Jewellery Making Machines

Top Manufacturer in China

- Over 15 years R&D experience of Jewellery rings, bracelets, beads, chains manufacturing.

- Provide One-stop production solution service for jewelers, gold digger, goldsmith.

- Have professional equipments for precious metals (gold, platinum, silver, etc) smelting to molding.

- Helping you get more profit in the jewelry industry.

New Jewelers Professional Solution Supplier

In the face of the rapid development of the jewelry market today, consumers have higher and higher requirements for various jewelry styles and quality. This creates a bigger challenge for jewelers. In the face of the cumbersome and difficult traditional craftsmanship, it is obviously unable to meet the rhythm of the current FMCG market and the unique needs of customers.

Therefore, SuperbMelt provides production equipment and one-stop production line solutions for all kinds of jewelry products, including bracelets, beads, bangles, rings, necklaces, pendants, etc. From the processing and smelting of precious metals, metal forging to the production of various types of jewelry (such as wax molds, carvings, diamonds, etc.), we have professional machinery that can help you achieve rapid mass production.

Whether you are a gold digger or a small or medium jeweler, even new jeweler, we have professional training programs to help you solve all your problems.

How Are Jewelry Made?

Jewelry manufacturing generally have these major process: drawing, melting, casting, rolling, forming, stamping and etc. There are many steps involved in making a specific piece of jewelry, turning precious metals such as gold, platinum, silver, etc. from a drawing into a beautiful finished product.

Drawing:

The first step of the production of a piece of jewelry requires design drawings. There are two ways, manual or electronic. In electronic version, a 3D scanner is often used to reproduce the original design.

Melting:

Melting process is the transformation of precious metals from solid to liquid. Our induction smelting technology refines the raw materials for jewelry casting in an economical and environmentally friendly way.

Wax Carving:

By hand-carving the design of the jewelry on the wax mold, or using a 3D printer, print out different styles of wax molds, and then realize direct casting.

Wax Inlay:

It is to set the gemstone in the wax model before using lost wax casting, and finally directly melt the wax model to form the finished product.

Casting:

The casting process includes the casting of semi-finished and finished products. The semi-finished product is to shape the precious metal into blocky, round rods, pipes, and other shapes. The casting of finished products generally uses the lost wax casting method to make finished jewelry such as rings, necklaces, bracelets, pendants, etc.

Rolling:

The rolling mill process is to realize the deformation of the metal material through the friction between the rotating roll and the metal material, such as turning a block into a sheet and a rod into a wire.

Forming:

There are many types of jewelry molding processes, such as drawing wires into fine threads, then making chains, and hammering hollow tubes into hollow beads.

Stamping:

The stamping process is to use molds and stamping equipment to apply pressure to the metal sheet and then emboss the pattern on the material. It can also be used to be pressed a material into a certain size and shape.

Decoration:

Use a high-speed rotating diamond milling cutter to carve regular horizontal and vertical stripes on the surface of metal accessories, such as beads, bracelets, etc., to form exquisite patterns.

Jewellery Making Machines By Different Manufacturing Process

If you’re looking for one or several types of jewellery machines, here we list some of the common machines needed in the jewellery making.

Jewelry Induction Melting Furnace

SuperbMelt induction melting furnace can be used for the raw materials for jewelry melting, such as gold, silver, copper, platinum and other metals, and can also smelt and reuse some old gold and silver jewelry and other jewelry waste.

The induction melting furnaces range from desktop to large, with a melting capacity of 1-250kg, It can melt ferrous and non-ferrous metals such as gold, platinum, silver, copper, iron, etc.

If you are a jewelry studio or a small jewelry store, you could choose a 2kg desktop gold melting machine, which is easy and convenient to use, or if you have any project ideas, just contact us, and we will recommend the suitable model for you.

Jewelry Casting Machine

Casting machines are widely used in various jewelry industries. Continuous casting machines can be used for high-density semi-finished products such as plates, round bars hollow tube and metal particles for chain and bracelet making,while vacuum pressure casting machines can be used for the production of finished jewelry, such as gold , silver, platinum bracelets, rings, pendants, etc. There are also various styles of metal jewelry that can be cast with this machine.

SuperbMelt casting machines are available in a variety of models, including vacuum pressure casting machines, vacuum granulating machines, ingot casting machines, and continuous casting machines. There is also a casting set designed specifically for small jewelers. It can be provided to customers with different casting needs, and the machine automation level is very high, which realizes the production of jewelry.

If you have a customized jewelry project, you could also consult us, and we have professional engineers to help you solve the problem.

Jewelry Stamping Machine

Jewelry stamping machines of different tons can be used to cut metal sheets, make metal pendants, and the production of some commemorative coins is also inseparable from the use of punching machines. Some gold ingots are printed with logos, text patterns, etc., which also require a stamping machine.

SuperbMelt stamping machines range from 20tons to 500tons and are suitable for different application scenarios, including small semi-finished factories, larger jewelry manufacturing factories, and metal processing industries.

Jewelry 3D Scanner

With the increasing popularity of jewelry, everyone has more pursuit of jewelry styles, and jewelry design always requires a lot of time and energy, so now 3D scanner equipment has emerged in the jewelry industry, which can be used to Scan the ready-made works and then form a CAD file. You can directly print this style with a 3D printer, or you can modify it on the basis of the original file to become a new style.

And SuperbMelt jewelry 3D scanner is very accurate, focusing on the scanning of jewelry, which can help jewelers to quickly achieve mass production.

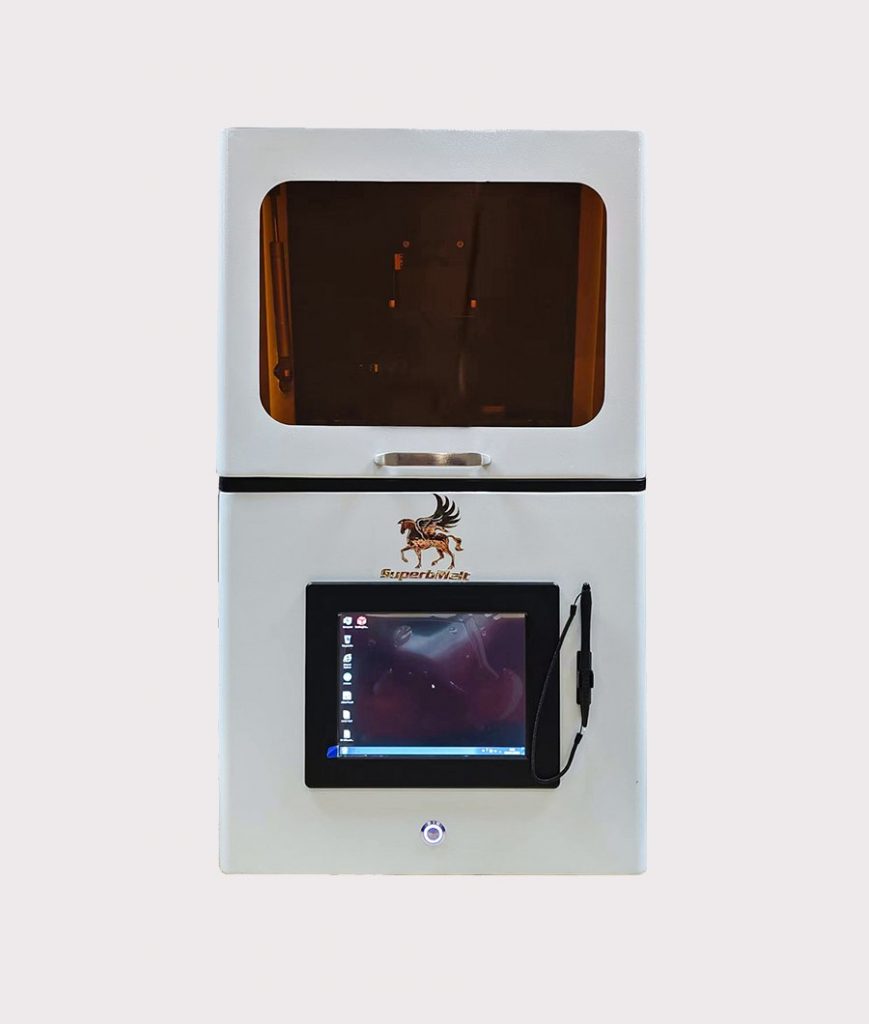

Jewelry 3D Printer

The emergence of 3D printers is a new development in jewelry manufacturing. Compared with the traditional hand-carved wax process, 3D printers can not only have more innovations in style, but also take a faster time to form molds, saving jewelry manufacturing time and labor costs.

SuperbMelt 3D printing equipment is available in wax, resin, direct-manufacturable and non-direct-cast types. Customers who have high requirements for finished product performance can use wax printers, while customers who want high cost performance can choose resin printers.

Jewelry Gold Testing Machine

The jewelry gold testing machine can be used to test the purity of jewelry raw materials, such as gold, silver, platinum and other metals. It is widely used in jewelry making factories, jewelry stores, pawn companies, precious metal recycling and processing factories, etc.

SuperbMelt gold testing machines are available in desktop models and portable models. For different metals, precision, and application scenarios, we have corresponding models to recommend. If you have inquiries about other applications of the gold analyzer, you could also contact us.

Jewelry Laser Welding Machine

Jewelry welding machine is used for repairing, filling holes, filling gaps, etc. of small jewelry, such as rings, bracelets, pendants, clocks, hardware, etc. It has great advantages for welding workpieces with small size and high welding quality requirements.

SuperbMelt jewelry welding machine has high welding precision. There are 30-300w to choose from. Different power machines can meet different welding needs. For products with a welding depth of 0.5-0.8mm, you can choose 200w, and the welding time also needs to be paid attention to , if it is only spot welding for a short time, then low power is enough, but for continuous welding and deep products, high power is required.

Our welding machines are mainly used in jewelry stores, hardware stores, watch stores, etc.

Jewelry Rolling Mill

Jewelry rolling mills are mainly used for the forming of metal materials, which can press blocks into flakes or thick round rods into thin wires. After this step is completed, the next hollow tube shape and the formation of fine lines can be obtained. The end result is beautiful beads, as well as jewelry chains.

SuperbMelt has a wide range of rolling mills, ranging from basic sheeting and pressing wire, to mirror-effect tungsten steel rolling mills, and upgraded belt rewinding, as well as continuous casting rolling mills. We are committed to improving the production efficiency of each customer. Under the pressure of the fast-selling market, high-output machines are worth investing in.

Wire Drawing Machine

SuperbMelt wire drawing machine works very efficiently. The equipment adopts high-quality material precision-manufactured wire wheel, which has strong wear resistance.

The motor adopts stepless speed regulation design, and also upgrades the functions of automatic wiring, automatic winding, and the use of automatic cooling system, which makes the machine stop automatically after the work is completed.

Jewellery Making Machines By Different Jewelry

If you’re looking for a series of specific machines for your jewelry production line, such as Rings, Bangles, and Chains. Here we list machines needed in each production line.

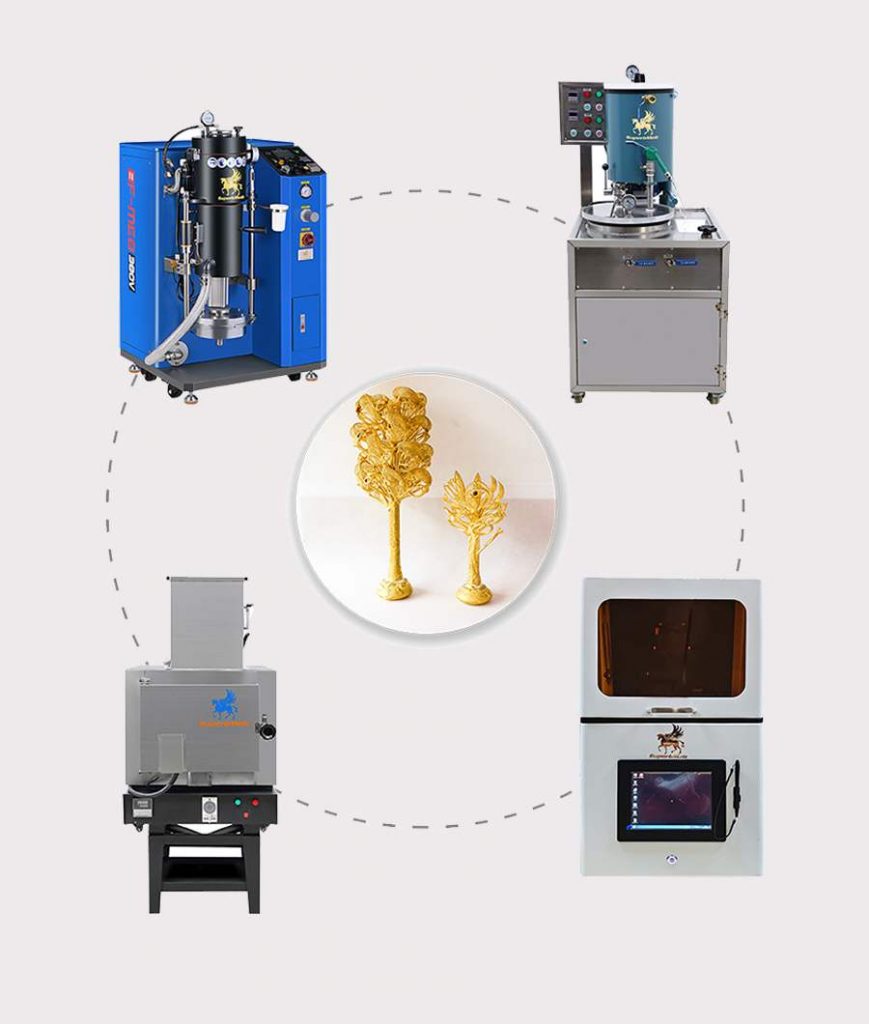

Jewelry Ring Making Machine

With the use of SuperbMelt ring making equipments, various styles of rings can be presented at the same time, and the styles are exquisite and very simple and efficient.

Step 1: Drawing the design on the computer, or use a 3D scanner to convert the existing style into a CAD file.

Step 2:Using a 3D printer to print the wax or resin casting mold.

Step 3: Using of a powder mixer to inject the gypsum slurry into the casting mold

Step 4: Melt the ring wax mold using a wax burning furnace.

Step 5:Put the plaster mold into the mini jewelry casting machine and inject the metal metal into the mold.

Then after casting, the plaster is cleaned to get a complete ring shape, and finally polished to get a beautiful ring.

Jewelry Bangle Making Machine

For gold and silver bangles on the market, most of the solid bangles can be completed by the lost wax casting method, and SuperbMelt has also developed a set of hollow bangles solutions.

Step 1: Turn the metal material into blocks using a continuous casting machine.

Step 2: Press the metal block into metal sheets of suitable size through a rolling machine.

Step 3: Use a slitting machine to cut the metal sheet to the appropriate width.

Step 4: Weld the sheets into tubes by a hollow tube making machine.

Step 5: Use a pipe drawing machine to change the inside diameter of the metal tube.

Step 6: Shape the metal tube using a winding machine.

Finally, use a bangle making machine to shape the hollow tube into different kinds of bangle shape.

Various shapes of hollow bangles can be realized with our equipment, such as circular arc, flat, inner flat and outer arc, etc.

Jewelry Hollow Beads Making Machine

Gold and silver beads are now used in many jewelry styles, and the mass production of beads is inseparable from the help of professional equipment.

So how are common beads produced?

Step 1:Using a jewelry continuous casting machine to make the entire metal block.

Step 2:Pressing the metal block into a sheet of suitable thickness using a jewelry rolling mill.

Step 3:Using a jewelry hollow tube forming machine to weld the metal sheet into a hollow pipe.

Step4:Using the jewelry beads making machine to make the tube into beads.

Finally, using a jewelry diamond cutting machine to add exquisite texture to each bead.

No matter what type of beads you need to produce, round, oval, or drop-shaped, etc., we have specialized production line equipment and process solutions to help you understand and enter the industry faster.

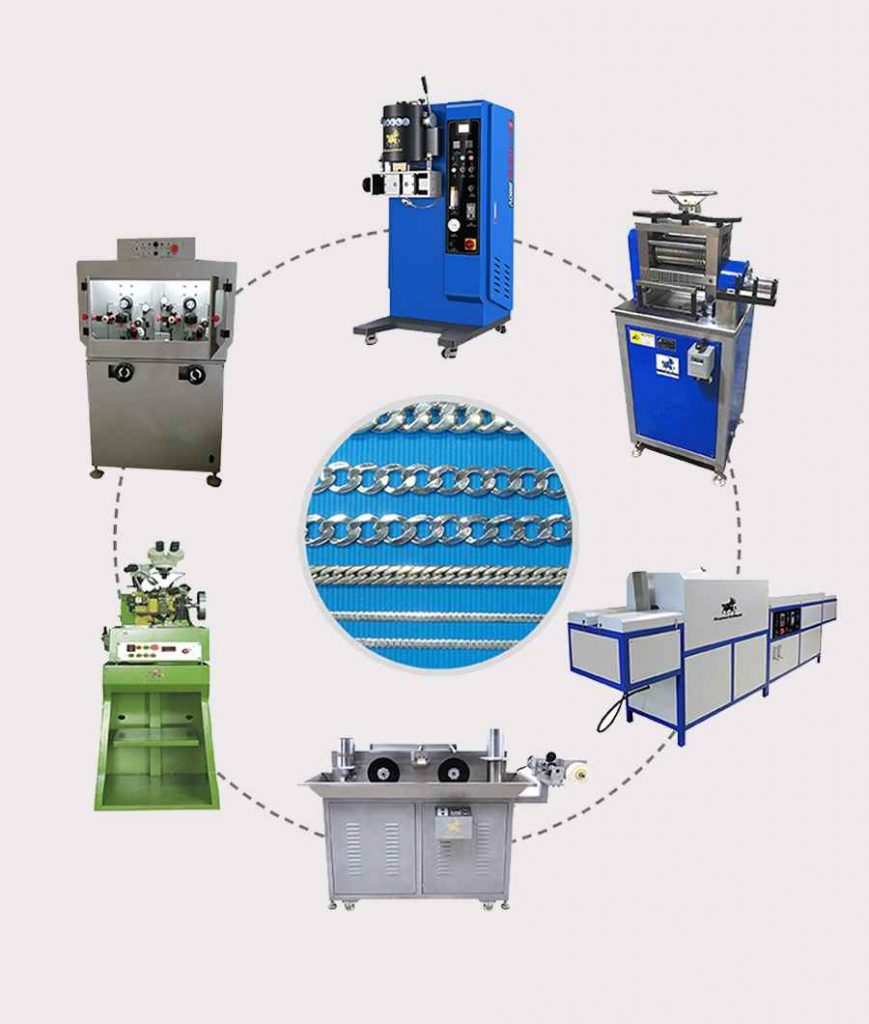

Jewelry Chain Making Machine

Another important production process in the jewelry industry is the jewelry chain. The necklaces and bracelets we will use now also have a complete production line process.

Step 1: Use gold continuous casting machine to make metal round bars

Step 2: Use a wire pressing machine to crimp the wire into thin wires

Step 3: Use the wire drawing machine to pull the thin wire more evenly and smoothly

Step 4: Use an annealing furnace to soften the thin wire

Step 5: Use the jewelry chain making machine to make various kinds of chains from the thin wire

Finally use a chain polisher to make it smoother and more shiny.

There are many styles of chains, including Cuban chains, wheat ear chains, box chains, cable chain, spiga chain, box chain, rope chain, cross chain,etc. There are professional manufacturing equipment in SuperbMelt, and our engineers will give customers a full range of training and explanations.

Gold Coin Making Machine

There are often many regular-shaped pendants in jewelry, such as round, square, etc. This type of pendant requires special production equipment, and such a production line is often used to make gold coins.

Here, a continuous casting machine is also needed to shape the gold coins. For example, if the final product needs to be made into a square pendant, the metal is made into a metal block, and then the sheet pressing machine is also used to press it into a suitable thickness, and a 20ton hydraulic press is used to cut it. Then use an annealing furnace to soften it, use a polishing machine to make the surface smoother and brighter, and finally use a larger tonnage hydraulic press to press out the pattern of the gold coin.

We have provided equipment services for gold coin lines for many customers around the world, and the feedback from customers is very good. We have done a very mature one-stop service for gold coin lines. If you are interested, you can contact us, and we will send previous solutions for your reference.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited