Double Head Jewelry Wax Setting Machine

SuperbMelt, a leader in Chinese technology, assists customers in achieving automated jewelry stone setting capabilities.

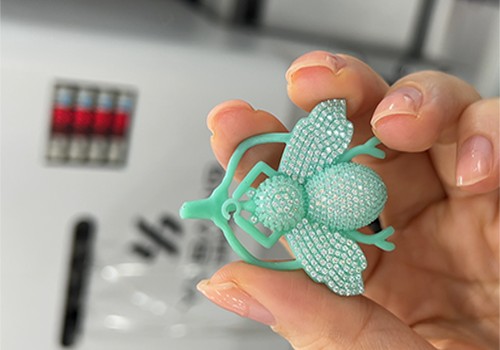

SuperMelt Double Head Jewelry Wax Setting Machine achieves automatic jewelry wax setting with a capacity of 18,000-20,000 pieces per hour. The machine features four flexible gem setting heads to ensure efficient work without damaging the wax or gemstones. Intelligent diamond recognition prevents oversights even during high-speed operation.

The seamless loading and unloading of wax molds with dual heads, without stopping the machine, help clients save time and improve production efficiency, making it an ideal choice for intricate jewelry wax setting. The machine excels not only in speed but also in intelligence, simultaneously recognizing and adapting to different colors and specifications.

For clients considering single or dual workstations, the advantages lie in the efficiency of changing wax molds and the ability to effectively address issues with large angles. Customize our machines based on your factory’s unique requirements and production needs, ensuring seamless integration of technology into your workflow.

| Equipment nam | Double- head Automatic Setting Machine |

| Equipment Model | SPB-5DZ4-2 |

| Table structure | lat double workbench and double rotating axis |

| Drilling speed | 18000-20000 drills/h |

| Number of suction drill head | 4 suction nozzles |

| Drill plate fixing method | movable force magnet on the upper side of the platform |

| Spot drilling accuracy | ±0.02mm |

| Control system | industrial grade five-axis motion controller |

| Main operating system | SuperbMelt self-developed system |

| Drive system | High-end servo |

| Transmission method | high precision screw guide |

| Z*Y*Z/A/C effective stroke | 550*150*110mm/+150°-90°/360 degrees |

| Working power | AC220V/50Hz |

| Rated voltage | 2.5kw |

| Working air pressure | 80psi(0.4Mpa) |

| Equipment size | (L)950×(W)750×(H)1400mm |

| Equipment weight | about 750KG |

- High-Speed Operation: Achieves an impressive output of 18,000-20,000 pieces per hour, ensuring rapid and efficient production.

- Dual Workstations: Left and right workstations allow seamless material loading and unloading without downtime, optimizing workflow efficiency.

- Four Flexible Stone-Setting Heads: Delicate and precise stone setting without causing damage to wax molds or stones, ensuring superior craftsmanship.

- Intelligent Diamond Recognition: Prevents oversights even at high speeds, enhancing accuracy and reducing errors in the stone-setting process.

- Five-Axis Flexible Workstation: Handles large angles and curves with ease, making it suitable for intricate and detailed stone setting.

- Continuous Operation: Dual-head design allows for continuous operation, providing infinite loops for maximum productivity.

- Color and Specification Recognition: Intelligent recognition system ensures synchronized completion of tasks, including sorting by color and specifications.

These features make our Four-Head Dual-Station Wax Setting Machine a cutting-edge solution, combining speed, precision, and intelligence for optimal performance in jewelry manufacturing.

Why SuperbMelt Double Head Jewelry Wax Setting Machine

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited