Gold Wire Drawing Machine

Precision Wire Drawing Machine helps users to produce jewelry made of gold, silver, and alloys through wire drawing.

SuperbMelt Gold Wire Drawing Machine aids jewelry manufacturers and craft processors in producing gold, silver, K gold, alloy, and other metal wires with diameters ranging from 0.3 to 8 millimeters, used for creating jewelry such as rings, necklaces, bracelets, earrings, and crafts. This wire drawing machine not only addresses production issues in the jewelry industry but also finds applications in various manufacturing sectors including telecommunications, automotive, construction, and metal component and product manufacturing.

- Speed: The machine can draw metal wires with diameters ranging from 0.3 to 8mm and lengths from 0 to 15m per minute.

- Coiling: Equipped with coiling function to increase drawing pressure and facilitate material collection.

- Features: The product is equipped with a spray cooling system to reduce material temperature, minimize wire damage, and features automatic shutdown and material shortage shutdown functions to reduce manual intervention during production.

For further inquiries about the wire drawing machine, please contact SuperbMelt for customized solutions!

| Model number | SPB- |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 7.5 kw |

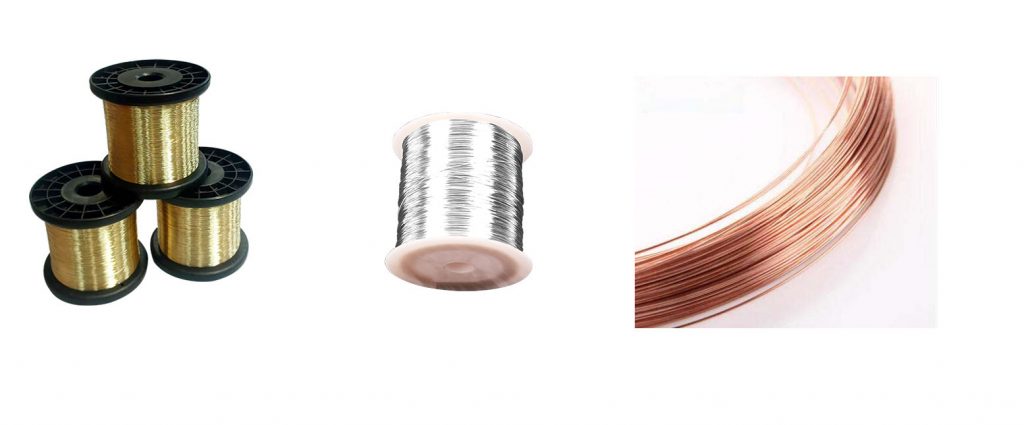

| Applicable metal | Gold, silver, copper, K gold, tin, etc. |

| Outgoing line speed | 0-15M/Min |

| Maximum cable diameter | 8mm |

| Minimum cable diameter | 0.3mm |

| Pulling direction | unidirectional |

| Dimension | 1860*1500*1850mm |

| Weight | 1600 kg |

| Additional features | Winding |

- High efficiency, capable of drawing up to 15 meters per minute at the fastest.

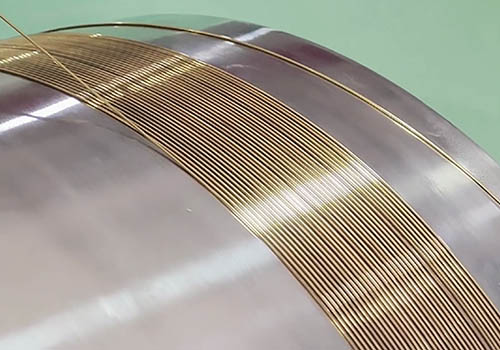

- High precision, servo-driven precision wire arrangement, preventing abrasion between wires.

- Intelligent control, PLC control system, easy and user-friendly operation.

- Automated production, featuring automatic shutdown and material shortage shutdown functions.

- Spray cooling system, reducing material and wire eye temperature to minimize wire damage.

- Coiling function, with automatic coiling capability, facilitating material collection and retrieval.

- Versatile Compatibility: Compatible with a wide range of materials including gold, silver, copper, and alloys, catering to diverse manufacturing needs.

- Enhanced Safety: Equipped with safety features such as overload protection and emergency stop buttons, ensuring operator safety during operation.

- Energy Efficiency: Utilizes energy-efficient components and design principles, minimizing energy consumption and operational costs.

- Maintenance-Friendly: Designed for easy maintenance and servicing, reducing downtime and maintenance costs in the long run.

- Customizable Options: Provides customizable options such as wire diameter settings and speed adjustments, allowing users to tailor the machine’s performance to specific production requirements.

- Jewelry manufacturing is the process of turning raw materials like gold, silver, and alloys into jewelry pieces like necklaces, bracelets, rings, and earrings.

- Manufacturing of Metal Parts: Involved in the creation of metal components for mechanical, electrical, and automotive applications.

- Telecommunication Sector: Employed in the production of metal wires, cables, and communication apparatus.

- Used in the construction industry to produce building supplies including metal pipes and wire mesh.

- Manufacturing of Art and Crafts: Used in the creation of several metal sculptures and ornaments.

- Manufacturing of Medical Equipment: Metal components for medical equipment and instruments are produced here.

- precise Instrument Manufacturing: Involves creating metal components for a range of equipment and precise instruments.

Why SuperbMelt Gold Wire Drawing Machine

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Any Question About SuperbMelt Gold Wire Drawing Machine

Any Question About SuperbMelt Automatic wire drawing machine

FAQ Guide of Gold Wire Drawing Machine

- 1. What is the process of drawing gold wire?

- 2. What is the use of wire drawing machine?

- 3. What is the raw material for wire drawing?

- 4. How does a gold wire drawing machine work?

- 5. What is a gold wire drawing machine?

- 6. What are the main components of a gold wire drawing machine?

- 7. What sizes of gold wire can be drawn using this machine?

- 8. What is the purpose of using a gold wire drawing machine?

- 9. What are the advantages of using a gold wire drawing machine?

- 10. Can other metals besides gold be drawn using this machine?

- 11. How fast can a gold wire drawing machine produce wire?

- 12. Is the drawn gold wire suitable for jewelry making?

- 13. What safety measures should be observed when operating a gold wire drawing machine?

- 14. How can I maintain a gold wire drawing machine for optimal performance?

- 15. Can a gold wire drawing machine be customized to meet specific requirements?

1. What is the process of drawing gold wire?

Melting gold into ingots is the initial stage in the preparation of gold ingots. After that, these ingots are rolled into long rods or strips with the appropriate diameter.

Annealing: After that, the gold rods or strips are annealed to make them softer. As a result, they are simpler to work with and more pliable while sketching.

Drawing: A sequence of dies with progressively decreasing diameters is used to feed the annealed gold rods. The gold rod is compressed in each die, lengthening and decreasing in diameter. Until the gold wire reaches the required diameter, this operation is repeated several times.

Intermediate Annealing: To keep the gold wire ductile and keep it from getting too brittle, it may be annealed again on occasion.

Final Drawing: To obtain the exact diameter needed for the application, the gold wire is drawn through one last set of dies.

Finishing: To improve its look and get rid of any surface flaws, the gold wire is usually cleaned and polished when it reaches the required diameter.

2. What is the use of wire drawing machine?

- Production of Wires: A wire drawing machine is primarily used to generate wires made of various materials, including alloys, steel, copper, and aluminum. Numerous products, such as electrical wiring, cables, springs, nails, screws, mesh, and fence, employ these wires.

- Jewelry Making: To create fine wires of precious metals like gold, silver, platinum, and their alloys, wire drawing machines are widely employed in the jewelry business. Jewelers then use these wires to construct elaborate designs for jewelry such as bracelets, necklaces, earrings, and rings.

- Metalworking: Wire drawing machines are used in the metalworking industry to manufacture wires that are utilized in various parts and components. To generate intricate forms and structures for equipment, automobile components, building materials, and other uses, these wires are frequently subjected to further processing such as bending, cutting, and welding.

- Electronics: In order to produce the tiny wires needed to make electrical components, circuit boards, connections, and cables, wire drawing machines are essential to the electronics sector. To guarantee the best possible performance and dependability in electrical equipment, these cables need to have exact measurements and premium surfaces.

- Craftsmanship and Artistry: To create sculptures, artwork, and ornamental features, artisan and craftsmen also employ wire drawing machines. These devices generate fine wires that may be formed and worked into complex patterns, giving visual interest to a variety of artistic endeavors.

3. What is the raw material for wire drawing?

- Steel: Because of its strength, resilience, and adaptability, steel is one of the materials most frequently utilized in wire drawing. It is used to make wires for many different uses, including as equipment, construction, automobiles, and home goods.

- Copper: Because of its exceptional conductivity and resistance to corrosion, copper is frequently utilized in electrical wiring and conductor applications. Power transmission, electronics, telecommunications, and electrical systems all depend on copper cables.

- Aluminum: Aluminum wires are ideal for applications where weight reduction and electrical conductivity are crucial, such as power distribution, electrical wiring, and aircraft, since they are lightweight, corrosion-resistant, and have strong electrical conductivity.

- Alloys: To get certain qualities like increased strength, resistance to corrosion, or visual appeal, wire drawing also makes use of a variety of metal alloys, such as bronze (copper-tin alloy) and brass (copper-zinc alloy). These alloys are used in the maritime, automotive, decorative arts, and jewelry-making sectors.

- Precious Metals: Fine wires used in jewelry-making, luxury items, and high-end electronics are produced by wire drawing using precious metals such as gold, silver, platinum, and their alloys. These metals are prized for their elegance, scarcity, and ability to withstand tarnish.

- Other Metals: In specialist sectors like aerospace, medical, and military, other metals including nickel, titanium, and tungsten may also be utilized as raw materials for wire drawing, depending on the particular needs of the application.

4. How does a gold wire drawing machine work?

In order to reduce a gold wire’s diameter while extending its length, a gold wire drawing machine works by dragging the wire through a succession of successively smaller dies. While cooling systems guard against overheating, tension control devices guarantee constant pulling. After processing, a longer, thinner wire that may be used for a variety of applications

5. What is a gold wire drawing machine?

A gold wire drawing machine is a specialized piece of equipment used to pull a gold wire through a series of dies to reduce its diameter and increase its length.

6.What are the main components of a gold wire drawing machine?

The main components include a wire feeding mechanism, drawing dies, tension control system, cooling system, and a take-up spool.

7. What sizes of gold wire can be drawn using this machine?

Gold wires with diameters ranging from 0.3mm to 8mm can typically be drawn using a gold wire drawing machine.

8. What is the purpose of using a gold wire drawing machine?

The primary purpose is to produce thinner and longer gold wires suitable for various applications, including jewelry making and electronics.

9. What are the advantages of using a gold wire drawing machine?

Some advantages include high efficiency, precision, automated operation, and the ability to produce wires with consistent quality.

10. Can other metals besides gold be drawn using this machine?

Yes, besides gold, this machine can also be used to draw wires from other metals such as silver, copper, and alloys.

11. How fast can a gold wire drawing machine produce wire?

The production speed varies depending on factors like wire diameter, machine capacity, and operational settings, but it can typically produce up to 100 meters per minute.

12. Is the drawn gold wire suitable for jewelry making?

Yes, the drawn gold wire is commonly used in jewelry making to create various types of jewelry such as rings, necklaces, bracelets, and earrings.

13. What safety measures should be observed when operating a gold wire drawing machine?

Operators should follow safety protocols regarding machine operation, maintenance, and handling of materials to prevent accidents and ensure a safe working environment.

14. How can I maintain a gold wire drawing machine for optimal performance?

Regular maintenance tasks include cleaning, lubricating moving parts, checking tension control systems, and inspecting dies for wear and tear.

15. Can a gold wire drawing machine be customized to meet specific requirements?

Yes, manufacturers often offer customization options to tailor the machine’s specifications and features according to the user’s needs.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited