Jewelry Faceting Machine

Superbmelt provide a one-stop service to solve any problems with your jewelry chain manufacturing line

The Superbmelt jewelry faceting machine is the universal help for self-alignment that is combined within the vertical as well as the horizontal head machines. It is quite simple and versatile in terms of its operations, and it produces greater work with a huge amount of profitability.

For longer life and interchangeable parts, they are built rigidly as this machine generally comes equipped with the additional motor being fixed with the main divider in terms of assembly with a separately adjustable speed controller for the rotational speed within the ring or the bracelet that lies under the protection of jewelry faceting machine. In order to cut the designs on every kind of jewelry named bangles, or rings, or even pendants, they can be crafted accordingly.

- Each time when you are cutting the stone, the repeated actions are thereby producing a similar effect here.

- You need not have to get the wheel reinvented for cutting out a round brilliancy. There is always the kind of referral point that can easily help you in guiding towards the cutting nature with the help of Superbmelt jewelry faceting machine.

- You will still be having a working machine in almost one year or even a decade, and more is what it means that these machines are reliable.

- If you are taking care of it in the best way, most of these machines will have a longer life, and reliability also includes the preciseness over the life of the machine with every included accessory that it has.

- You can easily cut out a stone here while comparing the machine’s beings about the greater challenges here in terms of speed. The machine is quite accurate here to help you in cutting out the perfect stone.

- Superbmelt jewelry faceting machine can help create the straightened faces on the rock along with holding it in the hands that are quite hard here.

- Cost is also among the deciding factors in addition to that of accuracy and speed. The amount of money that you will be paying will be the determining factor here.

- The production capacity is generally at number 5 making it highly reliable and the most cost-effective solution that is available easily.

| Model | SPB-2CSCM |

| Item | Parameter |

| Max. Chain Diameter | 12mm |

| Speed | 24000rpm |

| Voltage | 220V/380V 50Hz |

| Size | 70x85x150 cm |

| Weight | 500kg |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Jewelry Chain Making Line Solution

Any Question About SuperbMelt Jewelry Chain Making Line Solution

FAQ Guide of Jewelry Faceting Machine

- 1. What is a jewelry chain cut faceting machine?

- 2. Application field of SuperbMelt jewelry chain faceting machine?

- 3. What are the safety features of jewelry chain faceting machines?

- 4. Do operating SuperbMelt jewelry chain faceting machine require special training?

- 5. How to produce jewelry chains nowadays?

- 6. How does the SuperbMelt jewelry chain faceting machine work?

- 7. How long does it take to facet a gemstone?

- 8. What does faceting mean?

- 9. What does a faceting machine do?

- 10. What materials can the SuperbMelt jewelry chain faceting machine be used for?

- 11. How do you clean a jewelry chain faceting machine?

- 12. How durable is a jewelry chain faceting machine?

- 13. What machines are used to make jewelry chains?

- 14. Does a jewelry chain lose gold when cutting facets? How to collect this gold?

- 15. How to choose the best jewelry chain faceting machine manufacturer?

1. What is a jewelry chain cut faceting machine?

For years, humans have been using different tools and technologies for marking, cutting, forming, cleaning, welding, and engraving jewelry. Now, jewelers have moved from depending on the traditional hand tools to advanced faceting equipment. This machine has brought a great revolution in the field of making gold chains. Using this machine, you can attain more efficient, precise, customized, and accurate cuts.

When you have the best jewelry chain faceting machine, you can easily carry out different processes, such as creating accurate lines, lapping, plain cuts, chamfers cut, and more. All you need to program the device based on your finishing or cutting requirements, and you are ready to go. These machines are quite popular among jewelers to give a stunning decoration to gold as well as the silver chain. As a result, they attract more customers to buy jewelry pieces.

If you want to buy a good quality machine under your budget, then it is time to contact SuperbMelt. Our machines are manufactured under expert guidance and have superior quality components. What’s more? In order to meet the unique quality requirements of different buyers, all the machines are tested under multiple quality-control tests. Talking about some amazing features of this machine. The list includes:

- Smooth finishing

- Quality and reliable performance

- Impressive strength

- Creates stunning designs

- Less maintenance and better service life, and more.

2. Application field of SuperbMelt jewelry chain faceting machine?

Most of the jewelers are now using the best faceting machines to carry out different tasks such as polishing, lapping, and more. For example, you can use this to attain the desired level of shininess in the jewelry created using different base materials, for example, brass. Polishing and lapping using a faceting machine can provide you with a good cosmetic surface for a high-quality fold plating process.

What’s more? Sometimes, you may need to create bevels on the chain to make it appear more beautiful. For this, you can also use a faceting machine. Such a machine can easily create multi bevels designs around the edge of the chain for a unique shape.

Apart from all these things, you can use this to create plain cuts, straight or customized lines, chamfer cuts, and more.

3. What are the safety features of jewelry chain faceting machines?

Anyone working around or with the machinery needs to always remain alert towards the possible dangers at all times. With time, machines are getting more complicated and high-tech. After all, you are now witnessing Industry 4.0. So, to keep the process of jewelry making safe, you need to buy a machine with maximum safety features.

Choose a chain faceting machine with a speed adjustment feature so that you can attain the desired speed for cutting and polishing. Besides, it is advisable to buy a machine that has a robust and completely sealed structure to keep yourself protected from the machine’s moving parts.

What’s more? Some machines come with motors that adopt step-less speed modulation technology. For accurate cutting of gold chain, go for a faceting machine with such a feature. Some gold chain-making machines have an automatic cooling system. A machine equipped with such a system can perform 24×7, and you don’t have to worry about the overheating issue.

4. Do operating SuperbMelt jewelry chain faceting machine require special training?

SuperbMelt is one of the trusted and reputed manufacturers as well as suppliers of different types of chain-making machines. We offer a casting machine, roll mill, drawing machine, jewelry chain making machine, hammering machine, and jewelry faceting machine.

We are committed to supplying highly reliable and effective machines that are designed with superior quality raw materials and advanced technology. All our machines are known for their amazing features, for example, noise-free operation, high operation, amazing level of precision, perfection, long machine life, and rugged design.

Speaking about the usability of the machine, even though our chain faceting machine comes equipped with the latest technology, you will not find them complex to use. One can use the machine without going through any special training.

Our quality machines are perfect for every business dealing with the jewelry industry. Most of the machines are designed to carry out the process automatically so that you can enjoy a perfect product. They meet the required industrial quality requirements and are safe to use. To know more about our automatic faceting machine to get a free quote, you can visit our official site and contact our executives.

5. How to produce jewelry chains nowadays?

During ancient times, manual processes were used to make jewelry chains. But those were very time taking processes, and creating a chain with a simple design, it can take months. Well, things have now changed, and now you can make chains with complex designs within a few hours or days using jewelry chain-making machines, including chain faceting machine. Let’s talk about today’s jewelry chain-making process.

- Getting pure gold

Before you can start the chains-making process, you need to obtain pure gold with the desired level of purity. But how to do that? You can use a furnace or crucible to meld gold. Gold ores are melted to get gold. SuperbMelt suggests using an induction furnace and a quality graphite crucible for this process. Once done, you need to purify the gold and make gold bars or rods, to begin with, the jewelry chains making process.

- Making gold rod

The next step is to make a gold rod from the gold bar or gold. Here, most jewelers use a continuous casting machine of SuperbMelt. We have manufactured this machine using the latest technologies, durable materials, and you can make gold rods with the desired shape. You can go for a circular shape, rectangular, cylindrical, and more shapes using this single machine.

- Making thin wire from the rods

As you can use gold rods to make chains, you need to create thin wires from that gold rod. This is where you can use our high-quality rolling mill. Fed the rod into the machine, and it will convert that into a thin wire. It creates accurate pressure, and you will get gold wire with a shiny mirror effect and a smooth surface.

- Lowering the wire diameter

Now, you need to further process the wire to create a thin wire. Instead of using any manual method, you can use a jewelry chain drawing process to get this done faster. Once you obtain the desired diameter, you can use that to make chains.

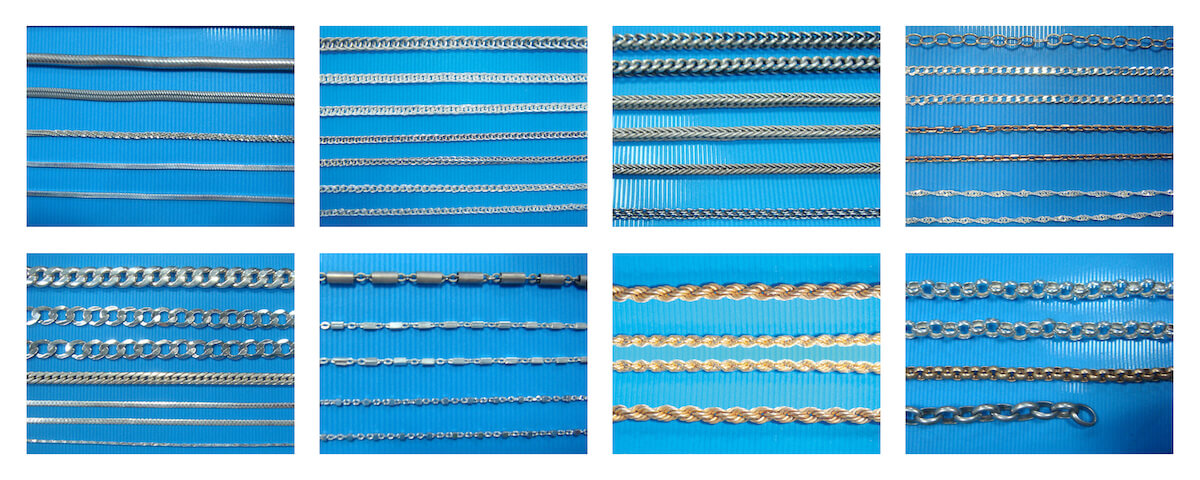

- Making chains

Nowadays, jewelers use a chain-making machine to make chains from different materials. For example, SuperbMelt’s chain-making equipment. This is quite versatile, and you can make different types of chains, such as snake chains, box chains, rope chains, and more, using this single machine. This machine can also be used to make double chains, and anchor chains.

You have successfully made a jewelry chain. Well, the process doesn’t end here. You need to make sure the chain is in the right shape. If not, then use a jewelry hammering machine to perfectly bind the gold parts for a perfect shape. It is very easy to use the machine. All you need to configure it, and the hammering machine will carry out the process automatically. Once done, you can use a chain faceting machine to cut the chain and get perfect shininess.

By using all these machines, you can make durable gold chains faster and without making any errors. Besides, you will enjoy the freedom of creating chains of any design. But for maximum benefits and features, you should buy a high-quality machine, and this is where SuperbMelt comes to play. Be it a continuous casting machine or a chain faceting machine, SuperbMelt has everything for you.

6. How does the SuperbMelt jewelry chain faceting machine work?

To understand the working principle of a jewelry chain faceting machine, let’s understand how does a normal faceting machine work. In general, every faceting machine comes with two important components.

One is the grinding wheel or a lap, and another one is mast or head assembly. Now talking about the process, a rough piece of gemstone or a chain is carefully attached to the head section.

Through rotation, angle, and adjustments of the head height, the object is gradually lowered into contact with the wheel until the facet has been ground. SuperbMelt’s faceting machine follows the same working process while working with a gold or silver chain.

7. How long does it take to facet a gemstone?

Well, this will depend on the size and design of the gemstone. However, in general, to facet a simple round gemstone, the process can take one to 2 hours. If you are faceting an ovals styles gemstone, the process may take around one to two and half hours. As per the experts, a medium sort of stone can take up to eight hours. Some other stones, such as sapphires, can take more time as such gemstones are very hard.

8. What does faceting mean?

In simple words, faceting means removing excess parts from an object without affecting the original shape of the product. Using the faceting method, you can create lines, cuts, and patterns on the object.

9. What does a faceting machine do?

The primary purpose of a faceting machine is to facet and polish the gemstone or jewelry chain at the same time. This way, you will save time as well as efforts that are required to polishing laps and inter-changing grinding on the single-wheel design.

10. What materials can the SuperbMelt jewelry chain faceting machine be used for?

SuperbMelt’s jewelry chain faceting machine can be used for the materials that you normally utilize to make jewelry chains. Speaking about some common materials that the machine can process are:

- Gold

It is a fact that more than 60 percent of gold is utilized to make jewelry. But the quality of the gold that generally use to make jewellery is not 100 percent pure. Why? It is very soft, and the hardness level of 100 percent pure gold is around 2.5 to 3 on the Mohs Hardness Scale. That’s why jewelers use 14K, 18K, 16K, or 21K gold to make gold chains. Various alloys are combined with gold to make it durable. However, SuperbMelt’s faceting machine can easily process all these types of gold.

- Silver

The machine can also use for a silver chain. Silver is a well-known metal, but jewelers don’t use 100 percent pure silver as this is very soft. In fact, it is softer than platinum and gold. So, jewelers normally add around 7 to 8 percent copper to enhance its hardness, brightness, and luster. That’s why the maximum purity level of silver is 92.5 percent, and it is generally called 925 silver.

- Copper

Copper is made into brass and bronze. In this case, the proportion of copper and the presence of other metals will determine how it will look. Compared to other metals such as gold or silver, copper is a little durable and can last for years. Our machine can be used to cut and polish copper-made chains.

- Platinum

Another common material that SuperbMelt’s faceting machine can process is platinum. Platinum is very durable, and it doesn’t tarnish. Don’t think that our machine can’t process it as this material is very dense. Equipped with advanced technologies, our face cutting machine can handle different metals. If you are looking for one of the best faceting machines, SuperbMelt has the best model for you.

11. How do you clean a jewelry chain faceting machine?

As all the bearings are properly lubricated and sealed, you don’t have to worry about the oiling of the bearing on SuperbMelt’s faceting machine. Now, talking about the cleaning of the machine, you need to clean it very often as such machines are built to precision, and you want to maintain that level. To clean the machine, you can use a dental brush or a soft-bristled paintbrush. The major areas on the machine that you should clean are the index gear and hard-to-reach sports on the faceting head and the base.

To clean the index gear, utilize a dental brush and carefully brush in between the teeth. Make sure that there is no swarf in gear. After that, use a small paintbrush and clean out all the loose particles.

Some parts, like the splash pan on a faceting machine, are easily removable. So, you can remove that and properly rinse it out, then put it back in place.

12. How durable is a jewelry chain faceting machine?

Well, a good faceting machine should be durable enough to process both silver and gold chains. Besides, you need to make sure that every time you cut the chain; you are getting the same effect. You don’t have to set the machine every time you want to cut a fine line. When it comes to buying a durable machine, you trust the machine available at SuperbMelt.

Our machine is made of high-quality metal and can keep functioning for years without developing any issues. Have a look at the faceting machines for sale and place your order now. For more information about our machines, please feel free to contact our experts anytime you want.

13. What machines are used to make jewelry chains?

Nowadays, most of the jewelers use advanced machines to make stunning jewelry pieces. For example, a jewelry faceting machine. Well, the jewelry-making process also involves some other machines. Let’s have a look at those machines.

- Continuous casting machine

The first machine that is used in the process is a continuous casting machine. This particular machine is used to cast melted gold into a rod. SuperbMelt’s machine comes with a gas insert melting protection technology to produce accurate as well as automate temperature control during the process.

- Jewelry roll mill

Once a gold rod is created, you need to convert that into thing wires. This is where you can use a jewelry roll mill machine offered by SuperbMelt. The machine can effectively roll the rods and offers you a thin wire.

- Wire drawing machine

SuperbMelt’s wire drawing machine can be used to create thin wire from a thick wire under the drawing process. You can easily get the desired standard of gold wire to produce the jewelry.

- Jewelry chain making machine

Once you are done with the wire making, you can use this machine to make a jewelry chain. All you need to insert the wire into SuperbMelt’s jewelry chain-making machine, and the machine will carry out the task. This single machine can handle cutting, welding, winding, and other important processes to make durable gold or silver chains.

- Jewelry hammering machine

After making the chain, you need to make sure that the chain is in the desired shape. If not, then you can attain the shape using our hammering machine. Insert the chain into the machine and attain the targeted shape within a few hours.

- Jewelry chain faceting machine

A chain faceting machine is used to attain a perfect finishing. Using this, you can get a good quality mirror finish lapping, lines, stars, accurate chamfers cut, plain cut, and more.

If you are looking for a reliable platform to buy all these machines, including a facet cutting machine under your budget, then don’t think much and get in touch with SuperbMelt now.

14. Does a jewelry chain lose gold when cutting facets? How to collect this gold?

Well, during the chain-making process, the gold chains lose gold. The road is processed to create a chain, and during the process, you may lose gold. This is quite common if you are using a manual method to make chains. In general, thin the jewelry casting process, the portion of unused casting can be more than the finished product.

To collect the unused gold or gold dust, you can simply clean the table on which you are making, and then you need to separate the gold dust from other things, like dust. However, if you are using a gold-making machine, you may not lose gold when cutting facets.

The machine used an advanced software program to offer you an accurate cutting process, preventing loss of gold. Besides, some machine comes with built-in gold particles collecting unit. If you want to buy the best faceting machine, then it is advisable to get in touch with SuperbMelt now. Check out our faceting machines for sale offer to get one at a discounted price.

15. How to choose the best jewelry chain faceting machine manufacturer?

Buying a jewelry faceting machine means you are making a huge investment, and for that, you need to make sure that you are buying it for a reputed manufacturer and supplier. So, how to choose the best manufacturer. Here are some factors that you should consider.

- Experience of the manufacturer

Before choosing a manufacturer, always check their experience in the industry because only a highly experienced manufacturer can offer you quality jewelry faceting machine supported by a robust R&D.

- Technical support offered by the manufacturer

Make sure that the company offers great technical support. These machines can develop technical issues while functioning. You should resolve them as soon as possible. A manufacture with a robust technical support team can help you in that, and you can enjoy an uninterrupted production process.

- Don’t forget to check the reputation of the brand

Before making your purchase, you prefer to check the reputation of the company in the industry. But how to check it? Well, you can go through the review posted online by the clients who have used their machines. However, you can always trust SuperbMelt to buy a good quality automatic faceting machine. The company is an AAA accredited company, and we follow a strict machine manufacturing procedure to make durable machines.

- Always pay attention to details

You need to make sure that the machine can provide the users with accurate perfection, long service life, high operation, utmost precision, and more. Besides, you should also consider some other features, like noise-free operation and rugged design. Well, SuperbMelt’s automatic faceting machine is created using solid metals, and it meets the necessary industrial quality standards.

Keep all these things in your mind, and you will be able to choose the best jewelry faceting machine manufacturer to buy the machine.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited