Gold Smelting Furnace

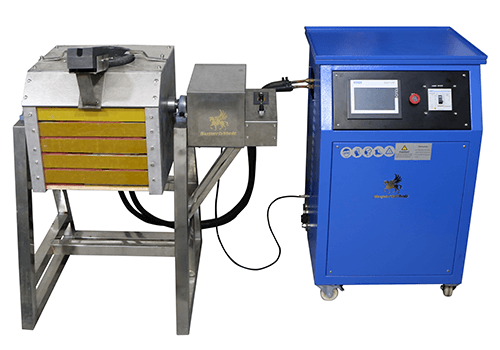

Your premier SuperbMelt 20-30kg gold (Ag, Cu, Al etc) smelting furnace

SuperbMelt gold smelting furnace unlike any other product on the market comes with awesome specifications. It has the capability of melting 20-30kg of non-ferrous metals like gold, silver, copper, aluminum. It can melt any metal up to a temperature of about 1800℃ based on an induction power supply of 25-35kw. All within a short time frame of 6 to 8 minutes.

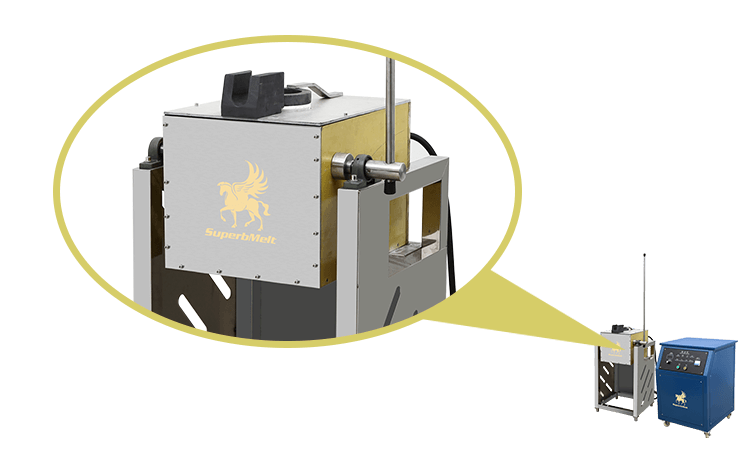

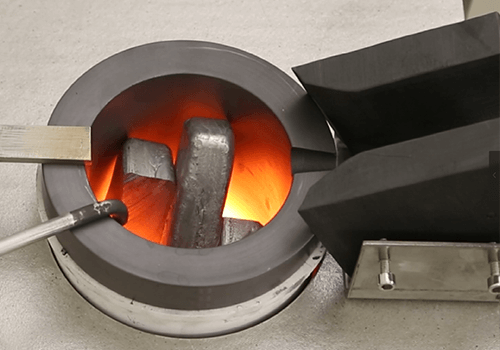

Induction gold smelting furnace split design enhances easy tilting. This feature which gives the room for pouring of liquefied metal without splashing or spillage.

Clere here to see more metal melting furnaces with different capacity

- The gold smelting equipment is a medium frequency IGBT induction technology-based device. It is highly energy efficient and cost-effective melting of non-ferrous metals like gold, silver, copper, aluminum and others.

- This product casting is highly durable based on the fact that the furnace is designed to work continuously for 24 hours. This prevents any irregularities due to interruptions in operations.

- This electric gold smelting machine is manufactured with various factors taken into consideration. Some of which includes floor space economy, safety, efficiency and of course top performance.

- A very strong electromagnetic stirring system was incorporated into the system. It improves mixing and ensure the homogeneity of the melted metal.

- Gold refinery factories will find their production efficiency enhanced with this product. This ensures production of high quality alloys and will definitely drive up your sales.

- The digital induction technology provides a seamless and efficient operation. Based on the advanced circuit which consumes very little energy which lowers energy consumption

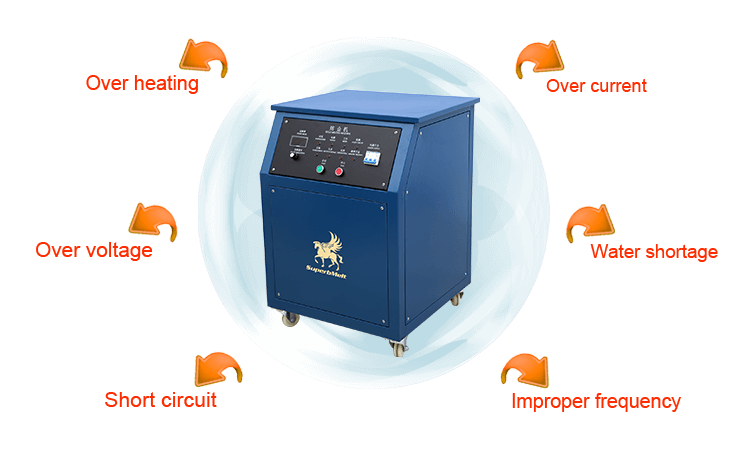

- An inbuilt omni-directional warning system of gold melting kit helps to keep operators safe by indicating dangerous operating conditions.

- The crucible and safety refractory shell are detachable. This enhances the ease of maintenance of the furnace. Meaning you can use this product for a long period of time without having to buy another one.

| Model number | SPB-TB25 | SPB-TB35 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 25kw | 35kw |

| Max current | 36A | 51A |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 6-8 mins | 6-8 mins |

| Max capacity | 24K Gold: 25.0 kg 925 Silver: 12.5 kg | 24K Gold: 30.0 kg 925 Silver: 15.0 kg |

| Max heating temperature | 1800℃ | 1800℃ |

| Power size | 690*500*1210mm | 690*500*1210mm |

| Furnace size | 650*520*1800mm | 650*520*1800mm |

| weight | 200kg | 215kg |

| Heat technology | IGBT Induction heating | IGBT Induction heating |

| Water pump | Build-in | Build-in |

| Cooling way | Water cooling | Water cooling |

Graphite crucible for gold/Silver melting Furnace

Integrated compact design, no need to disassemble it when you meet problem, we support the set replacement.

Why SuperbMelt Induction Gold Smelting Kit

Helpful Resource For Your Reference ( An expert about induction gold melting equipment )

More SuperbMelt Gold Melting and Casting Machines For Your Choice

Any Question About Induction Gold Smelting Furnace

SuperbMelt Induction Tilting Furnaces for Sale

Application Field of Smelting Machine

Have you ever tried to obtain a pure base metal before? Be it gold, silver, iron, or the likes? If you have, then the fact that it isn’t an easy process wouldn’t need much explaining. Stick with this buying guide to get all the info you would need to pilot a sustainable gold smelting process.

Mining of Gold

To get started, it’s important to note that the Gold mining process does not leave room for miners to extract pure gold from the surface of the earth. Gold is discovered in nature as Gold ores. While this ore can be referred to as gold, they contain impurities that are quite detrimental to the market value attributed to the metal. Gold ores can be mined via three different methods.

Placer mining: Are you planning to embark on your first gold hunting quest? This method is regarded as the most explored gold mining method for amateur gold miners. It usually requires the usage of gravity and water to separate the Gold ores from other materials. The processes involved in placer mining include metal detecting, panning, cradling, sluicing, and dredging. Placer mining is the most suitable means of extracting gold dust from non-metal impurities.

By-Product Mining: unlike most other mining methods on our list, the By-product mining doesn’t place gold as its first find. This mining process involves the usage of underground tunnel and pits dogged to extract coppers, gravel, sand, and other products to extract gold.

Hard Rock Mining; most of the gold circulating the world today are results of the Hard rock mining process. For this mining process to be practical, open pits and underground mining tunnels are dogged, paving easy access for miners to access the gold ores directly from the rock.

1.1, Smelting the Gold Ores

Gold is listed amongst the most valuable precious metal available in the market. Its ability to retain an ever-growing market value have made it rank as one of the most sought out precious metal of all times. To ensure that your freshly mined gold is appreciated for the value it portrays, smelting gold ore is necessary.

How to Smelt Gold Ores

- Chose a preferred smelting machine

- Crush gold and place in furnace.

- Allow to heat to over 1064 degree Celsius

- Add cyanide solution to remove impurities while smelting

- Pour in a mold and allow to cool.

1.2, For Recycling old gold

With gold usage dating as far back as ancient Egypt, it wouldn’t come as a surprise that over 35% of the gold materials circulating in the world today are made out of recycled gold. While gold can be recycled from electronics, dental filings and lots of other materials, we would be focussing on the process attached to recycling gold from jewelry.

Jewellery and coins are amongst the most common materials containing gold. Be it a family ornament that has withstood the test of time or gold coins passed down from generation to generation; you can acquire a handful of pure gold from them through the gold recycling process.

1.3, For Jewelry Casting

Gold and silver smelting are processes that requires as much care and precaution as possible. Smelting gold wrongly would not only affect the surface finish of the casted jewellery, it would also depreciate its market value; having the necessary smelting tools and smelting machine is a must.

It’s no news that you wouldn’t be able to cast a piece of fine jewellery with a gold material containing an impure substance. While a lot of jewellers are familiar with the traditional and homemade smelting styles that have prevailed over the years, its reliability in the 21st-century global market is continuously placed on a questionable spot when talking about how to melt down gold jewellery. The smelting reduction process involved doesn’t seem to be providing the desired output when smelting gold jewellery.

How to Use Gold Smelting Machine to Remove Impurities from Gold

- Apply flux {oxidation compounds like Borax, Sodium Nitrate and Silica} to the gold material.

- Place in the furnace and allow to heat at over 900-degree Celsius.

- Pour out flux and any other impurities floating at the top of the liquified material

- Place in a mold and allow to dry.

1.4, For Industrial Applications

Dentistry: the use of gold in the dental industry dates as far back as 700 BC. Generally known as a durable replacement for worn-out teeth and for making fillings. Gold has been able to retain its influence in the dentistry industry over the decades due to the biocompatible nature it possesses. The gold mostly used in the dentistry industry is white gold or gold alloy. To ensure that individuals are not provided with gold teeth containing impurities, the gold smelting technology has gained extensive usage around the industry.

Gold in Medicine: Gold is not just vital in the dentistry industry but even in the treatment of arthritis, cancer, and Lagophthalmos. A lot of medical equipment and diagnostic tools used in the medical sector are also by-products of the precious metal. While the need for pure gold can be compromised in the production of diagnostic tools and medical equipment—when it comes to the gold dust or gold salt required the treatment of arthritis or cancer, such compromise can cost a life. Gold smelting machines have had and still have a vital role to play in the medical industry.

How to Smelt Gold Nowadays

2.1, How to smelt Gold by Propane Torch

Propane torch is amongst the most common and inexpensive method for smelting silver coins, gold bars or jewellery. Suitable for home and enterprise usage, the gold smelting technique is regarded as the most used by individuals looking to smelt gold in small quantity.

Items Required

- Gold ore

- Cubicle

- Flux {mixture of sodium carbonate and borax}

- Propane touch

- Ingot

Steps Involved

- Make provision for a cubicle capable of withstanding heat of over 1,950-degree Fahrenheit.

- Obtain a mixture of Carbonate and Borax. A mixture of carbonate and borax is often referred to as flux. Apply the flux on the gold.

- Use a propane torch to melt the gold by it applying directly into the cubicle.

- Pour into a Metal or Ingot of choice.

While propane touch is less expensive, the processes involved can keep you smelting 2kg of gold for hours. Compared to the fast and efficient process induction furnace offers, propane torch is less durable and is not suitable for smelting huge amount of gold.

2.2, How to Smelt Gold by Resistance Furnace

It’s mostly regarded as a suitable technique for individuals looking to smelt a small amount of gold. While it’s quite productive and has stood the test of time, its usage is in no way environmental friendly and requires over 20 minutes to smelt 2kg of gold. It generates heat through electric or slag.

Steps involved

- Since you are looking to try out the homemade smelting process with a resistance furnace, you would have to create the furnace yourself. You can design the furnace with a metallic cubicle.

- Install a hair dryer to the furnace

- Smelt by lighting up in a hole surrounded with firebricks.

- During the smelting process add oxidizing agents to enable impurities rise to the top.

2.3, How to Smelt gold in Induction Furnace

What type of gold are you trying to smelt, is it white yellow or rose gold? Are you smelting gold freshly acquired from the ore or recycled gold? Regardless of what your answers are to these questions, the induction smelting furnace got you covered. Suitable for gold smelting companies, miners and gold enthusiast.

Items required to smelt gold with the induction Furnace

- Gold

- Flux

- Induction smelting furnace (Sometimes, you need a tilting furnace, if it is a big batch of gold)

Steps involved

- When smelting gold, it’s essential to bear in mind that gold is denser than most other metals. While most other compound floats in their liquified state, gold doesn’t. With the primary aim of smelting being to remove any impurities that might be contained in a piece of gold, oxidizing agents like sodium carbonate and borax are required.

- Unlike most other smelting processes, you can enjoy smelting with an induction furnace at the click of a button. Insert gold into the furnace and set to melt at desired temperature.

- Separate gold from flux by pouring out any impurity or slab that rises to the top before pouring gold into a mold.

Induction furnace has been and remains the top smelting techniques used in most modern-day smelting companies. Since most induction furnaces are termed a bit expensive for personal use, gold enthusiast or miners are advised bank with companies for the productive services it offers when looking to smelt gold or any other metals.

The Kinds of Gold Smelting Furnaces that SuperbMelt Can Provide

This section is geared towards enabling you to choose the right SuperbMelt melting furnace for your smelting needs. To ease the choosing process, our list contains some of the most reputable smelting machines available in our store. You don’t have to worry about where and how to purchase. Just leave a message with our 24 hours support team, and your order would be on its way in no time.

3.1, Mini 1-2Kg gold Melting Furnace

Mini 1-2Kg gold melting furnace is an desktop induction melting furnace. This is not a tilting furnace, you need to manually pouring when you are done. Designed with a single-phase power source and optimised to heat the metal to a max temperature of 1600 degree Celsius, the smelting furnace has gained reputable traction in small and medium-sized refining companies, gold recyclers, gold mining enthusiast, medical field etc.

3.2, Integrated 3-10Kg gold Melting Furnace

Integrated 3-10Kg gold melting furnace can be regarded as the upgraded version of the Mini 1-2Kg gold melting furnace. No, that didn’t come out right, the integrated 3-10Kg gold melting furnace is a more valuable option. While its focused on increasing the amount of gold or metals users can melt within a specific amount of time, the high-quality equipment and exceptional melting time it offers is quite extraordinary.

3.3, 20kg-30kg Manual Tilting Furnace

SuperbMelt has been at the forefront of the metal casting industry due to their renowned ability to provide machines that supersede the expectations and quality that most other experts in the industry deem probable. The SuperbMelt 20kg-30kg manual tilting furnace is unlike any other gold melting machine available in the market.

Features and Benefits of 20kg-30kg Manual Tilting Furnace

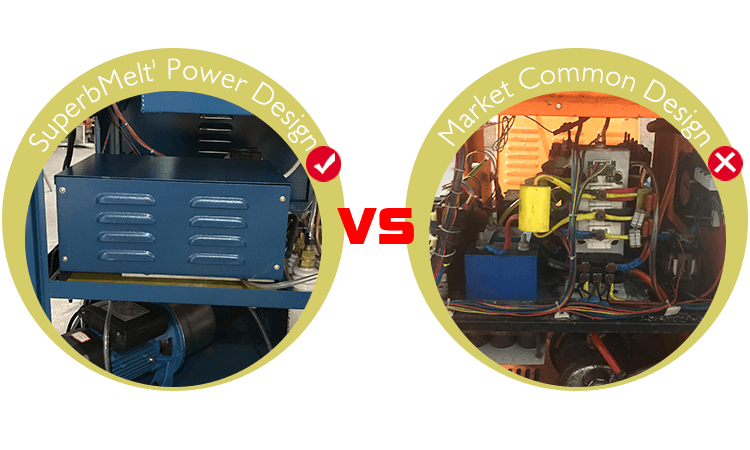

SuperbMelt is a renowned manufacturer of precious metal’s melting and casting machines. We have been in operation for over 15 years. Within this time, we have acquired a research and development team with professional credibility in proffering high-quality machines to metal smelting enterprises and companies across the globe.

When it comes to reliability or reputability of our product, we are geared towards ensuring that our users are provided with the best in every way possible. To ensure that you obtain the optimal performance you desire, 20kg-30kg manual tilting furnace uses semiconductor devices to replace all the mechanical parts. This makes it easy for our users to enjoy a smelting machine free of gaseous emissions.

Keeping up with the competition is quite essential, but we don’t think you would get the applaud you desire if you are doing it at the expense of your neighbour’s mental health.

To avoid having to cause environmental pollution each time you turn on your tilting crucible furnace, SuperbMelt took necessary measures to ensure that the 20kg-30kg manual tilting furnace operates with insulated current between the coil and power source.

This also helps in reducing the noise the smelting furnace emits while ensuring that the machine still provides the optimal working experience you desire.

We have been in the industry for quite a while. So, when we say we familiar with most of the issues faced by companies making use of smelting machines to pilot their day to day activities, you wouldn’t find much room for doubt.

A lot of fondlers are faced with unprecedented smelting issues on a daily due to negligence on the path of the smelting machine providers to provide a furnace capable of mixing and homogenizing the metal efficiently.

The 20kg-30kg manual tilting furnace is designed with high-performance asynchronous generators that enable users to obtain a melting point of choice at an incredibly faster rate.

Application Fields for the 20kg-30kg Manual Tilting Furnace

Refining Laboratories: metal testing remains an essential part of the global economy. Hundreds of labs geared towards examining the corrosive and non-corrosive nature of different metals are available worldwide.

Like most of the other smelting machines, we listed above, the 20kg-30kg manual tilting Melting Furnace stands a renowned option.

Jewellery Casting Companies; are you tired of having to change the coil of your melting machine on a weekly or daily basis? With durability, the 20kg-30kg manual tilting melting furnace can enable you to smelt as much metal as you would like smelted on a daily without running into issues of break down or unforeseen power outage.

The compact design and electromagnetic shielding the 20kg-30kg manual crucible melting furnace offers also makes it easier for jewellery casting companies to regulate hazardous fumes.

3.4, 10-50Kg Chain Tilting Furnace

The further you go, the merrier it becomes. We have talked about all the smelting machines available in our collection for melting precious metals below 50kg. With 10-50Kg chain tilting gold melting furnace being the first in line for SuperbMelt smelting machine capable of melting up to 50kg worth of metals at a go, the thought of the fantastic features it offers is quite exhilarating.

Features and Benefits of the 10-50Kg Chain Tilting Furnace

While the 10-50Kg chain tilting gold melting furnace is nor the biggest in our store, it might interest you to know that the melting degree doubles most of the numbers you might have come across thus far. The gold smelting machine possesses a max melting temperature of 1800 degree Celsius with a processing time ranging from 10 to 20 minutes.

By now, you are quite familiar with the fact that most of our machines operate with IGBT tech and electromagnetic shielding to keep the noise in check, ensuring proficiency and optimal operation while utilizing minimal energy.

10-50Kg chain tilting electric crucible furnace operates with greenhouse technology. This ensures that hazardous fumes are not emitted. With the 10-50Kg chain tilting furnace at your disposal, you can carry out your company operations without having to worry about the electricity bills or nosy neighbours calling the cops on you for environmental pollution.

The jewellery casting industry is amongst the biggest consumers of precious metals—medium-sized jewellery casting company smelts over 5000kg of gold on a daily. With the 10-50Kg chain tilting gold melting furnace being handy, keeping up with a scheduled metal smelting task wouldn’t be a problem.

3.5, 10-100kg Motor Tilting Furnace

Like all the other smelting machines we have made mention of thus far, the 10-100kg motor tilting melting furnace is suitable for smelting ferrous and non-ferrous metals. Its usage is widely accepted in factories and college researching companies.

Features and Benefits of the 10-100kg motor tilting furnace

In all our listings, we haven’t made mention of any furnace making use of the motor tilting engine. 10-100kg motor tilting melting furnace is capable of smelting up to 100kg of any metal at a go with a melting time of 20 to 30 minutes when the cubicle is hot, and 40 to 50 minutes when the cubicle is cold.

SuperbMelt took necessary precautions to ensure that users can utilise the smelting machine to its maximum potential by attaching a motor tilting furnace. The 10-100kg motor tilting melting furnace makes room for companies to enjoy a one-person operation while the issue of spillage is reduced to its barest minimum.

A lot of manufacturers find it hard producing heavy-duty machines that would be able to last for long hours. When we made mention of us being at the frontline of the metal casting industry for over 15 years, it might have come off as a brag, but that’s in no way the intended purpose.

Our reliability and proficiency in the industry earned us this reputation. Purchasing our 10-100kg motor tilting melting furnace would grant you instant access to a smelting machine capable of operating for 24 hours non-stop. Might seem like a bluff but not to worry, all our machines come with two years warranty.

If after making use of the 10-100kg motor tilting melting furnace for over 24 hours, its reliability stands questioned, you wouldn’t have a hard time getting in touch with our support service.

3.6, 50-250kg Hydraulic Tilting Furnace

The 50-250kg hydraulic tilting melting furnace is the last on our list and the biggest available in our store. The durability, portability, efficiency and reliability of the 50-250kg hydraulic tilting melting furnace can be seconded to none. This renowned giant is suitable for smelting any type of metal. Whether ferrous or non-ferrous. The 50-250kg hydraulic tilting melting furnace comes with different cubicles and induction coils suitable melting different metals.

Features and Benefits of the 50-250kg Hydraulic Tilting Melting Furnace

If you have been wondering if the 50-250kg hydraulic tilting melting furnace is as big as its capacity to smelt up to 250kg of gold at once, then yes, it’s quite big. While it doesn’t require a plot of land of its own, you would have to keep a sizable portion for it.

This smelting furnace operates with a hydraulic box control. It’s no news that you wouldn’t fancy even a pinch of the liquified metal touching your skin. To ensure that this result is at all times aborted, SuperbMelt made provision for the melting furnace hydraulic box control operational with a remote trolley panel. This ensures that you don’t have to be at a close proximity to the mold while pouring out the melted metal.

Operating with the potential of smelting over 250kg of gold at a go, the temperature at which the 50-250kg hydraulic tilting melting furnace heats would melt anything that comes its way. To ensure that it doesn’t end up melting its shell, SuperbMelt made provision for steel shell casings.

Its compact design style makes it possible for workers to pour or add metal into the furnace during the melting process without having to worry about the issue of spillage occurring.

Conclusion: How to Choose the Right Smelting Furnace

- According to Gold Capacity

Do you smelt over 10kg gold on a daily? Are you looking for a machine big enough to melt over 100kg of gold at once? How many kilograms of gold do you melt on a regular? Answers to this question would enable you know the melting furnace that would fit. Every time you melt large quantities of gold, you need a tilting furnace to ensure stability and safety during each tilting

- According to consumer business model

Different businesses require different models and different sizes. To ensure that all your smelting needs are well attended to, numerous models of all the above listed melting furnace are available in our store. To acquire credible info on which would be suitable for your business, check out our model specification sheet.

- Consider the price

Pricing remains an important aspect when trying to pick the right melting furnace for your business or home use. It’s essential you estimate the amount of funds available before scouting for a suitable melting furnace.

- Think about applicability

How often are you going to use the smelting furnace? In what industry? what’s the estimated amount of gold that’s going to be smelted on a daily? Before opting for any of our melting furnace, going through questions in line with its applicability is quite essential.

- Consider the reputation of the dealer

This is one factor a lot of individuals neglect when purchasing a melting furnace. The authenticity and reliability expected is highly dependent on the dealer you are making a purchase from. Banking with a dealer with a reputable track record would go a long way in helping you sustain a lucrative smelting process.

At SuperbMelt, your satisfaction is of utmost importance. All the features and benefits attributed to the melting furnace contained in this buying guide were in no way twerked or biasedly written to attract sales. Our machines are fully equipped with all the above-listed features and more. To save yourself the stress and time of having to visit our store, why don’t you place a call through to our support service today, or better still, get our live chat agent on the line with a ‘Hi’.

FAQ Guide

Does gold lose value when melted?

No, pure gold doesn’t lose its value. Instead, it acquires more value. Since gold is mined in an impure nature, the process of melting is required to help purify the gold. All the gold materials and pieces in circulation today underwent the melting process. Although, you might want to note that the melting process involved in gold purification is a bit tedious and can lead to spillage if care is not taken. Issue of spillage creates room for loss of a substantial amount of pure gold. To avoid such problems, it’s advisable you adopt advanced melting methods when looking to smelt your recycled gold or gold ores.

How do you smelt gold with borax?

To smelt gold using borax, you would have to create a mixture of disodium tetraborate {borax} and sodium carbonate. This mixture is generally regarded as a flux. After such mixture is obtained, application of the flux on the gold before heating would enable the impure substance attached to the gold rise to the top of the cubicle when heated. Borax which is also known as sodium tetraborate or disodium tetraborate is one of the most used oxidizing agents for smelting gold. Its usage in the smelting gold process requires a mixture with sodium carbonate. Note that: when applying the borax mixture to the gold, special attention should be placed on gold materials with rough surfaces to avoid engaging in a smelting process that doesn’t guarantee the attainment of gold piece or bars of high purity.

How do you separate gold from other metals by melting?

To separate gold from other metals by melting, you would have to remove or pour out the impure substance that rises to the top of the material after a liquified form {molten} of the precious metal has been attained. It’s essential to keep in mind that for the impure substance contained in the gold material to rise to the top, the application of flux on the content must be done effectively, and the melting point for the gold materials must be observed.

How do you smelt gold jewellery?

Gold jewellery is commonly smelted by gold recyclers. Just like the process involved in smelting gold ores, jewellery requires proper application of flux on the materials before being placed in a heating furnace. To remove impurities, you must allow the jewellery melt to the required melting point. It’s advisable you make use of induction heating furnace so you can accurately calculate the temperature range of the melting furnace at all times. When the required melting point is reached, the impure substance contained in the jewellery will rise to the top. Pour out the impure substance then place gold in a mold to dry.

How many degrees does it take to melt gold?

To melt gold, you would require a furnace that can heat as far as 2000 degrees Fahrenheit although the estimated melting point for gold is 1945 degrees Fahrenheit. Due to the high intensity of heat required to melt gold, utilizing an induction furnace remains the best bet for saving time and money. With smelting technique like propane torch and resistance furnace, it’s impossible to estimate the actual amount of heat reaching the precious metal at a time. Smelting gold without an accurate measure of its melting degree creates room for chaotic outcomes.

What is borax used for in melting gold?

Borax is used for oxidizing the gold piece or material before or during the smelting process. Gold smelting involved the removal of impurities from gold. Note that gold can be melted without being smelted, but it cannot be smelted without being melted. Borax, when mixed with sodium carbonate, serves as an oxidizing agent that enables impurities such as zinc, copper, iron and any other impurity in the gold rise to the top when the gold is melted to a specific degree. This process enables goldsmiths or metal melting companies to obtain gold piece or end products of higher purity.

Can you melt down gold to make jewellery?

Yes, to make jewellery, the gold material must be melted down. Jewellery has, for a long time, served as the most patronized by-product of gold. Note that due to gold’s fragile nature, most times to attain a piece of shiny and more durable jewellery, pure gold is mixed with alloys. Most of the jewellery available in the global market are mixed with such materials. White gold and rose gold jewellery are by-products of this mixture. It’s essential to bear in mind that jewellery casting is a complicated process. If you haven’t engaged in the art before, it’s advisable you consult an expert to put you through before you engage in the gold melting process.

Could we melt silver in this induction melting furnace also?

Yes, you can melt silver with our induction melting furnace. The induction melting furnace is designed to melt different types of metals. The mini and integrated melting furnace is suitable for melting a small amount of ferrous and non-ferrous {precious metal} metals. If you are looking to melt a large amount of metals like zinc, copper and other ferrous metals with our induction heating machine, you would have to opt for the motor tilting melting furnace or the hydraulic tilting melting furnace. You can check out the machine specification guide for detailed info on suitable metals.

How much gold is lost when melted?

If you are melting an 18-carat gold to obtain 24-carat gold, you will lose over 25% of the gold after the melting process. In situations where you are melting 9-carat gold and 18-carat gold combined to get 24-carat, you would lose up to 50% of the gold. The amount of gold lost is dependent on impurities and the combustible nature of the alloys contained in the gold material. In a few scenarios, you might also experience gold loss based on the melting process used and the carat of gold being melted. The gold lost during melting is as a result of the other alloys contained in the gold going out as slag or combusting into thin air.

How do you get gold from gold ore?

To get gold from gold ore, you would have to make use of an effective gold smelting technique. The three gold smelting methods available include, induction heating, propane torch and resistance furnace. Induction heating remains prevalent amongst the other two for the rare advantages it offers. While it remains one of the most expensive methods, its usage and durability can be seconded to none. In situations where you can’t obtain an induction heating machine, you can opt for propane torch. Resistance furnace is the least recommended.

How do you get impurities out of gold?

Getting impurities out of gold requires smelting and then refining. The smelting process removes impurities such as copper, iron and zinc while the refining process is necessary to extract precious metals like silver. Note that to remove impurities via smelting, a flux {oxidizing agent} is required. Gold smelting does not provide users with 99% pure gold. Obtaining 99% pure gold would require a refining process. There are a lot of gold refining companies that would enable you to remove any remaining impurities at affordable rates.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited