Basic Operation Steps of the Power Unit:

Pre-start:

- Connect the external power, and turn on the Air Switch on the back panel;

- Turn on the cooling water inlet, and check the outlet of the cooling water to make sure the status of water recycle;

Medium frequency power supply PLC operation procedures:

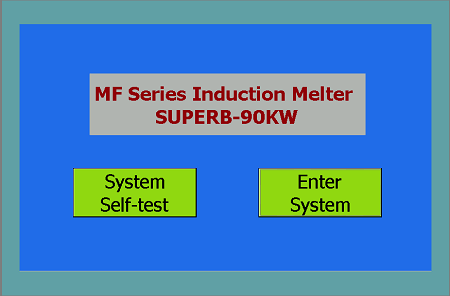

- After the above steps, the PLC will take 10 seconds to turn on, and display the below contents on screen:

(Indication Picture I)

- Touch

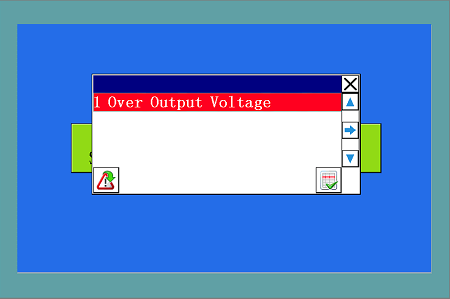

, the screen will display the below indication of Self-test:

(Indication Picture II)

This a auto display, indicating the regular pre-checks of the system; if the checking result is normal, the display will return to Indication Picture I.

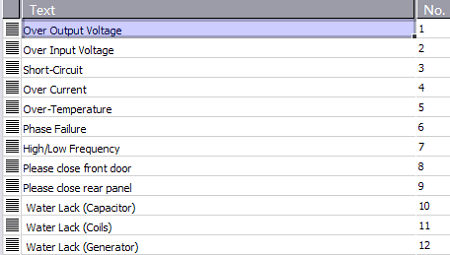

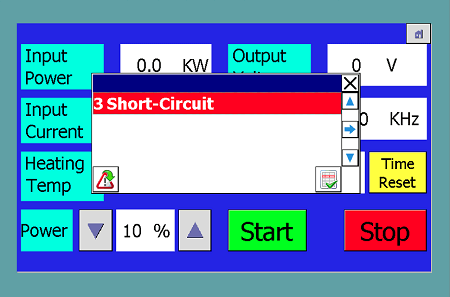

Note: All alarm options as the below picture

(Indication Picture III)

- Touch

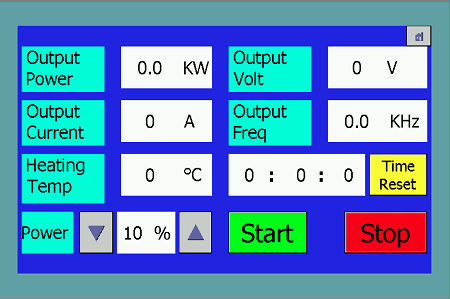

, the screen will display:

(Indication Picture IV)

In this section, touch

, the power unit start to work, providing heating power to the furnace;

The input wattage of the equipment can be adjusted by touchingor

:

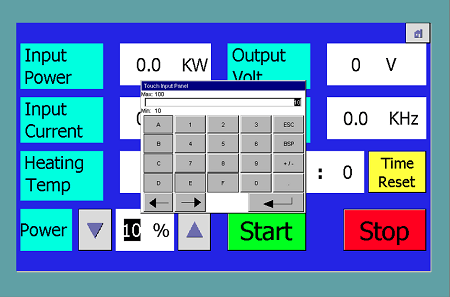

A short touch will change the wattage of 1%; or the user can touch

to turn on the digital adjusting function, see below picture:

(Indication Picture V)

In this section, you can select the target wattage and then touch

to achieve the wattage adjustment in a more flexible degree;

- Touch

, the Power Unit will stop heating, meanwhile the Timer will pause;Touch

, the Power Unit will continue heating, meanwhile the Timer will continue from the paused point.The Timer can be rest by touching

when the Power Unit is on the stop status, and the timing indication will be “0”.

- When the Power Unit is working, if abnormal condition occurs, e.g. short circuit, the screen will display the alarm message as below:

(Indication Picture VI)

When the fault is fixed, the alarm display will close and return to Indication Picture IV.

- To finish the working, please touch

to turn off the Power Unit, but keep on the cooling water for 30 minutes; Please keep the Air Switch on all the time, also keep it on when the Power Unit is not working.

Click here to learn about products(Chain Tilting Induction Furnace, Hydraulic Tilting Melting Furnace, Manual Tilting Metal Melting Furnace) with PLC.

to turn on the digital adjusting function, see below picture:

to turn on the digital adjusting function, see below picture:

to achieve the wattage adjustment in a more flexible degree;

to achieve the wattage adjustment in a more flexible degree; , the Power Unit will stop heating, meanwhile the Timer will pause;Touch

, the Power Unit will stop heating, meanwhile the Timer will pause;Touch  , the Power Unit will continue heating, meanwhile the Timer will continue from the paused point.The Timer can be rest by touching

, the Power Unit will continue heating, meanwhile the Timer will continue from the paused point.The Timer can be rest by touching  when the Power Unit is on the stop status, and the timing indication will be “0”.

when the Power Unit is on the stop status, and the timing indication will be “0”.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited