Metal Tag Stamping Machine

SuperbMelt Professional Gold, Silver, Aluminum Metal Embosser

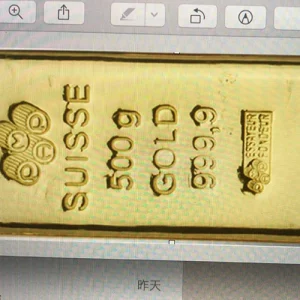

Discover the SuperbMelt metal tag stamping machine for sale, a versatile solution perfect for jewelry stamping needs. Whether it’s gold nuggets, silver nuggets, or iron nuggets, this machine excels in embossing and stamping labels with precision and finesse.

The SuperbMelt Jewelry Stamping Machine is not limited to metal tag stamping; it also caters to nameplates, hang tags, and various other jewelry label applications. Its adaptability makes it a must-have tool for jewelers and manufacturers looking to add a professional touch to their products.

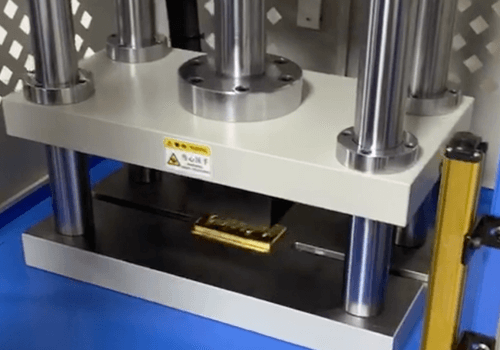

Engineered with hydraulic technology, the SuperbMelt Logo Stamping Machine applies fluid pressure to a cylinder, ensuring a seamless and efficient stamping process. Each impression is consistent and flawless, resulting in exquisite jewelry pieces with clear, well-defined markings.

| Model number | SPB-10TS | SPB-20TS | SPB-30TS | SPB-40TS | SPB-50TS |

| Nominal/ton | 2.5-10 | 5-20 | 8-30 | 10-40 | 15-50 |

| Max stroke/mm | 100-200 | 100-250 | 100-250 | 300 | 300 |

| Opening height/mm | 300 | 350 | 350 | 400 | 400 |

| Descending speed/mm | 88 | 68 | 48 | 38 | 38 |

| Rising speed/mm | 88 | 68 | 48 | 38 | 38 |

| Worktable area/mm | 450*350 | 500*400 | 500*400 | 600*500 | 600*500 |

| Table height from the ground/mm | 850 | 850 | 850 | 850 | 850 |

| Voltage/V | 380 | 380 | 380 | 380 | 380 |

| Motor power/kw | 3.75 | 3.75 | 3.75 | 5.5 | 5.5 |

| Weight/kg | 580 | 660 | 800 | 980 | 1200 |

- Adopting four-column and three-plate structure, the planar accuracy of the movable plate fish table is high, the four-axis precision linear self-lubricating guide sleeve is controlled, and the vertical accuracy is high.

- Imported high-quality hydraulic components, electrical components, low noise, high performance, stable operation

- Simple operation, pressure, stroke and closing height can be adjusted by pressing process requirements.

- Two-handed operation, with emergency stop and inch movement function, infrared hand protector, optional three-sided cover, safe and efficient.

- Press height, stroke, worktable size can be customized according to customer requirements. It can be equipped with cooling system, blowing device, pressure retaining device, pressure relay, force measuring display, PLC operating system, etc.

Why Choose a SuperbMelt Metal Embosser?

Metal Embossing Machine

A equipment used to emboss designs and patterns into metal surfaces is called a metal embossing machine. By exerting pressure to the metal surface using a specialized embossing die or roller, it raises the metal surface’s surface pattern.

It is possible to emboss a range of metals, including gold, silver, aluminum, brass, copper, and stainless steel, using the hydraulic SuperbMelt metal embossing machine. They are frequently employed to create ornamental metal goods like nameplates, signage, and gifts.

Follow the manufacturer’s directions when operating a metal embossing machine and put on the appropriate safety gear, such gloves and goggles. A metal embossing machine may be a very useful instrument in the production of high-quality metal items if it is used and maintained properly.

Helpful Resources For Your Reference (SuperbMelt Metal Embossing Equipment Specialists)

More SuperbMelt Gold and Silver Casting Machines For Your Choice

Any Question About SuperbMelt Hydraulic Logo Stamping Machine

About metal embossing machine FAQ

An embosser is a device that imprints text or graphics in raised or recessed areas on materials like paper, leather, or metal. It operates by leaving a visible and tactile imprint on a surface by pressing a die or plate against it. Embossing can be used to add a logo or stamp to a document, give texture to a piece of artwork, or add grip to a handle, among other aesthetic or practical uses. The hydraulic Metal Tag Stamping Machine from SuperbMelt works with metal embossers including gold, silver, and brass.

Although both metal stamping and embossing are methods of metal formation, they entail various procedures.

To cut or mould sheet metal into precise forms, such as coins, automobile parts, or electrical components, metal stamping is done using stamping machines and dies. To cut or shape the metal into the appropriate shape, a sheet of metal is sandwiched between a die set and a punch.

In contrast, embossing involves raising or lowering particular portions of a metal surface to produce a design or pattern. A metal embossing machine is often used to generate the required raised or depressed regions by applying pressure to the metal.

In conclusion, while embossing includes raising or lowering images on the surface of the metal, metal stamping entails cutting or shaping metal.

Decide what kind of material, such as paper, cardboard, leather, or metal, you wish to emboss. Select a machine for embossing that can handle the material you intend to use.

Size of the machine: Take into account both the machine’s size and the available workspace. You might want to go with a smaller, portable machine if your space is restricted.

Look for an embossing machine with a pressure setting that can be adjusted. As a result, you will be able to modify the pressure according to the material you are embossing.

Check the machine’s compatibility with dies and embossing folders to ensure that they work together. Make that the dies and folders you now own or want to buy are compatible with the equipment.

Ease of use: Pick an embossing machine with simple to follow instructions. Choose a device with simple to understand controls and directions.

The primary distinction between the two decorating or marking methods of engraving and embossing is how the pattern is produced.

A design is carved or engraved into the surface of a substance by using a sharp instrument, such a burin or laser. As a result, there is a sunken picture or writing that is tactile. Engraving is frequently used to generate stamps, plates, signs, and decorative patterns or inscriptions on materials like metal, wood, glass, and plastic.

To emboss a substance and produce a raised or three-dimensional image, the material is pressed against a mould. This method is frequently used to produce ornamental designs or patterns as well as to give texture and dimension to surfaces. It is frequently used on paper, leather, cloth, and metal. Embossing can be carried out manually or with the aid of a machine.

While embossing involves raising a design from the surface, engraving entails carving a design into the material.

There are various benefits of embossing, including:

Added Dimension: Embossing gives the material’s surface a raised, three-dimensional appearance. This can increase the prominence and aesthetic appeal of a design or piece of text.

Durability: Embossed pictures or text are elevated above the surface, which makes them less likely to wear out or fade over time. This makes them a durable alternative for labeling, marking, or adorning objects.

Embossing may provide distinctive textures and patterns that give a material a tactile quality that can be aesthetically and physically pleasing.

Versatility: A variety of materials, including paper, leather, cloth, and metal, may be embossed. This method is adaptable and may be used to produce a wide range of patterns and styles.

Cost-Effective: When compared to other decorative methods like engraving or die-cutting, embossing is a comparatively inexpensive approach to give items depth and aesthetic appeal.

Through the use of specialized tools or dies, the method of embossing improves the pattern of a metal surface. Metal is frequently embossed in jewelry-making to give it more depth and texture. To generate the required design, a piece of metal is placed on a soft, cushioned surface and pressure is applied using a specialized tool. The final design can be straightforward or complex, and it can be coupled with other jewelry-making methods like etching or engraving to produce a special item. Jewelry items including rings, bracelets, and other accessories are frequently made using embossing.Additionally, it may be utilized to make ornamental components like clasps, bases, and bezels. The primary benefit of embossing in jewelry design is that it enables the production of distinctive and detailed motifs that are impossible to accomplish using other methods. A piece of jewelry can also be embossed to provide texture and aesthetic interest, which makes it more attractive and unique.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited