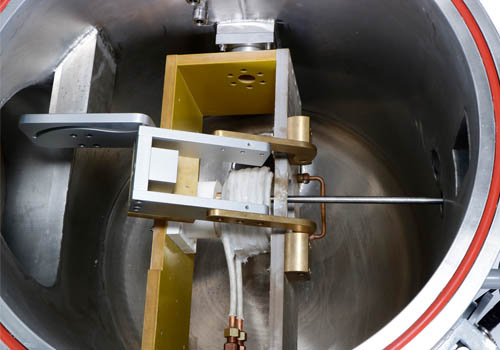

High Vacuum Melting Furnace

SuperbMelt China Leading Wholesale Supplier of Jewelry Smelting Equipment with Advanced Technology.

High Vacuum Melting Furnace rapidly reaches 2600°C, melting 4kg of metals like gold, silver, platinum, and palladium within three minutes. This furnace features a stirring function that ensures uniformity and bubble-free results in the melted liquid, making it the optimal choice for high-quality jewelry makers and producers of aerospace materials.

The furnace employs vacuum secondary feeding technology to prevent metal oxidation, enhancing product quality. Moreover, the High Vacuum Melting Furnace can operate continuously for 24 hours, significantly boosting production capacity.

Whether you are a high-quality jewelry manufacturer, aerospace material producer, or someone dedicated to top-notch smelting and refining, contact SuperbMelt now for a customized solution!

| Model number | SPB-HVM |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 10 kw |

| Applicable metal | Gold, Silver, Platinum, Palladium, and their alloys |

| Melting time | 3 minutes |

| Max capacity | Platinum: 4kg |

| Max temperature | 2600℃ |

| Cooling method | Water cooling |

| Dimension | 1760*720*1200mm |

| Weight | 550kg |

| Heating technology | Induction heating |

- High Density: Melts in a vacuum environment, resulting in a high-density final product.

- Anti-Oxidation: Features a vacuum secondary feeding function to prevent metal oxidation.

- Uniform Fineness: Equipped with a physical stirring function for a more uniform product fineness.

- Easy Operation: Controlled by a PLC system, ensuring simple and user-friendly operation.

- Continuous Operation: Capable of continuous loading for 24 hours, enhancing productivity.

- Safety Assurance: Multiple safety protections for worry-free and secure operation.

- Rapid Melting: Achieves quick melting at temperatures up to 2600°C.

- Optimal for High-Quality Jewelry: Ideal for jewelry makers who prioritize high-quality products.

- Bubble-Free Result: The stirring function ensures a final product free from bubbles.

- Energy-Efficient: Combines efficient melting with energy-saving features for sustainable operation.

- Jewelry Manufacturing: Perfect for creating fine jewelry made of metals including palladium, platinum, silver, and gold.

- Aerospace Industry: Used to guarantee the high purity and quality of metals in the manufacturing of aerospace products.

- Laboratory Research: Offers a melting environment at high temperatures that is appropriate for a range of metal investigations and studies.

- Production of High-Quality Alloys: This process is used to create metal alloys with a high degree of purity and quality.

- unique Metal Manufacturing: This process may be used to create a range of goods made of unique metals, including high-performance alloys.

- In these sectors, the High Vacuum Melting Furnace is a dependable melting solution that guarantees accurate and consistent quality in the finished goods.

Why SuperbMelt High Vacuum Melting Furnace

Any Question About SuperbMelt High Vacuum Melting Furnace

Any Question About SuperbMelt High Vacuum Melting Furnace

FAQ Guide of High Vacuum Melting Furnace

- 1. How does vacuum help in induction melting furnace?

- 2. Why use a vacuum furnace?

- 3. What is the vacuum level of a vacuum furnace?

- 4. What is a High Vacuum Melting Furnace?

- 5. How does a High Vacuum Melting Furnace work?

- 6. What metals can be melted in a High Vacuum Melting Furnace?

- 7. What is the temperature range of a High Vacuum Melting Furnace?

- 8. What is the significance of the vacuum environment in melting processes?

- 9. How fast can a High Vacuum Melting Furnace melt metals?

- 10. What industries benefit from High Vacuum Melting Furnaces?

- 11. Is a High Vacuum Melting Furnace suitable for research applications?

- 12. Can the furnace operate continuously?

- 13. What safety features are incorporated into these furnaces?

- 14. How does the furnace prevent gas porosity in melted metals?

- 15. Can the furnace be customized for specific melting requirements?

1. How does vacuum help in induction melting furnace?

- Preventing Oxidation: The main goal of producing a vacuum atmosphere is to drastically cut down on or completely remove oxygen. The absence of oxygen in a vacuum keeps the molten metal from oxidizing. This is particularly important when melting very reactive metals like titanium.

- Lowering Contamination: The presence of airborne pollutants can be reduced with the use of vacuum. This is especially crucial when melting metals that require high purity standards and are susceptible to contaminants.

- Increasing Melting Efficiency: Heat loss from convection and conduction is decreased in a vacuum environment when there is no air present. As a result, the melting process becomes more efficient, enabling the melting of metals more quickly and uniformly.

- Improving Degassing: Vacuum makes it easier to extract gasses and other volatile components from the molten metal. This is vital for preserving the metal’s purity, particularly in uses like the creation of premium alloys where a low gas concentration is necessary.

- Avoiding Metal Splash: Since there is no air present in a vacuum, there is less chance of metal splashing while melting. As a result, the melting environment is safer and better managed.

- Controlling Vapor Pressure: Vacuum control is useful in controlling some metals’ vapor pressure, especially those with low boiling points. To stop the evaporation and loss of volatile components, this is crucial.

2. Why use a vacuum furnace?

- Preventing Oxidation: Reducing or eliminating the amount of oxygen in the heating chamber is one of the main goals of employing a vacuum furnace. This ensures that the material maintains its original qualities without developing oxides on the surface by preventing metals and alloys from oxidizing throughout the heating process.

- Preserving Purity: In applications where a high degree of material purity is necessary, vacuum furnaces are essential. The furnace produces high-purity final products by minimizing the possibility of contamination from pollutants in the atmosphere by generating a vacuum environment.

- Improving Heat Treatment: Annealing, brazing, and sintering are heat treatment procedures that are frequently carried out in vacuum furnaces. Better heat treatment outcomes may be achieved by precisely controlling temperature uniformity, quenching rates, and other crucial factors when air is absent.

- Reducing Decarburization: A vacuum furnace aids in the reduction or elimination of decarburization, which is the surface loss of carbon in processes involving the heating of carbon-containing materials. This is significant for applications where keeping the carbon content constant is essential.

- Preventing Surface Reactions: When exposed to oxygen, some materials, particularly those utilized in cutting-edge industries like electronics and aerospace, might experience unfavorable surface reactions. By creating a regulated atmosphere, vacuum furnaces stop these kinds of reactions and guarantee the material’s integrity.

- Increasing Uniformity: When it comes to temperature consistency across the heating chamber, vacuum furnaces outperform traditional furnaces. This is especially helpful in situations when exact and constant heating is necessary to get the required qualities of the material.

- Lowering the Evaporation of Contaminants: Certain substances have volatile components that evaporate at high temperatures. The material’s composition is preserved by regulating and minimizing the evaporation of these components in a vacuum environment.

- Improving Material Quality: The creation of high-quality materials with better mechanical and metallurgical qualities is aided by the clean, regulated environment found within a vacuum furnace.

3. What is the vacuum level of a vacuum furnace?

- A vacuum furnace’s vacuum level is commonly represented in measures like millitorr (mTorr), torr (mmHg), or pascal (Pa), and is measured in terms of pressure. The level of vacuum or pressure within the furnace chamber is indicated by the vacuum.

- Depending on the particular needs of the application and the furnace’s construction, vacuum levels in vacuum furnaces might change. Typical vacuum settings for various kinds of vacuum furnaces consist of

Medium Vacuum: This pressure range usually extends from 1 to 10 mTorr (millitorr) or comparable units. Mechanical vacuum pumps are used to provide a medium vacuum, which is appropriate for a variety of heat treatment procedures. - High Vacuum: 10^-3 to 10^-6 Torr is the range of high vacuum levels. Diffusion pumps and turbomolecular pumps are frequently used in addition to mechanical pumps to achieve high vacuum. For procedures like brazing and sintering that need exact control and low contamination, a high vacuum is necessary.

- Ultra-High Vacuum (UHV): Vacuums of 10^-7 Torr or less are considered ultra-high vacuums. Advanced applications, like some research projects, the production of semiconductors, and particular aerospace uses, usually demand for UHV.

4. What is a High Vacuum Melting Furnace?

A High Vacuum Melting Furnace is an advanced industrial equipment designed for melting metals under high vacuum conditions.

5. How does a High Vacuum Melting Furnace work?

It works by creating a high vacuum environment inside the furnace chamber, which helps prevent oxidation and contamination during the metal melting process.

6. What metals can be melted in a High Vacuum Melting Furnace?

High Vacuum Melting Furnaces are versatile and can melt various metals, including gold, silver, platinum, palladium, and other precious metals.

7. What is the temperature range of a High Vacuum Melting Furnace?

The temperature range typically reaches up to 2600°C, allowing for the melting of high-melting-point metals.

8. What is the significance of the vacuum environment in melting processes?

The vacuum environment prevents oxidation and contamination, ensuring high-quality and pure melted metals, particularly crucial for sensitive applications.

9. How fast can a High Vacuum Melting Furnace melt metals?

It can achieve rapid melting, typically melting 4-6kg of metal within three minutes.

10. What industries benefit from High Vacuum Melting Furnaces?

Industries such as jewelry manufacturing, aerospace, and research benefit from the precise and contamination-free melting provided by these furnaces.

11. Is a High Vacuum Melting Furnace suitable for research applications?

Yes, it is often used in research settings due to its ability to provide a controlled and ultra-clean environment for metal melting.

12. Can the furnace operate continuously?

Yes, many High Vacuum Melting Furnaces are designed for continuous 24-hour operation, enhancing production efficiency.

13. What safety features are incorporated into these furnaces?

High Vacuum Melting Furnaces often include multiple safety measures to ensure secure and reliable operation, including overpressure and short-circuit protection.

14. How does the furnace prevent gas porosity in melted metals?

The vacuum environment minimizes gas porosity by removing gases from the molten metal, resulting in high-density and quality castings.

15. Can the furnace be customized for specific melting requirements?

Yes, SuperbMelt offers customization options to tailor High Vacuum Melting Furnaces to specific user needs and applications.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited