Michael Faraday’s Law of Induction is a fundamental principle in the field of electromagnetism. The law states that when there is a change in the magnetic field through a circuit, an electromotive force (EMF) is induced in the circuit. This induced EMF results in the generation of an electrical current in the circuit.

The amount of EMF induced in a circuit is directly proportional to the rate of change of the magnetic field through the circuit. This means that the greater the change in the magnetic field, the greater the induced EMF will be. Additionally, the direction of the induced EMF is such that it produces a current that opposes the change in the magnetic field that caused it. This is known as Lenz’s law.

Faraday’s Law of Induction has numerous practical applications, including the functioning of electric generators and transformers. In a generator, a rotating magnetic field is used to induce an EMF in a coil of wire, which generates electrical power. In a transformer, alternating current in one coil of wire induces a changing magnetic field, which then induces an EMF in a second coil of wire.

Michael Faraday’s Law of Induction is a fundamental principle in the field of electromagnetism. The law states that when there is a change in the magnetic field through a circuit, an electromotive force (EMF) is induced in the circuit. This induced EMF results in the generation of an electrical current in the circuit.

The amount of EMF induced in a circuit is directly proportional to the rate of change of the magnetic field through the circuit. This means that the greater the change in the magnetic field, the greater the induced EMF will be. Additionally, the direction of the induced EMF is such that it produces a current that opposes the change in the magnetic field that caused it. This is known as Lenz’s law.

Faraday’s Law of Induction has numerous practical applications, including the functioning of electric generators and transformers. In a generator, a rotating magnetic field is used to induce an EMF in a coil of wire, which generates electrical power. In a transformer, alternating current in one coil of wire induces a changing magnetic field, which then induces an EMF in a second coil of wire.

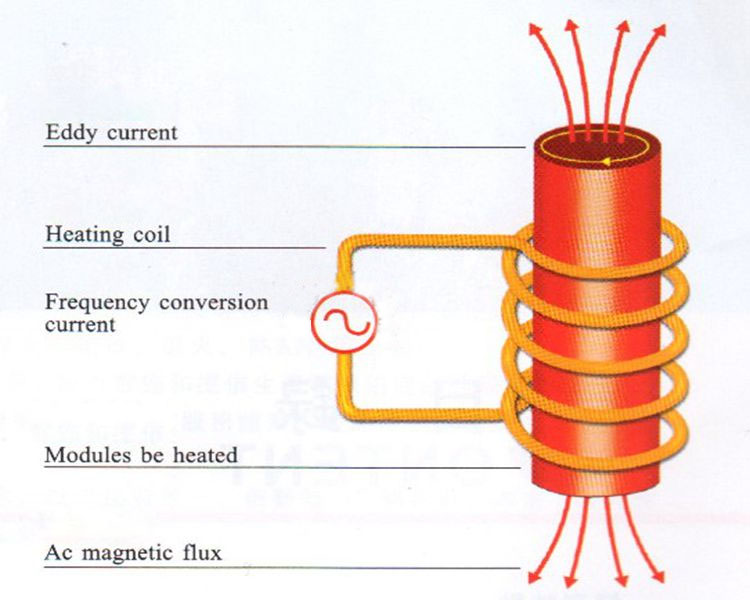

Induction heaters are a type of heating system that use an electromagnetic field to heat up a conductive material. This process is commonly used in industrial settings, particularly in metalworking and foundry applications.

One popular application of induction heating is the melting furnace, which is used to melt metal for casting and other manufacturing processes. In this blog post, we’ll take a closer look at how induction heaters work and how they can be used for melting metal.

At its core, an induction heater consists of a power source, a coil, and a workpiece. The power source generates an alternating current that passes through the coil, creating a magnetic field. When a conductive material is placed inside the coil, the magnetic field induces electrical currents within the material. These electrical currents generate heat, which causes the material to melt or reach a desired temperature.

In the case of a melting furnace, the workpiece is typically a crucible or other container that holds the metal being melted. The coil is positioned around the outside of the crucible, and the alternating current is passed through the coil to generate the magnetic field. As the metal heats up, it melts and can be poured into molds or used for other manufacturing processes.

One of the key benefits of using an induction melting furnace is that it can heat up metal quickly and efficiently. The heat is generated directly within the metal, which means there is minimal heat loss or wasted energy. This makes induction melting a more environmentally friendly and cost-effective process compared to other types of melting furnaces.

In addition to melting metal, induction heaters can also be used for a wide range of other applications, including brazing, soldering, and annealing. Whether you’re working in a foundry, a metalworking shop, or another industrial setting, an induction heater can help you heat up materials quickly and efficiently.

If you’re in the market for a melting furnace or other induction heating equipment, be sure to choose a reputable supplier with experience in the industry. At SuperbmeltManufacturing, we offer a wide range of induction heaters and related equipment to help you meet your manufacturing needs. Contact us today to learn more!

« I confirm the subscription of this blog to the Paperblog service under the username superbmelt »

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited