Metal Casting Machine

Transforming metals using SuperbMelt casting equipment.

- Any manufacturer of fully automatic metal forming equipment.

- Provide a one-stop metal casting solution.

- Automated production increases manufacturing efficiency.

- 24-hour after-sales service

Apply Our Best Quotation

Metal casting is an extremely important craft in human society, especially in the processing of precious metals like gold, silver, and platinum. Metal casting is not only the foundational technology for jewelry manufacturing but also an indispensable part of industrial production. By melting metals and pouring them into molds to form the desired shapes, it allows for the creation of various complex designs and structures with these precious metals.

Choosing a high-quality casting machine is crucial for any business engaged in metal processing. At SuperbMelt, we offer a wide range of casting machines specifically designed for jewelry-related applications. These machines help businesses improve production efficiency, enhance casting precision, and reduce costs.

Metal casting is more than just a production process; it is the cornerstone of modern industrial manufacturing and artisanal craftsmanship. With SuperbMelt’s advanced casting equipment, businesses can address issues related to production, casting techniques, and cost control, providing strong support in the competitive market.

Various Metal Casting Equipment

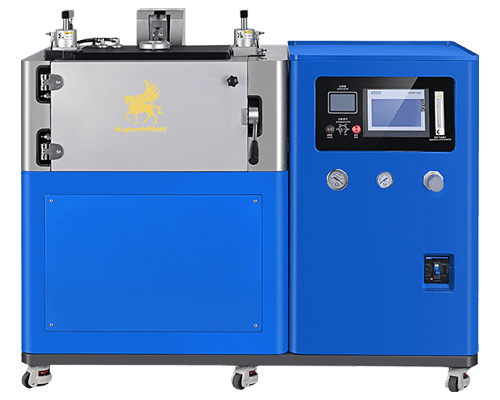

Gold Casting Machine

SuperbMelt Gold Casting Machine is a crucial equipment that melts gold and injects it into molds to produce various gold products, playing a pivotal role in the jewelry manufacturing and precious metal processing industries.

SuperbMelt Gold Casting Machine falls under the category of vacuum automatic casting machines, with a one-time casting capacity of up to 1-6kg (gold, silver, copper, and other precious metals).

Parameter

- Power:8.5 kw

- Applicable metal: Gold, Silver, Copper, Brass, Bronze, and their alloys

- The Max capacity:24K Gold: 2.0 kg 18K Gold: 1.5kg 925 Silver: 1.0 kg

Jewelry Casting Kit

SuperbMelt vacuum jewelry casting kit (SPB-MVC150) is a top-quality product that is specifically designed to hold metals whose weight do not exceed 300g gold, platinum or 150g silver.

The mini vacuum metal casting machine comes with a quartz and an inbuilt furnace. It is capable of heating up to a maximum temp of 2600℃. The above features makes this product suitable for casting tough metals such as gold, platinum, palladium and silver. etc.

- Power:8.5 kw

- Applicable metal: Gold, Silver, Copper, Brass, Bronze, and their alloys

- The Max capacity:24K Gold: 2.0 kg 18K Gold: 1.5kg 925 Silver: 1.0 kg

Centrifugal Casting Machine

SuperbMelt centrifugal casting machine is the ideal choice for casting high-temperature metals like palladium, platinum, stainless steel, and more in the field of jewelry casting centrifuge. These metals demand high melting temperatures, and our centrifugal casting machine can handle the heat, with a melting temperature reaching up to 2600 degrees Celsius.

The casting process involves pouring molten metal into a rotating mold, maintaining the precise temperature required to achieve the desired length and thickness before solidification. The mold’s rotation, driven by an electric motor, ensures the molten metal evenly distributes along its central axis.

Parameter

- Power: 6Kw

- Applicable:Pt, Pd, Stainless Steel

- Centrifuge method: Crankshaft

Automatic Casting Machine for Jewellery

SuperbMelt Automatic Casting Machine for Jewelry can cast 2kg of gold, silver, copper, K gold, and other metals in just three minutes. The entire machine is constructed with aerospace materials, ensuring excellent sealing properties that result in flawless, smooth, and high-quality finished products. This makes it ideal for customers aiming to produce high-quality items.

This fully automatic casting machine requires just a single button press to initiate the casting process, significantly saving on labor costs and boosting production efficiency. The Automatic Casting Machine for Jewelry features electromagnetic stirring, intelligent temperature control, overvoltage protection, short-circuit protection, and other functions, ensuring the quality of the finished products. These added features create a safe and user-friendly operating environment for workers.

Parameter

- Dissolution Time:3min

- Casting Mode:Automatic/Manual

- Application: Gold, silver, platinum, palladium, steel, copper

Silver Casting Machine

SuperbMelt silver casting machine (SPB-JD1) is designed for casting 1-2kg quality silver and gold bars. This casting machine comes with the flexibility to customize your silver and gold bar, ingot and bullion bars to any of your desired LMBA approved deal specifications.

The pressurized inert gas chamber of this silver and gold bar casting machine ensures that you have a final cast with top quality and impeccable appearance by completely eliminating all forms of porosity, water waves or shrinkage in your final piece.

Parameter

- Power:15kw

- Applicable metal: Gold and silver

- The Max capacity:2kg gold bar or 1kg silver bar

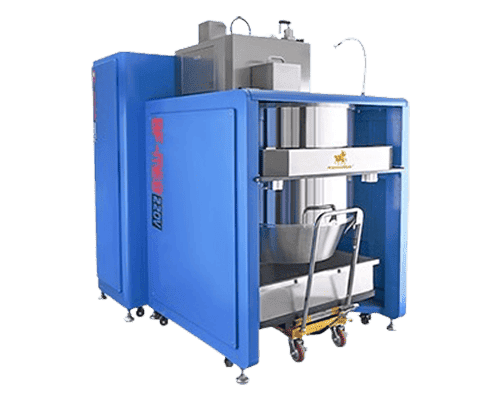

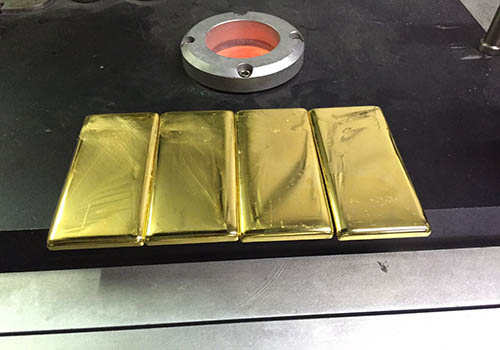

Gold Bar Making Machine

SuperbMelt gold bar making machine (SPB-JD) is designed basically for casting quality gold bars, ingot and bullion bar of all sizes. This machine has the capacity to accommodate up to 4 pieces of 1kg gold or silver bar at once (It can also accommodate up 15kg of a single gold bar).

SuperbMelt vacuum gold bar making machine (SPB-JD) be operated under vacuum conditions. It can also be operated with no flame. Thereby eliminating ripples and further oxidation of your final piece. No loss of precious metals and the bullion without oxidation, no ripple are our promise.

Parameter

- Power:45 kw

- Casting time:About 15 mins

- The Max capacity:4 pcs of 1kg bar or 15kg bar

Vertical Continuous Casting Machine

SuperbMelt vertical continuous casting machine can cast various shapes of jewelry materials, such as gold, silver, copper, and K gold, in a single operation, with a capacity of 50kg. It is designed for the production of high-quality raw materials for metal jewelry, including tubes, sheets, plates, and bars.

Equipped with precise and automated temperature control and stirring mechanisms, this vertical continuous casting machine ensures high-quality finished products. Its simple operation and high-quality output make it the optimal choice for jewelry businesses.

Parameter

- Power:15kw

- The Max capacity: 24K Gold: 5.0 kg 18K Gold: 3.5 kg 925 Silver: 2.5 kg

- Applicable metal:Gold, Silver, Copper, Brass, Bronze, and their alloys

Vacuum Continuous Casting Machine

SuperbMelt Vacuum Continuous Casting Machine utilizes its high vacuum pressure to cast high-quality, smooth, and pore-free raw materials for gold, silver, copper, K gold, and other metal jewelry, including sheets, tubes, and rods.

The Vacuum Continuous Casting Machine comes with stirring function, inert gas protection, and vacuum secondary feeding capabilities to prevent metal oxidation, ensuring uniform color in the finished products. This machine can cast 2kg of metal raw material in a single operation and is suitable for jewelry production, semiconductor manufacturing, solder production, and other industries.

Parameter

- Power:15kw

- The Max capacity:24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg

- Applicable metal:Gold, Silver, Copper, Brass, Bronze, and their alloys

Vacuum Metal Granulator

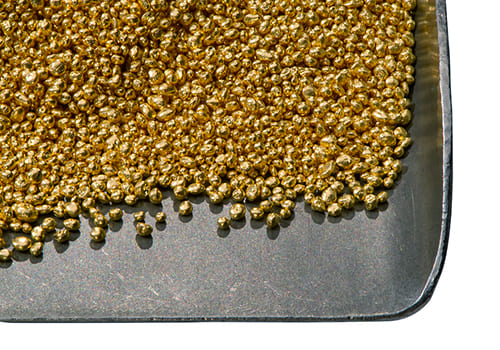

Vacuum metal granulators are used to granulate various precious metals such as gold, silver, copper and alloys. It works by first heating the metal material to its melting point in a vacuum chamber, then passing through a multi-hollow crucible as a current breaker, and finally flowing into a circulating water groove to cool into regular metal particles without oxidation.

SuperbMelt vacuum metal granulator performs smelting work under the environment of full vacuum inert gas, and is equipped with an electromagnetic automatic stirring device, so that the finished product of the metal particles can not be oxidized and has uniform spherical shape and luster.

Parameter

- Melting time:5-6 min

- The Max capacity:24K Gold: 5.0 kg 925 Silver: 2.5 kg

- Application:Gold, K-Gold, Silver, Copper, Brass, Bronze, and their alloys

Metal Granulating Machine

Metal granulating machine combines metal smelting and granulation to produce metal particles such as gold, silver, copper and the like, can realize the manufacture of 5 to 100 kg of metal particles, and is mainly used in metal recycling and processing plants. The liquid metal is produced by melting the metal material and then flowing the liquid metal into a mold with holes to create irregular metal particles.

SuperbMelt metal granulator has a simple structure, uses induction melting technology, and has a faster and more stable melting speed. And the cost performance is higher, is a good choice for many metal processing plants.

Parameter

- Casting method:Gravity granulation

- The Max capacity:24K Gold: 6.0 kg 925 Silver: 3 kg

- Applicable metal:Gold, K-Gold, Silver, Copper, Brass, Bronze

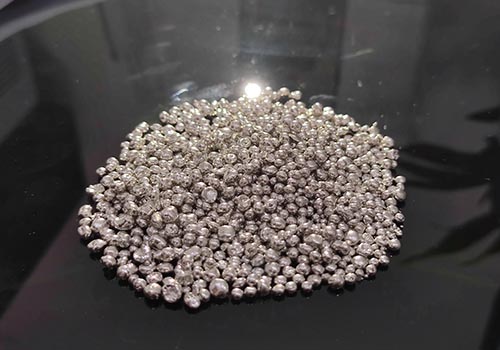

Copper Granulator Machine

SuperbMelt Copper Granulator Machine has the capability to use quartz or graphite crucibles for casting metal particles. This feature allows the machine to utilize quartz crucibles for casting metal particles with a melting point of 2600°C, such as platinum and rhodium. The machine can cast 15-30kg of gold, silver, platinum, and copper particles in a single operation, making it an ideal choice for jewelry processing plants, aerospace industries, and the medical sector!

The Copper Granulator Machine adopts a self-granulation method for particle formation, ensuring fast and continuous feeding. It can complete the casting of 15-30kg of metal raw material particles in a single operation within 8 minutes.

Parameter

- Melting time:8 minutes

- Max capacity:Gold:30kg

- Application:Gold, Silver, Copper,Platinum, Palladium, and their alloys

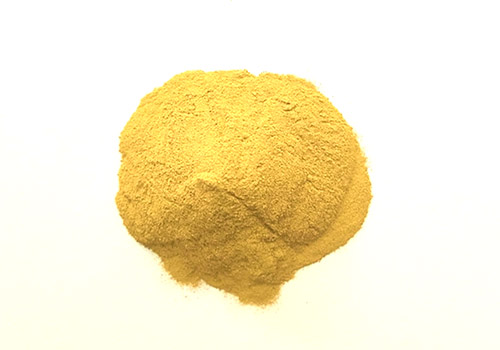

Water Metal Atomizer

- Mass production of gold, silver, platinum, palladium, copper, zinc, aluminum and other precious and non-precious metal powders.

- The water pressure can be adjusted to make the mesh sizes controllable.

- Capacity ranges 10-100kg metal rapid powder making.

- 80% of metal powder can reach less than 50 mesh.

- Reduced metal dissolving speed in aqua regia refining to increase production efficiency.

Parameter

- Melting Time:15-20Min

- Applicable Metals:Au、Ag、Cu、Pt、Pd、Rh

- Milling specifications: 50-200Mesh

Gold Powder Making Machine

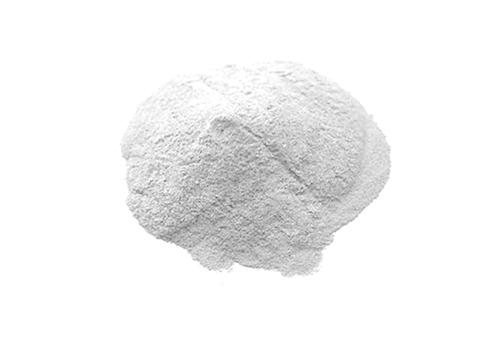

SuperbMelt Gold Powder Making Machine utilizes a vacuum melting process followed by high-pressure water atomization to produce finely and uniformly graded powder. This machine has the capacity to manufacture 2-50kg of metal powders such as platinum, palladium, gold, alloys, silver, and copper in a single operation.

The Gold Powder Making Machine adjusts nozzle shapes and process parameters, assisting customers in producing powders ranging from 50 to 200 mesh, ensuring particle consistency and precision. This technology enables large-scale production, enhancing the yield of metal powders.

Parameter

- Melting Time:15-20Min

- Applicable Metals:Au、Ag、Cu、Pt、Pd、Rh

- Milling specifications: 50-200Mesh

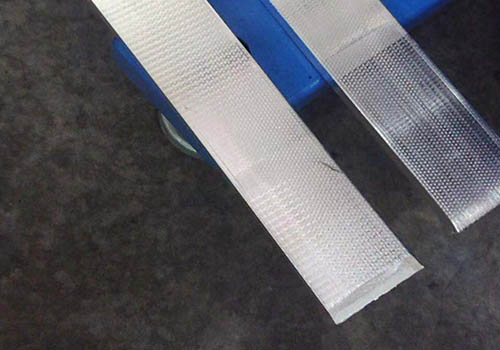

Gold Leaf Making Machine

Gold Leaf Making Machine is used to process metals such as gold, silver, platinum, alloys, etc., into thin sheets commonly known as gold leaf or silver leaf. These sheets are utilized in various fields including jewelry making, art, crafts, and food decoration.

Primary function of the SuperbMelt Gold Leaf Making Machine is to assist businesses in the jewelry industry in enhancing production efficiency. Gold leaf, compared to other refining materials, has a faster refining speed and higher efficiency because of its larger contact area when immersed in aqua regia, thus speeding up the production process.

This machine can produce 10-100 kilograms of uniformly shaped and sized gold, silver, platinum, palladium, and other metal foils with thicknesses ranging from 0.15 to 0.35mm within one hour, using water cooling for sheet casting. These foils can be used without drying, meeting the production needs of customers.

Parameter

- Applicable metal:Platinum, palladium, gold, silver, copper

- Melting time:12 min

- Max capacity:15 kg (platinum)、50 kg (Gold)、100 kg (Gold)

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Metal Casting Machine

FAQ Guide of Metal Casting Machine

What machine is used for metal casting?

Induction Melting Furnaces: These are used to melt metals at high temperatures using electromagnetic induction, making them ideal for precious metals like gold, silver, and platinum.

Centrifugal Casting Machines: These machines use centrifugal force to distribute molten metal into a mold, ensuring even distribution and reducing defects in the final product.

Vacuum Casting Machines: These are used for casting metals under vacuum conditions to reduce the risk of oxidation and improve the quality of the cast metal.

Continuous Casting Machines: These machines are used for the continuous production of metal rods, wires, or strips by casting molten metal through a mold.

Die Casting Machines: These machines are used to cast metal into precise shapes using reusable molds (dies) under high pressure, commonly used for non-ferrous metals like aluminum and zinc.

What machine for joining metal?

Arc welding machines: Melt and fuse metal using an electric arc. Stick welders, MIG (metal inert gas) welders, and TIG (tungsten inert gas) welders are a few examples.

Resistance Welding Machines: Often used for seam and spot welding, these machines use electric resistance to create heat and fuse metal.

- Brazing and Soldering Equipment:

Soldering stations are often used in plumbing and electronics to connect metals at lower temperatures.

Brazing machines: They work at greater temperatures than soldering, and they are mostly used to create stronger connections in metal pipes and other structures.

- Riveting Tools:

Pneumatic and hydraulic riveters are widely used in shipbuilding and aviation to attach metal sheets or plates by driving rivets through them.

- Machines for Laser Welding:

Use a concentrated laser beam to precisely combine metal components—perfect for complex and fragile metal parts that are often used in the aerospace and medical sectors.

- Arc Plasma Welding Equipment:

For high-speed applications and thicker metals, use a plasma arc to cut or weld.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited