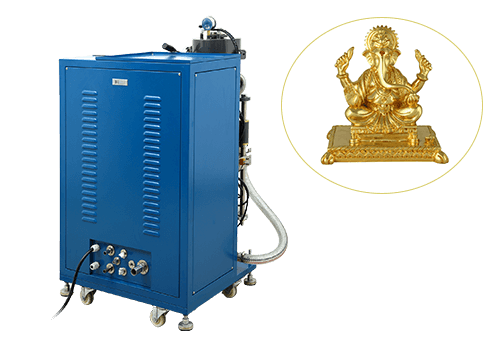

Jewelry Casting Machine

Leading Jewelry Machinery Manufacturer of Vacuum Pressurized Jewelry Casting (SPB-DM)

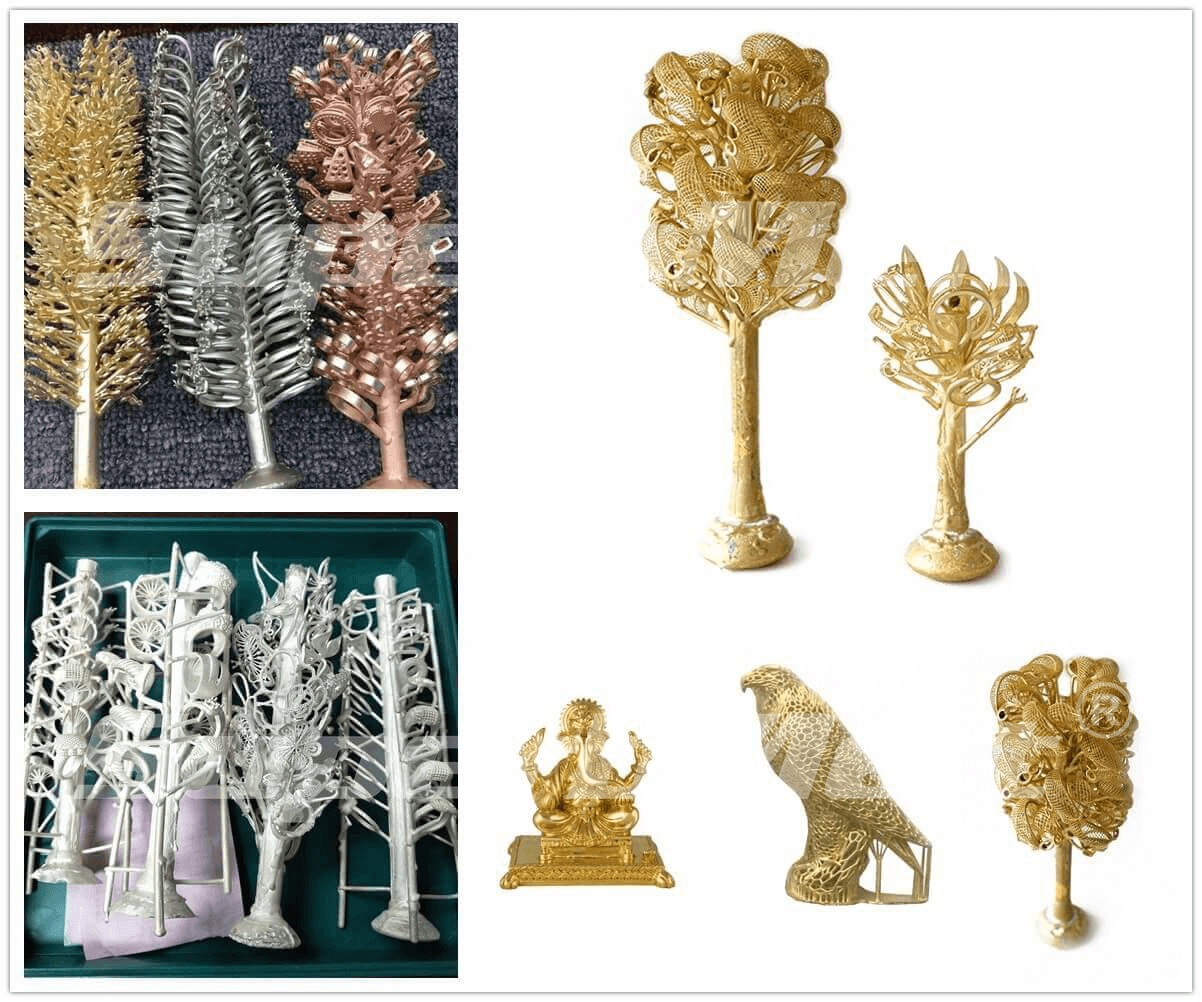

SuperbMelt jewelry casting machine (SPB-DM), also known as an automatic casting machine for jewelry, can be used for casting any precious metal in the weight range of 1-6kg. Precious metals such as gold, copper, and silver, or any other metal artwork, can be processed with this product. The vacuum jewelry making machine is the ideal choice when it comes to an automatic casting machine for jewelry. It offers exceptional speed and energy efficiency.

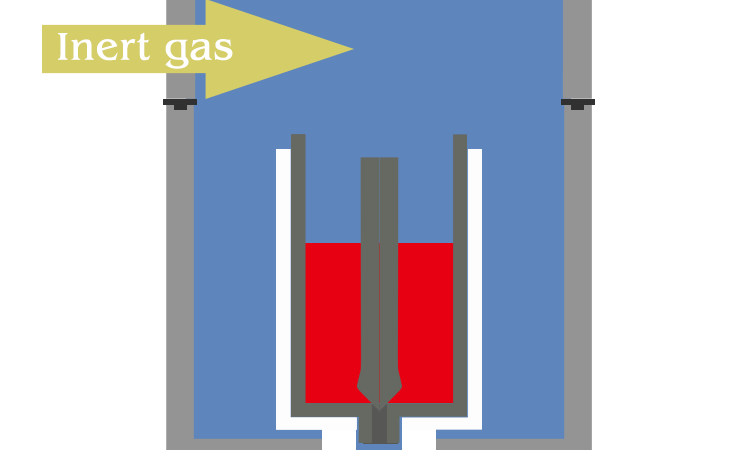

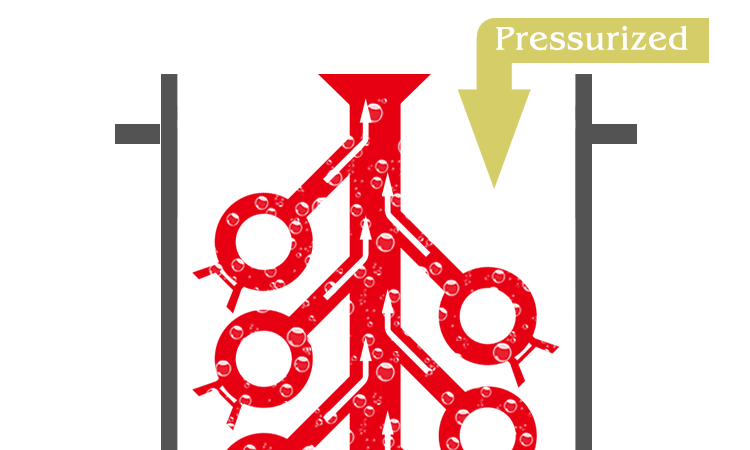

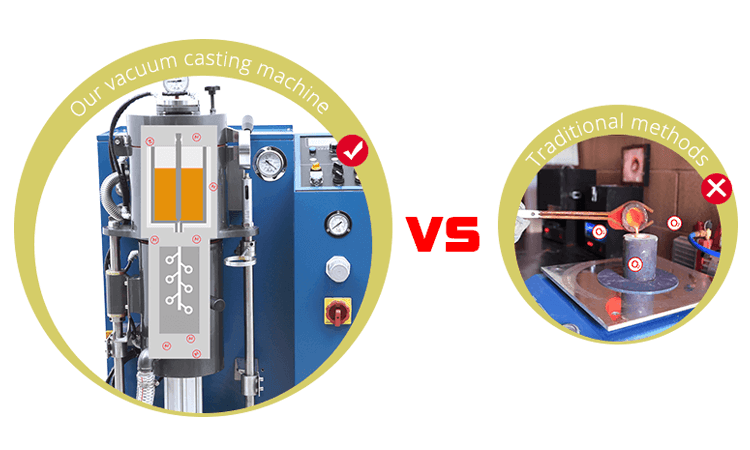

SuperbMelt jewelry casting machine (SPB-DM) ensures that you’ll never have to bother about density, shrinkage or air hole in your final piece. The casting machine comes with gas chamber which releases pressurized inert gases. This completely eliminates any of form of porosity or shrinkage. Thereby giving your final piece an impeccable appearance and a touch of class.

Strong induction stirring makes the gold alloy more uniform.

Link to more about jewelry casting equipment

- This product comes with an inbuilt Proportional, Integral and Derivative (PID) temperature controller. This automatically controls the whole system temperature once your operating parameters fully specified.

- SuperbMelt jewelry casting machine (SPB-DM) is also capable of reaching a maximum temperature of about 1600℃ in no time. It also comes with a temperature tolerance of ±2℃

- Also incorporated into the design of this jewellery casting tool is a 15Kw Induction generator. This generator is capable of melting any precious metal or artwork in 3-5 minutes. Thereby increasing your overall process efficiency coupled with saving in investment from lost saved hours.

- There are various alarm systems in place. They signal and automatically stops the machine when there any form of process abnormality is detected. This feature ensures both the safety of your operator and that of the machine.

- This product also comes with comparatively more space as compared with other metal casting machines.

- With the vacuum casting machine the quality of your final product is guaranteed. To top it all only relatively small space is actually needed for installation, owing to its small and compact design.

- When you are ready to make a purchase. You have the flexibility of either opting for a fully or semi-automated design depending on which best suits your production needs.

| Model number | SPB-DM2 | SPB-DM4 | SPB-DM6 |

| Power source | Single phase 220V/Three phase 380V, 50/60Hz | Single phase 220V/Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 8.5 kw | 15 kw | 25kw |

| Casting system | Vacuum pressure casting system | Vacuum pressure casting system | Vacuum pressure casting system |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 3-5 min | 3-5 min | 3-5 min |

| The Max capacity | 24K Gold: 2.0 kg 18K Gold: 1.5kg 925 Silver: 1.0 kg | 24K Gold: 4.0 kg 18K Gold: 3.0 kg 925 Silver: 2.0 kg | 24K Gold: 6.0 kg 18K Gold: 4.0 kg 925 Silver: 3.0 kg |

| Max temperature control R-type | 1600℃ | 1600℃ | 1600℃ |

| Max. temp control k-type | 1100℃ | 1100℃ | 1100℃ |

| Dimension | 720×700×1150 mm | 720×700×1150 mm | 720×800×1150 mm |

| Weight | 210 kg | 215 kg | 250 kg |

| Control of temperature | by PID | by PID | by PID |

| Pressure applied | Max. 0.25 Mpa | Max. 0.25 Mpa | Max. 0.25 Mpa |

| Protective gas | Nitrogen or Argon | Nitrogen or Argon | Nitrogen or Argon |

| Vacuum pump | 63 m³/hour | 63 m³/hour | 63 m³/hour |

| Oscillation | Induction heating | Induction heating | Induction heating |

| Max flask size | D101*H254 mm | Normal D101*H254mm (Customized) | Normal D160*H254 mm (Customized) |

| Ultimate vacuum | 10hPa | 10hPa | 10hPa |

| Accuracy of temperature | ±2 degrees Celsius | ±2 degrees Celsius | ±2 degrees Celsius |

| Pressure differential casting | Y | Y | Y |

| Vacuum filter | Y | Y | Y |

| Vacuum leakage detector | Y | Y | Y |

| Flask check before casting | Y | Y | Y |

| Flask and chamber lift | Y | Y | Y |

Why SuperbMelt Jewelry Casting Machine

Helpful Resource For Your Reference ( An expert about SuperbMelt jewelry casting equipment )

More SuperbMelt Metal Casting Machines For Your Choice

Any Question About SuperbMelt Jewelry Casting Kit

FAQ Guide of Jewelry Casting Equipment

- 1. What is jewelry casting equipment, and how does it work?

- 2. What types of jewelry casting equipment are available?

- 3. What materials can be used with jewelry casting equipment?

- 4. Is jewelry casting equipment suitable for small-scale artisans and large manufacturers alike?

- 5. What are the advantages of using jewelry casting equipment in the jewelry-making process?

- 6. Are safety precautions necessary when using jewelry casting equipment?

- 7. Where can I purchase reliable jewelry casting equipment?

- 8. Do I need specialized training to operate jewelry casting equipment?

- 9. Can jewelry casting equipment be used for custom or one-of-a-kind jewelry pieces?

- 10. What maintenance is required for jewelry casting equipment?

- 11.Does the product need polishing after demolding?

1. What is jewelry casting equipment, and how does it work?

Jewelry casting equipment includes machines and tools used to create jewelry through the casting process. It involves melting metal and pouring it into a mold to achieve the desired jewelry piece’s shape.

2. What types of jewelry casting equipment are available?

There are various types of jewelry casting equipment, including vacuum casting machines, centrifugal casting machines, and continuous casting machines. Each has its unique advantages and applications.

3. What materials can be used with jewelry casting equipment?

Jewelry casting equipment can work with various metals, including gold, silver, platinum, and more. The choice of material depends on the desired jewelry piece’s properties.

4. Is jewelry casting equipment suitable for small-scale artisans and large manufacturers alike?

Yes, jewelry casting equipment is available in different sizes and capacities, making it suitable for both small-scale jewelry artisans and large-scale jewelry manufacturers.

5. What are the advantages of using jewelry casting equipment in the jewelry-making process?

Jewelry casting equipment offers precision, consistency, and the ability to create intricate designs, making it a preferred method for jewelry manufacturing.

6. Are safety precautions necessary when using jewelry casting equipment?

Yes, safety precautions are crucial when working with jewelry casting equipment due to the high temperatures involved. Users should wear protective gear and follow safety guidelines.

7. Where can I purchase reliable jewelry casting equipment?

You can find reputable manufacturers and suppliers of jewelry casting equipment online or through jewelry equipment retailers. It’s essential to research and choose a trusted supplier to ensure quality.

8. Do I need specialized training to operate jewelry casting equipment?

While some experience and training are beneficial, many jewelry casting machines come with user-friendly features. However, professional training can enhance your skills and safety.

9. Can jewelry casting equipment be used for custom or one-of-a-kind jewelry pieces?

Yes, jewelry casting equipment is versatile and can be used for both mass production and creating unique, custom jewelry pieces.

10. What maintenance is required for jewelry casting equipment?

Regular cleaning, calibration, and maintenance are necessary to keep jewelry casting equipment in optimal working condition. Manufacturers often provide maintenance guidelines.

10. Does the product need polishing after demolding?

We use the SuperbMelt electro polishing machine for jewelry polishing. This machine can polish 20-138 pieces of jewelry at once, which is several times faster than traditional polishing methods, and at a lower cost. It also provides 360° polishing without any dead angles.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited