Electro Polisher

The ultimate solution for jewelry polishing.

- 360° Polishing Without Dead Angles

- Polishing up to 20-138 pieces of jewelry in a single cycle.

- Electropolishing uniformly processes complex and small jewelry components.

- The speed is more than ten times that of traditional methods, significantly improving production efficiency.

Apply Our Best Quotation

Electro polishing has become an essential process in the jewelry industry, offering several key advantages that significantly enhance the quality and efficiency of jewelry production. This advanced technique outperforms traditional polishing methods, making it the preferred choice for modern jewelers.

Electro polished jewelry can achieve a mirror-like finish that is smoother and more reflective than traditional mechanical polishing. The process ensures consistent material removal from the jewelry’s surface, providing a 360-degree uniform finish with no dead angles.

In today’s competitive jewelry industry, the ability to deliver high-quality products quickly and consistently is crucial. Electro polishing plays a critical role in achieving this goal, making it an indispensable tool for modern jewelers. It enhances the aesthetic appeal and durability of jewelry, solidifying its position as the preferred technique in the industry.

SuperbMelt offers comprehensive jewelry production solutions, including the most advanced electro polishers. With extensive experience in the jewelry industry, SuperbMelt provides the equipment and expertise to help businesses optimize their production processes. Whether you want to replace traditional methods or enhance your existing production line, SuperbMelt has the tools and knowledge to support your success.

Various Electro Polisher

Electro Polishing Machine

SuperbMelt Electro Polishing Machine can simultaneously complete the no-dead-angle polishing of 20-138 pieces of gold、silver and copper jewelry rings and bracelets, enhancing the aesthetic appeal of the jewelry while also boosting your production efficiency. It is an ideal choice for jewelry processing plants and electronic component manufacturing facilities.

Parameter

- Power:4.5kw Max 300A

- Machine hook:138psc

- Batch productioncapacity:Silver: 97.5kg Copper:97.5kg K gold:75kg

Electro Polishing Machine For Gold Jewellery

This electrolysis equipment is compact in size, affordable in price, and suitable for small-scale jewellery businesses and individual jewellery shops.

The machine can achieve 360° no-dead-angle polishing, ensuring the integrity of the jewellery appearance compared to traditional polishing methods.

- Power:2.3kw Max 150A

- Machine hook:60psc

- Batch productioncapacity:Silver: Silver: 52kg Copper:52kg K gold:40kg

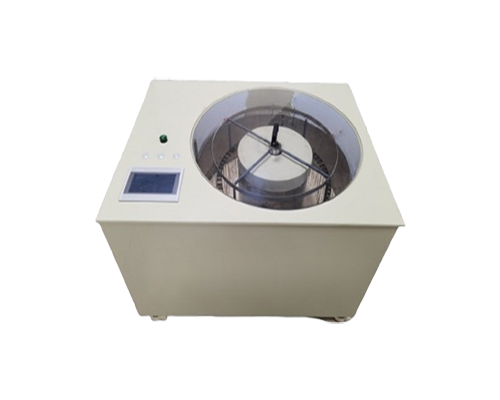

Small Jewellery Polishing Machine

- Efficiency: Compared to traditional polishing, electropolishing can complete the polishing process much faster, over ten times the speed of traditional methods, significantly enhancing production efficiency.

- Low Cost: This method can polish hundreds of jewelry pieces at once, reducing labor costs compared to traditional polishing, and also minimizes physical wear on the products, thereby lowering costs over the long term.

- High-Quality Finish:Electropolishing uniformly treats complex and small jewelry parts, ensuring every corner is precisely polished, improving the overall quality and aesthetics of the finished product.

Parameter

- Power: 1kw Max 50A

- Machine hook :20Psc

- Batch productioncapacity:6.5kg Copper:6.5kg K gold:5kg

Jewellery Liquid Polish Machine

SuperbMelt Jewellery Liquid Polish Machine can simultaneously polish three different types of metal jewellery (K gold, silver, copper), with a maximum capacity of 20 pieces for each metal type. This significantly increases the speed of processing jewellery to meet your production needs.

The Jewellery Liquid Polish Machine can polish 60 pieces of jewellery at once, including rings, necklaces, bracelets, etc., made of gold, silver, copper, K gold, and other metals. Compared to traditional mechanical polishing, this equipment offers clear advantages such as no-dead-angle polishing, high single-batch output, and low polishing costs.

Parameter

- Power:2.3kw Max 150A

- Machine hook:20*3pcs

- Batch productioncapacity:Silver: Silver: 52kg Copper:52kg K gold:40kg

Centrifugal Disc Finishing Machine

SuperbMelt Centrifugal Disc Finishing Machine can polish hundreds of jewelry pieces, including rings and necklaces, at once, making their surfaces smooth and clean.

- Compared to manual sandblasting, this machine is much more efficient, capable of polishing hundreds of gold, silver, and copper jewelry rings at once.

- The longer the polishing, the better the final product. Generally, it takes 2-3 hours to complete a batch of hundreds of jewelry rings.

Parameter

- Power: 750kw*3

- Machine hook :18L*3

- Required:crysrock grind material 200KG walnut grind 300kg polishing paste 50kg

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Electro Polisher

About Guide to the SuperbMelt Electro Polisher

What is Electro Polishing?

Electropolishing, also known as electrochemical polishing, is a metal finishing process that removes a thin layer of material from a metallic workpiece. It is done by submerging the metal in an electrolytic bath and applying an electrical current. This process smooths, deburrs, and brightens the surface, creating a clean and polished finish.

The main purposes of electropolishing are to:

- Enhance Surface Finish: It removes surface imperfections, leading to a shiny, mirror-like appearance.

- Improve Corrosion Resistance: By removing surface contaminants, it helps increase the metal’s resistance to corrosion.

- Deburring and Smoothing: It eliminates micro burrs and sharp edges, making the surface smooth and safe to handle.

- Cleaning and Passivation: It cleans the metal surface, removing oxides and other impurities, and helps in passivating stainless steel, making it less reactive to environmental factors

Electropolishing is widely used in industries such as medical devices, aerospace, food processing, and jewelry manufacturing due to its ability to produce high-quality, consistent finishes.

Why Choose Electro Polishing?

- Superior Surface surface: Electropolishing produces a mirror-like surface that is smoother and more reflective than conventional mechanical polishing. It leaves a surface with less roughness by eliminating micro-burrs and flaws.

- Enhanced Corrosion Resistance: Electropolishing improves the corrosion resistance of metals, particularly stainless steel, by eliminating surface imperfections and pollutants. In applications where metals are exposed to severe conditions, this is crucial.

- Enhanced Hygiene and Cleanliness: Electropolishing leaves a passive surface clean and clear of imbedded impurities. This is especially crucial in sectors where hygiene is critical, such food processing, medicines, and medical equipment.

- Better Mechanical Properties: The procedure may also reduce surface tension and lengthen the metal components’ fatigue life, which increases their toughness and longevity.

- Aesthetic Appeal: Electropolishing produces a brilliant, shining finish that improves the metal goods’ visual appeal, which is why it’s a popular option for jewelry and ornamental items.

- Versatility: Electropolishing is an adaptable option for a variety of applications since it works with a broad spectrum of metals, including copper, brass, aluminum, and stainless steel.

In highly regulated areas in particular, opting for electropolishing instead of conventional procedures may result in improved product quality, extended component life, and industry standard compliance.

Industries Suitable for Electro Polishing Machines

Medical and Pharmaceutical: In these sectors, cleanliness and biocompatibility are crucial. Electropolishing is used to finish surgical instruments, implants, and pharmaceutical processing equipment, ensuring that surfaces are smooth, free of contaminants, and highly resistant to corrosion.

Food and Beverage: Electropolishing is employed to finish stainless steel surfaces in food processing and packaging equipment. The smooth surfaces resist bacteria build-up, making them easier to clean and ensuring compliance with hygiene standards.

Aerospace and Defense: In aerospace applications, electropolishing improves the durability and fatigue resistance of critical components like fasteners, landing gear, and engine parts. The process enhances the mechanical properties and corrosion resistance of metals used in harsh environments.

Automotive: The automotive industry uses electropolishing for parts that require a high-quality finish and enhanced performance, such as exhaust systems, fuel lines, and other components exposed to corrosive environments.

Jewelry and Decorative Arts: In jewelry making, electropolishing provides a high-gloss, reflective finish, enhancing the visual appeal of precious metal items. It is also used for fine detailing and finishing complex designs.

Semiconductor and Electronics: Electropolishing is utilized to finish components used in semiconductor manufacturing, such as wafers and microelectronic devices. The process ensures that surfaces are smooth, free of contaminants, and have enhanced electrical properties.

Marine and Offshore: Components used in marine environments benefit from electropolishing due to its ability to improve corrosion resistance, especially for parts exposed to saltwater and harsh conditions.

Key Benefits of Electro Polishing in the Jewelry Industry

- Excellent Surface shine: Jewelry items that have been electropolished have a high-gloss, mirror-like shine that increases their visual attractiveness. The smooth and shiny surface that is required for fine jewelry may be achieved more successfully with this approach than with conventional mechanical polishing techniques.

- Enhanced Durability and Corrosion Resistance: Electropolishing reduces surface defects that might cause corrosion by removing a thin layer of material from the surface. Jewelry that has undergone this treatment is more resistant to tarnish and has a longer lifespan.

- Precision and Uniformity: elaborate intricacies and tiny fissures in elaborate jewelry designs are evenly smoothed out by electropolishing. This consistent polishing process guarantees that even the most fragile parts of a piece are flawlessly polished without running the danger of overpolishing or breaking the object.

- Time and Cost Efficiency: Electropolishing is quicker and more effective than hand polishing, enabling jewelers to work on many pieces at once. Because of its effectiveness in lowering labor costs and speeding up production, large-scale jewelry manufacture can afford to use it.

- Biocompatibility: Electropolishing improves biocompatibility by eliminating impurities and guaranteeing a smooth, clean surface that reduces the possibility of allergic responses for jewelry made of medical-grade materials or products meant for body piercings.

FAQ Guide of Electro Polisher

1. How long does electropolishing take?

It usually takes 2-20 minutes depending on the amount of metal you need to polish.

2. Can electropolishing remove rust?

Yes, rust on metal surfaces may be removed by electropolishing. Rust (iron oxide) and other surface impurities are removed off the metal surface in a thin layer during the electropolishing process. A spotless, polished surface is the result of this operation. It is important to remember that electropolishing is not a replacement for appropriate rust prevention techniques, even though it may eliminate rust and enhance the surface gloss. Electropolishing is not primarily utilized for rust removal; rather, it is intended to improve the surface qualities of stainless steel and other metals.

3. What solution is used for electropolishing?

Acid mixtures are usually used in electropolishing, with phosphoric and sulfuric acid being the most popular combination. This acidic solution’s precise composition may vary based on the metal being polished, but it is necessary to dissolve the metal surface during the electropolishing procedure. The metal’s surface is smoothed and brightened by the acid solution and electric current working together to remove a small layer of substance. Additional chemicals might be added to the mixture to improve performance or accomplish certain goals.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited