Induction Furnace

SuperbMelt induction furnace (SPB-HMF) for 50-250kg metal melting

SuperbMelt best electric furnace is equipped with hydraulic functionality, allowing remote control of hydraulic pouring, which greatly enhances safety measures.

The melting capacity of this induction furnace is customizable, ranging from 50 to 250 kilograms. It is commonly used in gold mining, refineries, and metal recovery for melting and refining various types of metals, including precious metals such as gold and silver, as well as other non-ferrous metals like copper, brass, and aluminum.

SuperbMelt is an induction furnace manufacturer offering various models to meet different melting requirements, from small-scale to large-scale production needs.

Power Supply Parameter of Induction Metal Melting Furnace

| Model | HTF-15 | HTF-25 | HTF-35 | HTF-45 | HTF-70 | HTF-90 | HTF-110 | HTF-160 | |

| MAX input power | 15KW | 25KW | 35KW | 45KW | 70KW | 90KW | 110KW | 160KW | |

| MAX input current | 23A | 36A | 51A | 68A | 105A | 135A | 168A | 240A | |

| Input voltage | Three-phase 340V ~420V 50/60Hz | ||||||||

| Oscillation frequency | 1K~20KHz | ||||||||

| Requirement of cooling water | Hydraulic pressure | ≥0.2Mpa | ≥0.3Mpa | ||||||

| Flow rate | ≥6L/Min | ≥20L/Min | |||||||

| Temperature of water | ≤45℃ | ||||||||

Melting Capacity Parameter of Tilting Metal Melting Furnace

| Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy | Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy | |

| HMF-15 | 3kg | 10kg | 3kg | HMF-70 | 25kg | 80kg | 25kg | |

| HMF-25 | 5kg | 20kg | 5kg | HMF-90 | 40kg | 120kg | 40kg | |

| HMF-35 | 10kg | 30kg | 10kg | HMF-110 | 50kg | 150kg | 50kg | |

| HMF-45 | 18kg | 50kg | 18kg | HMF-160 | 100kg | 250kg | 100kg | |

| Remark: Above melting capacity sheet for general reference; Melting duration: When the crucible is hot,20~30min./workload; When the crucible is cold(first melt),40~50min./ workload. | ||||||||

- The electric induction melting furnace gives the flexibility to melt different kinds of metals with just a single furnace; a feature which saves you a lot of money.

- This induction metal melting furnace is crucibles are quite convenient and super fast to replace. This also saves you energy and speeds up your melting process.

- As compared with the regular KGPS furnace and electric arc furnace, the SuperbMelt IGBT technology reduces your power consumption by 15-30% at while working at optimum capacity.

- It also comes with a hydraulic tilting design which can be controlled with the aid of a remote panel trolley.

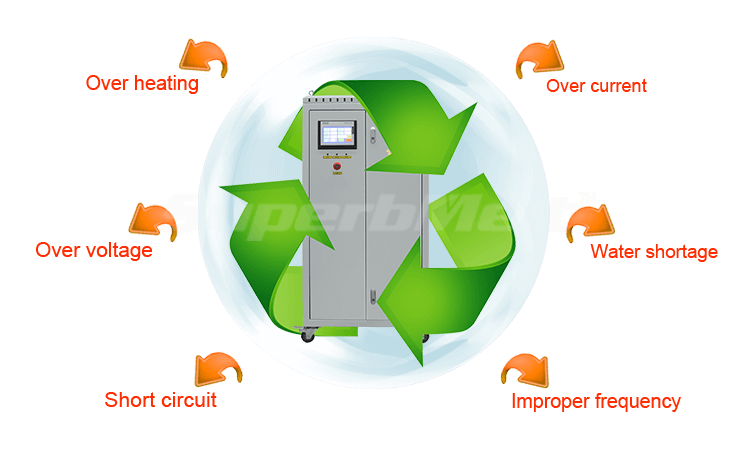

- The control system ensures that you do not go overboard with any of your input and output parameters. This feature guarantees the safety of you and your staffs.

- The omni-directional warning system ensures that you do not experience any form of system malfunction. Malfunctions such as system over-voltage, over-current, over-heating, short circuit and water shortage can easily be eliminated

- The induction melting machine can be operated continuously for 24hours. No room for downtime with this product.

- This product also comes with a magnet yoke. This yoke improves your melting efficiency, thereby saving you more energy.

An electrical furnace called an induction furnace melts metals via induction heating. Here is a quick explanation of how it operates:

Inside the induction furnace is a crucible made of a conductive material, like copper.

An intense magnetic field is generated around the crucible by running an alternating current via a coil of copper tubing.

In the crucible, the magnetic field causes an electrical current that, because to resistance, heats things up.

The metal in the crucible melts due to the heat produced by the induced electrical current.

The molten metal can subsequently be employed in other production procedures or poured into molds.

Precious metals, ferrous metals, and non-ferrous metals may all be melted in induction furnaces, among a variety of other uses. They have a reputation for being effective, quick, and temperature-controlled.

Adopt hydraulic tilting type furnace to realize the pouring of metal liquid, stability and safety.

Induction Melting

What is Induction Melting?

Using an induction furnace with a non-contact heating technique, induction melting is the process of melting metal.

The method relies on the electromagnetic induction principle, in which a coil of copper wires is subjected to an alternating current (AC), which induces a magnetic field.

The metal then experiences eddy currents due to the magnetic field, which causes heat to be produced and causes the metal to melt.

Metals such as iron, steel, copper, brass, and aluminum among others are melted using this method.

It is frequently employed in commercial settings including foundries, steel mills, and metal fabrication plants.

WhySuperbMelt Induction Furnace

Helpful Resource For Your Reference ( induction melting furnace)

More SuperbMelt Electric Induction Melting Furnaces For Your Choice

Any Question About Electric Induction Melting and Smelting Equipment

The melting point of precious metals in induction casting furnace

| Metal | Melting Point (°C) | Melting Furnace Model |

|---|---|---|

| Gold | 1,064 | 1-2kg Desktop Gold Melting Furnace |

| Silver | 961.8 | 3-5kg Gold Melting Furnace |

| Platinum | 1,768 | 1-4kg Platinum Melting Furnace |

| Palladium | 1,554 | 10kg Tilting Gold Melting Furnace |

| Rhodium | 1,966 | 20-30kg Tilting Melting Furnace |

| Iron | 1,538 | Chain Tilting Melting Furnace |

| Copper | 1,085 | Multi Tilting Melting Furnace |

User Guide for Induction Furnace

How Does an Induction Furnace Work

An induction furnace that utilizes the principle of electromagnetic induction to melt metals. Under the influence of the alternating electromagnetic field in the induction furnace, eddy currents are generated within the material, resulting in heating or melting effects. The stirring action of this alternating magnetic field ensures uniform composition and temperature of the material inside the furnace, allowing for forging heating temperatures of up to 1250°C and melting temperatures of up to 1650°C.

The induction furnace can be divided into induction heating furnaces and melting furnaces. The former is used for material melting or heat preservation, resulting in the material being in a liquid state. The latter is used for material heating, including uniform heating of the material, surface heating, or localized heating.

Its characteristics include fast heating speed, high production efficiency, minimal oxidation and decarburization, material and die cost savings, excellent working environment improving labor conditions and company image, pollution-free operation, low energy consumption, uniform heating, minimal core-to-surface temperature difference, and high temperature control precision.

Induction Furnace Manufacturers

2.1, Development History of Induction Furnaces

Induction heating is based on Faraday’s discovery of the electromagnetic induction phenomenon, where alternating currents induce eddy currents in conductors, resulting in heat generation. In 1890, Swedish technicians invented the first induction melting furnace, known as the coreless induction furnace. In 1916, an American inventor developed the core-type induction furnace, marking the practical application of induction heating technology.

The rapid development of power electronic devices and technology in the 20th century greatly contributed to the advancement of induction heating. In 1957, the milestone achievement of the thyristor, a power electronic device, marked the beginning of modern power electronic technology and revolutionized induction heating. In 1966, Switzerland and West Germany pioneered the use of thyristors in induction heating devices, leading to rapid advancements in induction heating technology.

In the 1980s, power electronic devices experienced rapid development once again, with the emergence of GTO, MOSFET, IGBT, MCT, and SIT devices. These new devices gradually replaced thyristors in induction heating equipment. Currently, IGBT and MOSFET are commonly used, with IGBT suitable for high-power applications and MOSFET for higher frequency applications. According to reports, overseas, IGBT-based induction heating equipment can achieve power exceeding 1000 kW and frequencies exceeding 50 kHz.

Induction heating technology continues to evolve and find applications in various industries, offering efficient and precise heating solutions for a wide range of processes.

2.2, SuperbMelt Induction Furnace Manufacturers

SuperbMelt offers a wide range of gold melting furnaces for sale. At SuperbMelt, you can find the induction furnace that suits your needs, regardless of your industry or the type of metal you need to melt. Whether you require a high-capacity induction furnace or any other specific requirements, SuperbMelt provides comprehensive information to assist you.

SuperbMelt excels particularly in the field of precious metal processing. Our induction furnaces are equipped with the most reliable and advanced IGBT induction technology available in the market. Additionally, you can explore more information about jewelry processing equipment on the SuperbMelt website.

Diy Induction Furnace

Creating a DIY induction furnace is an interesting and challenging task. If you are a professional, we highly recommend attempting it. Here are the materials and tools you’ll need:

- Materials and Tools Preparation:

Furnace Container: Choose a suitable high-temperature resistant furnace container, such as ceramic or metal.

Induction Coil: Create an induction coil using copper wire, ensuring that the winding and dimensions meet the design requirements.

Power Source and Electronic Components: Select appropriate components like capacitors, inductors, and circuit boards for the power supply.

Cooling System: Consider the furnace’s cooling system to ensure efficient heat dissipation and prevent overheating.

- Steps:

Design and Fabricate the Induction Coil: Choose the appropriate induction coil based on your needs and materials, and create the coil according to the design.

Install the Induction Coil: Securely attach the induction coil in the proper position inside the furnace container, ensuring the appropriate gap between the coil and the container.

Connect Electronic Components: Connect the power source and electronic components to the induction coil, ensuring that the circuit operates correctly.

Test and Debug: Before engaging in any melting operations, perform testing and debugging to ensure the furnace operates safely and efficiently.

Practice Safe Operation: When operating the furnace, adhere to safety protocols, wear appropriate protective equipment, and keep flammable and explosive materials at a safe distance.

The above steps outline the materials and procedures required for a DIY induction furnace. However, if you are not a professional, we do not recommend attempting to build one. It is an extremely hazardous project that requires careful consideration of electrical safety and constant vigilance against high-temperature risks.

SuperbMeltgold melting machine

SuperbMelt gold melting machine holds an irreplaceable position in the field of jewelry casting. With advanced manufacturing technology, SuperbMelt not only produces high-quality melting furnaces but also enjoys a great reputation in the market. We are proud to offer 24-hour technical support to our customers, ensuring their continuous success.

how to smelt gold at home?

Get a smelting furnace: You may buy one or build one using a steel drum and a few other components.

Get your supplies ready. To melt down the gold, you will need to get gold ore or scrap gold. Ensure that it is clean and impure-free. To assist remove contaminants from the gold, you will also need flux.

Set up your smelting furnace: To set up and test-drive your smelting furnace, go to the setup instructions that came with it.

Materials to be added to the furnace: Using a crucible or tongs, add the gold and flux to the furnace. Make sure the furnace is not overloaded.

Start the smelting procedure by turning on the furnace and letting it warm up. The impurities will melt and separate from the gold as it starts to melt.

Impurities should be eliminated: After the gold has melted, impurities should be removed using a skimmer or tongs.

Pour the molten gold into a mold to cool and solidify. After the impurities have been eliminated, gently pour the molten gold into the mold.

where can i get my gold melted down?

Local jewelers: Given that they frequently utilize gold to make jewelry, many neighborhood jewelers provide services for melting and purifying gold.

Companies that specialize in the smelting and refining of gold include a large number of refineries. Typically, these businesses will purchase your gold at market value, melt it down, and purify it for future sale.

Many online gold buyers are available to purchase your gold and melt it down for resale. But it’s crucial to do your homework and pick a reliable buyer.

Working with a precious metals trader is something you might want to do if you have a significant amount of gold to melt down or sell. These dealers often acquire gold in bulk, melt it down, and then sell it.

Smelting at home: In order to smelt gold at home, you must purchase a small smelting furnace and take precautions before smelting.

how to separate silver from other metals?

Cupellation is a time-honored technique for separating silver from other alloying metals. Silver is extracted from the other metals in the alloy by heating it in a special furnace and separating it as lead oxide.

Chemical precipitation: This process separates silver from other metals through chemical processes. Adding salt, for instance, can cause silver chloride to precipitate out of a silver solution, leaving behind other metals.

In the electrowinning process, silver is separated from other metals in a solution using an electric current. The silver ions in the solution travel toward the cathode, where they are deposited, as a result of an electric current flowing through a cell having an anode and a cathode.

Leaching with cyanide is a technique for separating silver from other metals in an ore. The ore is reduced to a fine powder and combined with a sodium cyanide solution. Silver is dissolved by the cyanide and may then be extracted from the other metals.

how to make silver coins?

The first stage in designing the coin is to come up with a design, which can be done by an artist or a graphic designer.

Making a master die: After the design has been decided upon, a master die is made by utilizing a specialized machine to engrave the design onto a piece of metal.

Making a working die: A working die is formed by stamping an impression onto a softer piece of metal with the master die.

The working die is then used to stamp the image onto a blank silver coin, which is usually composed of an alloy of silver to increase durability.

Finishing the coin: To improve its beauty and prevent tarnishing, the coin may be polished, plated, or given other finishes after it has been struck.

what temperature does platinum melt?

The melting point of platinum is about 3214 degrees Fahrenheit or 1768 degrees Celsius.

How to Choose The Right Melting Furnace?

There are crucial things that you must take into account if you want to invest in the best melting furnace. To help you stay on the correct path as you work on developing and establishing your business, we’ve included some of them below.

1.Based on Gold Capacity

You must keep capacity in mind if you want to get the best electric induction furnace. For instance, there are melting devices designed to melt 5 kg, 10 kg, 30 kg, and even 500 kg of metal. It is crucial that you consider the size of output you are considering while making this choice.

However, it is advised that you take into account choosing an induction furnace with a large capacity if you intend to conduct a large-scale production. You can make due with one with a lesser capacity if you don’t anticipate producing a lot. It is also true to say that the majority of goldsmiths favor utilizing the tiny gold smelter because of the extra benefits it offers.

2.Depending on the business model of the consumer

We suggest that small-scale gold miners, goldsmiths, and jewelry stores think about employing the micro gold melting equipment. It has several other benefits in addition to its compact size. It may quickly melt gold. However, with improved chain tilting and melting furnace, you could achieve that if you need something that can withstand heavy application. We at SuperbMelt advise that you think about employing a hydraulic tilting melting furnace if you have more than 50 kg of gold that has to be melted. You can still use a motor tilting melting furnace if you don’t like it.

3.Personal Finance

As a businessperson, it’s crucial that you stick to your spending plan. Make sure you have control over the money entering and leaving your company. Therefore, as you search for the best electric induction machine, begin by creating a realistic budget. You may determine what the company can afford at any one time using your budget. There are many different kinds of melting machines, but how effective and simple they are to use depends greatly on their price. It is not a good idea to purchase anything that your company might not require, though. As an illustration, consider a costly and power-intensive item.

4.Think about durability

In order to save as an investor, you must consider the long-term costs or expenses your company may face in order to survive. For instance, if your company wants to purchase a new induction melting furnace, it must be a durable one. This shouldn’t imply a trade-off between price and quality. Despite the fact that both aspects are equally significant, one is more significant. By purchasing a machine that will last long enough, we are hoping to prevent the company from having to spend additional money in the future. It is essential to invest a little extra money on an induction furnace to avoid taxing the company with frequent problems that cost money to address.

5.Usability

Only if a machine is simple to operate will it benefit the business. For instance, it is crucial to select an electric induction furnace that offers superior services and is easy for people to operate. Although we at Superbmelt tend to concentrate on cutting-edge technology, we also make sure that all of our products have user-friendly features. This is due to the learning curve’s potential length, which might take some time. Production need to be taking place rather than instruction on how to use a certain equipment. For this reason, our firm makes every effort to exclusively produce equipment that are straightforward enough to satisfy current demands without being overly complex.

6.The Company’s reputation

There are several businesses nowadays that advertise that their induction machines are the finest for melting and smelting gold and other ferrous and non-ferrous metals. Otherwise, the majority of them are not worth your money in terms of reputation. Some companies produce subpar machines that won’t satisfy your needs. A wise businessman would only purchase goods from reliable vendors like SuperbMel. They put their products through thorough testing before releasing them into the market to make sure they adhere to all industry standards needed by contemporary consumers. Visit a specific company’s official website and read the evaluations written by its current and former clients to determine whether or not it is a good business.To discover more about SuperbMelt, you may follow the same steps.

7.Space Available for Work

It’s crucial that you get an induction furnace that complements the characteristics of your workstation. There is a strong likelihood that you have infinite room if you are a big gold miner. Therefore, you are free to make an investment in a sizable machine that will quickly produce refined gold. On the other hand, there aren’t many places for melting or smelting at modest jewelry stores. They should only try to concentrate their efforts in these situations on purchasing compactly constructed induction furnaces. These remain incredibly dependable while not being overly space-demanding. Before you get in touch with your preferred manufacturing company, consider this crucial factor.

8.Maintenance costs

The best induction melting furnace producers will always provide you goods that are very practical and unlikely to malfunction. However, since every machine will eventually malfunction, repairs shouldn’t be too challenging. Unfortunately, not all manufacturers can live up to these expectations. This illustrates why you should use caution while choosing a vendor. Easy-to-repair induction machines that are also reasonably priced are good induction machines. Keep in mind that if your machine requires regular maintenance, it won’t be generating any income for you.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited