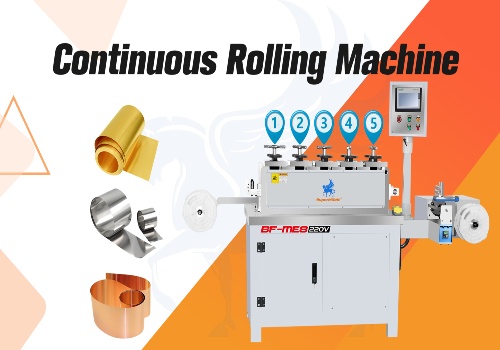

Continuous Electric Rolling Mill Jewelry

Chinese Manufacturer of High-efficiency Automatic Rolling Mills for Jewelry Industry

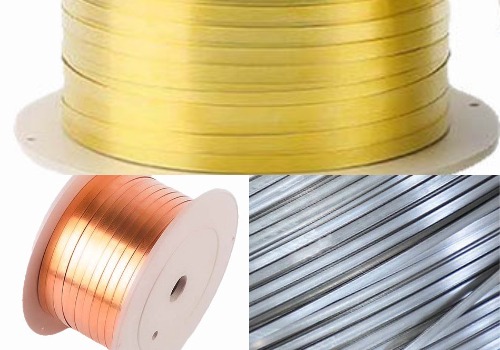

SuperbMelt Electric Rolling Mill Jewelry is used in the jewelry industry to produce sheets of gold, silver, platinum, and palladium. With 5 to 6 sets of rollers pressing simultaneously, it achieves the desired thickness of the material in one go. This is much more efficient and precise compared to traditional manual rolling methods!

Currently, this technology is still relatively unknown in the jewelry manufacturing industry. SuperbMelt is dedicated to the research and innovation of jewelry manufacturing machinery, helping jewelry processing factories achieve better results in jewelry manufacturing with the Electric Rolling Mill Jewelry!

The Electric Rolling Mill Jewelry is developed and produced by SuperbMelt specifically for medium to large-scale jewelry industries. It can be used to manufacture hollow tubes made of various materials such as gold, silver, copper, platinum, and aluminum, which are then made into bracelets and rings. It can also be customized into coins or gold bars in a block state of certain thickness.

Multiple Rollers Work at The Same Time

5-6 sets of rolls press and roll the material together, and it can be formed once in a short time, the efficiency is very high. Compared electric rolling mills require at least two workers to work together, this function realizes single-person to operate and makes mass production easier.

It solves the problems of high labor cost and low output in most medium and large jewelry factories.

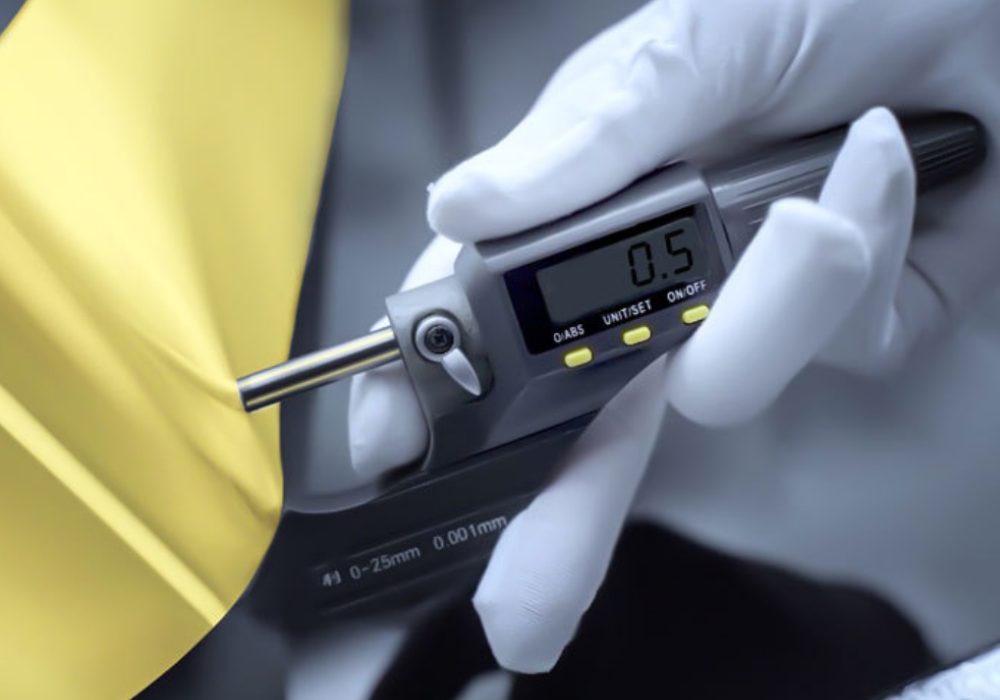

High Precision

The performance of the machine is stable, and the thickness of the finished product is accurate, the minimum can reach 0.5mm. The overall finished product is uniform and smooth, also the quality is very high.

PLC Control System

Separate and movable PLC control system with simple interface and high-sensitivity touch screen. After setting each parameter, it can work with one button. The operation is very simple, which not only saves complicated debugging, but also saves the training time and cost of employees.

Infrared Sensor

When the infrared ray detects that there is no material entering, the rolling will stop. The use of this function ensures the safety of the operator, at the same time does not waste the energy consumption of machine, so can better protect the machine rolls. And it also serves as a reminder, allowing workers to release materials and work more smoothly.

High Hardness HRC63 Finale

The finale is made of high-quality imported materials, which can be customized according to the customer’s finished product requirements, such as tungsten steel material, which can make the finished product extremely smooth and shiny. You can go directly to the next step of production without post-processing.

Remote Feeding

There is no need to manually feed the sheet like traditional electric rolling mills, so the risk of job injury is avoided, and the remote control operation is more convenient and simple, which saves manpower and material resources and is more efficient.

Automatic Winding

The machine is equipped with an automatic rewinding and unwinding device, which can be done automatically when the material is put into the slot. This device not only saves the labor of the workers, but also avoids the operation risk caused by manual rewinding, and also protects the complete smoothness of the material.

Automatic Oil Lubrication System

The oil will be supplied automatically inside the machine without manual operation, which makes the work more convenient and more humane. While ensuring the quality of the finished product, it also prevents the roll from being damaged due to excessive friction.

This machine is developed for the jewelry industry. It can press various gold, silver, copper and K gold materials. It is an efficient jewelry making machine favored by medium and large jewelry manufacturers and raw material processing factories.

The jewelry continuous rolling mill deforms metal materials such as gold, silver, copper, platinum, etc. under super pressure, from lumps to thin sheets or other required thicknesses, suitable for raw material processing plants and jewelry rough production.

All kinds of jewelry styles seen on the market today are inseparable from the use of electric rolling machines, such as hollow bracelets, beads, rings, and commemorative coins. It is necessary to press the raw material into a suitable size through an electric rolling mill, and then use a welded pipe machine, bracelet shaping machine and hydraulic press to make exquisite jewelry products.

| Model | SPB-LY5D | SPB-YP-60P-6 |

| Power Supply | 380V | 380V |

| Power | 7.5KW | 45KW |

| Final Shaft Size(D*L) | 120*80mm | 140*210mm |

| Largest Thickness | 5mm | 5mm(Gold) |

| Thinnest Sheet Thickness | 0.5mm(Gold) | 0.5mm |

| Optimum Sheet Width | Within a 30mm | Within a 60mm |

| Speed | 0-18RPM(Adjustable) | 0-12m/min |

| Roll Passes | 5 groups | 6 groups |

| Overall Dimensions | 1230*680*1250mm | 3500*1150*1520mm |

| Machine Weight | 700kg | 4500kg |

High Precision

The precision of the sheets produced by the continuous rolling machine is very high, the minimum can reach 0.5mm.

Infrared Sensor

It will automatically stop when it senses that there is no material, saving energy and protecting the machine

Automatic winding

It can save manpower and avoid operating risks, and can also protect the smooth integrity of materials

Why SuperbMelt Electric Rolling Mill for Jewelry

Any Question About SuperbMelt Electric Rolling Mill for Jewelry

Guide of SuperbMelt Electric Rolling Mill for Jewelry

What Products are Suitable for Jewelry Continuous Rolling Mill?

Metallic Material

There are also many types of metals that can be used, especially suitable for metals with good ductility, such as gold, K gold, silver, copper, and aluminum. These materials are metals commonly used in jewelry making.Metal Size

This continuous rolling mill is suitable for products that require high precision. The maximum material to be processed can reach 5mm, and the minimum thickness of the finished product can reach 0.5mm, which meets the size requirements of most jewelry production. In addition, the size of the incoming and outgoing materials can be adjusted according to the needs of customers, so as to adapt to the production of some personalized styles that are rare in the market.Finished Shape

If you need a machine that focuses on making metal sheets and pursues high-efficiency batches, this one is very suitable. It has 5 rails and 6 rails to choose from, and it can be formed at one time to meet the needs of mass production. Manual feeding is not required, and one machine only needs one worker to complete all operations.Jewelry Type

Our common jewelry styles include exquisitely carved gold and silver beads, pure gold or platinum diamond rings, and classic hollow bracelets, all of which need to go through the step of sheet press production. After the sheet is completed, the material can be made into hollow tubes by using a pipe welding machine , and then use a bracelet forming machine to turn into a bracelet or ring ,or use a hammer bead machine to divide the hollow tube into individual beads.How Does the Jewelry Continuous Rolling Mill Work?

The appearance of the electric tandem rolling mill is quite different from the ordinary electric rolling mill, but the working principle is basically the same. However automation level and efficiency of the electric rolling mill is higher. So how does it operate and what needs to be paid attention to when operating, please see the detailed description below:

1,1 Working Principle

The jewelry rolling machine generates friction between the roller and the metal workpiece when it rotates, so that the metal raw material is dragged into the gap between the two, and then the workpiece is shaped by extrusion and extension. The 5- and 6-track electric rolling mills are equivalent to adding several sets of finale on this basis, reducing the size in turn, so that the raw materials can be formed at one time. Its efficiency is 5 times that of ordinary electric rolling mills.

1,2 Operating Procedures

Step 1: Prepare Before Working

- A staff member needs to be assigned to the post to check whether the automatic lubrication device is normal

- Prepare the material, measure the thickness and width of the material to ensure that it can meet the range of use of the continuous rolling mill

Step 2: Start Work

- Turn on the main switch of the machine power supply, set the parameters, and fix the material at the feeding port

- Use the remote control to feed the material into the machine in a jog manner

Press the rolling button, the machine runs normally, and when the finished product comes out, it is fixed in the winding device to realize automatic winding.

Step 3: End Work

Turn off the power, take out the finished product to check the quality and measure whether the thickness is accurate

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited