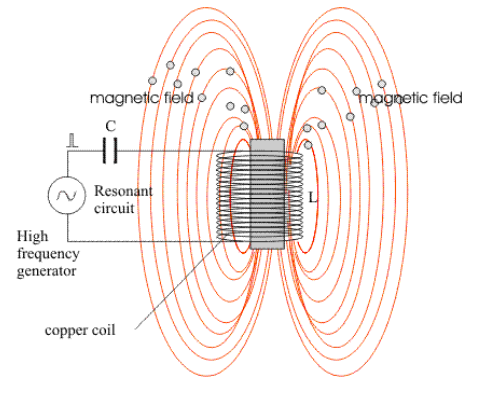

Induction System Principle

The high-frequency and high-frequency current flows around the heating coil which is made of circular or other shapes, (Usually with made of copper), great and instant magnetic bundle will be produced in the induction coil, This coil is either free standing for heating applications or placed inside of a furnace that acts like a melting pot. Magnetic bundle will heat through the whole object,the heating current in the opposite direction with inside part of the heating object, there will be corre-sponding large eddy currents, Because of the heated object memory in the resistance, it will have a lot of Joule heat, An object temperature rises rapidly. All metallic materials can achieve the purpose of heating. That is the induction system works way.

Application

1. The heat treatment: partial or total metal hardening, annealing, tempering, diathermy

2. Thermoforming: whole, local forging, hot forging

3. The welding: brazing metal products, a variety of cutter blade, serrated blade welding, steel, copper welding, the same kinds of dissimilar metal welding

4. Metal smelting: gold, silver, copper, iron, aluminum and other metals (vacuum) melting, cast-ing and evaporation coating;

5. High-frequency heating machine for other applications: semiconductor crystal growth, heat with bottle sealing, sealing toothpaste, powder coating, metal implants plastic.

Water cooling system is the essential part of the induction heating system because of the high amounts of electricity can generate a tremendous amount of heat, Induction coil directly adjacent to a heat source, it will withstand high temperatures, so we should keep the water travelled through the induction system during the process of heating , The water is recirculated throughout the induction system by a water pumping system and is cooled by a water cooling tower. Generally speaking ,the induction heating system is the most widely used heating method in the facilities, now it is an envi-ronmentally friendly, state advocates heating solutions.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited