Gold Silver Melting Machine

Precision Gold and Silver Melting Machines and Furnaces: SuperbMelt's Excellent Choice

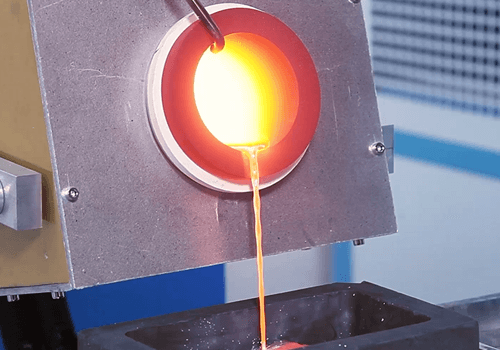

Gold Silver Melting Machine is a specialized device designed for melting precious metals like gold and silver using induction heating. It can efficiently melt between 4-12 kilograms of metals within 2-5 minutes, serving industries such as jewelry manufacturing, metal recycling, and laboratory research.

By employing advanced heating methods like induction or resistance heating, the machine ensures fast, efficient, and uniform melting.

It also provides precise temperature control, optimizing melting conditions for metals like gold, silver, and platinum. These features make it an essential tool for businesses and individuals looking to streamline their metal processing workflows effectively.

| Model number | SPB-TB2 | SPB-TB4 | SPB-TB5 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 15 kw | 15 kw |

| Applicable metal | Platinum, palladium, gold, silver, steel, copper and their alloys | Platinum, palladium, gold, silver, steel, copper and their alloys | Gold, silver, steel, copper and their alloys |

| Max capacity | 2kg platinum | 4kg platinum | 12kg gold / 6kg silver |

| Melting time | 2 minutes | 3 minutes | 5 minutes |

| Max temperature | 2800℃ | 2800℃ | 1800℃ |

| Dimension | 740*500*1360mm | 740*500*1360mm | 740*500*1360mm |

| Weight | 95 kg | 100 kg | 95 kg |

| Heating technology | IGBT Induction heating | IGBT Induction heating | IGBT Induction heating |

| Water pump | Equipped | Equipped | Equipped |

| Cooling way | Water cooling | Water cooling | Water cooling |

- Multi-Metal Compatibility: The melting furnaces of the SPB-TB series are appropriate for a variety of common metals, precious metals, and their alloys, including steel, copper, gold, silver, platinum, and more. This indicates that they function remarkably effectively in a variety of metal melting applications.

- Rapid Melting: These furnaces have effective IGBT induction heating technology, which allows them to finish the melting process quickly. Higher efficiency and shorter production times result from faster melting times.

- High Temperature Range: The melting furnaces of the SPB-TB series have an exceptional maximum temperature range that reaches up to 2800°C. When working with metals and alloys with high melting points, this high-temperature capability is very helpful for meeting the needs of specialised processes.

- Different Capacity Options: This series includes melting furnaces with options for 2kg, 4kg, and 12kg gold/6kg silver, among other capacities. This enables you to pick the model that most closely matches your demands for production.

- Energy-Effective Technology: These furnaces use the excellently energy-efficient IGBT induction heating technology. They help with cost management by reducing energy waste during the heating process.

- Water Cooling System: These furnaces are outfitted with a powerful water cooling system that guarantees the stability and dependability of equipment operation even at high temperatures. The equipment’s lifespan is increased as a result.

- Compact Design: The melting furnaces have relatively modest footprints and are therefore appropriate for smaller-scale businesses, such as jewellery casting.

The furnaces are powered by a three-phase, 380V power supply, which offers good electrical stability and efficiency.

A water pump is included in the furnaces, ensuring the efficient operation of the cooling system.

To sum up, the melting furnaces in the SPB-TB series have a number of benefits, including the ability to melt multiple metals simultaneously, a high temperature range, a variety of capacity options, energy-efficient technology, a stable water cooling system, a compact design, and the presence of a water pump. They are useful for the jewellery making, metal smelting, and other metal processing sectors and are an excellent choice for handling precious metals and common metals melting demands.

Jewelry Manufacturing:

Used by jewelers to melt gold and silver for crafting and shaping jewelry pieces such as rings, necklaces, and bracelets.Metal Recycling:

Essential in recycling facilities for reclaiming and refining precious metals from scrap materials.Laboratory Research:

Commonly used in research labs for material testing, metallurgical analysis, and experimental processes involving precious metals.Gold and Silver Bullion Casting:

Ideal for casting gold and silver into bars, coins, or ingots for investment or industrial use.Dentistry:

Employed in dental labs to melt and mold precious metal alloys for dental prosthetics like crowns and bridges.Electronic Component Manufacturing:

Utilized in melting precious metals for creating contacts and components in high-end electronics.Custom Crafting and DIY Projects:

Suitable for artists and small-scale manufacturers creating customized metal art or designs.

Why SuperbMelt Gold Silver Melting Machine

Any Question About SuperbMelt Precious Metal Melting Furnace

Helpful Resource For Your Reference ( An expert about Gold Silver Melting Machine )

Gold Silver Melting Machine: Your Comprehensive Guide

Understanding the importance of melting machines in precious metal processing

The use of melting machines is crucial to the processing of precious metals, which involves dealing with metals like gold and silver. Numerous sectors, including the fabrication of electronics, metal refining, and jewellery creation, are supported by these equipment. Listed below are some applications where melting equipment is essential:

- Precious metals are frequently created from scrap or unfinished sources. These materials must be melted in order to be malleable for various manufacturing processes. Melting machines play a key role in this process.

- Enhancing purity is important, especially in the fields of jewellery and electronics. By removing impurities, melting machines produce end products of higher calibre.

- Creation of Alloys: Numerous applications need for unique metal alloys with exact chemical compositions. Metal alloying and precise metal mixing are made possible by controlled environments created by melting equipment.

- Customization: Each industry and artisan has specific needs. Metal qualities can be tailored using melting equipment, guaranteeing that the finished product satisfies particular requirements.

- Efficiency: Melting machines are made to melt and heat quickly. Because of the time and energy it saves, this efficiency helps make production more cost-effective.

- Safety: Melting machines operate in a controlled environment, reducing safety issues connected to conventional open-flame melting techniques.

- Versatility: diverse melting machine types can be adapted to diverse purposes, from small-scale activities to big industrial applications.

In the process of transforming, removing impurities, and modifying precious metals, melting machines are crucial equipment. They have a role in quality, efficiency, and safety in the precious metal processing sectors, therefore their significance goes beyond only melting.

1.1, Types of Gold and Silver Melting Machines

There are different types of gold and silver melting equipment, each created for certain uses and specifications. Here are a few typical examples:

Electromagnetic induction is used in induction melting furnaces to produce heat inside the metal itself. They are extremely adaptable, accurate, and effective. These furnaces are common in jewellery production, metalworking, and industrial applications because they can melt different amounts of gold and silver.

Resistance Melting Furnaces: In a resistance melting furnace, heat is produced by running an electric current through a substance used as a resistor. They are still commonly used for small-scale gold and silver melting, especially in jewellery workshops, despite being less energy-efficient than induction furnaces.

- Melting with a Propane Torch: Hobbyists and jewellery makers frequently employ portable, easy-to-use propane torches for small-scale melting. They offer focused heat for melting trace amounts of priceless metals.

- Electric Arc Furnaces: Electric arc furnaces melt metals by creating an electric arc. They can handle larger quantities of gold and silver and are frequently utilised for larger-scale operations.

- Crucible Furnaces: A crucible is a small, portable furnace that is used to store the metal. They are adaptable and frequently used in small-scale metal casting and jewellery production.

- Furnaces with a graphite crucible are used to melt gold and silver in these furnaces. Crucibles made of graphite can resist high temperatures, which makes them appropriate for melting valuable metals.

- Gas-Fired Furnaces: Gas-fired furnaces, such those that run on propane or natural gas, offer an electric furnace alternative. They are frequently used in metalworking and foundry applications for melting bigger amounts of metal.

- Tilting Furnaces: As their name implies, tilting furnaces allow for simple pouring of molten metal. Large-scale metal casting and refining enterprises frequently employ them.

- Vacuum Melting Furnaces: To prevent oxidation during the melting process, vacuum melting furnaces produce a controlled environment with low oxygen levels. High-purity metals and alloys, particularly specialised aircraft materials, are produced using them.

- Miniature melting devices: These are compact, tabletop devices made for amateurs, modest jewellery manufacturers, and educational uses. They are simple to use and perfect for melting little amounts of priceless metals.

The quantity of metal to be melted, the necessary level of purity, energy efficiency, and the particular application are all aspects that must be taken into consideration when selecting a gold and silver melting machine. Different businesses and craftspeople choose the kind that best matches their requirements.

1.2, Exploring various technologies, including induction heating, resistance heating, and gas furnaces.

Exploring Various Melting Technologies for Gold and Silver

When it comes to melting gold and silver, several technologies are available, each with its own advantages and applications. Here, we’ll delve into three primary melting technologies: induction heating, resistance heating, and gas furnaces.

- Induction Heating:

How it Works: Induction heating relies on electromagnetic induction to generate heat directly within the metal. An alternating current (AC) passes through a copper coil, creating a rapidly changing magnetic field. When a metal object is placed inside or near the coil, it experiences induced electrical currents, which generate heat due to resistance.

Advantages: Induction heating is highly efficient, precise, and versatile. It offers rapid and uniform heating, making it ideal for melting gold and silver with minimal energy loss. It’s widely used in jewelry making and industrial applications where precision and consistency are crucial.

- Resistance Heating (Electric Furnaces):

How it Works: Resistance heating involves passing an electric current through a resistor material, such as a wire or graphite, which generates heat due to its resistance to the electric flow. The heat is then transferred to the metal to melt it.

Advantages: Resistance heating is cost-effective and suitable for small to medium-scale operations. It’s commonly used in jewelry workshops and small foundries for melting gold and silver. However, it’s less energy-efficient compared to induction heating.

- Gas Furnaces:

How it Works: Gas furnaces, fueled by propane or natural gas, use a flame to heat a crucible or chamber containing the metal. The combustion of gas produces intense heat, melting the metal.

Advantages: Gas furnaces are versatile and can handle larger volumes of metal. They are used in foundries, metal casting, and some industrial applications. While they might be less precise than induction heating, they are efficient for certain melting tasks.

The choice of melting technology depends on factors like the quantity of metal to be melted, precision requirements, energy efficiency, and budget constraints. Industries and artisans often select the technology that best suits their specific needs, whether it’s the rapid precision of inductio

Discover the wide range of industries and applications that rely on these machines, from jewelry crafting to metal refining

Examining Various Uses for Gold and Silver Melting Equipment

Due to their effectiveness in converting solid metals into liquid form, gold and silver melting machines are crucial in a variety of sectors and applications. Let’s examine the several sectors and applications that depend on these machines:

- Making jewellery: Gold and silver are essential to the jewellery business. Beautiful jewellery is made using melting machines, which enable craftspeople to mould and shape precious metals into complex patterns. Particularly induction melting machines provide accurate temperature control for creating special alloys with required qualities.

- Metal Refining: To refine raw metals, refineries and metal processing facilities use melting equipment. In order to adhere to industry norms and specifications, this includes purifying and alloying gold and silver.

- Foundries: Foundries use melting equipment to cast metal components and parts for a variety of industries, including the construction, aerospace, and automotive sectors. These devices make sure that metals are melted and prepared for casting.

- Dental Industry: Gold and silver are frequently used in dental laboratories to make dental prosthesis and restorations. For the production of dental alloys with the proper composition and properties, precise melting devices are essential.

- Electronics Manufacturing: Accurate gold and silver alloys are frequently needed for electronic components. These specialised alloys, which are used in connectors, circuit boards, and other electronic components, are produced with the aid of melting equipment.

- Healthcare Product Manufacturing: Precious metals are frequently used in the construction of medical equipment. These components are made in part using melting machines, which guarantee the highest quality and purity.

- Research and Development: Melting machines are used in laboratories and research facilities to create new alloys. The development and testing of novel materials with particular qualities is made possible by these machines.

- Art and sculpture: To use precious metals in their creations, artists and sculptors use melting machinery. These tools give artists the ability to execute complex and original artistic visions.

- vehicle Industry: Specialised gold and silver alloys are needed for some vehicle components, including sensors and connectors. These alloys can be produced more easily thanks to melting machinery, which benefits the car industry.

- Aerospace Applications: Precision is crucial in the aerospace sector. High-performance alloys are produced using melting machines for vital parts such as turbine blades and engine parts.

Gold and silver melting machines are essential equipment that promote creativity and quality in a wide range of industries, from creating beautiful jewellery to advancing cutting-edge technology. They are a fundamental component of contemporary production and craftsmanship because of their capacity to precisely melt, refine, and shape precious metals.

2.1, Advantages of Gold and Silver Melting Machines

Advantages of Induction Heating in Gold and Silver Melting Machines

Different heating techniques are used by gold and silver melting equipment, with induction heating being a popular option. The benefits of using inductive heating in these devices are as follows:

- Extremely accurate temperature control is made possible by induction heating. When melting gold and silver, this accuracy is essential since even small temperature fluctuations can have an impact on the end product’s quality and qualities.

- Induction heating is extremely energy-efficient. It minimises heat loss to the environment by directly heating the metal inside the crucible. This effectiveness cuts operational expenses while simultaneously reducing energy use.

- Quick Heating Induction heating provides quick and even warmth. Metals can be swiftly and evenly heated to the point of melting, saving crucial production time.

- Clean and Environmentally Safe: Since induction heating doesn’t use combustion or open flames, it is a clean and safe way to heat a space. During the procedure, no hazardous gases or contaminants are produced.

- Security: Induction heating is by nature secure. Accidents are less likely to occur because there are no exposed flames or hot surfaces. Induction heating systems frequently have controls and safety features to assure the safety of the users and the equipment.

- Minimal Material Contamination: The risk of material contamination is reduced by induction heating. There is no chance of impurities or contaminants being added during the melting process because the heating element does not come into close contact with the metal.

- Flexibility: Induction heating is flexible for diverse melting applications since it may be tuned for varied crucible sizes and shapes. Induction systems can be customised to your needs, whether you’re melting tiny amounts for jewellery or huge volumes for industrial uses.

- Less Maintenance: Compared to other heating techniques, induction heating systems typically have fewer moving parts. Longer equipment lifespan and less maintenance are the results of this.

- Precision and Consistency: Induction heating ensures uniform alloy composition and quality. It also provides accurate and consistent heating. This is crucial in sectors like aerospace and electronics where material qualities are essential.

- Greater Efficiency: Induction heating reduces material waste and provides greater melting process control. As a result, production is more efficient, costs are lower, and the final goods are of greater quality.

Induction heating has a number of benefits when used in gold and silver melting devices, to sum up. It is a popular option for companies that demand the greatest levels of quality and performance in the processing of precious metals due to its precision, efficiency, safety, and environmental benefits.

2.2, Advantages of Gold and Silver Melting Machines

A number of industries depend on gold and silver melting machines, which provide the following benefits:

- Accurate temperature control is necessary because gold and silver have distinct melting points. This control is provided by melting equipment, which makes sure the metals reach their liquid state without overheating.

- Energy Efficiency: Modern melting equipment is built with energy efficiency in mind. They minimise heat loss during melting, which lowers energy use and expenses associated with running the business.

- Rapid Heating: These devices can heat metals to their melting temperatures very quickly. Fast heating speeds up the production process.

- Safe and Clean Operation: Melting machines, particularly those that use induction heating, perform in a secure and clean manner. Compared to open flame technologies, they don’t emit toxic pollutants and have a low danger of accidents.

- Versatility: Gold and silver melting equipment is adaptable and can melt various metal quantities. Due to their adaptability, they can be employed for both large- and small-scale industrial applications.

- Consistency and Quality: Metals melted by melting machines are consistent and of high quality. This is crucial for sectors like aerospace and electronics because the performance of the finished product is directly impacted by the material qualities.

- Customization: A variety of melting equipment can be modified to meet certain production requirements. They are adjustable to diverse melting requirements since they can handle varying crucible sizes and shapes.

- Less Material Waste: Efficient melting equipment produces little waste. Maximising the yield of usable metal is made possible by precise temperature control and even heating.

- Better Material Properties: Controlled melting procedures, particularly in induction heating systems, can produce better material characteristics. Improved mechanical, thermal, and electrical properties are part of this.

- Environmentally Friendly: A lot of contemporary melting equipment is made with the environment in mind. They contribute to a cleaner, more environmentally friendly industrial process by generating fewer emissions and toxins.

- Safety Features: To protect operators and avoid accidents, these machines frequently have safety features and controls installed, further boosting workplace safety.

- Less Maintenance: Melting machines that are well-designed often have fewer moving parts, which leads to less maintenance and a longer equipment lifespan.

Machines for melting gold and silver assist the environment while providing accuracy, efficiency, safety, and benefits. They are crucial equipment for many different sectors, ensuring the high-quality melting of precious metals for a variety of uses.

Essential safety precautions and best practices to follow when operating melting equipment.

To protect both the operators’ safety and the equipment’s integrity when using melting equipment, such as gold and silver melting machines, careful adherence to safety procedures and best practises are necessary. The following are some crucial safety precautions to take:

- Training and Education: Ensure that operators are properly instructed on how to operate the particular melting equipment they will be utilising.

- Protective Gear: Operators should dress in flame-resistant clothing and wear the proper personal protective equipment (PPE), such as heat-resistant gloves and safety eyewear.

- Ventilation: Use exhaust systems or work in a location that is well-ventilated to get rid of any fumes or gases produced during the melting process. A safe workplace is maintained with the aid of proper ventilation.

- Fire Safety: Make sure you always have fire extinguishers, fire blankets, and other fire safety supplies on hand. Make sure that employees are trained to use fire safety equipment by conducting frequent fire drills.

- Appropriate Handling: When putting materials into the melting machine and taking them out, use the correct tools and equipment. Avoid overloading to guarantee smooth melting and prevent mishaps.

- Crucible Safety: Check crucibles frequently for damage or cracks that could cause spills or accidents while melting. Immediately replace any cracked crucibles.

- Monitoring: Keep an eye on the melting procedure constantly to avoid overheating and make sure the metal gets to the desired liquid state without any problems.

- Establishing defined emergency protocols and ensuring that all operators are aware of them are important. This covers shutdown processes, evacuation strategies, and emergency contact details.

- Equipment Maintenance: Conduct routine maintenance and inspections of the melting equipment to spot and quickly remedy any problems. This include inspecting cooling systems, gas supplies, and electrical and electrical-related components.

- Isolation: Keep uninvited visitors away from the melting area. To stop unintentional access, use barriers or safety markers.

- First Aid: Ensure that you have a first aid kit that is fully stocked and that staff members are taught in the fundamentals of first aid.

- Safety Checks: Before beginning any melting operation, check the equipment’s electrical connections, coolant levels, and, if necessary, its gas lines.

- Operator Presence: – Keep an operator on hand at all times when the metal is melting. When the device is in use, never leave it unattended.

- Electrical Safety: – Ensure that all electrical components are in excellent working order and that the electrical systems are correctly grounded.

- Continual Training: – Provide ongoing safety training and refresher courses to all staff operating melting equipment.

You can reduce the possibility of accidents, ensure the secure operation of melting equipment, safeguard the safety of your operators, and safeguard the environment by adhering to certain safety precautions and best practises. Any industrial operation involving high temperatures and possibly dangerous materials should always put safety first.

FAQ About Gold Silver Melting Machines

- 1. At what temperature do gold and silver melt?

- 2. Can you mix melted silver and gold?

- 3. What is the best furnace for melting gold?

- 4. Can a gold and silver melting machine be used for other metals?

- 5. Are these machines safe to operate?

- 6. What industries benefit from gold and silver melting machines?

- 7. What maintenance is required for these machines?

- 8. Where can I purchase a reliable gold and silver melting machine?

- 9. Can I customize a gold and silver melting machine to suit my specific needs?

- 10. Are there eco-friendly options available for gold and silver melting machines?

1. At what temperature do gold and silver melt?

The melting points of gold and silver are as follows:

- Gold (Au): 1,064°C (1,947°F)

- Silver (Ag): 961.8°C (1,763°F)

These temperatures are critical in various applications, such as jewelry making, bullion casting, and industrial processes. Precise control of these melting points is essential to avoid overheating and to ensure the quality of the melted material.

2. Can you mix melted silver and gold?

Yes, you can mix melted silver and gold, creating what is known as an alloy. When combined, these two metals form electrum or other customized alloys used in jewelry and decorative items.

Key Points About Mixing:

Properties of the Alloy:

The resulting alloy will have physical and chemical properties influenced by the ratio of gold to silver, such as color, melting point, and durability.Applications:

- Jewelry making: Alloys of gold and silver are often used to achieve specific colors or characteristics, such as white or rose gold.

- Industrial uses: Mixed metals are sometimes utilized for electrical conductivity or specialized manufacturing purposes.

Melting and Mixing Process:

- Both metals must be heated to above their individual melting points (gold: 1,064°C; silver: 961.8°C).

- Uniform mixing requires stirring at high temperatures, typically in a controlled environment to prevent oxidation or contamination.

Considerations:

Care must be taken when blending, as the metals’ proportions impact the alloy’s karat and overall quality.

This practice is common in metallurgy and the jewelry industry, offering versatility and customization in design and function.

3. What is the best furnace for melting gold?

The best furnace for melting gold depends on your specific needs, including the amount of gold to be melted, the desired efficiency, and the available budget. Here are a few options commonly regarded as effective:

1. Induction Furnaces

- Advantages: Fast, energy-efficient, and capable of precise temperature control. They are ideal for high-purity gold melting as they minimize contamination.

- Best for: Jewelers, gold refiners, and manufacturers who need to process large quantities.

2. Electric Melting Furnaces

- Advantages: Easy to use and maintain, suitable for small to medium batches.

- Best for: Hobbyists and small-scale jewelers.

3. Gas-Fired Furnaces

- Advantages: Cost-effective and capable of handling high temperatures.

- Best for: Larger operations where cost-efficiency is a priority.

4. Propane Melting Furnaces

- Advantages: Portable and affordable, suitable for small-scale operations.

- Best for: DIY enthusiasts and hobbyists.

Recommendations:

If you are melting gold for professional purposes, SuperbMelt Induction Gold Melting Machines are highly recommended. They are designed for fast melting, energy efficiency, and precise temperature control, making them suitable for jewelers and industrial applications.

If you’re a hobbyist or work on small-scale projects, a tabletop electric furnace like the Tabletop Gold Melter is a good choice due to its compact design and ease of use.

4. Can a gold and silver melting machine be used for other metals?

While primarily designed for gold and silver, many melting machines can also work with other metals like platinum, palladium, copper, and various alloys. The machine’s versatility depends on its specifications.

5. Are these machines safe to operate?

Gold and silver melting machines are generally safe when operated according to manufacturer guidelines. Proper safety precautions, including protective gear and proper ventilation, should be followed to ensure safe usage.

6. What industries benefit from gold and silver melting machines?

These machines are essential in jewelry making, metalworking, and precious metal refining industries. They play a crucial role in crafting jewelry, creating bullion bars, and recycling precious metals.

7. What maintenance is required for these machines?

Regular maintenance, such as cleaning, inspecting heating elements, and ensuring proper electrical connections, is essential to keep these machines operating efficiently. It’s advisable to follow the manufacturer’s maintenance guidelines.

8. Where can I purchase a reliable gold and silver melting machine?

You can find reputable manufacturers and suppliers of gold and silver melting machines both online and through industry contacts. It’s crucial to choose a trusted provider known for quality and customer support.

9. Can I customize a gold and silver melting machine to suit my specific needs?

Many manufacturers offer customizable options to meet your specific requirements, including variations in capacity, heating technology, and additional features. Customization ensures your machine aligns with your business needs.

10. Are there eco-friendly options available for gold and silver melting machines?

Yes, some machines are designed with energy-efficient features and pollution control measures to minimize environmental impact. Choosing eco-friendly options can be beneficial for both your business and the environment.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited