Mesh Belt Furnace

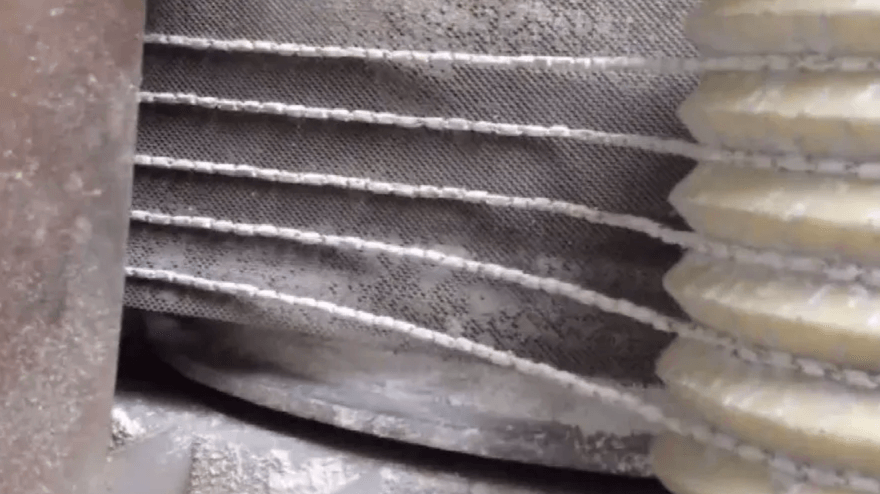

The Superbmelt mesh belt furnace is used for heating metal workpieces above its recrystallization temperature and then cooling once the workpiece has been maintained at required degree celsius for a suitable amount of time.

There are three stages in the mesh belt furnace; annealing, recrystallization, and grain growth under ammonia gas. The mesh belt furnace is an annealing oven used for chain welding, metal annealing, metal tempering, jewelry annealing. In the coin minting line, the mesh belt furnace to heat precious coins or bars to make them soft and ready for acid washing.

The mesh belt furnace is used for annealing K-gold and silver link parts, and welding of chains. The mesh belt furnace improves the machinability, mechanical and electrical properties of materials.

Superbmelt annealing oven is equipped with a temperature regulator, cooling chamber linear regulator, chamber thermal regulator for a controlled and efficient annealing of workpieces.

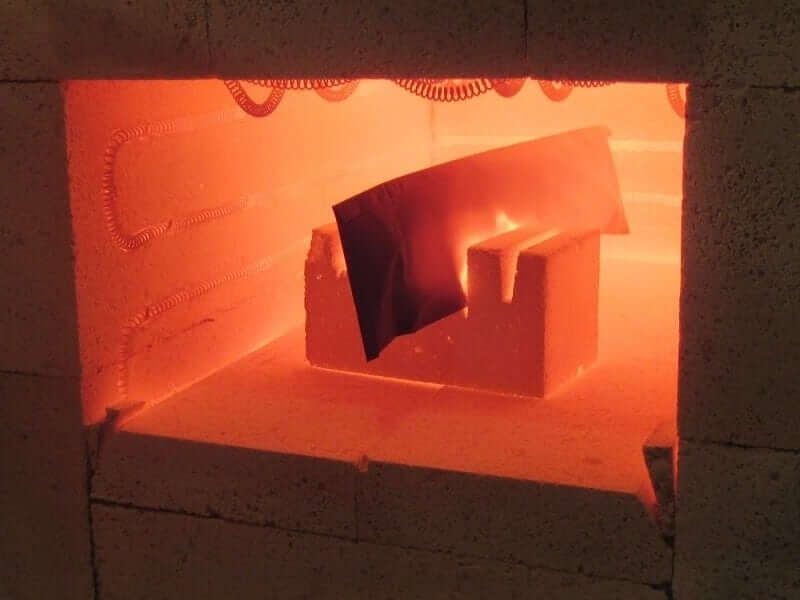

- The mesh belt furnace is divided into two parts. The left side has the furnace chamber ammonia flowmeter and the right side has the cooling water ammonia flowmeter.

- The maximum power required for the mesh belt furnace is 13kw with a maximum temperature of 950 degree celsius.

- The mesh belt furnace is designed for the hardware industry, especially the jewelry making industry and the coin and bar minting industry. It applies to K-gold, silver, steel, cast iron workpieces.

- The combine frame of the mesh belt furnace is easy to install and dismantle.

- The mesh belt furnace is equipped with a purification device of nitrogen produced via ammonia decomposition.

- As a mesh belt furnace manufacturer, we equip our annealing oven with a temperature regulator, cooling chamber linear regulator, timing setter, speed regulator for the mesh belt, etc, for proper control and efficiency in workpiece annealing.

- The timing setter control allows an automatic process of annealing, whereby users can easily set the start and finish time.

- The mesh belt furnace heats workpieces above the recrystallization temperature, the workpiece becomes more ductile, therefore, ready to be worked once more.

- The speed of annealing is a stepless speed regulation, whereby users can set the speed of the mesh belt as desired.

- The temperature must reach at least 860 degree celsius before the fire can start. Workpieces are then fed into the annealing oven.

- The entire annealing process is completed under ammonia gas protection to ensure that the tempering surface does not oxidize, change colour or lead to losses, and to meet common processing standards.

- The entire dimension of the mesh belt furnace is 3000*600*1500 (W*L*H mm), and a network bandwidth of 50mm.

- The mesh belt furnace heats workpieces above the recrystallization temperature, the workpiece becomes more ductile, therefore, ready to be worked once more.

- The mesh belt furnace removes stresses that can occur when a metal workpiece solidifies.

- The water cooling unit regulates the annealing oven temperature and ensures a continuous annealing process for production.

- Superbmelt annealing oven is a good equipment for bright annealing, solution treatment, continuous welding, and lead welding of different metals and stamping parts.

| Model number | SPB-AWF |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 13kw |

| Max. temperature | 950℃ |

| Speed | Stepless speed regulation |

| Cooling way | Water cooling |

| Used gas | Ammonia |

| Working slot | 70*40 (W*L mm) |

| network bandwidth | 50mm |

| Dimension | 3000*600*1500 (W*L*H mm) |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Mesh Belt Furnace

Any Question About SuperbMelt Mesh Belt Furnace

Mesh Belt Annealing Furnace Buying Guide

Maybe this is the first time you are coming across the term mesh belt furnace, but we are quite certain you have heard about annealing ovens.

Regardless, just know that this buying guide is dedicated to helping you answer any and every question you have about mesh belt furnace or annealing ovens. In summary, from all you need to know about mesh belt furnaces to the manufacturing and selling process, this buying guide covers it all.

Introduction to Annealing Process

To kickstart this journey, lest look at the basic definition of annealing. Annealing simply means heating (metal or glass) and then allowing it to cool slowly, in order to remove internal stresses and toughen it. That simply means anybody and everybody can anneal.

And in line with that notion, let’s look at the definition of anneal with reference to a furnace. An annealing furnace simply helps you anneal better. That’s to say, it facilitates a faster, durable, and more efficient process of annealing.

1.1, What is Annealing Process?

The annealing process is a heat treatment cycle that restores some of the ductility to a product being cold-worked so it can be cold-worked further without breaking. And mesh belt furnaces are ideal for the annealing process.

An annealing furnace works by heating a material above the recrystallization temperature and then cooling the material once it has been held at the desired temperature for a suitable length of time.

Mesh belt furnace is used for heating metal workpieces above its recrystallization temperature and then cooling once the workpiece has been maintained at the required degree Celsius for a suitable amount of time.

1.2, Introduction to Annealing Method

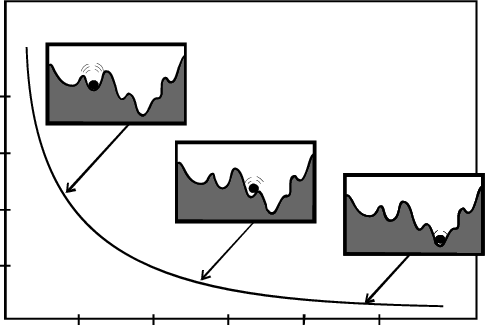

Annealing works in three stages – the recovery stage, recrystallization stage, and the grain growth stage.

Recovery Stage: This stage is where the furnace or other heating device is used to raise the temperature of the material to such a point that the internal stresses are relieved.

Recrystallization Stage: Heating the material above its recrystallization temperature but below its melting point causes new grains to form without any residual stresses.

Grain Growth Stage: Cooling the material at a specific rate causes new grains to develop. After which, the material will be more workable. Subsequent operations to alter mechanical properties can be carried out following annealing.

1.3, The Purpose of Annealing

The purpose of annealing is simple ‘help restores some of the ductility to a product being cold-worked so it can be cold-worked further without breaking.’

Annealing is used to reverse the effects of work hardening, which can occur during processes such as bending, cold forming, or drawing. If the material becomes too hard, it can make working impossible or result in cracking.

By heating the material above the recrystallization temperature, it is made more ductile and therefore ready to be worked once more. Annealing also removes stresses that can occur when welds solidify.

Hot rolled steel is also shaped and formed by heating it above the recrystallization temperature. While steel and alloy steel annealing are common, other metals can also benefit from the process, such as aluminum, brass, and copper.

Metal fabricators use annealing to help create complex parts, keeping the material workable by returning them close to their pre-worked state. The process is important in maintaining ductility and reducing hardness after cold working. In addition, some metals are annealed to increase their electrical conductivity.

1.4, Precautions of Annealing

The process of annealing can keep you working all day long. Working in high temperatures, exposure to chemicals, and the risk of explosion or fire is high. Without taking the necessary precautions, you might hurt yourself.

Keep your work area free of oil contamination. Consider the actual properties of the elements used in quenching, construction, design, maintenance, and monitoring of the annealing furnace. This will help you understand how best to use the machine when annealing.

Some of the precautionary measures to keep in mind when making use of an annealing oven include wearing a certified face shield, certified safety glasses, appropriate heat-resistant protective clothing, and appropriate gloves when handling hot metal.

Before you commence working and after you are done, be sure to check all the safety devices such as air switches, shut-off valves, and exhaust fans are in their perfect conditions. Do this before lighting or rather turning on the annealing furnace.

Introduction To The Tempering Process

With a basic understanding of annealing described above, it might interest you to know that you would also come across the term ‘mesh belt furnace’ during the tempering process.

Tempering can be best described as one of the most applied heat treatment techniques used on precious metals to ensure that they achieve the best greatest toughness possible.

2.1, What is The Tempering Process?

Tempering is a process used in metallurgy and involves the use of heat to improve the characteristics of precious metals. The process involves heating the precious metal to a high temperature but below its authentic boiling point and then cooling it in the air.

The process will always lead to the toughening of the precious metal while reducing brittleness and internal stress. There are different tempering temperatures based on the type of material you are dealing with and its design application.

With reference to the use of mesh belt furnace in the tempering process, annealing ovens help hasten the production process while streamlining all-around efficiency.

2.2, Introduction to The Tempering Method

Tempering can be best described as one of the most applied heat treatment techniques used on precious metal to ensure that they achieve the best greatest toughness possible. The process works by decreasing the overall hardness of the metal.

Usually, the reduced toughness is accompanied by amazing results such as enhanced ductility, which then reduces the brittleness of the entire metal. Tempering, as a process, is most of the time performed after a perfect quenching, which is the rapid cooling of a given metal to place it in its hardest state.

The quenched workpiece is subjected to a high level of heat but must not go beyond its boiling point. It can also be described as the lower critical temperature, or rather the lower transformation temperature. This is the temperature at which the crystal of the precious metal starts to form one phased solid solution known as austenite.

Note that heating above that temperature must be avoided by all means as that will prevent the process from attaining the desired results. If this temperature is exceeded, there will be significant destruction of the quenched microstructure.

The tempering process requires perfect control of time and temperature so that the desired physical properties are excellently attained. Very low tempering temperatures are strongly discouraged because they will only rid the internal stresses and reduce the precious metal’s brittleness while keeping the hardness of the metal constant; that is not what you would be looking to achieve.

High temperatures are great because they will help reduce the hardness, sacrifice tensile strength, and yield strength for increased plasticity and elasticity. Nevertheless, in numerous precious metals, it is okay to temper at low temperatures as that would be enough to increase the hardness.

Most precious metals with high concentrations will act like the precipitation, which will yield the opposite effects under the very same conditions.

2.3, The Purpose of Tempering

After the hardening process, precious metals are supposed to be tempered to make it possible to achieve an impressive level of strength and hardness. All this will be attained by letting the carbon diffusion take place within the microstructure of the metal.

Note that after the precious metal has been hardened, it can attain a high level of hardness and brittleness. On the other hand, when the precious metal doesn’t get hard enough, it will not be able to have enough strength and high resistance to abrasion required for various applications in a range of fields.

By tempering, things such as improved machinability and formability of the hardened precious metal can be easily attained. This will then reduce the chances of the metal failing due to internal stress. Is this something you would like to attain, then precious metal tempering should be at the top of your priority list.

There is a range of instances where tempering becomes the best application process. For instance, tempering will always be used, or rather should be used after a quenching operation.

If precious metal is heated and then quenched very fast, it can become too brittle and hard. Therefore, by tempering it, some of its ductility will be restored, and it can then be used in a number of applications.

2.4, Precautions for Tempering

Tempering is a good process for reducing the hardness of given precious metal as well as relieving the stress of any welded component. Welding precious jewelry’s involves a lot of heat that can lead to the creation of a localized zone that is very hard due to that heat. When making use of a mesh belt furnace, wear a certified face shield.

Work-hardened material will always require tampering. There is a range of processes through which materials can become work-hardened, such as bending, punching, drilling, rolling, or forming.

Some of the precautionary measures to keep in mind when tempering precious metals include certified safety glasses, appropriate heat-resistant protective clothing, and appropriate gloves when handling hot metal.

Why Choose a Superbmelt Annealing Furnace

Since you now know all there is to know about annealing ovens and the need for a reputable mesh belt furnace; it’s high time we talked about the type of annealing furnace available in our catalog.

SuperbMelt is a leading annealing furnace manufacturer dealing in the sales and distribution of melting, casting, and forming machines. The mesh belt furnace is popularly known for its ability to anneal K-gold and silver link parts, and welding of chains is amongst the most notable product in our catalog.

This chapter provides a brief overview of all the annealing furnace SuperbMelt offers. By the end of this section, we believe you will have all the information needed to purchase the right annealing furnace for your production line.

3.1, What Annealing Furnace Can Superbmelt Provide?

At SuperbMelt, we provide the mesh belt furnace and the annealing oven. Both furnaces possess all the features and specifications needed to meet your needs.

Our annealing ovens can help you heat metal above recrystallization temperature. Unlike most machines available, using our mesh belt furnace allows you to enjoy a streamlined process designed to provide the perfect heating procedures you desire.

Anealing Furance

With our annealing oven, the required result is guaranteed. Our machines are optimized to provide the best user experience via the recovery stage, recrystallization, and grain growth stage.

Another major benefit you get to enjoy from using our mesh belt furnace in your production line is a stress-free heating process. With our annealing oven, everything is conducted in ammonia gas protection, so you don’t need to worry about the workpiece getting oxidized.

Amongst the wide range of industries where mesh belt furnaces are popularly used, chain welding annealing, jewelry annealing, and metal tempering remain at the forefront. You might also want to keep in mind that our annealing ovens are equipped with PID intelligent temperature control, a 24-hour alarm, and a water timer switch.

Mesh Belt Anealing Furance

3.1.1 Types of Superbmelt Annealing furnace

While our catalog is fully loaded with multiple furnaces and equipment, it might come as a surprise to find out that when it comes to mesh belt furnaces, the SPB-AWF is the only product in our catalog.

The SPB-AWF mesh belt furnace is easy to install and dismantle. The maximum power required for the SPB-AWF mesh belt furnace is 13kw with a maximum temperature of 950 degrees Celsius.

Well equipped with a furnace chamber ammonia flowmeter on the left and a cooling water ammonia flowmeter on the right, the annealing oven guarantees smooth and efficient heating and cooling process to individuals in the hardware industry and beyond.

Since it’s no news that all of us at SuperbMelt are dedicated to helping you enjoy the best annealing and tempering experience possible, the SPB-AWF annealing furnace comes with an instructional manual/guide with detailed instructions to guide you through assembling and usage.

3.1.2 How Superbmelt Annealing Furnaces Work

Annealing ovens are generally known for their ability to heat metals above crystallization temperature. These ovens have played notable roles in a wide range of industries and are generally regarded as many as to use in creating the ductility of metals.

A mere glimpse of the SPB-AWF meh belt furnace available in our catalog can keep you wondering. How does the annealing oven work, and what is required for it to work efficiently over a long period of time?

To keep it simple, the SPB-AWF mesh bel machine makes use of electricity. After turning on the switch, you need to adjust the speed to the desired temperature. Our mesh belt furnace makes use of a temperature regulator, cooling linear chamber regulator, stepless speed regulation, and a timing setter control, making it easy to enjoy seamless heating and cooling process.

And while SuperbMelt mesh belt furnaces make use of electricity just like every other type of annealing oven available in the market, the amount of electricity required for continuous annealing furnace operation is quite low.

3.1.3 Technical Specification of Superbmelt Annealing Furnaces

For the technical savvy folks, this buying guide wouldn’t do much good if we don’t highlight the major technical specifications attributed to the SPB-AWF mesh belt furnace. This section contains all the technical specifications attached to our annealing ovens. However, if you are looking for a detailed rundown of all the features, specifications, and benefits, we recommend you contact SuperbMelt customer service.

- Model number: SPB-AWF

- Power source: 3 phase 380V, 50/60Hz

- Power: 13kw

- Temperature:950℃

- Speed:Stepless speed regulation

- Cooling way: Water cooling

- Used gas:Ammonia

- Working slot:70*40 (W*L mm)

- Network Bandwidth:50mm

- Dimension:3000*600*1500 (W*L*Hmm)

3.2, Features and Advantages of Superbmelt Annealing Furnaces

We have talked about all there is to know about the mesh belt furnace in our catalog; from the types of furnaces we provide to the technical specifications attached, we’ve covered it all. However, it doesn’t come as a surprise that this buying guide wouldn’t do much good if we fail to cover the basic features and advantages of an annealing furnace.

Ans to ensure that you make the best of the continuous mesh belt furnace heating process our SPB-AWF annealing oven is equipped to provide; below is a detailed list of all the features and advantages you get to enjoy from having our mesh belt furnace in your corner.

Reversing the entire effects of hardening: annealing furnaces are known for their ability to heat workpieces high above the crystallization temperature. With reference to reversing the entire effect of hardening, our annealing furnace can help you stabilize the working process.

Ammonia Gas Protection: nothing is more soothing than a working environment that guarantees little to no risk. Our mesh belt furnace comes with ammonia gas protection that protects the surface from getting oxidized or losing color.

Heat Treatment: jewelry, gold-silver-copper stamping parts, and hardware require occasional heat treatment to regain stability. You can regulate our mesh belt furnace to provide you with the temperature required to carry out such menial heating processes.

Safety Rod: exposing your skin to a very high temperature daily can cause wrinkles at a very young age. To keep your skin at bay, our SPB-AWF mesh belt furnace comes with a rod you can use to feed the workpiece into the temperature chamber.

Speed Regulator and Timer; amongst the many productivity and efficiency tools our mesh belt furnace is equipped to offer, the speed regulator and timer stand out. The simplicity and ease of operation they bring simplifies your everyday workload in remarkable ways.

Application Of Annealing Furnace

Annealing is used across a variety of industries where metals need to be worked into complex structures or worked on several times. To round it up, let’s look at some of the basic places or industries where annealing furnaces are enjoying widespread usage.

4.1, For Chain Welding

Welding jewelry chain requires a simple yet complex process. Especially if you are not familiar with all the processes and intricacies involved. However, since the introduction of the mesh belt furnace to chain welding, a simple and more subline welding process have been streamlined.

Most jewelry chain welders know that the process of chain welding requires the use of a lot of heat that might affect the hardness and ductility of precious metals. With that in mind, the mesh belt furnace is all about dimensional stability and can offer a high level of tolerance.

So, if you are a jeweller looking to maximise the risk attached to jewelry chain welding, while enjoying a smooth and efficient welding process, we recommend you introduce the mesh belt furnace into your production line.

4.2, For Metal Annealing And Tempering

The annealing process is a heat treatment cycle that restores some of the ductility to a product being cold-worked so it can be cold-worked further without breaking. And mesh belt furnaces are ideal for the annealing process.

An annealing furnace works by heating a material above the recrystallization temperature and then cooling the material once it has been held at the desired temperature for a suitable length of time.

The tempering process, on the other hand, is used in metallurgy and involves the use of heat to improve the characteristics of metals, especially steel. The process involves heating the metal to a high temperature but below its authentic boiling point and then cooling it in the air.

The process will always lead to the toughening of the metal while reducing brittleness and internal stress. There are different tempering temperatures based on the type of material you are dealing with and its design application.

If you are looking to make use of an annealing oven in carrying out metal annealing or tempering task in your production line, SuperbMelt SPB-AWF streamlines stress-free and more efficient methods.

4.3, Annealing Sheet Metal Wire and Varying Alloys

Remove protective plastic before annealing. This can sometimes be kept when performing various piercing applications.

When buying a sheet, always assume that it will need annealing.

It will be easier to decide whether 1mm round wire is soft. However, it’s not as simple when working with a 5mm wire. Therefore, you should always begin annealing with a thicker wire.

Pure 999.9 silver and 24-carat gold do not oxidize as they are intrinsically soft. They will only need annealing if extensive work has been performed.

Perform your annealing with a soft flame by gently pushing it up the length of the metal rather than waving it from side to side.

Ensure your metal is completely dry after quenching. This is essential as you do not want to rust the tools you work with. Check that your tools have no marks as they can be passed on to your metal.

4.4, Annealing Of Jewelry And Precious Metals

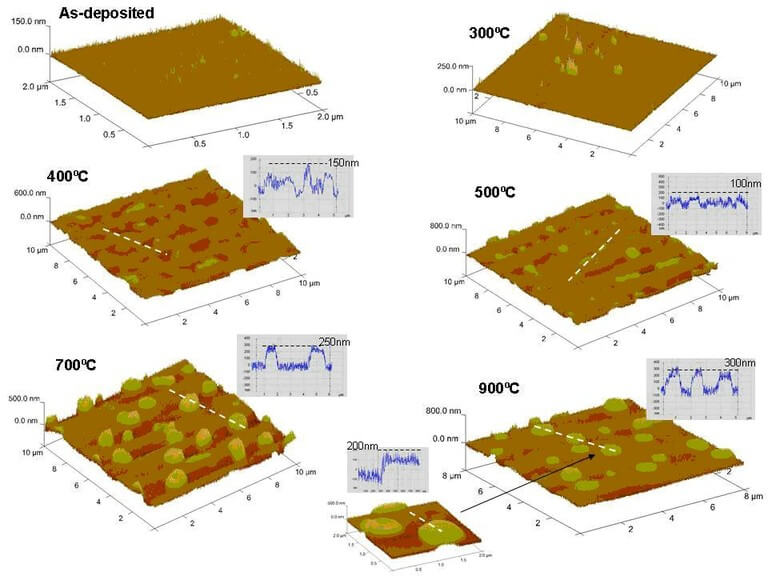

Generally, anytime you heat a typical jewelry alloy to a red color (above 1050°F), the alloy will begin to get softer. Exceptions would be 950Pd and 950Pt alloys; they will not soften until much higher temperatures are reached (above 1700°F).

Mesh belt furnaces are quite popular in annealing precious metals. Here is a framework of the temperature gold, silver, and platinum are meant to have been cold-worked to before being annealed.

Gold: Karat golds are a little more complicated because compositions vary considerably. But in general, yellow, green, and red alloys can be softened by heating to 1250°F (677°C) for 10 minutes, followed by a water quench.

Time will be determined by the alloy and the size and shape of the piece. Green and yellow gold can be cold worked up to 60% before annealing is required. When referring to red gold, it can be cold worked up to 50% before annealing is required.

Silver: To soften sterling silver, heat to 1100°F (593°C) followed by a water quench. Silver can be cold worked up to 70% before annealing is required.

Platinum: To soften Platinum, heat material to bright orange color, 1800°F (982°C). Let the piece air cool or quench after reaching bright orange color. Platinum can be cold worked up to 70% before annealing is required.

4.4.1 For Making Coins

Working silver, gold, copper, and similar metals require you to anneal the metal. Annealing is simply heating the coin to a dull red glow which makes the metal more malleable and easier to work with. Throughout the crafting process of pressing and stretching, the coin will work-harden and need to be annealed a few times.

4.4.2 For Handmade Jewelry and Crafts

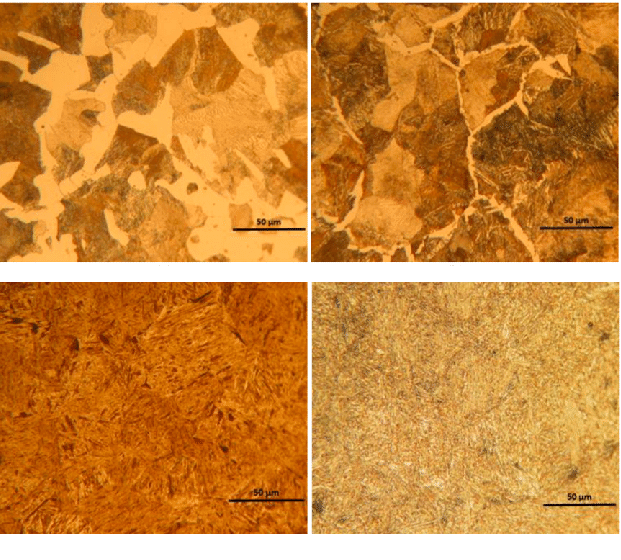

When annealing jewelry or craft metals with a mesh belt furnace, it will turn into an obviously darker color followed by blackening. This is a chemical process known as oxidizing.

The annealing heat treatment process has to be continued throughout oxidization until the metal reaches a red color. This cherry red color occurs when the precious metal has reached a critical temperature.

Heat must be removed from the jewelry or craft as soon as it reaches this point. Otherwise, you run the risk of melting the metal. It must then be placed in cold water. This is known as “quenching” the metal, and the color will last for a few moments until the metal relaxes.

The annealing process can be repeated several times with one piece of metal – there is no limit. However, it is always best to anneal the metal as soon as you feel it start to harden. That way, you avoid causing irreversible damage to your piece.

FAQ Guide

Can you anneal gold?

Yes, you can anneal gold. However, you might want to bear in mind that gold annealing is for continued processing. Gold has a particular annealing temperature, which is distinguished by the color it turns when it is heated.

Can any metal be annealed?

A large range of metals, including copper, aluminum, and brass, can be subject to an annealing process known as solution annealing. Steel, also a metal, undergoes annealing. By the use of the mesh belt furnace, many precious metals are heat-treated/annealed.

What do annealing brass cases do?

Annealing brass cases summarily means treating brass workpieces in a metal annealing furnace like the mesh belt furnace (using, for example, brass cartridge cases) the neck and shoulder, to allow softening followed by sealing of the chamber during firing. Heat-treating or annealing brass -unlike most metals, which may become harder -annealing makes it softer to enable workability.

What does annealing do to stainless steel?

Stainless steel is heat-treated based on the steel type and reason for treatment using a mesh belt furnace or a variable alternative. Following the annealing of stainless steel, there is an improvement in its corrosion resistance, desired machinability, and formability. Annealing of stainless steel is usually done at temperatures higher than 1040°C though certain steel types can be annealed at controlled temperatures below 1010°C while considering the fine grain size. Stainless steels are generally heat-treated in controlled conditions to reduce the possibilities of scaling. There are four main classes that common stainless steel is divided into. The austenitic steel cannot harden following heat treatment. They attain hardness during manufacturing and formation. This is known as work-harden. Annealing this type of stainless steel in the annealing furnace softens them, adding ductility and improved resistance to corrosion. An example of this type of steel is the 300-series stainless steel. The martensitic stainless steel hardens via annealing. The hardness of this steel depends on the amount of carbon content it has meaning, the more the steel contains, the harder it becomes during annealing while using an efficient mesh belt furnace. Ferritic stainless steels are not hardened by heat treatment. They, however, have maximum ductility, corrosion resistance, and improved impact toughness. They are scaling resistant, especially at high temperatures. Precipitation-hardening stainless steel has more corrosion resistance qualities when compared to martensitic stainless steel.

Why do we anneal copper?

HEAT-TREATING/annealing of copper in an annealing furnace makes it softer and less brittle, which allows bending without breaking. This malleability allows it to undergo hammering and molding, allowing for the shaping of copper without cracking the metal. There is quite a range of quality annealing ovens for sale with annealing furnaces prices that are very affordable.

Can you heat brass to bend it?

ANNEALING makes brass softer. Brass has the potential to break when exposed to an excess of heat -it does not bend with heat. Nonferrous metals need to be annealed before bending. Heating in a mesh belt furnace may be immediately followed by quenching in cold water or allowed to slow cool though quenching doesn’t make brass harden.

How often do you anneal brass?

According to research, the timing for annealing of brass in a mesh belt furnace or alternate furnace is variable. Using the brass cartridge cases, for example, It is important to note that annealing case necks only is done. The rest of the case is work hardened during manufacturing. It must be strong enough to contain the pressures of firing, and annealing any part of the case except the neck is potentially dangerous. Annealing should be done before any resizing. This eliminates possible spring backs, allows for repeatable and accurate shoulder bumping and neck sizing.

How do you make gold harder?

To make gold harder, the addition of varying alloying elements, copper, silver, zinc, palladium, and even nickel, is done. Gold as a pure metal on its own is soft. It bends and wraps easily, making it a poor metal for jewelry that needs to retain its shape.

Does gold hold heat?

Gold conducts heat and electricity. Gold tends to get softer when annealed in a furnace-like the mesh belt or annealing furnaces or oven. There are annealing ovens for sale at SuperbMelt. Heat treating your precious metals can now be done more efficiently and in record time too.

Does quenching brass harden it?

Quenching of brass in water doesn’t harden the brass. Brass workpieces harden due to sizing and firing and a host of other possible processes. This is why brass cracks after multiple firings and loadings, especially if they have not been annealed. Slow cooling after annealing of brass workpieces instead of quenching is applicable.

Can you bend a 14k gold ring?

A 14k gold ring contains about 58% pure gold; the other percentage is filled with metals and alloys. These alloys and metals strengthen gold because pure gold is too soft for everyday use. This means that it is hard for a 14k gold ring to bend easily, and it is the perfect ring if you are involved in sports and physical activities.

How do you harden a wire with heat?

Place the wire fireproof ceramic soldering surface, and heat your soldering torch to a medium flame. Apply the flame to the wire and allow it to anneal for a few minutes. This process will increase the hardening capacity of the wire. If you want to harden a larger quantity of wire, you can use a mesh belt furnace.

How do you soften brass bending?

The annealing process is a heat treatment procedure that is used to soften your brass. All you need to do is heat up the brass with a mesh belt furnace until you see a dull red heat, then slowly allow it to cool to room temperature. This will enable you to work on your brass and bend it without cracking it. There are different types of annealing furnaces, and one of the best is the Hydrogen annealing furnace which has a higher heat transfer than air or nitrogen plus hydrogen gas mixture.

Why did my gold ring bend?

Gold tends to tarnish, scratch, and bend over time, especially if you wear it frequently. Pure yellow gold is easy to bend. Most gold rings are mixed with other alloys and metals to strengthen them. If your gold ring has more pure gold and contains fewer other materials, it will bend easily.

Does gold bend easy?

Pure gold is soft and can bend very easily. In making jewelry like rings, gold is mixed with other materials like alloys, silver, and metals to strengthen the gold. An 18k gold ring has 80% gold and contains little materials like copper and silver, and it can bend easily.

How do you clean copper after annealing?

You can clean your copper with vinegar, salt, and baking soda to keep it from tarnishing. Get two containers, mix the salt and vinegar in one container, and your baking soda with water in another container. Place your copper in the container with vinegar and salt and let it sit there for thirty minutes. Take it out and place it in the container with baking soda for five minutes. Take out your copper and wipe it with a clean cloth.

How do you soften hard gold wire?

Place your hard gold wire in a pre-heated mesh belt furnace, and heat it for 1200-to-1400-degree Fahrenheit for fifteen minutes until it becomes a dullish red. Take out your gold wire, air cool it for a minute, proceed to quench it in a pickle solution. It is advisable to coat your gold in a boric acid-alcohol solution before the heat treatment; to prevent oxidization. You can check online for an annealing furnace for sale.

Can you harden copper with heat?

You can harden copper using machines like mesh belt furnaces to heat treat large quantities of copper. Hardening increases the strength and wear property of the copper. Hardening is often done through the quenching method. Heat the copper into an austenitic crystal phase and then quickly cool it.

How do you anneal gold with a torch?

Before you anneal your gold with a torch, coat it with a boric acid-alcohol solution to prevent oxidation afterward. Place your gold sheet on a fire brick, light the torch and make sure the flame burns blue rather than yellow. Hold the torch about two inches above the gold and move it across the length of the gold. Move the torch back and forth until the color of your gold changes into dark red. When the gold is dark red, put off the torch, pick up the gold with pliers or tweezers and quench it in a bowl filled with water. A torch is better than a mesh belt furnace when annealing a small quantity of gold.

How do you harden gold wire?

To harden your gold wire, pull the gold wire multiple times through the jaws of the nylon jaw plier until the wire feels stiff. This hardening makes the wire stronger. Another technique is to place your gold wire between the nose of two flat head pliers and twist until it hardens.

Can you anneal gold-filled wire?

Yes, you can anneal a gold-filled wire, but before annealing, you need to know which metal is used as the base metal core. The annealing temperature of the metal should be lower than the melting temperature of the gold.

What is annealing, and why is it done?

Annealing is a heat treatment using an annealing furnace to change the physical and sometimes chemical properties of a material to increment its ductility and reduce its hardness, making it more serviceable. It includes heating a material above its recrystallization temperature, keeping a reasonable temperature for an appropriate amount of time, and then cooling. In annealing, atoms move in the crystal lattice, and the quantity of separations diminishes, prompting an adjustment in ductility and hardness. Annealing Is used to switch the effects of work hardening, which can occur during cycles like twisting, cold molding, or drawing. The collaboration is huge in keeping up flexibility and diminishing hardness.

What are the three stages of annealing?

There are three main stages in the annealing process: Recovery: Metal is made out of a cross-section of precious stone designs that are known as grains. Sometimes, the design of the actual grains causes pressure on the metal. During the principal period of the toughening cycle, called recovery, the heat in the anneal oven is used to raise the temperature of the material to the point that it eliminates internal stress.

- Recrystallization: during recrystallization, an annealing furnace raises the temperature of the metal to just below its melting point, sufficiently high that the atoms recrystallize and low enough that it doesn’t soften.

- Grain Growth: During the grain development stage, new crystal grains become completely evolved as the metal cools that don’t have the metal’s unique pressure. The last organization, including the ductility and hardness–is controlled by the pace of cooling. When the metal is annealed, there might be other preparations such as molding, stamping, or framing.

What is the difference between tempering and annealing?

Tempering is utilized to expand the sturdiness of gold and other precious metals. Precious metals are exceptionally hard however is excessively weak for most applications. Tempering is generally done after hardening to reduce hardness. Tempering is utilized to modify Hardness, Flexibility, Sturdiness, Strength, Primary stability. Annealing includes heating the precious metal to a predefined temperature and afterward cooling at a very slow and controlled rate. Annealing is generally used to soften a metal for cold working; improve machinability—Upgrade electrical conductivity.

What does annealed mean?

Annealed is a state where metal has been heated by a continuous annealing furnace resulting in its ductility and improved merchantability.

Why is annealing needed?

Annealing is expected to reverse the impacts of work hardening, which can happen during cycles like bending, cold shaping, or drawing.

What are the types of annealing?

Annealing can be classified into different types :

- Full Annealing

- Partial Annealing

- Processing Annealing

- Diffusion Annealing

- Recrystallization Annealing

Does annealing make metal stronger?

No, annealing doesn’t make metal stronger, it makes metal softer. Annealing changes the physical and chemical properties of the metal to build ductility and lessen hardness. This works with molding, stepping, or framing measures and allows the metal to cut out easily.

Does annealing increase strength?

Annealing is a heat-treating measure used to change the properties of cold-worked metal. These progressions bring about a decrease in the metal’s yield and elasticity and an increment in its ductility, enabling further cold working.

What is the full annealing process?

A piece of metal is made out of a grid of gem structures known as grains, and sometimes these grains adjust so that they cause extra pressure to the metal piece in general. In the principal phase of annealing steel or different metals, known as recovery, the metal is heated to a point where these inside stress can disperse. Further heating the metal to just below its melting point permits new grains to shape that don’t have the previous stress of the old grains. This development of new grains is called recrystallization. To control the development of these new grains, the metal is allowed to cool at a specific rate, in what we call the grain growth stage. The completion of this entire process results in metal with superior ductility and reduced hardness.

What are the effects of annealing?

The annealing treatment builds the system strength by diminishing dislocation emanation long sources and improves material ductility through strengthening grain limits’ protection from intergranular cracks.

Conclusion

It’s true that annealing furnace prices are quite high, but the same goes for the heightened efficiency and productivity its adds to the tempering and annealing process. Nevertheless, we have come to the end of this piece.

And at this junction, we believe you have all the information you need to make the right mesh belt furnace buying decision. However, if you are still skeptical and yet to decide, then we recommend you contact our support service.

SuperbMelt’s 24-hours support service can help you highlight all the simple yet profound information you need to make the right buying decision, proffer multiple options for you to choose from, and give you the flexibility to weigh budget with mesh belt furnace price before settling for any. Get in touch today.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited