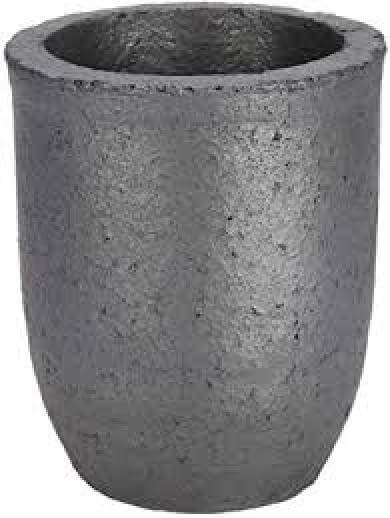

Graphite Crucible

Top Graphite Crucible Manufacturer in China

- Designed for 1-30kg gold/silver/copper smelting

- Top quality, durable crucible supplier

- As the source factory, large inventory, fast delivery

Get Price For Batch Order (MOQ 10pcs)

Top Graphite Crucible for Sale

Graphite crucible is a unique product that is needed for every melting and casting activity. The graphite crucible is made from choice materials that allows different metals of different melting temperatures to be melted. In terms of structure, the graphite crucible may take different shapes of a barrel, cylinder or cone. The graphite crucible is a cost saving alternative to crucibles made of metals like copper, platinum, quartz or porcelain. The graphite crucible is chemically inert and temperature resistant that fares well in the furnace.

The crucible is made from high quality graphite which makes the graphite crucible to have a good thermal conductivity, resistant to acidity and alkalinity and a high temperature resistance, therefore, ensuring quality of products.

As the graphite has a great heat performance, the time spent on melting is short, therefore saving energy.

The graphite crucible is suitable for foundries, jewelry industry and other industries where metal melting and casting is necessary.

SuperbMelt Graphite Crucibles list

Crucibles for melting gold are usually made from superior garde graphite material and can be widely used in different kinds of furnaces . The gold melting crucible can be used to melt gold as well as silver and other metals such as aluminium, copper, brass, iron, zinc, lead, etc. A crucible for melting gold can be properly maintained and can last a very long time without any form of crack.

Parameter

- Melting Capacity: 1-30kg

- Application: Pure gold, K gold, gold alloy

The crucible for melting silver comes in various sizes that can be used to melt different batches of not only silver but also gold, aluminium, lead, zinc and their alloys. Crucibles for melting silver can withstand temperature reaching up to 2000 degree celsius. The body of the crucible for melting silver is made from natural graphite. Therefore it keeps its original physical and chemical properties.

Parameter

- Melting Capacity: 1-30kg

- Application: Pure silver, Silver Alloy

Superbmelt graphite crucible is used for melting and casting of metals and certain alloys. This is the part of the induction furnace that holds molten metal during melting processes. The crucible is made up of graphite which makes it a high quality induction furnace graphite crucible. The high density body of the furnace crucible and its structure makes the furnace crucible a better compression property.

Parameter

- Melting Capacity: 1-30kg

- Application: Gold, Silver, Iron, Copper, Aluminum etc

3 reasons why you must choose SuperMelt

01

We are the source factory

02

Graphite products with different densities

Provide high-density, low-porosity graphite products, extremely durable, very effective for smelting and casting, and have a longer service life than competitors’ products.

03

Graphite products are shipped extremely fast

As a top manufacturer, we manufacture 10,000 graphite crucibles every day and have a large inventory, which can meet the needs of various urgent orders for fast delivery.

Why You Could Choose SuperbMelt

AAA credit audited enterprise

The government Audited Superb as AAA credit company (top level).

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Ultimate Graphite Crucible Buying Guide

How to Choose the Right Crucible for Smelting Various Precious Metals

1.1, Application of Crucible?

A crucible is a cylindrical container that is used to hold metals for melting and smelting in a furnace and it is needed to withstand the extreme temperatures encountered in melting metals. Crucibles generally are made of different materials, materials that have higher melting degrees than the metals to be melted. The crucible material must have a much higher melting point than the metal being melted and it must have a good strength even when red hot.

Crucibles have been in use since ancient times for melting and testing metals, crucibles were possibly named from the Latin word “crux”, meaning cross or trial. Modern crucibles may be small laboratory equipment used for conducting high temperature chemical reactions, analysis or large industrial vessels for melting and calcining metal and ore, built-in place liners for industrial iron or aluminum melting in primary production plants and metal casting foundries. Alternatively they may be of a much smaller size, for use in laboratory applications.

They may be made of clay, graphite, silicon carbide, porcelain, water cooled corper or a relatively infusible metal. Metals such as nickel and zirconium are also used as melting crucibles.

Graphite crucible can withstand the high temperature of metals and has a good resistance to chemical erosions and thermal shock. Graphite crucibles are most especially ideal for melting precious metals, aluminium, copper, etc.

Furnace crucible comes in different shapes and sizes, from small shapes like teacups to larger cylindrical, wide form, high form, barrel or cone shapes with spout; and typically come with correspondingly-sized lid. The lids are loose-fitting to allow gases to escape during the melting process. The various sizes are 1kg to bigger kilograms to contain large melting of metals.

1.2, Crucible Usage Tips

When using a furnace crucible for melting, there are certain actions that should be avoided. Such action includes stuffing a furnace crucible with cold metal such as aluminium, as there are strong chances that the metal will expand and crack the furnace crucible. Also, make sure to never allow the metal to solidify in the bottom of the furnace crucible for the same cause.

Furnace crucibles should be properly tested for cracks prior to each application. Replace the cracked furnace crucibles with new ones. Keep furnace crucibles in a dry place and pre-heat them and the metal to be melted as the furnace heats up. A little bit of moisture can cause the furnace crucible to crack on heating.

The furnace crucibles should be handled with care using properly fitting tongs. Tongs are lifting tools that are used to protect furnace crucibles from damage or failure.

It is better to use different furnace crucibles for different types of metals to avoid contamination. Also ensure you completely empty the furnace crucible after each use as the metal left to solidify may expand on reheating, which may destroy the furnace crucible.

The graphite crucibles should be tempered before use. Heat the empty graphite crucible for a temperature of about 260 degree celsius and hold it for 20 minutes. Then work the crucible to red heat. Turn off the heat and leave the furnace crucible to cool slowly. This process takes off any moisture in the furnace crucible. The furnace crucible is now ready for use.

Place metal very loosely into the furnace crucible. Do not pack the furnace crucible, as the material will expand on heating and damage the furnace crucible. When metal has been melted, carefully load more material into the puddle for melting.

Warning- In the case where any moisture is present in the new material, steam explosion may occur.

This time again, do not tightly pack in the metal. Keep adding the metal into the furnace crucible until the required quantity has been melted. Make use of proper equipment to transport and pour the melt. The use of safety equipment is essential as metal melting is a dangerous activity.

1.3, Why Do You Need a Crucible for Melting?

In some applications, such as refining and melting precious metals, base metals and other metal products, crucibles are designed for melting at 1600 degree celsius. In other applications, crucibles that allow the inductive field to pass through them and heat the metal charge directly are used. The benefits of a crucible lie in its ability to withstand very high temperatures which makes it suitable for melting different types of metal for metallurgy. The importance of furnace crucibles cannot be overemphasized in the process of melting and casting metals as it increases the effectiveness and efficiency of melting with an induction furnace.

Graphite crucibles prevent contamination of molten metal with the components of the crucible. The graphite material that makes up the graphite crucible itself is tightly fused together and no part becomes loose when metal is being melted, therefore, your metal is protected from contamination. Graphite materials are durable and robust, they are made from high quality graphite. They offer very good resistance to temperature changes, as well as chemical resistance and outstanding thermal conductivity.

1.4, Which Material of Crucibles Is the Most Suitable?

Furnace crucibles are made from materials that have higher melting temperature than metals being melted. The very first furnace crucibles were made of clay. One of the earliest uses of platinum was to make crucibles. Other materials used to make crucibles were porcelain, alumina or any inert metal.

The recent furnace crucibles come in a variety of metal constructions such as clay-graphite, silicon-carbide, graphite crucible and so on. High temperature operations are involved in almost all industries dealing with the treatment of ores and other metals for the manufacture of metallurgical, chemical products, equipment used for treatment of these materials must sustain the operating temperature and other working conditions such as corrosive, erosive and load conditions.

Porcelain crucible

In the production of furnace crucibles, it is important to know their component raw materials, their important properties and correlation between these properties and the actual use of the furnace crucible.

Of all furnace crucible types and materials, the best and most suitable furnace crucible material is graphite. Graphite crucibles are made from raw graphite. Graphite material is typically grayish-black in colour, opaque, and has a radiant blaack sheen. Graphite is a distinct material that displays the properties of both metal and nonmetal. Although graphite is flexible, it is not elastic and it has high electrical and thermal conductivity. It is also chemically high and highly refractory.

Alumina crucible

Since graphite displays these features and more, this makes it ideal for furnace crucibles. Therefore, graphite crucibles have an excellent heat performance and save a lot of energy when it is used for melting metals. Graphite crucibles are highly resistant to alkalinity and acidity, making them last for a long time.

Platinum crucible

1.5, Classification of Crucibles

- Graphite crucibles: They are refractory crucibles of high thermal shock resistance with little tendency to oxidize their contents. They are highly resistant to chemicals except to oxidation. They can be otherwise called refractory carbonaceous. The crucible (graphite crucibles) usually contains 30 – 50% flake natural graphite. Binders such as clay, plastic clay, tar or pitch and silicon powder (2%) are usually added in weight percent to give strength before firing and prevent further oxidation respectively.

- Alumina crucibles: They are characterized with very high refractoriness to boiling or fused alkaline. They also exhibit high thermal conductivity resistance to acid and basic slag. They can be prepared from the following raw materials: Bauxite diaspore plus refractory fireclay, sintered corundum and binder, fused alumina and binder or mixture of the three.

- Graphite/Silicon carbide crucible: They are carbonaceous in nature. The raw materials used in manufacturing include graphite, silicon carbide and tar.

- Silicon carbide crucibles: These are characterized with high thermal conductivity and therefore fuel saving, high resistance to thermal shock and spilling, clean pouring but stain some contents such as glass. The raw materials include silicon carbide, bond clay or other binders.

- Magnesia crucibles: These are used for melting of platinum and other refractory materials and in electric furnaces. Raw materials used include dead burnt magnetite (fired above 1550 degree celsius), binders such as caustic magnesia and magnesium chloride.

- Sillimanite crucibles: It is being used for melting glasses for optical and experimental purposes. The body type is alumino-silicate which gives sillimanite. Raw materials used include ball clay, China clay, sillimanite minerals and alumina. They have better resistance to acid than to basic slag.

The crucible types listed above have variety of properties, however, the graphite crucible surpass all other crucible types due to its relatively outstanding qualities such as high thermal conductivity, heat shock resistance, high heat resistance, corrosion resistance, oxidation resistance, anti-adhesion, resistance to slag remover, resistance to acidity and alkalinity, and so on.

1.6, Shapes of Crucibles

Crucibles are available in a number of designs and shapes including barrel-shaped, conical, cylindrical, high form, skull melting, tongue and groove of furnace liners and wide form.

- Barrel crucibles: Barrel crucibles have an opening with a top outer diameter that is essentially the same as or only slightly smaller than the base or bottom outer diameter. The side walls bulge out producing a barrel shaped crucible.

- Conical or tapered: This type of crucibles has an opening with a top outer diameter that tapers down to smaller base or bottom diameter. The side walls are straight.

- Cylindrical or straight walled crucibles: They have an opening with a top outer diameter that is essentially the same as or only slightly smaller than the base or bottom outer diameter. The side walls are straight sided without any bulging out.

- Skull melting crucible or melting hearth: This type of crucible has water or salt cooled copper shell that maintains an unmelted skin or skull of metal. The unmelted layer contains the melt. The melts are arc, plasma or electron beam heated.

- Tongue and groove crucibles: They are a modular crucible system consisting of a series of interlocking components that stack together to form a furnace lining or crucible. Tongue and groove crucibles may use a backup of ramming cement behind the crucible, but not within the interlocking grooves. The absence of refractory cement between the ceramic crucible portions improves lining life and melts quality.

Wide form crucibles: They are low, shallow or flat profile vessels with short walls compared to high form crucibles. The crucibles have a very wide opening with an outer diameter that tapers down to a much smaller base diameter. The sidewalls typically have a slight outward bow or bulge.

Factors to Consider when Choosing a Crucible

To select a crucible for your operations, you need the right crucible from the wide range of crucible types and materials available to you. The following should be considered when choosing an induction heating graphite crucible:

2.1, Type of Smelting Furnace

The capacity, dimension and type of furnace you use will determine your choice of furnace crucible. If you know the capacity your furnace was designed for, you will know what capacity your crucible should provide. Likewise, the dimension of the space of the graphite crucible in your furnace will dictate the dimension and shape of your graphite crucible. This will also determine if your furnace crucible must include a pouring spout. However, choosing a crucible to match your furnace type will give you many other less obvious factors to consider. There are different furnace types and different crucibles peculiar to each.

Fuel Fired Furnace:

Fuel fired furnaces include furnaces powered by coke, propane, oil or gas. Each of these fuels directly exposes the furnace crucible to the heating source and each provides a different level of heat, normally measured in BTUs (British Thermal Unit). Any furnace crucible selected must be able to withstand the maximum BTUs the furnace fuel is able to apply to the graphite crucible. In gas, oil and propane furnaces, the graphite crucible must be able to withstand the effects of the burner flame at the base of the furnace and the crucible must be tapered to allow the flame to circulate around the graphite crucible from bottom to top. This allows even heating of the graphite crucible. The crucible material must be able to resist oxidation damage from the flame and accommodate the rate of thermal change the crucible will experience.

Good thermal conductivity and even heating are important crucible factors in transferring the heat from the interior of the furnace through the crucible to the metal charge. Crucibles with high graphite content in the carbon binder have high thermal conductivity for fast melting in gas fired furnaces.

Resistance Furnace:

Electric resistance furnaces provide even, all round heating to a graphite crucible and are ideally suited for even and precise temperature control in metal holding application. Energy efficient crucibles with high graphite content in the carbon binder are often selected to provide high thermal conductivity for faster melting in this type of furnace.

Crucibles designed for resistance furnaces are normally basin shaped and provide a uniform distance between the crucible and furnace heating elements.

Induction Furnace:

Selecting a crucible for an induction furnace is a more complex task. In some applications such as refining precious metals, crucibles designed to heat in the furnace’s inductive fields are used to melt the charge. In other applications, crucibles that allow the inductive field to pass through them and heat the metal charge directly are used. Therefore, it is important to match the electrical characteristics of the graphite crucible to the operating frequency of the furnace and to the melting application. For instance, in some designs, lower frequency induction furnaces require crucibles with high silicon carbide content and in other applications, higher frequency induction furnaces require crucibles with high clay content. Matching a crucible’s electrical resistivity to the induction furnace is key to preventing crucible overheating.

Most graphite crucibles designed for induction furnaces are cylindrical to provide a uniform distance between the crucible and the furnace coil. However, some small furnaces designed for removable crucibles feature a tapered coil to match the profile of bilge-shaped crucibles.

Vacuum Induction Melting Furnace:

Vacuum induction melting has high application potential in comparison to alternative melting techniques. Vacuum induction melting (VIM) is a commonly used melting and casting technique which involves melting an alloy under vacuum or an inert atmosphere by electromagnetic induction using coils. Vacuum induction melting can be hindered by lack of appropriate crucible. A suitable crucible must combine low with metal being melted at 1600 degree celsius, have thermodynamic stability and thermal shock resistance. Titanium and titanium alloys are widely used in a variety of fields including; the aerospace and automotive industries, manufacture of biomedical components and surgical instruments, chemical and petrochemical engineering, marine applications, etc These industries adopt the vacuum induction melting furnace for melting titanium.

Vacuum Arc Remelting Furnace:

Vacuum arc remelting is a secondary melting process for production of metal ingots with elevated chemical and mechanical homogeneity for highly demanding applications. The furnace crucible commonly used in a vacuum arc remelting furnace is made of copper, which is usually surrounded by a water jacket used to cool the melt and control the solidification rate.

Electron Beam Melter: Electron E-beam crucibles are designed to offer E-beams users improved evaporation performance the bare hearth modes. Graphite crucibles used in electron beam furnaces act as an energy efficient thermal barrier between the molten evaporant and the water cooled copper hearth.

Plasma Arc Melting Furnace:

The plasma arc furnace is a device used to melt a substance by low-temperature plasma flow, typically created by an electric arc heater (plasmatron). The main field of application of the plasma furnace is electrometallurgy. There are three types of the plasma furnaces: plasma furnaces for melting in a ceramic crucible; plasma furnaces for melting in a crystallizer and plasma furnaces for melting in a scull. The ceramic crucible plasma furnaces are used mainly for melting steel, nickel-based alloys and waste metals with alloying additions. Plasma furnaces with a crystallizer are used mainly for the metal refining process. By contrast to electroslag, vacuum-arc and electron-beam refining processes, the main technological means of action on the liquid metal is the gas phase. The plasma furnaces for melting in a scull are designed to make steel castings, high-temperature alloys and refractory metals.

2.2, Furnace Power Limit

Induction furnace power can be categorized into three: Low power frequency (less than 400Hz), medium power frequency (400-1000Hz) and high power frequency (more than 1000Hz). The higher the operating frequency, the greater the maximum amount of power that can be applied to a furnace of a given capacity and the lower the amount of turbulence induced. The power supply system has two functions, to provide power to the primary coil and the other to control the melting of the metal.

The principle of induction heating is that a high voltage electrical source from a primary coil induces a low voltage, high current in the metal, or secondary coil. Induction heating is simply a method of transferring heat energy. A good furnace crucible must be able to adapt to the heating principle of the induction furnace. Therefore, this will influence your choice of crucible.

2.3, The Type of Precious Metal Determines the Crucible

Understanding the metal type or alloy will let you know the characteristics you are looking for in a furnace crucible. Your detailed catalogue of the metals you intend to melt will help to establish the maximum temperature the crucible must support for melting or holding, will define how the metal will interact with the furnace crucible material both chemically and physically and it will be a key factor in determining what characteristics your optimal crucible should offer. For example, in melting copper based alloys in fuel-fired furnaces, roller formed silicon-carbide crucibles perform better due to higher thermal shock resistance. In other types of furnaces, crucibles are often selected because of their high density. Less dense and more porous crucibles may allow erosion.

Carbon-bonded and ceramic-bonded clay graphite and silicon carbide crucibles are widely used in melting aluminium and aluminium alloys, aluminium bronze, copper, copper based alloys, cupro-nickel, and nickel-bronze alloys, precious metals, zinc and zinc oxide. Crucibles are also used in melting cast iron. Taken together as a group, these metals represent a temperature range from 400 degree celsius to 1600 degree celsius.

While some crucible types support metal temperature encompassing a broad spectrum of metals, it is necessary to select furnace crucibles targeted to melt specific metals or alloys. Selecting such crucibles are often more advantageous because they offer permanence characteristics important to your operations. For instance, using a crucible that is able to melt metal from iron to zinc may not be as important to your aluminium alloy melting operation having a crucible limited to the temperature range you need but able to resist corrosion damage from your metal treatment fluxes.

The most applicable crucibles for melting precious metals are the graphite crucible and the silicon carbide crucible. The melting temperature of a silicon carbide crucible is up to 1600 degree celsius. Clay graphite on the other hand has a melting temperature ranging from 850 degree celsius to 1600 degree celsius. Graphite crucibles are for melting precious metals such as gold, silver, platinum, palladium. The graphite crucible has extremely good thermal shock resistance allowing fast melting from cold.

However, metals that have melting points reaching up to or more than 1600 are melted using the quartz crucible. Platinum and palladium fall under this category.

Platinum has a melting point of 1768 degree celsius while palladium has a melting point of 1555 degree celsius.

Quartz crucible has fused silica as main material and its many desirable properties includes high chemical purity, high corrosion resistance, high melting point, extreme hardness, low coefficient of thermal expansion, high refractoriness, good thermal stability, high thermal shock resistance.

2.4, Melting and Holding Temperatures

The melting temperature of the metal and alloy you melt or hold will determine the temperature range within which your furnace crucible must be able to operate. Crucibles must never be heated above their maximum temperature, this can lead to crucible failure. Operating below the crucible temperature limit can also cause problems. For instance, crucibles designed for high temperature melting of copper based alloys will oxidize if used at low temperatures for zinc melting.

Melting and holding practices are important factors that need to be considered when selecting crucibles. If your operations involve superheating, you will need to take the higher metal temperatures into account.

2.5, Rate of Temperature Change

The ability of a furnace crucible to handle the rate if temperature change is as important as its minimum and maximum temperature limits. If your operations usually involve frequent heating and cooling cycles, which means it is subject for rapid temperature change, you will need to select a crucible that is resistant to thermal shock. For instance, a high carbon content of the graphite in a crucible imparts high thermal conductivity and non-wettability and provides high thermal shock resistance. This is critical to foundry applications which can change by several hundred degrees in seconds.

2.6, How the Crucible is Charged

If your crucible is charged with only molten metal, then there is no requirement for a crucible designed to be highly resistant to physical damage. In the case where heavy metals make up the bulk of your charge, you will need to select a crucible that is mechanically strong and able to survive physical shocks. Crucibles featuring high carbon content and a directionally oriented graphite structure provide excellent impact resistance.

2.7, Fluxes and Additives

All furnace crucibles offer some level of resistance to corrosion and chemical attack. Fluxes and other metal treatments used in melting aluminium and other nonferrous metals are highly corrosive and require a crucible that offers a high level of resistance to chemical attack. This resistance is best imparted by both a consistently dense crucible material structure and a durable protective glaze. If your metal application involves the use of corrosive metal treatments, you need a furnace crucible offering the appropriate level of protection against these agents.

2.8, Degassing and Refining

Degassing aluminium and aluminium alloys typically involves bubbling inert gas, usually nitrogen, through the molten bath with a rotor designed to break apart and disperse the gas bubbles. These small bubbles then pull the undesirable hydrogen and oxides out of the bath and carry it along with dross and inclusions to the surface where the gas escapes into the air and the solid material can be removed. This process is often used along with fluxing agents that physically erodes the crucible and attacks it chemically. Therefore, a dense and strong furnace crucible that is highly resistant to chemical attack is needed. Graphite crucibles provide excellent resistance to elevated temperature erosion and to chemical corrosion.

In refining and melting precious metals, it is important that the crucible you use provides clean metal by incorporating non-wetting properties.

2.9, Slag and Dross Removal

A dense and non-wetting crucible helps to reduce slag and dross accumulation and will make it easy to clean the crucible when empty.

2.10, Emptying the Furnace

Crucibles for melting need to be designed for easy access to the metal. This allows the furnace to hold the metal at the proper temperature that prevents wastage of power or fuel.

Crucibles for furnaces that are tilted for pouring often require integral pouring spouts that provide the reach and accuracy needed for the pour.

2.11, Atmosphere type

- Air/Oxidizing- Furnace or thermal processing system employing an air or oxidizing atmosphere. Furnace crucibles that are resistant to oxidation or burn-up at the end-use temperature should be chosen. Graphite or refractory metal crucibles may burn up if used at high temperature in an oxidizing atmosphere.

- Inert- Furnace or thermal processing system employing an inert gas such as argon as an atmosphere or shielding blanket.

- Reducing- Furnace or thermal processing system employing a reducing gas such as hydrogen atmosphere. Furnace crucibles should be chosen without constituents that can be reduced at the end-use temperature. Iron oxides or silica could be reduced to iron or silicon under high temperature and reducing conditions.

- Vacuum- Furnace or thermal processing system employing a vacuum as an atmosphere. Furnace crucibles should be chosen that do not consist of volatile or high vapor pressure components at the end-use temperature.

2.12, Capacity of melting

Melting capacities can be small, medium or large. Depending on the size of your production, you can choose the furnace crucible size that is only needed. There are 250g, 500g, 1kg and 2kg crucibles for small scale melting and 4kg to 6kg crucibles for medium scale melting and 8kg to 10kg crucibles for large melting.

2.13, Price of crucible

The cost of a furnace crucible is very important. As mentioned earlier, metals like tungsten and platinum are used as furnace crucibles, these crucibles can be very expensive to purchase. Graphite crucibles are less expensive crucibles and perform excellently for melting.

Understanding all the aspects of your melting furnace, the melting temperatures of your furnace and the size or capacity of your melting will help you to choose the best graphite crucible for your melting activities.

Why Choose Superbmelt’s Crucibles: How We Produce the Crucibles

3.1, Manufacturing of Graphite Crucible

Refractories are manufactured from naturally occurring substances in the earth’s crust- graphite. Graphite materials do not occur in their pure form hence needs some treatment before manufacturing. Initial processing may include an extensive survey of the deposit, selective mining, stockpiling by grade, and beneficiation techniques such as weathering, grinding, washing, heavy media separation, froth flotation etc are employed.

Though some can be used without pre-processing, many must be subjected to heat treatment. Calcination is also carried out in some of the pre-treatment. Originally, calcinations refer specifically to the treatment of calcareous minerals to remove CO2. The term has come to be used to indicate heat treatment to sinter or burn (dead burn) the refractory grain to stable dense material as well as to decompose minerals. The materials obtained after calcinations are hard burnt materials and they are called grain, clinker or grog.

3.2, Control Raw Materials

Graphite is an allotrope of carbon and it is gray to black, opaque, very soft, has a low density and a metallic lustre. It is flexible and exhibits both metallic and nonmetallic properties, making it suitable for diverse industrial applications.

Global natural graphite production is approximately 1 to 1.2 million tonnes (Mt) per annum, of which flake graphite is estimated to be about 600-800 kt per year, amorphous graphite about 300 kt and vein graphite around 4 kt. The leading world producers of flake graphite in 2018 were China and Brazil. Mozambique is ramping up production significantly, having produced around 0.1 Mt in 2018, it is anticipated to overtake Brazil and become the second largest global producer in 2019.

China is also seeing increased flake graphite production, mainly from Heilongjiang Province, to supply the battery anode market. The major uses of graphite are in refractories, batteries, expandable graphite, plus brake linings, lubricants and steelmaking and foundry operations.

At Superbmelt, we produce our crucibles from graphite made from processing petroleum coke and pitch coke. The graphite used in the manufacturing of crucibles go through some degree of processing with our sophisticated equipment, dedicated for such a function. The primary components of our graphite are:

Pitch coke (produced from coal tar that appears during coke production). Pitch coke is manufactured by coking the destructive distillation of coal tar pitch from high purity carbon residue. It has high content of carbon and low content of sulphur and ash. Pitch coke also has high thermal conductivity. It is a byproduct of coal gas manufacturing.

Petroleum coke (petcoke) is the gray-to-black solid carbonaceous residue left by the destructive distillation of petroleum residua. Petcoke is used in the production of graphite, smelting and chemical industries.

We produce graphite of various densities with these components. The level of density has an impact on the level of porosity of our graphite crucibles, which implies that the higher the density of graphite, the lower the porosity of the crucible and the lower the density of the graphite, the higher the porosity of the crucible. Also, the higher the durability of the furnace crucible, the higher the melting qualities; this gives the furnace crucible a longer service life for vacuum utilization.

| Grade | NX601 | NX602 | NX603 | NX604 | NX605 |

| Grain size (µm) | 25 | 25 | 25 | 25 | 25 |

| Bulk Density (≥g/cm3) | 1.55 | 1.72 | 1.80 | 1.85 | 1.90 |

| Compressive strength (≥MPa) | 35 | 45 | 60 | 65 | 70 |

| Flexural strength (≥Mpa) | 15 | 20 | 30 | 33 | 35 |

| Porosity (≤%) | 23 | 20 | 17 | 14 | 11 |

| Specific resistance (≤µΩm) | 12 | 12 | 12 | 12 | 12 |

| Ash content (≤%) | 0.08 | 0.07 | 0.06 | 0.05 | 0.03 |

| Shore hardness | 35 | 45 | 50 | 55 | 60 |

3.3, Process Levels that can Meet Different Standards

There are three different graphite processing levels for Superbmelt graphite crucibles, they are; the moulded graphite process, isostatic pressed graphite process and medium coarse graphite process.

- Moulded graphite process

Moulded means it is cold pressed by molding. It is a type of graphite that is isostatically pressed. The resulting graphite material that has excellent properties uniformly distributed throughout the entire mass without having a grain direction. Combine that with high density and small particle size, and the result is a highly engineered material, very strong, with good machinability, and capable of retaining very fine details. It is resistant to high temperatures in controlled environments, electro-conductive and has self lubricating properties.

- Isostatic pressed graphite process

The isostatic pressing technology is a super high pressure hydraulic equipment and its working principle is that products formed under the condition of equal pressure and high pressure in all directions and closed high-pressure containers. Properties of isotropic, structural balance, high conductivity, high purity, high strength, high density, high mechanical strength; superior thermal shock, high temperature resistance, resistance to oxidation and corrosion; fine-grained, low receptivity, and easy for precision machining. The isostatic pressed graphite has the highest quality of all the three which comes with a higher price compared to the other two technologies. Isostatic graphite means that the raw material mixture is compressed into rectangular or round blocks. In addition, isostatic graphite generally tends to have the smallest grain sizes of all artificial graphites. In this process, crucible void content is low and density is large, homogeneous and erosion resistance is strong.

- Medium coarse graphite process

The graphite particles are coarse this is as a result of the low compression resistance and bending resistance. The medium coarse graphite is used mostly for heat exchangers and heating elements. The medium coarse graphite is best used for frequently used crucibles and furnaces.

3.4, Precision CNC Machining

The graphite crucible is widely used for experiment and melting metals. Graphite crucible materials with high purity, high strength, high density graphite material; through high precision CNC machining equipment, graphite crucibles, graphite casting crucible, graphite oil groove, slide, drawing tablets, pull rod of mold graphite products.

The well laid CNC machining centre backs us to manufacture these precision crucibles using high grade graphite materials. Our highly skilled machinists combine all raw materials to allow the CNC to machine graphite to the most demanding specifications and exacting tolerances.

3.5, Testing

The graphite from which the graphite crucibles are made is frequently tested by the manufacturer for porosity, it is common only to test a small test sample. Unfortunately, a single pore or fissure of substantial size anywhere throughout the length of the crucible can cause cracking and render the entire piece unusable.

A method of testing graphite crucibles for the presence of undesirably large pores or fissures, this method comprises immersing the crucible in water, reducing the atmospheric pressure over the surface of the water to a point where bubbles are observed coming from the pores in the graphite surface and visually determining the existence of any pores which yield air bubbles of a diameter sufficient to indicate an undesirably large pore or fissure in the graphite crucible.

3.6, Ways to Maximize Crucible Service Life

How a graphite crucible is handled, operated and maintained may be the difference between a crucible that consistently performs well and one that fails to meet even minimal standards may have nothing to do with the furnace crucible itself. Rather, the performance difference may have everything to do with how the crucible is handled, operated and maintained at the foundry. For example, if some furnace crucibles provide a long service life while other identical crucibles fail after a couple of heats, the operating conditions at the foundry typically causes those premature failures. Often, following some basic operational procedures will eliminate early crucible failures. Here are the practices that will help prolong your furnace crucible service life.

- Check crucible for cracks and damage when received. Be sure to handle and store it properly. Improper handling easily damages crucibles. When a new crucible arrives, inspect it carefully for chips, cracks and abrasions and never put a damaged crucible into service. Also, when moving crucibles to a furnace or into storage, never roll them: this damages theprotective glaze. And, never stack crucibles one inside the other because they will crack. Never sit them directly on a concrete surface because they will absorb water on the bottom.

- Install furnace crucibles according to the manufacturer’s instructions. While installing a crucible is quick and easy, care must be taken to follow the instructions regarding base size, clearances between the crucible and the furnace and the initial preheating of the crucible. A very small base may fail to provide sufficient support, and the wrong base height in a fuel-fired furnace may cause the burner flame to create an overheated and oxidized area on the crucible. Insufficient clearances between the crucible and the furnace sides and top may cause cracking when the heated crucible expands. Also, insufficient initial heating may result in crucible failure on first use.

- Prevent thermal shock with proper preheating. While some types of furnace crucibles are designed to resist damage from rapid heating, all crucibles require careful preheating if allowed to cool between melts. Thermal shock causes cracking in crucibles heated too quickly. Follow specified preheating recommendations.

- Every furnace crucible has a maximum temperature limit. If you exceed that limit the crucible will be damaged and may fail. Keep close control of crucible temperatures. Allowing molten metal to solidify in the crucible also may damage the crucible when that metal is reheated for pouring.

- Avoid physical damage by charging correctly and carefully. Dropping a heavy casting or ingot into a furnace crucible may chip or crack the crucible, leading to failure. Follow proper charging practice of first loading small charge materials and then carefully lowering heavier materials on top of cushioning base. It is important also not to pack charge materials tightly into the furnace. When wedged material is heated, it expands and can crack the crucible.

- Guard against chemical attack by minimizing flux usage and adding flux only after metal is fully molten. All furnace crucibles, even those designed to resist chemical attack, can be damaged flux additives. The most effective way to minimize this damage is to add flux only after the bath is fully molten and able to dilute the material. Adding flux with the solid charge allows the concentrated flux to attack the crucible surface during the melting process. It is important also to use the minimum amount of flux that is required.

- In a fuel-fired furnace, operating the burner with excess air and direct flame impingement on the crucible surface will produce damaging oxidation of the crucible. In all furnaces, placing ceramic fiber between the crucible and its base or wedging ceramic fiber against the top edge of the crucible also will cause oxidation and cracking in those areas. Allowing a metal bath to be held at a minimal temperature for a lengthy period of time will accelerate crucible oxidation.

- Control dross build-up by cleaning regularly. Dross or slag build-up is bad in several ways. It has low thermal conductivity necessitating higher furnace temperatures. It absorbs flux and accelerates chemical attack on the furnace crucible. And, its high expansion rate causes internal pressure on the crucible that can damage it. Follow a consistent program of frequent and thorough dross and slag removal, using a scraping tool that matches the curve of the crucible’s interior surface to avoid gouging.

- Maintain a careful log of furnace crucible use, inspect the furnace crucible often, and replace it when worn or damaged. Keeping an accurate log of crucible use is essential to the effective and safe operation of crucibles. It allows you to create a history that will reveal what crucible service life you should anticipate in normal operations. With this information, you can set up a program of routine crucible replacement that will minimize downtime. However, such a program is not a substitute for frequent crucible inspections that may reveal wear or damage that requires immediate crucible replacement.

- Select the right crucible for your operations and processes. Selecting the right tool for the job is essential for most tasks and crucibles are no exception. The most important way to maximize crucible service life is to begin by selecting the right crucible match for your application. You must consider the full range of metals and alloys you melt or hold, the type and size of the melting or holding furnace you use, the temperature ranges the crucible will experience, the rate of temperature change the crucible must sustain, the fluxes or additives to be used, your operating schedule, how the crucible will be charged and emptied, how the crucible will be handled, and how it will be maintained. With this information in hand, you get proper recommendations of crucible choice from Superbmelt.

Conclusion

No matter where you are in the manufacturing process, we offer you the graphite crucibles that are right for you. We are a graphite crucible manufacturer that adopts the highest level of expertise and technology in the production of our furnace crucibles. Our graphite crucibles are high density, low porosity, effective and durable for all smelting and melting activities.

We manufacture large graphite crucibles as well as small graphite crucibles for large and small scales of melting. It is important to note that despite all the brilliant features of our crucibles, Superbmelt graphite crucible price is very affordable.

You enjoy good thermal conductivity, high quality precious metal melting without loss of precious metal, easy maintenance, high thermal stability, high mechanical strength, resistant to alkalinity and acidity, etc. New furnace crucibles types with enhanced performance characteristics are becoming available frequently and we keep you up to date with this information.

FAQ

What is a graphite crucible?

A graphite crucible is a container made of graphite and it is used to melt and hold metals. They can be used at temperatures of up to 1600 degrees celsius and are suitable for refining and melting precious metals and base metals and other products. The graphite crucible is the crucible of choice for many users due to its outstanding properties, which include:

- High thermal conductivity: Due to the use of graphite, and other raw materials in high thermal conductivity, it ensures good thermal conductivity, shortens the time to melt and reduces energy consumption.

- Heat shock resistance: The heat shock performance of graphite crucible is strong, it is not easy to break for the urgent cold, urgent heat and any process.

- High heat resistance: Graphite crucibles have figures as high temperature and it is high temperature resistant 1200 to 1600 degree celsius.

- Corrosion resistance: Uniform and fine matrix design graphite of crucible make it strong to erosion against melt and delay the erosion degree of the product.

- Anti-mechanical shock: Graphite crucibles have a certain impact on the strength of the impact of mechanical properties.

- Oxidation resistance: Graphite is easy to be oxidized in the high temperature oxidation aerial fog, it has less consumption of oxidation due to the prevention of oxidation treatment.

- Anti adhesion: The sokage and adhesion of molten metal to graphite crucible is impossible because of the strict control of the material composition and rear metal contamination.

- Resistance to slag removal: Graphite crucible has a good resistance to slag effect.

- Acid resistance: Graphite crucible is resistant to acidity and alkalinity.

- Quality stability: The production technology and quality assurance system of high pressure forming method of graphite crucible fully guarantee the stability of the melting quality.

Are graphite crucibles good enough?

Yes, graphite crucibles are the best for melting precious metals and other types of metals because graphite crucibles have many benefits to its users, such as; good thermal stability, highly resistant to shock, resistant to acidity, high temperature resistant, long lasting, easy to maintain, etc. Graphite, being an inert material, is most suited for making crucibles for melting ferrous and non-ferrous metals in the industry.

How hot can a graphite crucible get?

Graphite crucibles are temperature resistant and that is why they are mainly used in furnaces. It is essential that graphite crucible melting temperature is higher so it does not break when melting metals with very high temperature. The graphite crucible must have a much higher melting point than that of the metal being melted. Graphite temperature can range from 1600 and 2760 degree celsius.

What is the best material for a crucible?

The best material for crucible is graphite. Graphite is an allotrope of carbon, which is a good electrical conductor. Being the most stable form of carbon under standard conditions, it is mined naturally to produce graphite crucibles.

Should you temper graphite crucibles?

Heat empty graphite crucible slowly at 200 degree celsius to eliminate any moisture, then heat on low power at 600 degree celsius. Heat on full power till bright red heat. Crucibles for melting application should continue to be heated on full power until the desired temperature is reached.

What needs to be checked before using a crucible?

Furnace crucible should be tempered before use. Heat the empty crucible at a low temperature for about 20 minutes. Then work the graphite crucible till red hot. Turn off the heat and leave the crucible to cool slowly. This process takes off any moisture in the crucible. Furnace crucibles should be properly checked for cracks prior to each application.

How big is a 4kg crucible?

Measurements: 5-1/4”, high x 4-3/4” in diameter (exterior dimensions); 4-3/4”, deep x 3-3/4” in diameter (interior dimensions).

What is the melting point of graphite?

The temperature at which the graphite is 3600 degree celsius.

What does a crucible look like?

A crucible is a cylindrical container made of graphite that is used to melt different types of metals. There are different sizes of crucibles for different ranges of melting, from small graphite crucibles to large graphite crucibles.

Why is it called a crucible?

The word “crucible” is from the medieval Latin word “crucibulum”. “Cruce” means pot, or jug and “ibulum” meaning censer.

Why is graphite used to make crucible?

Graphite is used to make crucibles because it is a good conductor of heat and electricity. The fact that graphite is able to resist chemicals and has a high melting point, also graphite is a good conductor of heat makes it adopted in the making of crucibles.

Which material is used to make crucibles?

Crucibles come in high resistant materials usually porcelain, alumina or an inert metal. They also come in a variety of other materials such as clay graphite, silicone carbide, graphite, etc. The best material is graphite because they are the best electrical conductive material known to man, four times of steel, five times of copper, and hundred times of nonmetallic materials. They also give higher thermal conductivity than steel, iron and lead. The graphite material is highly resistant to acid, alkali and organic solvents.

What are the different types of crucibles?

The different types of crucibles are graphite crucibles, clay graphite crucibles, crucibles for melting gold, crucibles for melting silver, silicon carbide crucibles. The graphite crucible is the best type of crucible because of its properties and affordability.

What can be used as a crucible?

Oftentimes, containers that have a higher melting temperature than the metal being melted is used as crucible. The best type of crucible for melting is the graphite crucible.

How do you make a crucible melt gold?

Preheat or temper the furnace crucible. Gently place your gold in a furnace crucible and allow it to melt at 1064 degree celsius. After melting, pour in a mold.

What is a melting crucible made of?

Melting crucible can be made of graphite, clay and graphite or silicon and graphite.

How much gold will I lose when I melt it in a crucible?

If it is 24 karat gold, none is lost during the melting processes it does not oxidize or vaporize. During pouring, some may be lost by spilling and some may remain in the crucible, although these are not lost, just need to be captured and remelted.

Why do you preheat a crucible?

A new crucible should be preheated slowly and evenly to 600 degree celsius on low power. Subsequently, the full heat input rate should be utilized to achieve a uniform bright red condition over the whole crucible at which point the crucible should be charged immediately taking care to avoid packing metal tightly or bridging ingots across the crucible. Preventing a crucible is done for the following reasons:

- Helps to reduce thermal stress.

- To ensure accurate measurements. If a crucible is weighed cold or below room temperature, it is possible that moisture may be trapped in the material of the crucible. This moisture leads to variable amounts of excess weight.

Why do we not allow the crucible to become red hot?

The procedure recommended for preheating graphite crucibles depends on the frequency of the furnace. In 3 kHz furnaces, crucibles should be preheated with the crucibles empty. Run the furnace for 1/2 hour at 20% of maximum power and then increase to 50% until the crucible shows signs of red heat. Loosely charge the crucible with metal. Keep the power at 50% of maximum until approximately half the crucible contains molten metal. Then increase to maximum power. In 1 kHz furnaces the crucible does not absorb power; therefore the crucible should be preheated with a charge loosely in place. Run the furnace at 20% of maximum power until the crucible shows signs of red heat. If after 1/2 hour the crucible shows no evidence of red heat, increase the power input to 50% of maximum. Hold at 50% until half the crucible contains molten metal, then increase to maximum power. crucibles are prone to thermal shock if the rate of temperature charge is too rapid. To preheat the crucible use whichever power level is smaller, 100KW or 50% maximum power input. Heat until the crucible is bright red, this should take 20–40 minutes. The crucible can be preheated with or without charge material, depending on the specific furnace conditions

How do you heat a crucible?

When melting metals in a furnace, indirect heating is used for melting in a graphite crucible. Graphite is a very nonmetallic material, it has very high electric and thermal conductivity, thereby, allowing the graphite crucible to be easily heated through electromagnetic induction.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited