Gold Bar Mold

As a top graphite molds supplier, Superbmelt provides various molds for gold/silver/copper casting

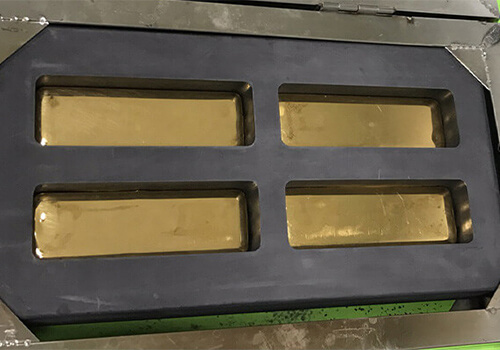

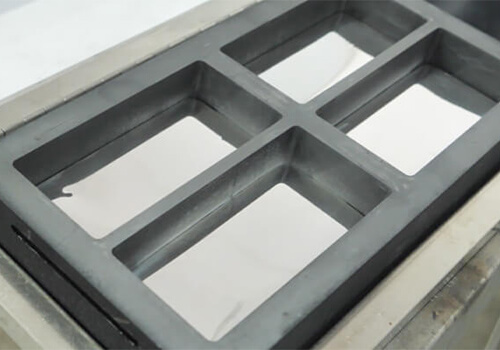

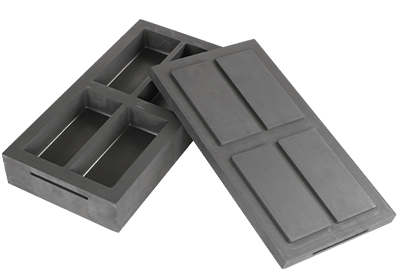

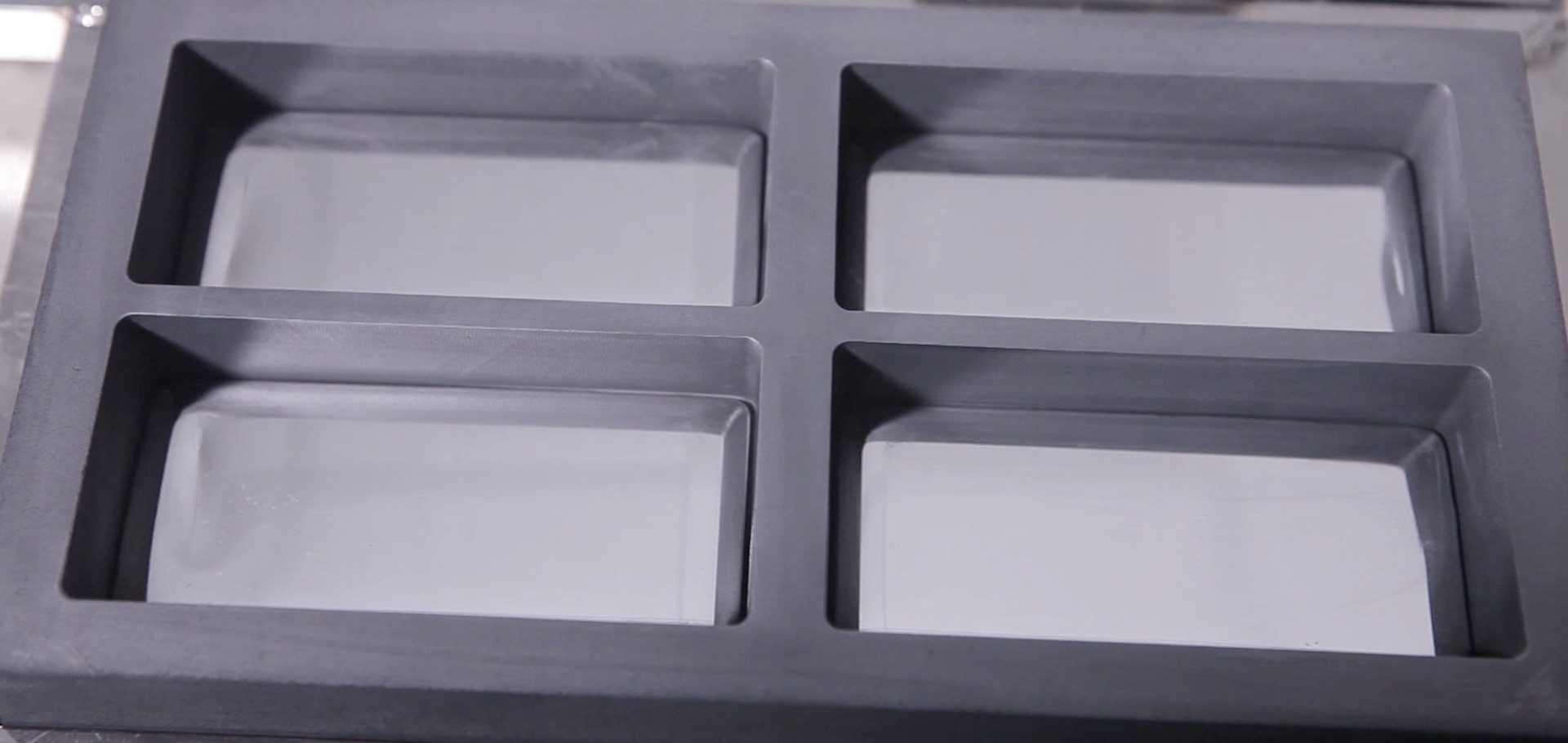

Superbmelt gold bar molds are made of high quality graphite that are specially made for casting precious metal ingots in a vacuum gold bar casting machine. The gold bar molds come in different sizes and forms. There are four in one bar molds, two in one bar molds and single bar molds that are all accompanied with a lid. The bar molds are suitable for all gold ingot casting capacities; small, medium and large, ranging from 100g to 1kg.

Superbmelt gold bar molds are often made with fine grain graphite that is machined from solid graphite forced out in the form of bars and has a very smooth finish that makes precious metal ingots to have smooth and clean appearance. The graphite mold is used to make ingots of gold, silver, copper, platinum and other metals.

Gold bar mold’s durability makes them highly recommended and usable for casting ingots in precious metal foundries and other mechanical industries. The gold bar molds are highly durable and cost effective for all industries.

Superbmelt gold bar molds have these exceptional properties; excellent thermal resistance, corrosion resistance, good thermal conductivity, resistance to acidity and alkalinity, impact resistant, energy saving and ingots are easily removable after casting. Ingots cast with the gold bar mold are of high quality and long lasting.

- Superbmelt gold bar mold has a good thermal stability and it is suitable for emergency heat and cold usage conditions.

- The mold has a good corrosion resistance, acid and alkaline resistance. This means that the gold bar mold is capable of casting whatever metal irrespective of its chemical properties.

- Precious metals are not contaminated when cast with a gold bar mold because all physical and chemical properties of the mold are tightly fused together.

- The smooth cavity finish of the gold bar mold makes it very convenient to remove gold ingots after casting.

- The gold bar mold has a good thermal stability that can withstand high temperature of molten metals that needs to be cas. The mold does not expand or shrink in size when it comes in contact with heat.

- Gold bar molds are widely used in foundries, metallurgy, chemical, mechanical and electrical power industries. It is also applicable in continuous casting mold, pressure foundry mold, glass molding with die, sintering mold, centrifugal casting mold, smelting gold and silver.

- Gold bar molds are made from high density fine grain graphite that makes it suitable for multiple casting capacity in one mold.

- The ashes of graphite (i.e. the components of the gold bar mold) is less than 0.1%, which means that your precious metals do not get contaminated during the casting process.

- Superbmelt gold bar mold can be used as graphite crucible melting into nonferrous metals, test analysis and as ingot mold.

- Our gold bar molds are one of the most heat resistant materials that have a good thermal shock, no cracks will occur on your mold when the temperature is hot or cold.

- Excellent thermal conductivity and conductive properties are topnotch features of the gold bar mold.

- The mold good self lubrication that makes the gold bars easily removable after casting and abrasion resistance.

Melting gold dust into molten gold with a propane torch can be done in a gold bar mold. This is a common practice among small makers of jewelries. Melting of gold in a gold bar mold is only possible because the mold is able to withstand high temperature.

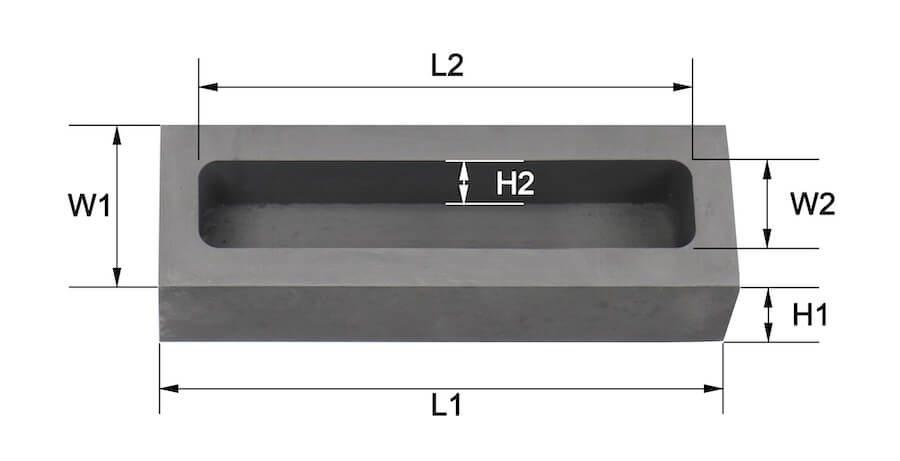

| Description | Model | Size | |||||

| L1 | W1 | H1 | L2 | W2 | H2 | ||

| 100g graphite ingot mold | G.GI.Y0100 | 55 | 40 | 20 | 35 | 20 | 10 |

| 200g graphite ingot mold | G.GI.Y0200 | 70 | 45 | 20 | / | / | / |

| 250g graphite ingot mold | G.GI.Y0250 | 67 | 50 | 26 | 47 | 25 | 16 |

| 300g graphite ingot mold | G.GI.Y0300 | 70 | 57 | 20 | / | / | / |

| 400g graphite ingot mold | G.GI.Y0400 | 75 | 67 | 20 | / | / | / |

| 500g graphite ingot mold | G.GI.Y0500 | 70 | 67 | 26 | 50 | 47 | 16 |

| 1kg graphite ingot mold | G.GI.Y1000 | 135 | 42 | 32 | 115 | 22 | 22 |

| 2kg graphite ingot mold | G.GI.Y2000 | 160 | 48 | 38 | 140 | 28 | 28 |

| 3kg graphite ingot mold | G.GI.Y3000 | 175 | 52 | 42 | 155 | 32 | 32 |

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Graphite Gold Bar Mold

As a professional graphite mold manufacturer, it is our responsibility to provide you with the highest quality graphite mold

High Quality

Any Question About SuperbMelt Graphite Gold Bar Mold

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

How to Choose Graphite Mold for Casting: Gold Bar Mold Buying Guide

What Materials of Gold Bar Molds Are in the Market?

Casting is generally defined as the process of forming a substance into a specific shape using a mold. Gold and silver bars have to be formed in gold bar molds before they can be appreciated for their value. Precious metals need to be cast in a mold before they can be stored, sold, invested or transformed for other uses.

There are however different materials that are used to cast precious metal bars. Metal casting employs a variety of casting materials and metals to create the molded end product and dates back to many years. The following properties are desirable with an ingot bar mold material:

- High strength and toughness at elevated temperatures and good thermal conductivity, which means good resistance to thermal shocks, thermal cycling and oxidation.

- Insignificant shrinkage during solidification and good workability.

1.1, Cast iron mold

Cast iron molds are usually formed from gray cast iron material because it has about a good resistance to repeated temperature changes. Cast iron molds are made of steel, iron or copper, they are used for casting precious and nonferrous metals into rectangular forms. The working temperature of cast iron mold is between 1250 to 1300 degree celsius.

In permanent mold casting, also called diecasting, here, a desired shape is machined from cast iron or steel. If molten metal flows into the mold by gravity, the process is called permanent mold casting. If the molten metal is forced under pressure, the process is called die casting. Die casting dies are water cooled, consequently, they can produce parts with thinner walls at a higher rate than permanent mold machines. The rapid cooling creates a stronger part than sand casting, but ductility may be poorer due to trapped gas and porosity.

Thermal coefficient of cast iron is lower than steel as a result, steel on solidification contracts more on cast iron which makes removal of ingot easier from the cast iron bar mold. Inner walls of the mold are coated by tar or fine carbon. The coated material decomposes during solidification which prevents sticking of solidified ingots with the inner walls of the mold.

This is one of the various, precision casting methods utilizing permanent molds in which rapid solidification permits the almost immediate shakeout of castings, greatly reducing production cycle time and improving the mechanical properties of the cast parts. Since the initial cost of die is substantial, metal molds are cost effective only when many identical parts are to be made.

Gray iron is one of the most frequently used casting materials in industrial manufacturing. Accounting for a large portion of casting supply markets, it is a strong and versatile substance. Gray iron can be machined easily, tested for quality without using destructive methods, formulated to meet specific application requirements, and is cost-effective at high volumes. It is suited to a variety of applications, including those that require; damping or vibration control, high strength to weight ratio and dimensional stability.

Using cast iron for ingot casting has many defects, among which are pipe formation, blow holes, segregation, ingot crack and nonmetallic inclusions.

Pipe formation: This is caused by steel contraction upon solidification.

Blow holes: Evolution of gas during solidification of steel. Entrapment of gas produces blow holes in the cast ingot.

Segregation: Segregation is the difference in composition of steel within the ingot than some average composition.

Ingot cracks are formed due to friction between mold and ingot surface. The improper design of mold taper and corner radius cause surface cracks.

All defects mentioned above leave ingots cast to lose their value as ingots are prone to oxidation, cracks and in some cases, gold or silver bars stick to the base of cast iron mold. In order to achieve high quality gold bars, a graphite gold bar mold is recommended.

1.2, Ceramic mold

Ceramic mold is a group of metal casting that uses ceramics as the mold material. It is a combination of plaster mold casting and investment casting.

The main advantages of ceramic molds are; reusable pattern, close dimensional tolerances, thin cross sessions and intricate shapes can be cast. The main disadvantages are; it is only cost effective for small to medium sized production and ceramic is not reusable. Ferrous and high-temperature non-ferrous metals are most commonly cast with these processes, other materials that can be cast include; aluminium, copper, magnesium, titanium and zinc alloys.

Ceramic mold casting is an expendable process in which reusable and cheap patterns made of wood, metals, plastic or rubber are used. Patterns with intricate designs can be used since the molding material supports castings of complicated castings.

In ceramic mold casting, there are two different types of slurries used, which are known as the true ceramic molding and shaw process. The patterns are kept as a flask and aggregate is poured over the pattern. Molding material sets in a rubber like consistency around the pattern. The rubber like consistency makes it easy for the pattern to be stripped out of the mold. The mold which is made in cope and drag form, is heated to make it harden.

The strong mold is useful for high temperature pours, which can be done when the mold is still hot. With a creative bent of mind, ceramic molds can be designed in any imaginative shapes. The slurry used for ceramic mold casting can be made of a mixture of zinc, calcined, high-alumina mullite slurries or as in shaw process, the molding mixture consist of mixture to refractory filler, hydrolyzed ethyl silicate and a liquid catalyst.

Generally the mold is heated in an oven by combining the shaw process and the lost wax process, the advantage of both the process can be gained. High temperature pours possible therefore suitable for steels and other alloys, creative complex designs can be made, can be used for mass production, casting with accurate dimensional accuracy possible, little machining is required therefore difficult-to machine alloys can be cast, supports both industry and home foundry operations, complicate and innovative designs can be cast.

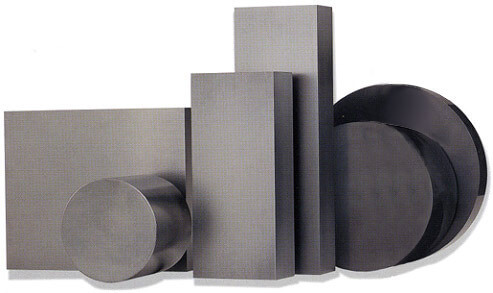

1.3, Graphite mold

Graphite molds are made of pure graphite and they are used for casting various shapes and sizes of precious metal bars in a vacuum gold bar casting machine. Although, they can also be used for casting after melting metal in a vacuum induction furnace. The graphite bar mold is used to cast gold, silver, copper, non-ferrous metals, stainless steel products, etc.

There are however some common misconceptions about graphite. A common misconception is that graphite is weak and can easily be damaged. Graphite is a crystalline structure, it is therefore very rigid and it retains its dimensions really well. Graphite is very strong and can withstand a significant amount of stress. In addition to these misconceptions, the life expectancy of a graphite mold is commonly thought to be relatively short. This is a total misconception. The metrics representing overall performance, graphite approaches the same performance as metal materials. If the reduced production cost of graphite mold is accounted for, the cost per run is far better than other materials.

Graphite bar molds has the following properties; excellent thermal shock resistance, excellent thermal conductivity and electrical conductivity, low coefficient of thermal expansion, self lubricating properties such that cast ingots are easily removable, light weight, good chemical stability and corrosion resistance to acidic and alkaline solvents.

The coefficient of thermal expansion is an important factor that determines why graphite is used as mold material. The low coefficient of thermal expansion that graphite exhibits allows the graphite bar mold to function without deforming or cracking. Another important factor is self lubrication. Graphite is a solid lubricant that allows for low friction between the mold and the cast material. Subsequently, graphite allows smooth extraction of the casting.

There are various factors determining the lifetime of a gold bar mold. From the composition of the cast materials to the casting temperature, to the cooling rates all affect the life of the graphite mold. In general, graphite bar molds can operate continuously in excess for 100 hours. Graphite bar molds can also be re-machined to smooth surfaces and used again.

Other characteristics of the graphite mold are:

Low wettability: In order to prevent sticking and breaking of cast ingots, the mold material should possess poor adhesion to the solidifying metal. It is achieved by low wetting of the mold by the liquid metal. Graphite is not wettable by most molten non-ferrous metals and alloys. Ferrous alloys wet graphite due to the reaction with carbon. Graphite is also wetted by alloys containing nickel, zinc or tin.

High thermal conductivity: Thermal conductivity of the mold material should be high enough to provide fast heat removal.

Low coefficient of thermal expansion: Low thermal expansion of the mold material helps to prevent distortion of the mold shape and secures the casting geometry.

Good machinability: Graphite is easily machine. Molds of complicated shapes with close tolerances may be obtained by milling, turning, sawing, grinding and surface finishing. Fine finish of the inner mold surface is important for decreasing material wettability and friction.

How to Choose Molds for Gold Bar Casting

2.1, The size of the gold bar

There is no single uniform size to the production of gold bars, although casting gold bars must meet the standard conditions of manufacture. Superbmelt gold bar mold sizes vary from 100 grams to 3 kilograms. Gold bar molds size and depth contributes to the size of gold bars.

The graphite gold bar mold could have four cavities in one mold, two cavities in one and a single cavity. The size of your production will determine the mold of choice. The four in one graphite gold bar mold is suitable for large ingot production where many gold bars need to be cast at once.

This helps in casting several gold bars to save production cost and time. The single cavity gold bar mold can be used for smaller casting applications. The weight of each gold bar would depend on the metal you are working with and the measurement of metal in each cavity.

Ingots are commonly round, square or rectangular in shape. Each ingot constitutes a certain amount of metal.

2.2, The production mode of gold bar

Cast gold bars are normally produced from gold that has been melted. However, production mode may vary based on the size of production, resources available, among other factors. As large gold bars are usually manufactured to an approximate weight, the method of manufacture normally varies from that adopted for casting smaller ranges of gold bars.

For massive production of gold bars, gold is melted in a large holding crucible. Induction furnaces are used to melt precious metals. By tilting the holding crucible, precious metal is transferred into a preheated transfer crucible. Using a gantry is necessary, melted gold in the transfer crucible is poured through a soft gas flame into a preheated and dressed gold bar molds. The gold bar mold, during pouring is positioned on a balance. When the balance records the required weight of gold or silver, the pouring stops. Few seconds after pouring, the gold bar mold is tilted to release the cast gold bar.

For medium and small precious bar production, refined gold which has been assayed at the required purity is converted into granules or small cut pieces. This is weighed directly into graphite gold bar molds. The exact weight of the bar is what is measured in granules and directly into molds as there is minimal loss in casting with the vacuum gold bar casting machine. The vacuum gold bar casting machine is an excellent means of casting high quality gold and silver ingots.

Usually, the amount of granules weighs slightly more than the required bar weight. This is done to compensate for any minor anticipated precious metal loss in the manufacturing process, for instance, vapourization, remains in the crucible, as well as to ensure that the final bar weight is not less than the specified weight to be marked on bar. However, when casting gold bars with the vacuum casting machine, there is little or no precious metal loss.

Casting gold bars directly in gold bar molds enable multiple ingots to be cast at the same time.

Coin casting also occurs when molten metal is being poured into a graphite coin mold or cast directly in a vacuum gold bar casting machine.

The manual method of melting gold in a furnace and pouring in a mold for casting Is becoming almost extinct as it takes time and requires more manpower for large productions. A more suitable method of casting high quality gold bars is the use of a gold ingot casting machine. The gold ingot casting machine is an automated technology for casting high quality gold and silver ingots, less stressful and does not require a large manpower before gold bars are cast.

The graphite gold bar molds fits directly in the gold ingot casting machine for ingot casting. The process of casting simply requires weighing gold or silver nuggets into graphite gold bar mold and setting all required parameters; casting is therefore complete within 15 minutes.

The outstanding benefits derived from using the vacuum gold bar casting machine include, high quality precious ingots, accurate casting operation, reduced casting time and cost of production, safety as operators are not exposed to dangerous molten metal, multiple ingots can be cast at once to save more on production time, less power use, etc.

The gold ingot mold quality and capacity makes it suitable for all ingot casting capacities, that is, from small scale ingot production to larger scale ingot production.

2.3, Purity the gold

By whatever process gold might have been extracted from its ores, it is necessary to melt the crude bullion and cast into bars so that its value may be ascertained and that it may be put into a form convenient for transportation and sale.

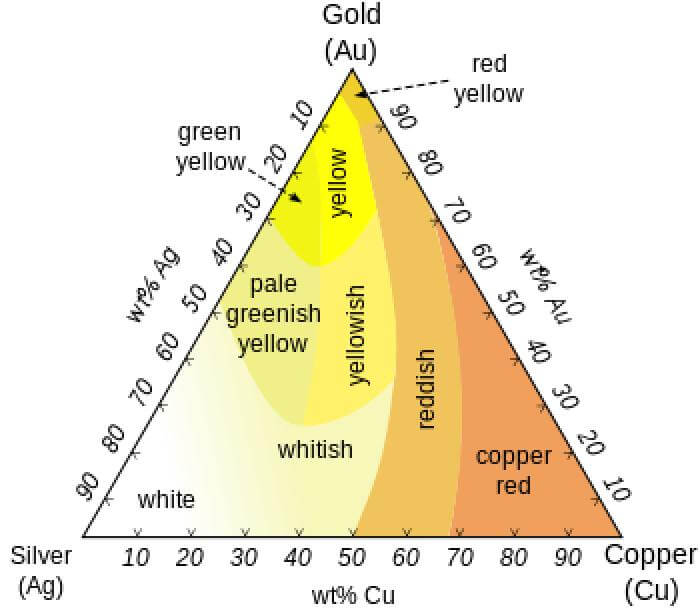

The purity of gold varies, you may have a number followed by “K”. The “K” refers to karat which is an ancient form of weight but it is now used to determine the pureness of the gold in question. For gold to be qualified as 24K, it has to have 99% of purity.

For example, 12K (which is half of 24K), would tell you a gold item has 50% actual gold inside it with the rest being other types of metals such as copper and silver. Whatever the karat value of your gold, divide it by 24 and multiply by 100 to reach the percentage of purity that your gold holds. In many countries, gold of 10K purity cannot be sold as gold jewelry.

When you understand the purity of your gold, you cannot just select any method of casting or select any type of mold that can result in contamination of gold or loss of precious metal.

When purity of gold is low, cast iron molds are used for casting ingots. However, gold with a high level of purity is cast with a graphite mold, this maintains its level of purity after casting.

2.4, Production efficiency of gold bar

Gold can be extracted from large mines or by means of artisanal mining activities, also known as small scale mining; gold has to be cast into bars of easy transportation to the next manufacturing plant, storage and also casting for other uses.

The production of precious metals into ingots is a well developed process. Typically the final result is a quantity of molten metal with the desired material consistency. The molten metal is usually poured into large molds of basic shape, ingots, or fed into a continuous casting system. Continuous casting production has the advantage of a higher rate of production, also raw metals produced can be cut into different desired lengths.

A continuous casting operation can increase industrial efficiency by being fed directly into a rolling operation. Ingot casting production is equally is a fast process, whereby molten metal is cast into graphite gold bars molds, which sits and solidifies within a quick time.

However, ingot casting can produce large amounts of gold bars using the graphite gold bar mold, with less production complications than continuous casting process. Graphite gold bar molds ensure there is no wastage of precious metals during the gold bar casting process.

For casting ingots in an efficient way, we highly recommend Superbmelt gold bar making machine. The gold bar casting machine provides only a seamless and energy conserving ingot casting operations. The machine removes stress, loss of production time, reduces manpower while increasing ingot production output and quality.

Why Choose Superbmelt’s Graphite Mold: How We Produce Graphite Mold

3.1, Control raw materials

Graphite has been used in mold production for over 50 years. Advancements in available materials have created the options that allowed graphite to be used in a variety of applications. Graphite ingot molds are commonly used in aluminum, gold and silver casting. Benefits of graphite permanent molds are realized by combining the low cost associated with machining graphite and high strength common to graphite materials.

Proper selection of the graphite grade is essential in the performance of the manufactured mold. Generally, given the relatively large porosity, extruded graphite grades are not recommended in the manufacturing of graphite ingot molds requiring fine detail. There are certain high density extruded grades that could be a solution when budget restraints or low volumes dictate an economical solution.

Most of the time, applications using fine detail graphite molds, utilize either molded or Isostatically pressed graphite grades. Both types of grades display high density and small particle size, perfectly suited for very high strength, very good gold casting finish and excellent life. Isostatically molded graphite has the best qualities for intricate mold designs and high volume runs.

The graphite materials we use for graphite bar mold production does not wrap, twist, or crack when it comes in contact with molten metal or is placed directly in the vacuum gold bar casting machine. Gold and silver bars can be cast with a higher accuracy than sand and iron molds. The graphite mold can also be stored indefinitely without changing shape, rusting, oxidizing or deteriorating in any way.

Superbmelt gold bar molds have tapered edge design for easy extraction of ingots.

3.2, Process levels that can meet different standards

We produce graphite of various densities, the level of density has its own impact on the level of porosity of graphite gold bar molds. This means that the higher the density of the graphite, the lower the porosity of the finished product and vise versa. The higher the durability of the gold bar mold product , the higher the melting and casting qualities; which also implies a longer service life.

| Grade | NX601 | NX602 | NX603 | NX604 | NX605 |

| Grain size (µm) | 25 | 25 | 25 | 25 | 25 |

| Bulk Density (≥g/cm3) | 1.55 | 1.72 | 1.80 | 1.85 | 1.90 |

| Compressive strength (≥MPa) | 35 | 45 | 60 | 65 | 70 |

| Flexural strength (≥Mpa) | 15 | 20 | 30 | 33 | 35 |

| Porosity (≤%) | 23 | 20 | 17 | 14 | 11 |

| Specific resistance (≤µΩm) | 12 | 12 | 12 | 12 | 12 |

| Ash content (≤%) | 0.08 | 0.07 | 0.06 | 0.05 | 0.03 |

| Shore hardness | 35 | 45 | 50 | 55 | 60 |

Superbmelt graphites are usually processed with 3 different technologies:

- Moulded graphite technology

Moulded means it is cold pressed by molding. It is a type of graphite that is isostatically pressed. The resulting graphite material that has excellent properties uniformly distributed throughout the entire mass without having a grain direction. Combine that with high density and small particle size, and the result is a highly engineered material, very strong, with good machinability, and capable of retaining very fine details. It is resistant to high temperatures in controlled environments, electro-conductive and has self lubricating properties.

- Isostatic pressed graphite technology

The isostatic pressing technology is a super high pressure hydraulic equipment and its working principle is that products formed under the condition of equal pressure and high pressure in all directions and closed high-pressure containers. Properties of isotropic, structural balance, high conductivity, high purity, high strength, high density, high mechanical strength; superior thermal shock, high temperature resistance, resistance to oxidation and corrosion; fine-grained, low receptivity, and easy for precision machining. The isostatic pressed graphite has the highest quality of all the three which comes with a higher price compared to the other two technologies.

- Medium coarse technology

The graphite particles are coarse this is as a result of the low compression resistance and bending resistance. The medium coarse graphite is used mostly for heat exchangers and heating elements. The medium coarse graphite is best used for frequently used crucibles and furnaces.

3.3, Precision CNC machining

Superbmelt creates this high degree of precision using computer numerical control (CNC), replacing manually operated machines, vertical millers, and lathes with a centralized automated system. CNC machines convert computer-aided design (CAD) models into mass-produced parts with as little as .0001 variation between parts. The CNC precision machines operate via advanced manufacturing technology, removing material from a solid block using a variety of cutting tools to achieve the intended design. There are three basic processes of CNC machining:

Milling: This process mounts the part onto a bed and removes material using rotational cutting tools, creating products in a wide variety of shapes.

Turning: This process mounts the part on a rotating chuck and removes material using stationary cutting tools, creating axially symmetric end products.

Electrical Discharge Machining (EDM): This process uses controlled electrical discharge to obtain desired shape.

CNC machining operates with many common materials including aluminium, stainless steel, brass, graphite and other types of metals.

The cost of building a quality graphite bar mold tool usually constitutes the most significant financial investment in the gold bar making process. Simply because millions of ingots can be cast using these molds.

It is important that we ensure the reliability and accuracy of graphite gold bar mold up front in order not to have inaccuracies and faults overtime. Using CNC machining to manufacture gold bar molds has many advantages that benefit users:

It requires few steps to produce parts, resulting in high efficiency.

The process is more precise than manual machining and can be repeated in the same manner over and over again.

The machine provides the ability to produce complex shapes with a level of precision.

Operates with advanced CAD software to produce outputs and multiple functions, that cannot manually be replicated.

Fully automated systems mean that the operator is not exposed to safety risks.

3.4, Testing

After our graphite ingot molds goes through the process of milling and CNC machining, we ensure that they are tested and free from porosity and other forms of defects. A single pore or fissure no matter how tiny can lead to cracks and render the ingot bar mold totally unusable.

The method we adopt for testing gold bar molds for the presence of undesirably large pores or fissures, is by immersing the entire graphite bar mold in water. This process reduces the atmospheric pressure over the surface of the water to a point where bubbles are observed coming from the pores in the graphite surface and visually determining the existence of any pores which yield air bubbles of a diameter sufficient to indicate an undesirably large pore or fissure in the graphite bar mold. However, if there are no bubbles, this indicates that there are no holes or pores in the graphite casting mold. Which also means they are ready for end users.

Conclusion

The equipment and tools you use in casting ingots really matters as this determines the quality of ingots, which is the reason why Superbmelt has introduced the gold bar casting machine for a smooth and efficient ingot casting process. The mold in which gold bars are cast is equally important as this contributes to the quality of ingots. The graphite ingot molds are specially designed for casting high quality ingots in a gold bar casting machine.

Graphite gold bar mold applications in a gold bar casting machine represent a good alternative to other types of molds especially when you are looking for quality, strength and durability of ingots. Graphite gold bar molds provide a very smooth and attractive finish for your precious metal bars. The gold bar casting machine represents a viable and cost effective solution for gold and silver ingot casting.

Superbmelt graphite ingot mold guarantees safety during use, able to last long even after repeated use in a gold ingot casting machine, no contamination of precious metal during casting as the graphite material is tightly fused together and the gold bar casting machine operates under vacuum conditions. The graphite gold bar molds are lightweight, compact structure and come with lids and they are convenient to carry. There are different styles for you to choose from, which can meet different needs.

FAQ Guide

What is a gold mold?

Gold molds are rectangular containers made of high quality graphite that consists of 99% and less than 0.1% of ash. Gold molds are used to cast ingots also known as bullion. Gold molds can cast ingots of various metals such as gold, silver, copper, brass, bronze, etc. The gold mold can be used for casting directly in a vacuum gold bar casting machine. It can also be used for casting after melting of metal in complete in an induction melting furnace.

What are bar molds made of?

Bar molds are often made of materials such as cast iron, ductile iron, steel, aluminium, ceramic and graphite.

How do I make mold bars?

Mold bars are simply made with cast iron, steel or aluminium. Graphite can also be used to make mold bars. Mold bar materials essentially have a higher melting temperature than the casting metal.

How do you make mold from graphite?

Graphite bar mold casting technique is a modern affordable, quick and perfect casting methodology to produce graphite molds. Superbmelt graphite goes through different processing techniques; moulded graphite technology, isostatic pressed technology and medium coarse technology. All these processes go through CNC machining for precision, high tolerances, quality and long term durability of graphite molds.

How do I make bars?

Making gold and silver bars is very easy using a vacuum gold bar casting casting machine. The vacuum prevents ingots oxidation, shrinkage and water waves. The vacuum gold bar casting machine makes use of argon, vacuum pump and chiller for an effective casting process. Casting can be done by measuring precious material and placing directly into the graphite gold bar mold. The mold is then covered with the graphite mold lid. The power main switch is switched on and parameters are set (heating time, pump run delay time, vacuum time, cooling time and alarm time). Graphite mold is placed carefully in the vacuum gold bar casting machine. Press the “auto” button to begin casting. Alarm goes off once casting is complete. Graphite mold is removed to reveal the already cast gold or silver ingots. Ingots are easily removable from graphite gold bar molds with a mirror surface. The process can be repeated over and over again.

How long does a graphite mold last?

Graphite bar molds have excellent qualities that make them last a very long time. Such qualities include; low wettability, high thermal conductivity, low coefficient of thermal expansion, high thermal shock resistance, good mechanical strength, etc.

How do you make silver bars?

Silver bars are made by measuring the desired quantity of silver material into graphite gold bar mold. The graphite mold goes through the process of melting and casting in a gold bar casting machine. Once casting is complete, the silver bars that have mirror appearance are easily removed.

How do you make a mold for casting metal?

Making a mold for casting metal requires the use of sand cast method. The sand casting process involves the use of furnace, metal, pattern and sand mold. The first step in the sand casting process is to create sand mold for the casting. A sand mold is formed by packing sand into each half of the mold. The sand is packed around the pattern, which is a replica of the external shape of the casting. When the pattern is removed, the cavity that will form the casting remains. The mold cavity is first lubricated to facilitate easy removal of the casting. The molten metal is then poured into mold. Casting is removed from sand for trimming and cleaning, although ingots cast using this method are full of defects. In order to avoid the stress of casting gold bars with sand mold, graphite bar molds are highly recommended. The only preparation required is to place precious material into mold and place in a gold bar casting machine; or pour molten metal into mold after melting. Casting ingots with graphite molds are easier, faster and casting quality is high.

How do you melt silver and gold?

Silver and gold can be melted in a melting furnace at approximately 1200 degree celsius. A graphite crucible holds the silver or gold to be melted but the crucible needs to be tempered first before melting can begin. After melting, molten gold or silver is transferred into gold bar mold.

What is the best material for making a mold?

The best material for making a mold is graphite. Graphite is the material of choice because they are resistant to thermal shock, easily machined, low coefficient to thermal expansion, high mechanical strength, good thermal conductivity, corrosion resistance, better dimensionally accurate castings are achieved at a lower rate, etc.

What is a bar mold?

A bar mold is an object that is made of graphite or cast iron and it is used to cast metal bars or gold and silver ingots.

How do you make gold molds?

Making gold and silver bars is very easy using a vacuum gold bar casting machine. The vacuum prevents ingots oxidation, shrinkage and water waves. The vacuum gold bar casting machine makes use of argon, vacuum pump and chiller for an effective casting process. Casting can be done by measuring precious material and placing directly into the graphite mold. The mold is then covered with the graphite mold lid. The power main switch is switched on and parameters are set (heating time, pump run delay time, vacuum time, cooling time and alarm time). Graphite mold is placed carefully in the vacuum gold bar casting machine. Press the “auto” button to begin casting. Alarm goes off once casting is complete. Graphite mold is removed to reveal the already cast gold ingots. Ingots are easily removable from graphite gold bar molds with a mirror surface.

Where can I buy graphite molds?

You can purchase high standard graphite molds for your business from high reputable companies such as Superbmelt. At Superbmelt, all graphite are made from only the best graphite materials that are processed with specialised technologies. All graphite bar molds produced are adequately tested to ensure that they are long lasting and cast only quality ingots.

What is a gold ingot?

Although the word is probably used much loosely, an ingot is technically a specific type of gold bar. The word refers to the process by which gold bars are manufactured; they are produced by pouring molten precious metal into a mold. The word “ingot” comes from the mold in which the bars are cast. It is this process that differentiates them from other smaller bars which are produced by minting or stamping sheets of gold bullion.

What are the types of gold bullion?

Gold bullion refers to gold that gets its value from its purity and weight, as opposed to jewelries or antiques where other factors such as aesthetics, colour, design, history come into play. Gold bullion is useful for gold investors as well as gold fabricators. Gold bars: Gold bars often take rectangular shapes, although gold bars take multitude of shapes as long as they are refined. Gold bars can be cast or minted. Gold bars that are cast are thicker and are generally called ingots. Gold that is stamped is thinner and flatter, and they are called gold wafers/biscuits. Gold bars come in many different shapes and sizes and can generally be split into 55 categories. Only about 30 types of gold bars are in general circulation around the world with the Good Delivery gold bar being the most popular. Gold bullion coins: It is often mistaken that gold coins are expensive because they are usually antiques or precious collectors items. This form of gold works exactly the same way as the metal bars, except their shape is in the form of coins and are usually much smaller. Many countries produce their gold coins with national emblems embedded onto them. The most popular ones in the market today are Eagles, Maple, Kruggerands, Pandas, Prittannias and Sovereigns. Numismatic gold coins: These types of gold coins generally do not have a fixed weight or purity to it and tend to be old gold coins that are no longer in production. This makes these gold coins have more value than their weight in gold. Unrefined gold: Gold in its original state is naturally unrefined and can take different forms. For example, gold nuggets are naturally occuring pieces of native gold that have quite large sizes and their purity ranging from 20K to 23K. Unrefined gold can also be in the form of gold dust or other types of gold deposits. Gold scrap: Gold scrap refers to any gold item that has more value for the gold inside it, than it’s worth as an item.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited