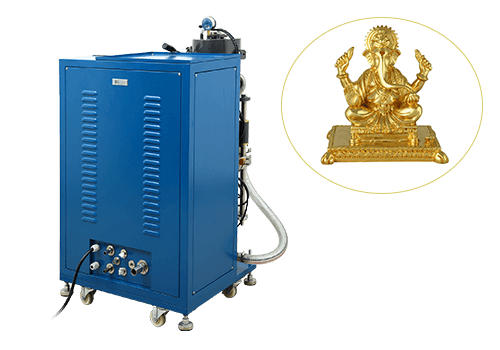

Gold Casting Machine

China Premier Jewelry Casting Machine Manufacturer

SuperbMelt Gold Casting Machine is a crucial equipment that melts gold and injects it into molds to produce various gold products, playing a pivotal role in the jewelry manufacturing and precious metal processing industries.

SuperbMelt Gold Casting Machine falls under the category of vacuum automatic casting machines, with a one-time casting capacity of up to 1-6kg (gold, silver, copper, and other precious metals).

Vacuum casting ensures the exquisite perfection of finished jewelry, making it the perfect choice for jewelry manufacturers and small-scale businesses!

| Model number | SPB-DM2 | SPB-DM4 | SPB-DM6 |

| Power source | Single phase 220V/Three phase 380V, 50/60Hz | Single phase 220V/Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 8.5 kw | 15 kw | 25kw |

| Casting system | Vacuum pressure casting system | Vacuum pressure casting system | Vacuum pressure casting system |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 3-5 min | 3-5 min | 3-5 min |

| The Max capacity | 24K Gold: 2.0 kg 18K Gold: 1.5kg 925 Silver: 1.0 kg | 24K Gold: 4.0 kg 18K Gold: 3.0 kg 925 Silver: 2.0 kg | 24K Gold: 6.0 kg 18K Gold: 4.0 kg 925 Silver: 3.0 kg |

| Max temperature control R-type | 1600℃ | 1600℃ | 1600℃ |

| Max. temp control k-type | 1100℃ | 1100℃ | 1100℃ |

| Dimension | 720×700×1150 mm | 720×700×1150 mm | 720×800×1150 mm |

| Weight | 210 kg | 215 kg | 250 kg |

| Control of temperature | by PID | by PID | by PID |

| Pressure applied | Max. 0.25 Mpa | Max. 0.25 Mpa | Max. 0.25 Mpa |

| Protective gas | Nitrogen or Argon | Nitrogen or Argon | Nitrogen or Argon |

| Vacuum pump | 63 m³/hour | 63 m³/hour | 63 m³/hour |

| Oscillation | Induction heating | Induction heating | Induction heating |

| Max flask size | D101*H254 mm | Normal D101*H254mm (Customized) | Normal D160*H254 mm (Customized) |

| Ultimate vacuum | 10hPa | 10hPa | 10hPa |

| Accuracy of temperature | ±2 degrees Celsius | ±2 degrees Celsius | ±2 degrees Celsius |

| Pressure differential casting | Y | Y | Y |

| Vacuum filter | Y | Y | Y |

| Vacuum leakage detector | Y | Y | Y |

| Flask check before casting | Y | Y | Y |

| Flask and chamber lift | Y | Y | Y |

SuperbMelt Gold Casting Machine boasts several distinctive features and advantages, making it the preferred choice for gold casting:

- Vacuum Casting Technology: It utilizes vacuum casting technology, which allows for casting in an oxygen-free environment, significantly reducing the formation of bubbles and impurities, ensuring the purity and quality of the finished products.

- High Precision and Consistency: The machine is equipped with precise temperature and pressure control systems, enabling precise control over the melting and injection of gold, resulting in highly consistent finished products.

- Large One-Time Capacity: Capable of casting 1-6kg of gold in a single operation, it suits various production scales, from small-scale customized jewelry manufacturing to large-scale industrial production.

- Exquisite and Flawless Finished Products: Vacuum casting contributes to the superior quality and flawless finish of the products, making it ideal for crafting high-end jewelry and art pieces.

- Efficient Production: The machine is user-friendly and enhances production efficiency, allowing for the completion of a substantial volume of casting work in a shorter timeframe.

- Customizability: SuperbMelt Gold Casting Machine can be customized to meet specific production requirements, accommodating the unique needs of different manufacturers.

In summary, this gold casting machine combines advanced technology with efficient production capacity, providing manufacturers with a reliable tool to produce high-quality gold products. Its vacuum casting technology and highly precise control systems set it apart in the jewelry manufacturing and gold processing fields, offering manufacturers the opportunity to create exquisite jewelry.

SuperbMelt Gold Casting Machine finds applications in a wide range of industries, including but not limited to:

- Jewelry Manufacturing: This equipment is the ideal choice for jewelry manufacturers, used to craft various gold jewelry items such as rings, necklaces, bracelets, and earrings. Its high precision and vacuum casting technology ensure high-quality and exquisite jewelry pieces.

- Precious Metal Processing: The Gold Casting Machine is not limited to gold but can also be used for casting and processing silver, copper, and other precious metals. This versatility is crucial for gold and silver processing facilities.

- Craftsmanship and Artistry: Artists and craftsmen can employ the Gold Casting Machine to create various metal craft items and art pieces. The vacuum casting technology guarantees high-quality and artistic finished products.

- Custom Manufacturing: The equipment can be customized to meet specific customer requirements, making it invaluable for manufacturers catering to diverse markets and customer demands.

In summary, the SuperbMelt Gold Casting Machine serves a broad spectrum of industries, providing manufacturers and artisans with the opportunity to produce high-quality metal products. Whether it’s crafting jewelry, or meeting specific customization needs, this equipment is a versatile and reliable tool

Why SuperbMelt Gold Casting Machine

Any Question About SuperbMelt Gold Casting Machine

SuperbMelt Gold Casting Machine Guide

How is jewelry cast

The casting of jewelry is a comprehensive process that involves multiple steps including design, model-making, casting, fine finishing, and inspection. These steps are essential to ensure the production of high-quality, exquisite jewelry pieces. Each stage requires a high level of skill and craftsmanship to meet the demands of the market and customers.

1.1, Creating wax patterns

Import the designed jewelry shape into a 3D printer and then use a 3D wax printer to print the jewelry model.

1.2, Casting

The plaster mold, along with the jewelry model, is placed inside a furnace. The wax mold is melted at high temperatures, leaving behind a hollow mold. Subsequently, jewelry manufacturers pour molten precious metals like gold or silver into the mold. Once the metal cools and solidifies, the plaster mold is removed, revealing the cast jewelry.

SuperbMewlt gold jewellery casting machine

- Centrifugal Casting Machines

- Vacuum Casting Machines

- Continuous Casting Machines

2.1, Vacuum Casting Machines

A vacuum casting machine is an indispensable piece of equipment in jewelry manufacturing. This machine creates a controlled environment by removing air from the mold, allowing molten metal to fill the mold cavity without any bubbles or gaps. Vacuum casting machines play a crucial role in producing high-quality and precise jewelry pieces.

2.2, Centrifugal Casting Machines

Centrifugal casting machines are commonly employed in jewelry manufacturing. These machines utilize centrifugal force to evenly distribute molten metal into the mold cavity, ensuring that the resulting jewelry pieces are free of air bubbles and possess a uniform density. This casting method is particularly well-suited for producing rings, bangles, and other circular jewelry items with intricate details.

2.3, Continuous Casting Machines

Continuous casting machines are crucial tools in jewelry manufacturing. These machines enable the continuous and automated production of jewelry items with consistent shapes and sizes. Molten metal is continuously poured into the molds, resulting in a continuous stream of solidified jewelry pieces. This method is highly efficient for producing jewelry components like chains and bracelets. Continuous casting machines contribute to maintaining high levels of precision and productivity in jewelry production.

2.3, Comparison

The choice between these SuperbMelt jewelry casting machines depends on your specific needs and budget. Here are some key points of comparison for these jewelry casting machines:

Vacuum Casting Machine: Ideal for high-quality and precision jewelry manufacturing. It prevents the formation of bubbles and defects, providing excellent finished products.

Centrifugal Casting Machine: A great choice for making circular jewelry items like rings and bangles. It ensures even filling through centrifugal force but may not be suitable for complex designs.

Continuous Casting Machine: Suitable for high-volume jewelry manufacturing, especially for chains and bracelets. It can continuously produce jewelry with consistent dimensions.

Your choice should depend on your production requirements, the type of jewelry you need, and your budget. Before making a decision, it’s advisable to have a detailed discussion with SuperbMelt or jewelry manufacturing professionals to ensure you select the machine that best suits your needs.

Conclusion

In the world of jewelry manufacturing, precision and quality are paramount. SuperbMelt’s range of jewelry casting machines empowers artisans and jewelry manufacturers to create pieces that are flawless and exquisite.

Whether you require the meticulous precision of our Vacuum Casting Machine, the versatility of the Centrifugal Casting Machine for circular designs, or the efficiency of the Continuous Casting Machine for high-volume production, SuperbMelt has you covered.

Craftsmanship meets innovation with SuperbMelt’s jewelry casting machines. Elevate your jewelry crafting to new heights, ensuring each piece meets the highest standards of quality and artistry.

Choose SuperbMelt for your jewelry manufacturing needs and embark on a journey of creativity, precision, and excellence. Your jewelry deserves nothing less.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited