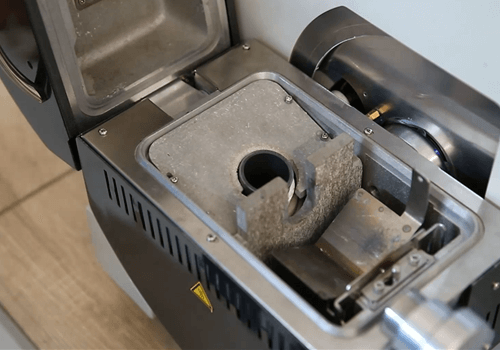

Dental Casting Machine

The most popular dental casting equipment (SPB-MVC150) on the market

SuperbMelt dental casting machine is one of the top-quality products on the market, and is precisely designed to hold materials of weight of up to 300g, which makes it one of the best options.

The primary dental casting machine features a quartz and inbuilt furnace. It has the capacity to heat to a maximum temperature of 2600 degrees Celsius. Due to the features above the product is suitable for casting tough materials (Precious and non-precious metals), such as gold palladium, porcelain, resin, silver, palladium, etc.

This dental casting kit is equipped with a gas chamber. The gas chamber that releases pressurized inert gases which completely do away any kind of porosity and oxidation amid the casting process. This is the feature that ensures you get a touch of class and quality. Our team ensures that customers get exactly what they are looking for. Therefore, once you have placed an order, you will be taught how to use the machine.

- This lost wax dental projecting hardware is made for just little amount of valuable metals that measure inside 300g.

- It includes an inbuilt vacuum siphon dissimilar to other projecting packs in the market.

- The vacuum projecting machine will consequently stop the machine in the event that there is a mistake.

- The item comes completely computerized. Both the dissolving projecting chambers can be flipped consequently in the midst of the activity. Because of this component, you will have the option to set aside your cash as far as labor expected to deal with the activity.

- The valuable dental projecting gear can project any valuable metal in the briefest period conceivable. This machine can possibly arrive at the projecting temperature in a matter of split seconds by 4.5kw acceptance generator.

- The heater power in-developed generator speeds the cycle while guaranteeing that you get the chance to spare however much force as could reasonably be expected to reduce the expense of creation.

- The Simen Control System (PLC) of the dental projecting device gives more precision to your temperature readings. The heater regulator can quantify any surrendered temperature to the exactness of ±2°C

- Taking everything into account, would you say you are searching for a reduced and little estimated dental projecting machine? This is a dental projecting pack that accompanies an inbuilt metal flip that can naturally turn your chamber. At that point the vacuum dental projecting unit is your smartest choice.

| Model | SPB-MVC150 |

| Power Requirement | 220V |

| Power Consumption | 4.5kw |

| Maximum Temperature | 2600 ℃ |

| Melting Method | Induction Heating |

| Capacity | 300g |

| Application | Gold, silver, platinum, palladium, steel, copper |

| Control System | PLC |

| Melting Time | 5-6mins |

| Gas Pressure | Max. 3.5 MPa |

| Pressurized Atmosphere | Argon |

| Ultimate vacuum | -0.1 MPa |

| Type of Crucibles | Quartz crucible |

| Cooling System | Water cooling |

| vacuum pump | built-in |

| automatic vacuum function | Y |

| Flip function | Automatic flip and vacuum casting |

Mini vacuum investment powder mixer parameter

| Model | SPB-MIPM1 |

| Power source | 220V |

| Power | 350w |

| Dimension | 540*510*390mm |

| Weight | 18kg |

Mini wax burnout furnace parameter

| Model | SPB-MWF1 |

| Power source | 220V |

| Power | 5kw |

| Chamber size | 300*200*120mm |

| Max Temperature | 1200 ℃ |

| Weight | 60kg |

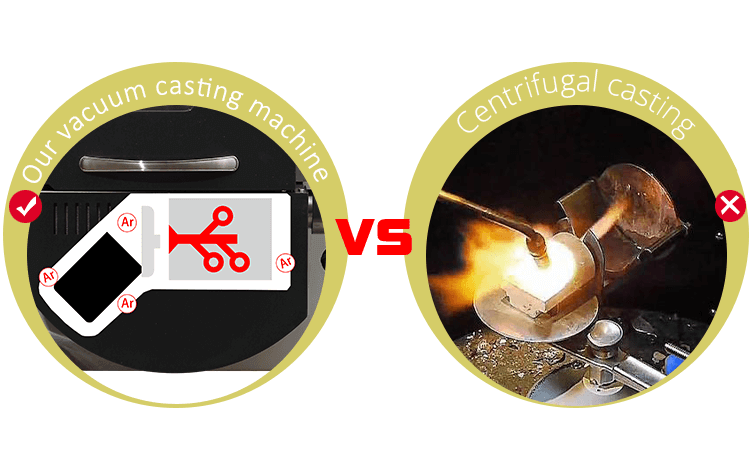

Compared with centrifugal casting, it greatly improves safety and ensures the personal safety of operators.

PLC control system can realize intelligent automatic casting, and a full range alarm system ensure safety.

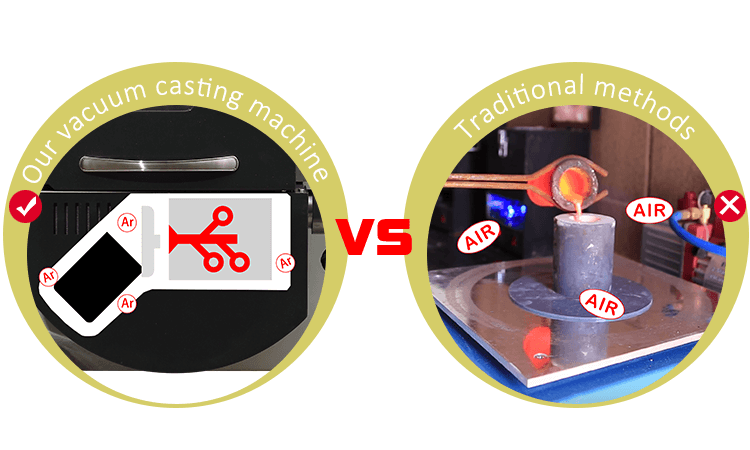

Comparing with traditional casting, it improves casting success and quality of dental under vacuum and pressurized.

Why SuperbMelt Vacuum Dental Casting Machine

Any Question About SuperbMelt Dental Casting Kit

Ultimate Dental Casting Machine Buying Guide

Application of Dental Casting in Tooth Restoration

1.1, What Kind of Damaged Teeth Can Be Repaired With a Cast Crown?

There are times when cast crown become the only thing to save the situation. However, you might have to use them each time something is wrong with your teeth. Therefore, there are only those special situations where your dentist will strongly recommend a cast crown.

The first situation is when you have split teeth. If anything, split teeth most of the time, do not heal. Therefore, you will learn that the only best way to go is a cast crown. Note that your tooth might be split slightly or deeply. However, as long as you are struggling with pain, you will always need a cast crown to make your trouble go away.

The next instance is when you have rotten tooth to an extent that it is completely damaged. In that case, your dentist will get rid of the remains of your rotten teeth and give you something that you will love. Most of the time, you will be asked to consider the difference that you will get and then the procedure will be carried out after you have consented to it.

Cast crown can also be used for cosmetic purposes. If you are not happy with your natural tooth for some reasons, it is okay to opt for a cast crown. You will have your looks greatly improved. Make sure that you are sure that this is the best decision since it costs money, and above all, is permanent.

SuperbMelt has some of the best cast crowns, and we can also design` them based on your taste and preference. We have worked with clients from different parts of the globe, and therefore, we understand the essence of client satisfaction. Even as we focus on providing quality, we still have some of the most competitive prices on the market.

1.2, Benefits of Casting Crowns

Full-metal crowns can be highly biocompatible, especially when a noble or precious metal alloy is chosen. Metal alloy (gold crowns in particular) have extremely good biocompatibility with gingival tissue and are unlikely to promote any allergic reactions. They are not susceptible to accumulating plaque, offer good corrosion resistance, and do not absorb fluids.

Full-cast metal crowns have a high tensile strength which is an advantage when preparing the tooth because the crown doesn’t need to be very thick, allowing you to preserve more of your patient’s original tooth. The strength of modern dental alloys allows our dental lab to create a much thinner restoration compared to a PFM or all-ceramic crown. A full-cast crown can be a particularly good choice when space is limited.

While full-cast metal crowns and bridges are very strong and are unlikely to be fractured by chewing forces, they are extremely kind to opposing dentition, reducing the risk of excessive wear because they offer a similar coefficient to tooth enamel. If the risk of wear to opposing teeth is a concern, it’s typically better to choose precious or semi-precious dental alloys when planning your patient’s treatment because these are softer yet still very durable. Additionally, the coefficient of expansion is similar to natural teeth.

The major disadvantage of choosing a full-cast metal crown or bridge is its appearance. It’s important that your patient is aware that their new restoration will be quite visible in the mouth whenever they smile or laugh if in the same “smile zone”. Precious metal and gold crowns and bridges can be expensive depending on the market cost of gold. In rare occasions, micro-gaps may be present after casting, which could increase the risk of decay. But if the crown has been fabricated in a high noble metal, it may be pliant enough to allow for minor adjustments.

It is important to check your patient doesn’t have any metal allergies, particularly if you would prefer not to use a precious or semiprecious metal. Base-metal alloys frequently contain nickel, beryllium, or chrome which can promote an allergic reaction. It is also important to discuss whether your patient wishes to have a white or yellow crown or bridge, as obviously the choice of alloy will dictate its color.

Please be reminded that our experienced technical team is here to assist you should you wish to discuss a case in more detail. If plaque is allowed to build up, it forms tartar, which is impossible to remove by brushing and flossing, and can lead to cavities and gum disease. Your dental hygienist or dentist will use special tools to thoroughly clean hard-to-reach areas of your mouth.

1.3, What Metal Can Be Used To Cast Teeth?

Metals used in crowns include alloys that have a high content of gold or platinum, or base-metal alloys (for example, cobalt- chromium and nickel-chromium alloys). Metal crowns withstand biting and chewing forces well and probably last the longest in terms of wear down. Also, metal crowns rarely chip or break. The metallic color is the main drawback. Metal crowns are a good choice for out-of-sight molars.

Since the early 1900s, a wide range of metals and their alloys are used in surgically implanted medical devices, prostheses and dental materials, in order to provide improved physical and chemical properties, such as strength, durability and corrosion resistance.

The classes of metals used in medical devices and dental materials include stainless steels, cobalt–chromium alloys, and titanium.

In addition, dental casting alloys are based on precious metals (gold, platinum, palladium, and silver), nickel, and copper and may in some cases contain smaller amounts of many other elements, added to improve castability, handling, ceramic bond, or other physical properties.

Ceramics are considered the best class of materials able to mimic the natural appearance of teeth; in spite of this, until some years ago ceramics were used only for veneers, due to their inherent brittleness.

The solidus temperature is important to soldering and formation of ordered phases, because during both of these operations, the shape of the alloys is to be retained. Therefore during soldering or hardening-softening, the alloy may be heated only to the solidus before melting occurs. In practice, it is desirable to limit heating to 50° C below the solidus to avoid local melting or distortion of the casting.

Improvement of Dental Casting Method

2.1, The Earliest Dental Casting Method

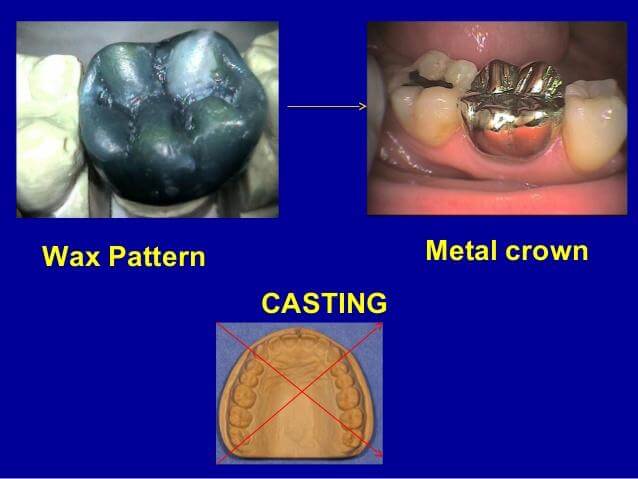

The lost-wax casting technique is used in dentistry to produce inlays, onlays, overlays, all-metal crowns, porcelain-fused-to-metal crowns and components of partial removable dentures. Casting is a method that allows for making precise copies of a wax pattern of a prosthetic work by changing a wax model into a metal cast. The technique employed is known as the “lost-wax casting process”. The name means that in this process, the wax, which is the model of the cast item, is totally burned away without leaving any residue, and then molten metal alloy (for instance gold alloy) fills this space during the casting process.

Prepare a cast with a removable die of high strength dental stone, and model a previously planned restoration using casting wax: a) prepare the abutment teeth – uncover the preparation margin, isolate it with a layer of spacer lacquer in order to create space (20-35 μm) for the cementation of the final fixed denture on the patient’s tooth produce a wax pattern by modeling the tooth in wax (the Adapta Deep Drawing System) or by modeling by way of utilizing a calibrated wax casting 2. Prepare a molding form by attaching sprue and sprue cone to the previously made wax pattern.

Ensure appropriate preparation of the wax structure for proper contact with the investment material, by covering it with the special substance to increase the surface tension and create a smooth model surface. 4. Replace the wax casting with metal alloy using the lost-wax casting technique: a) place a previously prepared wax structure in a casting ring and invest (pour into the mold the investment material). Regarding gold alloys, the employed investment material has a mid-melting point (temperature range 700-1200°C). However, other widely available investment materials for both noble and non-noble metals can be utilized after the investment material has set, the casting ring should be placed within an oven and heated according to the manufacturer’s recommendations: the burn-out process leaves a void that would be filled with the liquid gold alloy.

2.2, Centrifugal Casting Method

Centrifugal casting is a process that delivers components of high material soundness. As a result, it is the technology of choice for applications like jet engine compressor cases, hydro wear rings, many military products, and other high-reliability applications. It has also proven to be a cost-effective means of providing complex shapes with reduced machining requirements and lower manufacturing costs as compared to forgings and fabrications.

In the centrifugal casting process, molten metal is poured into a preheated, spinning die. The die may be oriented either on a vertical or horizontal axis depending on the configuration of the desired part.

By spinning a mold while molten metal is poured into it, centrifugal force acts to distribute the molten metal in the mold at pressures approaching 100 times the force of gravity. The combination of this applied pressure and the engineering mechanics of controlled solidification and secondary refining produces components of superior quality.

2.3, The Latest Vacuum Pressure Casting

This lost wax casting equipment is designed for casting only small quantity of precious metals (within 300g). It is designed very simple; leaving room for a DIY casting. This product comes with an inbuilt vacuum pump as compared to other castings kits in the market which doesn’t always come with a vacuum pump.

The automatic intelligent Simen control system (PLC) makes your whole casting process very safe seamless. The vacuum casting machine automatically stops the machine when an error is detected. This product is designed fully automated. Both your melting and casting chambers can be flipped automatically during operation. This feature saves you more money in terms of manpower needed to handle your casting operations.

The precious metal casting equipment can cast any of your precious metals in the shortest amount of time possible. This machine is capable of reaching your metal casting temperature (max. temp of 2600℃) in split seconds by a 4.5Kw induction generator. The furnace powerful inbuilt generator speeds up your production process coupled with savings in utility for power consumed.

The Simen intelligent Control system (PLC) of the mini casting tool gives more accuracy to your temperature readings. This furnace controller can measure any temperature up to an accuracy of ±2°C. In conclusion, are you on the lookout for compact and small-sized metal casting kits? A casting kit with an inbuilt metal melting flip that can automatically rotates your chamber. Then, the vacuum pressure casting kit is your best bet.

Gold/silver vacuum mini casting machine is designed for dental castings. This machine is designed to meet the more severe needs in wax casting production. This machine works with new concepts and has several advantages as compared to other ordinary machines.

Introduction to the Process of Vacuum Pressure Casting

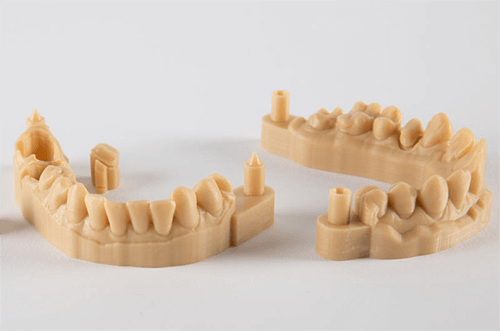

3.1, Make a Tooth Mold

For this sculpture, we select the “poured block mold” method.

Here are the reasons that we are eliminating other methods:

Brush-on Mold: We are concerned that air bubbles may form in the intricate details on the base of the sculpture. Also, brush-on molds tend to have thick and thin spots – thin spots end up being weak points in the mold.

Poured Blanket Mold: One of the steps in the poured blanket mold process is to form a layer of clay on top of the original model (review a poured blanket mold tutorial here). This step would most likely deform the clay original.

Based on the shape of the sculpture, we also know that the mold will require a cut in order to remove the original sculpture and subsequent castings.

3.2, Making a Plaster Mold

Molds are very useful to speed up the process of repeating forms. Plaster is cheap and can be bought from specialist suppliers in a dry state. The first step is ensuring that the modeled tooth is attached to a slab of clay and surrounded by a cottle (clay wall). The plaster is then mixed as follows. Firstly, the volume of plaster needed is estimated by looking into the cavity created by the cottle and estimating the amount of water needed to fill this space.

Pour the final amount of water into a large bowl or bucket. The plaster is then sieved over the surface of the water until an island of plaster appears, whereupon one more handful of plaster is sprinkled around the outer edge of the water in the bucket. Leave the plaster and water for a couple of minutes until all the plaster has been soaked through, then gently agitate the mixture from the bottom until it becomes thicker, being careful not to introduce air into the mix.

When the mixture begins to thicken, it can be poured into the prepared cavity. It is then gently pushed down to ensure that the plaster has been forced into every detail of the model and that air bubbles have been encouraged to the surface. If the estimated amount of plaster is not enough, then the surface should be roughened by dragging a finger through it as it is becoming solid, so that another mix can be made and poured over it. If too much plaster has been mixed then the excess should be poured into a rubbish bag, NOT down the sink, where it will block the drain hole.

3.3, Smelting and Casting Metals

Once you have any quantity of molten gold or platinum, moisture becomes an extreme danger. A drop of molten gold or platinum on concrete (which holds moisture) will turn the water in the pores to steam, causing a small explosion which will propel liquid golden or palladium and chips of concrete into the air. Now think about what would happen if you spilled a whole crucible Always carry and pour molten gold over dry sand.

If you stick anything—a stirring rod, a skimmer, more pieces of metal to melt—into the crucible when there is molten gold in it, that object needs to be DRY. This is as simple as preheating molten gold or platinum on top of your furnace while it is running, and holding the end of any tools in the exhaust flame for a few seconds, but if you forget you will cause the molten gold to explode while you are standing there with your face over it. Likewise, your ingot molds (where you pour the leftover gold after filling your molds) need to be preheated on the furnace, or an explosion will occur.

In the modern times, there has been an increased rate at which elements such as cobalt-chromium-molybdenum alloys alongside nickel-chromium alloys are used. Also, some companies and dentists have for a long time used stainless steel and titanium alloys to come up with perfect dental casting to suit the needs of various clients globally.

3.4, Polishing Teeth

If you are wondering which is the most economical way to make any prototype? Then you should try vacuum casting. In vacuum casting, you’re require to have the correct optimum temperatures when curing the materials.

For castings, you require 30 degrees Celsius to minimize shrinkage at vacuum pressure time of 5 min and a mold temperature of 60 degrees Celsius.

Vacuum casting is the same as duplication using a silicon mold. Plastic vacuum casting using silicon molds was developed in the 1960s in German universities.

This is a casting process for elastomers which uses a vacuum to draw any liquid material into the mold. Vacuum casting is used when air entrapment is a problem with the mold.

Additionally, the process can be used when there are intricate details and undercuts on the mold. Also, it is applied if the material used to make the mold is fiber or a reinforced wire.

The process is sometimes called thermoforming because the manufacturing process involves rapid prototyping where the plastic sheets are preheated. The materials are preheated in an automated vacuum casting machine until they are soft and pliable.

Conclusion

Vacuum casting process requires you to have a high-quality master model. The high-quality master model can be the industrial part itself. Additionally, you can use a model created using stereolithography, which is a case for the prototyping applications.

You should always ensure that the master model being used is of the correct dimensions and looks. This is to ensure that no flaws are transferred to the model prototype after finishing the process.

The master model is then encapsulated into a two-part silicone rubber mold. The mold is cured under high temperatures to ensure that the two parts stick together. This is used to strengthen the mold and make it more durable.

After the mold is cured, it is cut open to reveal a hollow space at the center, which has the exact dimensions of the master model. After the mold is cut into two, it is placed in the vacuum chamber. Then, later on, the mold is filled with the designated material to make a product.

You should fill the mold with the designated material. The resin replicates the characteristics of industrial material. The resin material is usually mixed with metallic powder or any coloring pigment to achieve aesthetic or specific functional properties.

After the mold is filled with the resin material, it is placed in the vacuum chamber. It is placed in the vacuum chamber to ensure that there are no air bubbles in the mold. This is to ensure that the final product is not ruined or damaged.

How Do We Solve The Problem of Dental Casting?

Employ a scientific method. Take the problem piece, and change one variable per flask. For instance, set up ten separate flasks. Each one will have one difference: flask temperature; melting temperature; different types of spruing; different waxes; different people making the waxes; different batch of investment etc.

Then cast them up, finish samples from each lot and see which comes out best. This simple procedure alone will go a long way toward narrowing down what is and what isn’t the problem area.

While setting up this type of test, you should also delicately enquire of your customer whether or not he might be doing something different in his processes.

In order to employ any kind of scientific problem-solving techniques, you must keep accurate records. A rule of thumb is when something starts going wrong, it continues, going from bad to worse. Things rarely get better or solve themselves.

If you keep accurate records, you may be able to see patterns emerge. For example at Atkin Casting, a chart recorder for burnout ovens was issued. This is basically a thermocouple that plugs into the oven to record time and temperature. It turns on automatically at the start of the burnout cycle, shows the time it takes to reach the proper temperature, and shows the exact temperature variation as the oven cycles on and off all night. At 8 a.m. the oven is turned down to casting temperature from its high of about 1400(F. This chart is compared with previous charts to check ovens once every six months. If any variations are noticed, something is happening; most probably the oven’s thermocouples are wearing out (thermocouples are sneaky; they go very, very gradually).

Look for patterns. In tracking down a problem, keep written records and look for common threads to emerge. Make up a problem chart and study it for patterns that show up rather like the connect-the-dots most of us did as children.

For example suppose you have prongs cracking. As you experiment to change the elements of the process, you find something showing up: An increase loss factor. You usually have X% loss per melt (you should know exactly what your loss factor is). All of a sudden, there’s a variation; the percentage of loss begins to go up. In all probability, you’re going to find other things happening as well.

Let’s say the gold is beginning to show pinkish or red. All of these things are beginning to point to alloy or melting trouble. The patterns show the way. Let’s say a customer calls and complains about incomplete or unfilled castings. This generally suggests a temperature problem-either oven or flask temperature. If it’s casting temperature, then perhaps your oven calibration is wrong-thermocouples have gone or are going. Maybe there was a radical variation in the ambient room temperature (the casting room will be cooler in winter and warmer in summer from the air circulating through the building ducts), which you didn’t compensate for in the casting temperature. If you are doing vacuum casting, it may be simply that the gold isn’t being drawn into the flask with enough force.

In the casting of models for the production of dental casting, a major problem being faced by producers often has to do with the occurrence of various forms of defects.

These defects take place at difference stages of the production process and a source of revenue loss. Experienced players in the dental casting production industry are always seeking new and innovative ways to prevent and deal with the occurrence of casting defects.

This article seeks to contribute to these efforts by identifying a couple of common defect mechanisms in dental casting, and suggesting ways by which they may be prevented and mitigated.

At Superbmelt, we use high-quality equipment that leverages the best technology to ensure that you do not experience problems related to cracks, bubbles, etc.

FAQ Guide

How do you cast gold teeth?

The first step is to have a mold made of both your top and bottom teeth. This can actually be done at home using a special kit; otherwise you have to make a trip to either your dentist or a jeweler. The process of molding your teeth is quite simple and not at all painful.

Dye stone is poured into the mold in order to make an impression of your teeth. This is a precursor to casting the mold, which is the most important step in the process. Before the casting there is a wax lining added to the mold. Once that is done, make sure to polish your gold teeth.

This lost wax casting equipment is designed for casting only small quantity of precious metals (within 300g). It is designed very simple; leaving room for a DIY casting. This product comes with an inbuilt vacuum pump as compared with other castings kits in the market which doesn’t always come with a vacuum pump.

The automatic intelligent Simen control system (PLC) makes your whole casting process very safe seamless. The vacuum casting machine automatically stop the machine when an error is detected. This product is designed fully automated. Both your melting and casting chambers can be flipped automatically during operation.

This feature saves you more money it terms of manpower needed to handle your casting operations.The precious metal casting equipment can cast any of your precious metals in the shortest amount of time possible. This machine is capable of reaching your metal casting temperature (max. temp of 2600℃) in split seconds by a 4.5Kw induction generator.

The furnace powerful inbuilt generator speeds up your production process coupled with savings in utility for power consumed. The Simen intelligent Control system (PLC) of the dental casting tool gives more accuracy to your temperature readings. This furnace controller can measure any temperature up to an accuracy of ±2°C.

What do dentists use to make a mold of teeth?

What Stuff is in the Mold? There are a few materials used to make impressions of your teeth. Perhaps the most commonly used material is called alginate. It is a powder compound made from seaweed or kelp that is added to water to make something that looks like silly putty.

How long does it take to do a dental impression?

The setting time can be between 1 – 4.5 mins which can be varied by the temperature of water used: the cooler the water, the slower the set and vice versa. You want to ensure that the material is fully set before removal from the mouth. The water content that the completed impression is exposed to must be controlled.

How do you make fake teeth?

It all depends on what you mean by fake teeth. This is because the process we have discussed above is one of the most applicable ways to make fake teeth. Note that as long as your teeth is not natural, whatever you have used to replace it is referred to as fake teeth. You can have your fake teeth made from silver or gold.

What is dental putty used for?

Dental Putty is also called as Polyvinyl siloxane (PVS), also called poly-vinyl siloxane, vinyl polysiloxane, or vinylpolysiloxane, is an addition-reaction silicone elastomer (an addition silicone). It is a viscous liquid that cures (dries) quickly into a rubber-like solid, taking the shape of whatever surface it was lying against while curing. As with two-part epoxy, its package keeps its two component liquids in separate tubes until the moment they are mixed and applied, because once mixed, they cure (harden) rapidly. Polyvinyl siloxane is widely used in dentistry as an impression material.

How long does dental plaster take to set?

Typically, it can be de-molded in about 30 to 45 minutes. If it is cool to the touch it has at least set. But, set time is not the same as cure time. In order to fully cure, the cast will usually take between 48 and 72 hours with good ventilation to allow any excess water to escape.

What is gypsum dental?

Gypsum (calcium sulphate dihydrate) is a naturally occurring mineral used in dentistry to fabricate models, casts and dies. Calcination is the process of heating the gypsum to dehydrate it (partially or completely) to form calcium sulphate hemihydrate.

How long does it take to get a mold of your teeth?

This is a silicone-based material that can take anywhere from 2-5 minutes to set properly. Orthodontists might also use polyethers to create an impression.

How do you make fake teeth with acrylics?

Color the teeth with acrylic paint. Pour the paint into your mold and then dip the teeth in it. Use white paint for the teeth and a pinkish-red color paint for the gumline. Sand down any rough spots to finish the teeth

How do I make a mold?

In order to make a dental impression, a thick liquid material, such as alginate or polyvinylsiloxane, is dispensed into an impression tray that is shaped like a U in order to properly fit into a mouth. Alginate is found within the cell walls of brown seaweeds. The seaweed is part of the phylum Phaeophyceae family and is harvested internationally to be converted into the raw material sodium alginate. This substance is what’s used to create the Alginate product. Depending on the species of seaweed, various chemical structures can be found within each plant.

What is dental putty?

Dental impression material putty is used to make molds and casts that help creating dental models, braces and reconstructions.

How do I cast my teeth?

If you can’t get your supplies locally, there are lots of places to look on the internet. I went directly to one of my favorite companies, Monster Makers. They sell everything you need, plus videos, to show you how to make awesome, gnarly teeth (and a bunch of other cool stuff). Make the impressions one tray at a time. They only take about a minute to set up, so there’s really no point in trying to do both at once and risking failure due to uncontrollable gagging.

Why dentists make teeth molds?

Preliminary impressions are accurate reproductions of a patient’s mouth. This type of impressions is usually used to construct study models for the diagnosis, documentation of dental arches, and as a visual aid for education.

How do you invest in casting?

Investment casting is a manufacturing process in which a wax pattern is coated with a refractory ceramic material. Once the ceramic material is hardened its internal geometry takes the shape of the casting. The wax is melted out and molten metal is poured into the cavity where the wax pattern was.

What is dental casting?

In dentistry, casting is a process by which a detailed wax pattern of a dental restoration is converted into alloy or ceramic. … Casting is used to fabricate inlays, onlays, crowns, ceramic–alloy crowns, some all-ceramic crowns, partial dentures, implant restorations and frameworks, and occasionally a complete denture.

What is the difference between sand and investment casting?

The sand is often reclaimed and reused multiple times. Molds for sand casting usually have two distinct halves that are tightly fastened together when being used. Investment casting, also called lost-wax casting, makes parts from molten metal, usually stainless-steel alloys, brass, aluminum, and carbon steel.

What to use for fake teeth?

Dentures also commonly known as false teeth are fitted to act as a prosthesis for missing teeth. They’re often made of acrylic, nylon, or metal. They can be used in place of one tooth, several, or all of your teeth, and they fit snugly over the gums.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited