate a smooth and efficient silver melting process. With a graphite melting crucible for silver, you enjoy a corrosive free melting process with a dimensional accuracy like no other.

How hot does a crucible get?

Crucibles can withstand different temperatures depending on their density and material—every crucible making material possess heating and cooling time peculiar to its design. Placing our focus on the graphite crucibles for melting gold available in SuperbMelt’s store, our crucible can heat at high as 2000 degrees Celsius in less than 5 minutes. Note that the melting furnace you are making use of also determines how hot your crucible can get. To be on a safe path, contact our support team to obtain adequate info on the efficiency of different gold melting crucible types on specific melting furnaces.

How do you clean a clay graphite crucible?

To clean a clay graphite crucible, place the crucible in a melting furnace or use propane touch to heat. Set the temperature to 700 degrees Celsius and wait till every metal contained in it melts. When everything thaws, drain out the metal. Rinse in hot water and use a clean cloth to wipe. Another method is to turn your gold melting crucible upside down inside a melting furnace and set to 700-degree Celsius. When the metal melts, it will drain out on its own. Note that the second method is not as effective as the first because it leaves stains on your melting furnace.

What temperature can a crucible withstand?

The temperature a crucible can withstand varies based on the material and density of the crucible. For instance, a gold melting graphite crucible can withstand a temperature of up to 5000 degrees Celsius. The design and type of graphite used determines how long the crucible would take to heat to such a point. With many industries relying on the productive value crucibles offer when tending to their smelting and melting needs, it’s important you carry out proper research on the type of crucible you need for a specific task. Such a study gives you a relatable understanding of the temperature you should and shouldn’t expose your crucible to.

What is a silica crucible?

Silica crucibles, also known as crucibles made from quartz, are transparent metal melting crucibles optimized to provide refractories with a refined metal cast. These glass-like crucibles can be used to melt ferrous and non-ferrous metals. Silica crucibles are long-lasting. They provide a unique surface finish from a melting process not reliant on lubricants. Compared with graphite crucibles, silica does not offer the smooth and corrosion free casting process graphite crucibles provide. From the bench jewelers to foundry owners, melting laboratories, ferrous and non-ferrous casting companies, etc.—silica crucibles are used in multiple industries.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited