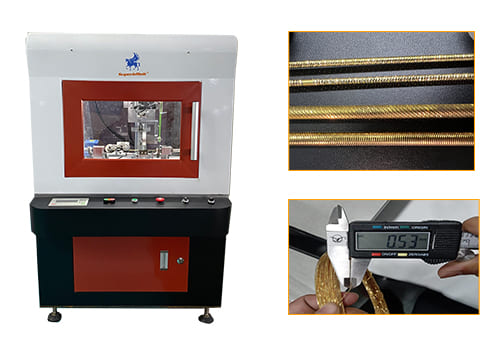

Gold Tube Cutting Flower Machine

SuperbMelt Gold Tube Cutting Flower Machine helps process patterns on gold, silver, copper, and platinum round tubes and wires.

SuperbMelt Gold Tube Cutting Flower Machine is designed to process gold, silver, copper, and platinum tubes and wires, creating intricate patterns such as fish scale, nail, and cross patterns in just one minute.

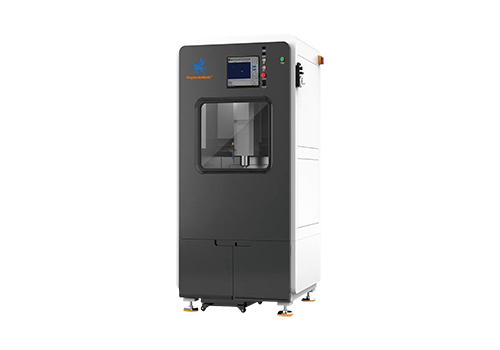

Equipped with automatic straightening, material collection, and batch processing features, this machine significantly reduces labor costs and enhances production efficiency. It is an ideal solution for jewelry manufacturers seeking high-precision, automated engraving for decorative jewelry components.

Processing capacity:

- Wire diameter: ∅1.6mm – ∅4.0mm

- Tube diameter: ∅1.0mm – ∅4.0mm

| Technical Parameters | Values |

| Model | SPB- |

| Voltage | 220 V |

| Processing Specification (Wire) | Ø0.3~Ø1.0mm |

| Processing Specification (Tube) | Ø1.0~Ø4.0mm |

| Working Efficiency | 500-1000 mm/min |

| Maximum Spindle Speed | 24000r/min |

| Total Power | 1.8kw |

| Air Pressure | 3-4kg |

| Dimensions | 1280x700x1450mm |

| Weight | 150kg |

| Control Method | Switch Control |

High-Efficiency Automation

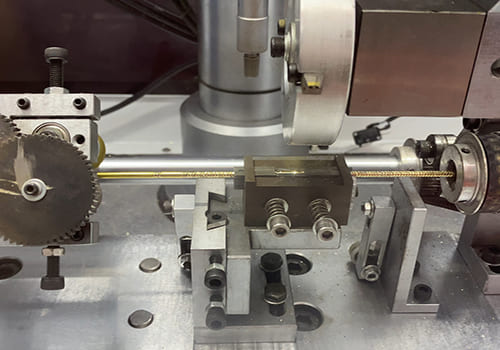

Equipped with automatic straightening, pattern engraving, and material collection functions, reducing manual intervention and significantly improving production efficiency.

Capable of processing entire rolls without the need for individual handling, making it suitable for large-scale production.

Wide Material Compatibility

Suitable for precious metals such as gold, silver, K-gold, platinum, copper, silver, and aluminum, as well as other metal materials for tubes and wires.

Can process straight lines and tubes with diameters ranging from ∅1.6mm to ∅4.0mm, meeting various jewelry manufacturing needs.

Multiple Exquisite Patterns

Capable of batch processing patterns such as fish scale, nail, and cross patterns, enhancing the design appeal and market competitiveness of jewelry.

Clear and delicate patterns meet the processing requirements of high-end jewelry.

Wide Range of Applications

Suitable for jewelry manufacturers, gold and silver processing factories, and accessory processing factories, supporting large-scale production.

Ideal for decorative processing of wires and tubes used in rings, bracelets, necklaces, pendants, and jewelry accessories.

Jewelry Industry – Pattern processing for gold, silver, K-gold, and other jewelry wires and tubes.

Metal Crafts Industry – Surface pattern engraving for metal decorative items.

High-End Custom Jewelry Manufacturing – Meeting personalized jewelry pattern design requirements.

This equipment, with its high-efficiency automation, precise processing, and diverse pattern options, is an ideal choice for jewelry manufacturers to enhance production efficiency and product quality.

Why SuperbMelt Gold Tube Cutting Flower Machine

More SuperbMelt jewelry Processing Equipment for You to Choose

Any Question About SuperbMelt jewelry Processing Equipment

FAQ Guide of Gold Tube Cutting Flower Machine

- 1. What is a Gold Tube Cutting Flower Machine?

- 2. What materials can this machine process?

- 3. What are the supported tube and wire sizes?

- 4. What types of patterns can this machine engrave?

- 5. How does the automatic system improve efficiency?

- 6. How fast can this machine engrave metal tubes and wires?

- 7. Is this machine suitable for mass production?

- 8. Can this machine work with customized designs?

- 9. What industries use this machine?

- 10. Does this machine require skilled operators?

- 11. How does this machine ensure engraving accuracy?

- 12. Can this machine be integrated into an existing production line?

- 13. What is the power consumption of this machine?

- 14. How do I maintain the machine for long-term use?

- 15. Does SuperbMelt provide technical support and training?

1. What is a Gold Tube Cutting Flower Machine?

A Gold Tube Cutting Flower Machine is a specialized device used for engraving decorative patterns on gold, silver, platinum, and other metal tubes and wires. It features automatic straightening, engraving, and material collection, making it ideal for jewelry manufacturing.

2. What materials can this machine process?

This machine is suitable for processing gold, silver, K-gold, platinum, copper, aluminum, and other precious and non-precious metals used in jewelry manufacturing.

3. What are the supported tube and wire sizes?

- Tube diameter: ∅1.0mm – ∅4.0mm

- Wire diameter: ∅1.6mm – ∅4.0mm

4. What types of patterns can this machine engrave?

The machine can engrave a variety of intricate patterns, including:

- Fish scale pattern

- Nail pattern

- Cross pattern

- Custom decorative designs

5. How does the automatic system improve efficiency?

The machine features automatic straightening, batch engraving, and automatic material collection, significantly reducing manual labor while increasing processing speed and consistency.

6. How fast can this machine engrave metal tubes and wires?

The machine is capable of engraving 500-1000mm tubes per minute, making it highly efficient for large-scale jewelry production.

7. Is this machine suitable for mass production?

Yes, the Gold Tube Cutting Flower Machine is designed for high-volume jewelry manufacturing. It can process whole rolls of wire or tubes continuously, reducing downtime and enhancing production efficiency.

8. Can this machine work with customized designs?

Yes, the machine allows for customized engraving patterns based on jewelry design requirements, offering flexibility in production.

9. What industries use this machine?

This machine is widely used in:

- Jewelry manufacturing (rings, bracelets, necklaces, pendants)

- Luxury metal accessories production

- Decorative metal craftsmanship

10. Does this machine require skilled operators?

No, the fully automated system makes it easy to operate. However, basic training is recommended to ensure proper usage and maintenance.

11. How does this machine ensure engraving accuracy?

The machine is equipped with high-precision cutting and engraving tools, ensuring uniform and flawless decorative patterns on all processed tubes and wires.

12. Can this machine be integrated into an existing production line?

Yes, the Gold Tube Cutting Flower Machine can seamlessly integrate into automated jewelry production lines, improving overall workflow efficiency.

13. What is the power consumption of this machine?

Power consumption depends on the specific model, but it is designed to be energy-efficient while maintaining high performance.

14. How do I maintain the machine for long-term use?

Regular maintenance includes:

- Cleaning the engraving tools

- Checking and lubricating moving parts

- Ensuring proper material feeding and collection

15. Does SuperbMelt provide technical support and training?

Foundry is one of the most energy intensiYes! SuperbMelt offers installation guidance, operational training, and after-sales support to ensure smooth operation and maximum productivity.ve metallurgical industries. Various sections of foundry melt, pattern making, melting, core making compressed air, etc.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited