Gold Furnace

Introduction:

A gold melting furnace is an essential tool for anyone who works with gold, whether you are a jeweler, hobbyist or metal refiner. In this blog post, we will give you some tips on how to choose the right gold melting furnace for your needs, taking into account factors such as capacity, fuel source and budget.

Section 1: Capacity

Consider the amount of gold you want to melt at one time, as this will determine the capacity of your furnace you will need.

Furnaces come in a variety of sizes, from small tabletop models that can melt a few ounces of gold at a time to large industrial furnaces that can melt hundreds of ounces of gold.

Supermelt gold and jewelry equipment manufacturer has several popular melting machines for you to choose from

If you are a gold jewelry or jewelry lover, you can carefully check the parameters of this product, it is suitable for jewelry making, dental laboratory research and development, art casting, but please note that its capacity is only 1-2kg, this furnace can precisely control the melting temperature, which can improve the melting quality of all materials

Section 2: Fuel Sources

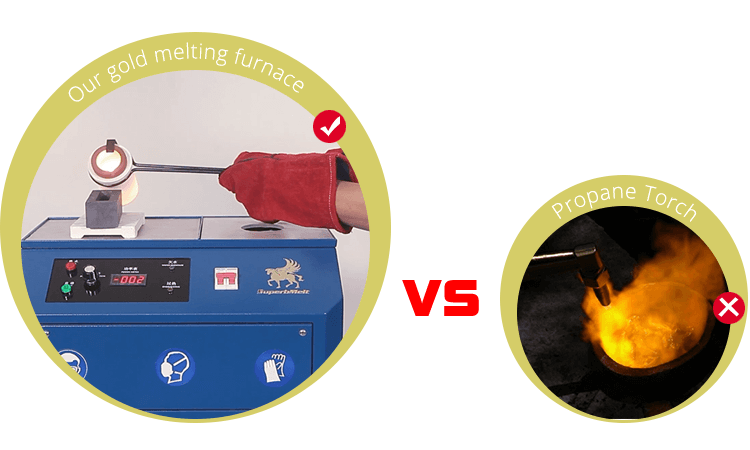

Gold furnaces can be powered by a variety of fuels, including propane, natural gas, electricity, and even charcoal.

Consider the availability and cost of fuel sources, as well as any safety concerns associated with their use.

Electric furnaces are a popular choice for small-scale melting because they are clean, easy to use and can be powered from a standard electrical outlet.

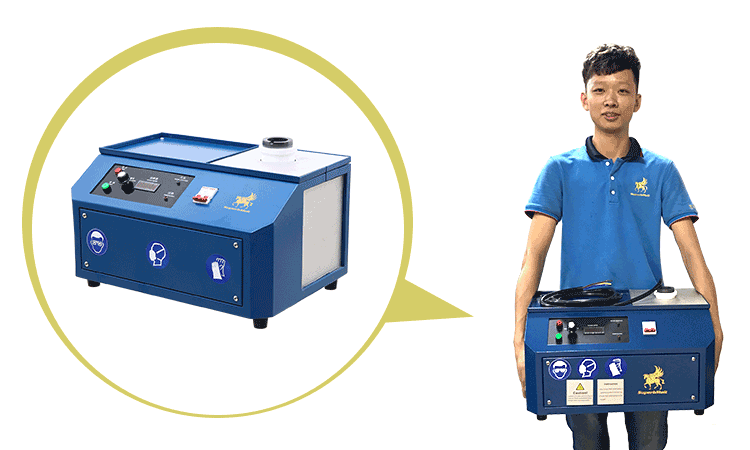

The 3-5kg melting furnace is indispensable for some professionals. Its heating element is made of more high-quality graphite material and has a longer service life. The design is easy to store and does not take up space. It is very suitable for some small gold jewelry. or jewelry maker

Section 3: Temperature and Control

Different gold alloys have different melting points, so it is important to choose a furnace that can reach the temperature required for a particular application.

Look for furnaces with temperature controls, such as digital displays or thermometers, to ensure you can accurately monitor the temperature of the molten gold.

The induction melting equipment is equipped with all-round protection to ensure the safety of the machine and operators.

Compared with the messy circuit design in the market, it adopts advanced microcomputer to control the power supply, saving more than 30% of electricity. More durable and stable. The tilting furnace design prevents spillage, reducing the risk of operator injury from splashing hot liquid metal.

Section 4: Budget

Gold melting pots can range in price from a few hundred dollars to several thousand dollars.

Consider your budget when choosing a stove, but remember that investing in a high-quality stove can save you time and money in the long run.

Crucible: The furnace is equipped with a crucible made of high-quality materials such as graphite, ceramics or quartz, which has the characteristics of high temperature resistance and corrosion resistance.

Safety features: Furnaces are often equipped with features such as over-temperature protection, short-circuit protection, and ground-fault protection.

Energy saving: use the least amount of energy to melt the material, and have high melting efficiency.

Versatility: The furnace can be used to melt 20-30KG of various metals, including gold, silver, copper and aluminum, as well as other materials such as glass or ceramics.

Induction gold melting furnaces come with comprehensive safety features to guarantee the protection of both the machine and its operator.

All-round high-temperature melting, fast melting and refining is completed, saving energy and time

Our induction gold melting furnaces feature a tilting furnace design that prevents spillage and minimizes the risk of operator injury from splashing hot liquid metal

Section 5: Types of Gold Furnaces

There are different types of gold melting furnaces available, each with its own unique features and benefits.

A propane melting furnace is a popular option for those who need portability and versatility, as it can be used in a variety of settings and can be easily transported.

A natural gas melting furnace is a good choice for those who need a reliable and efficient furnace for melting large quantities of gold on a regular basis.

An electric melting furnace is a great option for small-scale melting, as it is easy to use, produces little to no emissions, and requires minimal maintenance.

Foundry: Foundries use chain-type tilting melting furnaces to melt and process metal scrap, ingots, and other materials to produce castings of various shapes and sizes.

Recycling: Recycling facilities use chain-link tilting melting furnaces to melt scrap metal, such as aluminum cans or auto parts, and recycle it into new products.

Die casting: Die casting facilities use chain-type tilting furnaces to melt metal alloys and pour them into molds to create precision parts for various industries, including automotive, aerospace and medical devices.

Metalworking: Metalworking facilities use chain-type inclined furnaces to melt and process metals for a variety of applications, including forging, extrusion, and rolling.

Jewelry Making: Jewelry makers use chain tilting furnaces to melt precious metals such as gold, silver, and platinum to create jewelry pieces of various designs and styles.

- Introducing superbmelt’s top-of-the-line compact induction furnace that can melt virtually any metal you choose. Our small induction hobs have an impressive 10kw ~80kw power rating and can easily accommodate up to three different hobs without any issues.

- Our advanced IGBT sensing technology means you can reduce power consumption by up to 30% compared to conventional KGPS furnaces with higher consumption rates. This means significant energy savings and reduced costs for your business.

- Superbmelt small tilting melting furnace is designed with motor-driven chain tilting technology, which can improve work efficiency and pour metal easily. You have more flexible control over the melting process and the ability to adjust the tilting speed to your liking.

- Our furnaces also feature a full range of warning systems to alert you to any system issues that could damage your equipment or create a safety hazard, such as overvoltage, overcurrent, overheating, short circuits, lack of water, or improper frequency to your workers.

- Say goodbye to the hassle of changing furnace crucibles with our superbmelt mini induction furnace. Our design allows for easy and quick crucible changes, saving you valuable time and effort in the process.

- Choose superbmelt for a safer, more efficient and more cost-effective melting experience with our top of the line compact induction furnaces.

Power Supply Parameter Of Chain Tilting Electric Induction Furnace

| Model | SPB-CTF-15 | SPB-CTF-25 | SPB-CTF-35 | SPB-CTF-45 | |

| MAX input power | 15KW | 25KW | 35KW | 45KW | |

| MAX input current | 23A | 36A | 51A | 68A | |

| Input voltage | Three-phase 340V ~420V 50/60Hz | ||||

| Oscillation frequency | 1K~20KHz | ||||

| Requirement of cooling water | Hydraulic pressure | ≥0.2Mpa | ≥0.3Mpa | ||

| Flow rate | ≥6L/Min | ≥20L/Min | |||

| Temperature of water | ≤45℃ | ||||

Melting Capacity Parameter Of Chain Tilting Melting Furnace

| Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy |

| CMF-15 | 3kg | 10kg | 3kg |

| CMF-25 | 5kg | 20kg | 5kg |

| CMF-35 | 10kg | 30kg | 10kg |

| CMF-45 | 18kg | 50kg | 18kg |

| Remark: Above melting capacity sheet for general reference; Melting duration: When the crucible is hot,20~30min./workload; When the crucible is cold(first melt),40~50min./ workload. | |||

Graphite crucible for gold/Silver melting Furnace

Section 6: Maintenance and Safety

To ensure the longevity and efficiency of your gold melting furnace, it’s important to perform regular maintenance and cleaning.

Follow the manufacturer’s instructions for cleaning and maintenance, and be sure to inspect your furnace regularly for any signs of wear or damage.

Safety is also a crucial factor to consider when using a gold melting furnace. Always wear appropriate protective gear, such as gloves and eye protection, and never leave the furnace unattended while it’s in use.

Recycling of metal scraps: MTMFs are widely used in metal recycling facilities to melt and refine various types of scrap metals such as aluminum, copper, and brass.

Production of specialty alloys: MTMFs are used to produce specialty alloys such as nickel-chromium, stainless steel, and high-speed tool steel.

Production of small castings: MTMFs are ideal for producing small castings such as automotive parts, jewelry, and industrial components.

Production of superalloys: MTMFs are used to produce superalloys that are used in high-temperature applications such as turbine blades, aerospace components, and nuclear reactors.

Continuous casting: MTMFs can be used for continuous casting of metal bars, billets, and ingots.

Why SuperbMelt Silver Melting Furnace

in conclusion:

Choosing the right gold melting furnace can be a daunting task, but by considering factors such as capacity, fuel source, temperature control, budget, and furnace type, you can make an informed decision that meets your specific needs. You can read more about superbmelt introduced above and remember to also prioritize maintenance and safety when using your stove to ensure it lasts a long time. With the right gold melting furnace, you can efficiently and safely melt gold for a variety of applications from jewelry making to metal refining.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited