Desktop Laser Welding Machine

SuperbMelt, the Leading Manufacturer of Desktop Laser Welding Machines in China

SuperbMelt Desktop Laser Welding Machine features a compact design, allowing for high-precision welding in limited spaces, making it ideal for small workshops, jewelry manufacturers, repair shops, and other small-batch production environments that require precise welding.

With the rapid development of consumer electronics, jewelry, medical devices, and micro-manufacturing industries, the demand for desktop laser welding machines is continuously increasing. Laser welding is a process that uses laser energy as a heat source to melt materials, forming a joint.

The Desktop Laser Welding Machine, with its high precision, efficiency, and ease of operation, has become an indispensable tool in many industries. As technology continues to evolve and industry demands change, the functionality of desktop laser welding machines will become more diverse, and the performance of the equipment will continue to improve.

| Model | SPB-150WB |

| Wavelength | 1064nm |

| Max output power | 150W |

| Max pulse energy | 80J |

| Pump source | Single lamp |

| Pulse width | 0.1-20ms |

| Pulse frequency | ≤50Hz |

| Aiming and positioning | Microscope + camera system |

| Application | Welding and repairing various precious metal trinkets |

| Host power consumption | ≤5KW |

| Electricity demand | AC220V±5%/50Hz |

| Cooling system | Water cooling + air cooling |

| Dimension | 660x385x435mm |

| Weight | 49kg |

Features:

- Compact Design: Its small size allows for easy integration into limited workspace environments like small workshops, jewelry studios, and repair shops.

- High Precision Welding: The machine offers exceptional precision, ideal for delicate and intricate welding, particularly for small components such as jewelry and medical devices.

- User-Friendly Operation: Equipped with an intuitive interface, it is easy to operate, making it suitable for both novice and experienced users.

- Powerful Laser Technology: Utilizes high-powered laser beams to achieve deep and clean welds, ensuring strong and reliable joints.

- Adjustable Parameters: Welding parameters such as laser power, pulse duration, and spot size can be adjusted to suit different materials and applications.

- Efficient Cooling System: Built-in cooling systems help prevent overheating during continuous operation, extending the machine’s lifespan and ensuring stable performance.

- Versatile Application: Can be used for welding a variety of materials including gold, silver, platinum, stainless steel, copper, and more.

- Small Batch Production: Designed for small-scale, high-precision welding tasks, making it ideal for custom jewelry, prototypes, and repair work.

Advantages:

- Space-Saving: The compact nature of the machine makes it highly suitable for small or crowded workshops where space is a premium.

- Cost-Effective for Small Batch Production: Perfect for industries requiring small-batch production, such as jewelry making, where high-volume machinery is not necessary.

- High Welding Quality: Offers clean, precise, and strong welds, ensuring high-quality finished products with minimal material wastage.

- Improved Efficiency: Faster welding times compared to traditional methods, allowing for higher productivity and reducing labor costs.

- Reduced Heat Affected Zone (HAZ): Due to the concentrated heat source, laser welding minimizes the heat-affected zone, reducing the risk of distortion or damage to surrounding materials.

- Increased Flexibility: The ability to weld various materials with different thicknesses and compositions makes the machine versatile across industries.

- Minimal Post-Weld Cleanup: The high precision of the laser welding process often results in minimal post-weld cleanup, saving time and effort.

- Long-Term Durability: Built with robust components that ensure long-term use, even under continuous or high-frequency operation.

- Environmentally Friendly: The precision and focused energy usage of the laser minimizes waste and reduces the environmental impact compared to traditional welding methods.

Why SuperbMelt Desktop Laser Welding Machine

Any Question About SuperbMelt Desktop Laser Welding Machine

Who is suitable to use Desktop Laser Welding Machine?

Who Uses Desktop Laser Welding Machines?

From jewelry workshops to dental labs, the desktop laser welding machine is becoming a trusted tool for professionals who need precision and control. Jewelers use it to fix delicate gold chains or create intricate ring settings without overheating nearby stones. In dental studios, it helps craft strong, clean welds on crowns and bridges. Even electronics technicians rely on it to join tiny metal parts without damaging circuits. Compact, efficient, and easy to use, this machine fits perfectly in small studios and labs, helping creators bring their fine metalwork ideas to life with accuracy and speed.

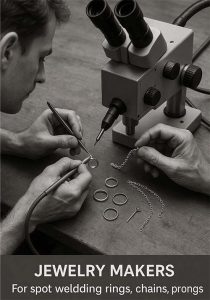

1.1, Jewelry makers: For spot welding rings, chains, prongs

Jewelry makers use desktop laser welding machines to perform ultra-precise tasks such as repairing fine chains, joining tiny jump rings, securing gemstone prongs, and welding earring posts or clasps. These machines are especially favored for working with precious metals like gold, silver, and platinum, as they generate a focused, low-heat weld that minimizes thermal stress and oxidation.

For example, when repairing a broken gold chain, a jeweler can align the delicate links under a microscope and apply a pinpoint laser pulse to create a seamless, nearly invisible bond—without removing the gemstone or damaging adjacent components. In prong re-tipping, the laser can rebuild worn tips with micrometer accuracy, ensuring both durability and aesthetic perfection.

Laser welding is also ideal for custom jewelry creation, where intricate parts must be joined without compromising surface finish or design precision. The desktop format offers a compact footprint while maintaining professional-grade performance, making it a top choice for jewelry studios, repair shops, and independent designers alike.

1.2, Dental technicians: For welding crowns, bridges, orthodontic parts

Dental technicians rely on desktop laser welding machines to perform precise and clean welds on components such as crowns, bridges, clasps, implant abutments, and orthodontic appliances. These machines allow for microscopic-level precision, making them ideal for delicate tasks where traditional soldering could compromise the integrity or fit of the prosthetic.

For instance, when assembling a metal framework for a dental bridge, technicians use laser welding to join segments without introducing excessive heat, which can cause distortion or affect the fit. Similarly, in orthodontics, lasers are used to weld fine wires or custom parts, maintaining their exact shape and alignment.

Laser welders are also crucial in repair scenarios, such as fixing a fractured cobalt-chrome crown or adjusting titanium parts, where a strong, clean weld is required without removing ceramic or composite materials.

The compact design of desktop laser welders fits easily into dental labs, and their non-contact, low-heat process preserves surrounding materials while ensuring biocompatibility and long-term durability—making them an essential tool in modern dental prosthetics and restorations.

1.3, Watchmakers: For precision welding of small components

Watchmakers use desktop laser welding machines for the precision repair and assembly of tiny, intricate watch components. These machines enable high-accuracy welding on delicate parts such as watch cases, bezels, clasps, crowns, lugs, and bracelet links, where traditional soldering methods could risk damage due to excessive heat or lack of precision.

For example, when restoring a luxury watch case, laser welding allows for seamless filling of dents or scratches using the same metal type, preserving the aesthetic and structural integrity. It’s also ideal for re-welding fine metal joints in vintage watches or for resizing and repairing metal watch bands without disassembling the entire piece.

Thanks to low thermal impact and microscopic control, laser welders minimize the risk of deforming heat-sensitive components like gaskets or movement housings. The hands-free operation and precision targeting also allow for exact placement of welds, essential for working with high-value timepieces.

In short, desktop laser welding machines have become an indispensable tool in modern and vintage watch repair, enabling watchmakers to deliver flawless, nearly invisible repairs with high efficiency and accuracy.

1.4, Electronics technicians: For micro-welding of metal contacts

Electronics technicians rely on desktop laser welding machines for precision micro-welding tasks in the assembly and repair of electronic components. These machines are ideal for welding small metal contacts and conductive elements with minimal thermal distortion. Typical applications include:

Repairing FPC (Flexible Printed Circuit) solder joints

Welding battery tabs in power cells and lithium batteries

Sealing sensor housings (e.g., pressure or temperature sensors)

Welding RF module enclosures for high-frequency communication

Wire bonding and re-bonding in microchips

LED terminal welding or repair

Connecting metal contacts in medical-grade wearable electronics

Laser welding is non-contact, which protects heat-sensitive components from damage, reducing the risk of PCB warping or component failure. It also ensures high accuracy, with a typical laser spot size under 0.1 mm and repeatability of ±0.01 mm—making it suitable for MEMS devices, radar modules, and precision RF circuits.

For technicians dealing with compact, delicate assemblies, desktop laser welders offer unmatched control and reliability in micro-scale metal joining.

1.5, R&D labs and educational institutions

R&D laboratories and educational institutions often utilize desktop laser welding machines for materials research, microscale fabrication, and hands-on technical training. These compact, precise machines provide a safe and controlled environment for exploring laser-based joining technologies.

In research settings, they are used to:

Study weld behavior across different alloys and metal composites

Experiment with welding parameters (power, pulse width, focus) for new applications

Prototype micro-devices, MEMS components, or sensor housings

Conduct thermal analysis of laser-affected zones

In technical universities or vocational schools, they help students:

Learn the fundamentals of laser welding and beam-material interaction

Gain practical skills in metal joining, especially for jewelry, medical tools, or microelectronics

Safely practice with a low-power, desktop-scale system that requires minimal infrastructure

The machine’s compact footprint, precise control, and low energy requirements make it ideal for classroom environments, innovation centers, and academic cleanrooms. It’s also valuable for developing curricula around smart manufacturing and laser processing technologies.

User Benefits

2.1, Minimal heat distortion

Minimal heat distortion is one of the key advantages of using a desktop laser welding machine.

- Thanks to the highly focused laser beam and short pulse durations, the heat-affected zone (HAZ) is kept extremely small. This allows users to:

- Weld delicate components (such as prongs, micro-contacts, or watch parts) without damaging adjacent materials

- Maintain the original shape and surface finish of thin metal pieces

- Achieve clean welds with little to no post-processing required

- Avoid common issues like warping, discoloration, or cracking in fine jewelry or precision assemblies

This makes desktop laser welders ideal for applications where precision and material integrity are critical.

2.2, Precise control over small welds

Precise Control Over Small Welds: Deep Technical Insight

Desktop laser welding machines offer unparalleled precision in micro-welding applications. These systems are engineered for operations where tolerances are often within ±0.01 mm, and even the smallest thermal distortion can compromise structural integrity or aesthetic quality.

Key technical advantages include:

- Laser Spot Size: Adjustable down to 0.1–0.3 mm, enabling welds on components smaller than a grain of rice—ideal for rejoining prongs on 0.5 mm gemstone settings or fusing ultra-fine watch spring ends.

- Pulse Duration Control: Typically ranging from 0.1 ms to 20 ms, allowing tailored energy delivery. For example, a 0.5 mm gold chain link might only require a 1.5 ms pulse at 20–25 J of energy to achieve a full-penetration weld without discoloration or overburn.

- Power Range: Systems offer fine modulation between 10 W to 200 W continuous or pulsed output. For instance:

Thin platinum prongs (~0.3 mm) are best welded at 30–40 W, 3 ms pulse

Dental frameworks (~0.6 mm CoCr) need 100–120 W, 8–10 ms pulse

- Energy Consistency: Laser systems provide pulse-to-pulse energy stability within ±3%, ensuring repeatability across production runs—critical for aligning weld seams on symmetrical parts like watch case lugs or bridge structures.

- Microscope Integration: High-magnification binoculars (10x–15x) and coaxial crosshair lasers guide operators with sub-millimeter accuracy, preventing weld creep and minimizing risk of collateral heat damage on adjacent stones, circuits, or precision parts.

- Heat-Affected Zone (HAZ): With focused energy input and fast pulse delivery, the HAZ is typically restricted to <0.2 mm, minimizing material warpage. This is especially important in high-reflective metals like gold or silver, and heat-sensitive substrates in electronics.

These features make desktop laser welders indispensable in high-precision sectors where manual torch methods or resistance welding cannot meet the required accuracy, consistency, or cosmetic finish standards.

2.3, Clean process with little post-processing

Clean Process with Minimal Post-Processing: Technical Advantage Explained

Desktop laser welding machines offer a highly controlled and localized energy delivery system that drastically reduces the need for secondary finishing steps.

Why It’s a Clean Process:

Non-contact welding: The laser beam interacts with the material without physical contact, eliminating contamination from electrodes or filler wires.

Focused energy input: With beam diameters as small as 0.1–0.3 mm, heat is applied only where necessary—no oxidation or excessive melting on surrounding areas.

Shielding gas (argon): Actively protects the weld pool from air exposure, preventing discoloration, oxidation, or porosity.

Post-Processing Reduced or Eliminated:

No soot or flux residues: Unlike torch welding or soldering, laser welding doesn’t produce carbon residues or require chemical cleaning agents.

Minimal to zero polishing needed: The weld seams are smooth and narrow—often requiring only light buffing, especially on materials like gold, silver, or platinum.

No distortion correction: Heat-affected zones are confined to <0.2 mm, preserving part geometry. This is crucial in watch dials, dental parts, or gemstone settings where precision alignment is mandatory.

Real-World Impact:

Jewelry welders often finish post-weld polishing in under 30 seconds.

Watchmakers report no re-machining of the case surface after micro-welding operations.

Dental labs skip acid cleaning after laser welding due to clean seams.

FAQ Guide of Desktop Laser Welding Machine

- 1. What materials can the Desktop Laser Welding Machine work with?

- 2. Can the machine handle intricate and detailed welding tasks?

- 3. Is the machine suitable for small-scale jewelry workshops?

- 4. What file formats are compatible with the machine for design input?

- 5. Does the laser welding process performed by the machine result in permanent welds?

- 6. How efficient is the Desktop Laser Welding Machine in terms of production speed?

- 7. Can the machine be used for applications beyond jewelry making?

- 8. What safety features are integrated into the machine?

- 9. Does the machine require special training for operation?

- 10. How does the Desktop Laser Welding Machine contribute to reducing material waste?

- 11. Can the machine handle both repair work and new jewelry production?

- 12. What kind of maintenance does the machine require?

- 13. Is the Desktop Laser Welding Machine suitable for beginners in laser welding?

- 14. Can the machine weld different thicknesses of materials?

- 15. How does the machine contribute to the customization of jewelry designs?

1. What materials can the Desktop Laser Welding Machine work with?

The machine is designed to work with various materials, including gold, silver, platinum, and other precious metals commonly used in jewelry making.

2. Can the machine handle intricate and detailed welding tasks?

Yes, the Desktop Laser Welding Machine excels in precision and can handle intricate and detailed welding tasks with high accuracy.

3. Is the machine suitable for small-scale jewelry workshops?

Absolutely, the compact size and user-friendly design make it an ideal choice for small-scale jewelry manufacturing and design studios.

4. What file formats are compatible with the machine for design input?

The machine is compatible with vector graphic software and accepts file formats like DXF, TLP, and AI for design input.

5. Does the laser welding process performed by the machine result in permanent welds?

Yes, the machine ensures permanent and durable welds, contributing to the longevity of the jewelry pieces.

6. How efficient is the Desktop Laser Welding Machine in terms of production speed?

The machine operates with high efficiency, providing quick welding solutions to enhance overall production speed.

7. Can the machine be used for applications beyond jewelry making?

Certainly, the versatility of the machine allows for applications in various industries, including metal manufacturing, automotive, and aerospace.

8. What safety features are integrated into the machine?

The machine includes safety features such as protective enclosures and emission control mechanisms to ensure a secure working environment.

9. Does the machine require special training for operation?

While the machine is user-friendly, training is recommended to optimize its capabilities. SuperbMelt provides comprehensive user manuals and training resources.

10. How does the Desktop Laser Welding Machine contribute to reducing material waste?

The precision of the laser welding process minimizes material waste, making it a cost-effective and environmentally friendly solution.

11. Can the machine handle both repair work and new jewelry production?

Yes, the machine is versatile enough to handle both repair work and the production of new and customized jewelry pieces.

12. What kind of maintenance does the machine require?

Regular maintenance involves cleaning the optics, checking cooling systems, and ensuring proper calibration. SuperbMelt provides detailed maintenance guidelines.

13. Is the Desktop Laser Welding Machine suitable for beginners in laser welding?

Yes, the machine is designed with user-friendly features, making it suitable for beginners. Training resources are available for those new to laser welding.

14. Can the machine weld different thicknesses of materials?

Yes, the machine is capable of welding different thicknesses of materials, providing flexibility for various design requirements.

15. How does the machine contribute to the customization of jewelry designs?

The machine allows for intricate and customized designs, empowering jewelry designers to create unique and personalized pieces for their clients.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited