Metal Forming Machine

SuperbMelt Jewelry Precious Metal Forming Machine

- Sheet, Rod, and Tube Production Machine

- From Sheet to Bracelet Forming Equipment

- Jewelry Automation Production Machine

Apply Our Best Quotation

Metal forming machines are essential in modern manufacturing for shaping, stretching, cutting, and processing metals, and they play a crucial role in jewelry production. SuperbMelt’s metal forming equipment, including tube-making machines, wire-drawing machines, ring-cutting machines, sheet-slitting machines, and bracelet-forming machines, is designed specifically for the jewelry industry, greatly enhancing production efficiency and precision.

In traditional jewelry making, artisans invest significant time and effort to manually transform metal sheets or wires into finished pieces. While handcrafting can produce beautiful jewelry, it becomes cumbersome and inefficient when dealing with intricate designs. Complex structures and fine details are difficult to achieve consistently by hand, often resulting in errors, material waste, and higher costs.

In contrast, SuperbMelt’s metal forming machines enable automated, high-precision jewelry production. For example, the tube-making machine precisely shapes metal tubes, ideal for creating necklaces and bracelets with complex structures. The wire-drawing machine quickly produces uniform metal wires for rings or chains, while the ring-cutting and sheet-slitting machines efficiently cut metals with exact dimensions. The bracelet-forming machine rapidly and accurately processes metal sheets into bracelets, even for intricate designs.

Compared to traditional methods, automated metal forming equipment offers significant advantages in production speed, accuracy, and cost reduction. It ensures consistent precision in every piece, especially in large-scale production. SuperbMelt’s metal forming machines have become essential in modern jewelry manufacturing, enabling the creation of high-quality, complex jewelry designs while significantly improving production efficiency.

Superbmelt Metal Forming Machine list

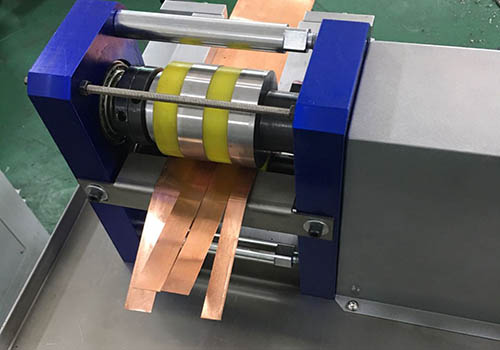

Sheet Metal Slitting Machine

SuperbMelt Sheet Metal Slitting Machine can cut metal sheets of gold, silver, platinum, rhodium, copper, etc., into strip products within one minute. It has a length range of 1-25m, thickness of 0.1-1.3mm, and width of 3-200mm.

SuperbMelt offers three different models of the slitting machine, including the basic model and those with features like edge alignment and winding functions, catering to the diverse production needs of jewelry businesses.

Parameter

- Slitting width:2-200mm

- Application: Gold, gold, silver, copper, platinum and their alloys

- Slitting speed:0-20 meters per minute (variable frequency speed regulation)

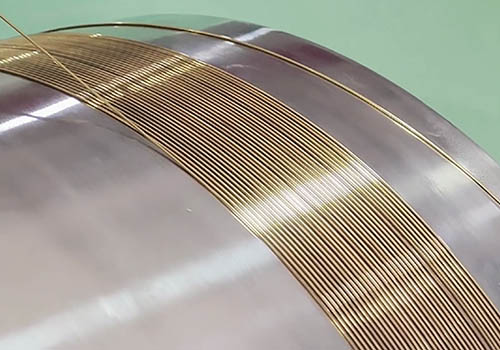

Tube Drawing Machine

SuperbMelt Tube Drawing Machine has the capability to reduce the thickness of the tube wall and adjust the diameter of the wire, facilitating the production of various jewelry items such as rings, bracelets, necklaces, jewelry components, as well as decorative crafts, assisting jewelry industry factory owners in achieving high-quality jewelry processing and production.

The machine produces cylindrical hollow tubes made of materials such as gold, silver, K gold, alloys, etc., with lengths ranging from 0 to 8 meters every 8 minutes. These tubes are utilized in various applications.

Parameter

- Diameter:10mm (Personalized)

- Efficiency:0-8M/8min

- Thickness: 0.32 -0.5mm (Frequency control)

Gold Wire Drawing Machine

- Speed: The machine can draw metal wires with diameters ranging from 0.3 to 8mm and lengths from 0 to 15m per minute.

- Coiling: Equipped with coiling function to increase drawing pressure and facilitate material collection.

- Features: The product is equipped with a spray cooling system to reduce material temperature, minimize wire damage, and features automatic shutdown and material shortage shutdown functions to reduce manual intervention during production.

Parameter

- Outgoing line speed: 0-15M/Min

- Maximum cable diameter: 8mm

- Minimum cable diameter :0.3mm

Automatic Rod Cutting Machine

SuperbMelt Automatic Rod Cutting Machine can cut 50-220 pieces of metal evaporation materials such as gold, platinum, silver, copper, aluminum, nickel, and titanium per minute, with diameters ranging from 2-6mm.

- Features: The cut products are mainly used in the electronics and semiconductor industries for thin film deposition and coating.

- Investment: The rod cutting machine is also suitable for cutting gold wire into dimensions required for processing into gold beans used for investment, wealth storage, and financial transactions.

Parameter

- Cut off speed: 50~220 pieces/minute

- Cut off diameter: Ф2/3/4/5/6mm

- Length tolerance: plus or minus 0.02mm

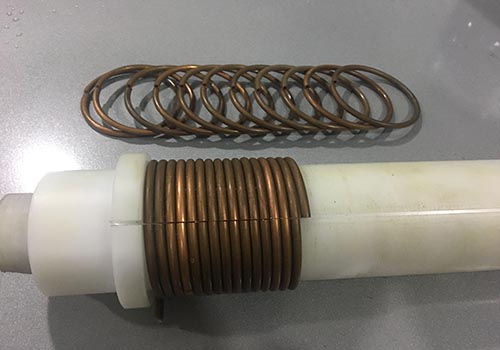

Tube Coiling Machine

This machine achieves the coiling operation by feeding the tubes into the coiling device at preset angles and speeds. With variable frequency speed control, it can coil 0-40 turns per minute, significantly improving the efficiency of bracelet manufacturing for jewelry makers.

In the jewelry manufacturing industry, the tube coiling machine can be used to create the basic structures of metal bracelets and rings, providing jewelry makers with customizable and innovative design options. By adjusting the machine settings, tubes of different diameters, lengths, and shapes can be produced to meet various jewelry styles and design requirements.

Parameter

- Circle diameter:15~80MM

- Rotating speed:Adjustable speed 0~50r/min

- Applicable metal: Gold, K gold, silver, etc.

Roll Cutting Machine

SuperbMelt Roll Cutting Machine is designed for cutting gold, silver, and alloy coil materials or tubular materials. It is used to cut pre-made semi-finished gold or silver bracelets, rings, or coils. The Roll Cutting Machine is commonly used in industries such as decorative arts, jewelry pendants, and handicrafts.

This machine features a spray cooling device to reduce the surface temperature of the saw blade, extending the tool’s lifespan. It can precisely cut materials and adjust to different widths and lengths as needed to meet various production requirements.

Utilize SuperbMelt’s Roll Cutting Machine to efficiently produce batches of bracelets and rings! Contact us immediately if you require other jewelry casting solutions!

Parameter

- Pressure: 0.7MPa

- Power: 3kw

- Application: Gold, K gold, silver, etc.

Induction Foundry Furnace

SuperbMelt circular bending machine can produce 4-8 gold, silver, platinum, K gold, and alloy jewelry bracelets, rings, or other round artworks per minute in a fully automatic manner.

The circular bending machine is a mechanical equipment used for metal processing, primarily for bending metal sheets or metal tubes into curved shapes.

It is also applicable for manufacturing pipelines, bent parts, curved metal frames, and various other shapes of metal components. This type of machine is widely used in the metal processing and manufacturing industries, applicable for producing structural components, automotive parts, ship parts, furniture, and various other products.

Parameter

- Integrated production capacity: 4-8 pieces/ minutes

- Applicable metal: Gold, Silver, Platinum, Palladium, and their alloys

- Max capacity:Platinum, gold, silver, copper, K gold and their alloys

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why Choose a SuperbMelt Induction Melting Furnace

Guide to Metal Forming Machine

Jewelry Industry Guide to Metal Forming Machines

In the jewelry industry, precision, efficiency, and design complexity are critical factors that determine the quality of the final product. Metal forming machines have revolutionized jewelry production, enabling manufacturers to create intricate designs at higher speeds and with greater accuracy than traditional methods. This guide explores the importance of metal forming machines in jewelry making, highlights their key applications, and offers insights into how modern automation can enhance your production process.

1.1, Key Applications of Metal Forming Machines in Jewelry

Metal forming machines play a crucial role in transforming raw metal materials into jewelry components. The machines used in jewelry production can be categorized by their function, which includes shaping, cutting, and assembling various jewelry parts.

- Tube-Making Machines: Ideal for producing hollow tubes used in necklaces, bracelets, and earrings. These machines are perfect for creating uniform, lightweight pieces that require structural integrity without sacrificing design.

- Wire-Drawing Machines: Essential for creating thin, durable metal wires used in chains, rings, and other delicate jewelry components. Wire-drawing ensures consistent wire thickness and quality, essential for complex designs.

- Ring-Cutting Machines: These machines cut metal into precise rings, ensuring uniform dimensions, which is key for consistency in mass-produced jewelry, such as wedding bands or bracelet links.

- Sheet-Slitting Machines: Used to slice metal sheets into thin, accurate strips for further processing. This process is fundamental for producing earrings, pendants, or parts of other jewelry that require precise metal cutting.

- Bracelet-Forming Machines: Specifically designed to shape metal sheets into perfect bracelets, allowing for complex curvature and intricate detailing that would be difficult and time-consuming to achieve by hand.

1.2, Benefits of Metal Forming Machines Over Traditional Methods

In the past, most jewelry was handcrafted, requiring skilled artisans to cut, shape, and assemble pieces with minimal machinery. While traditional craftsmanship adds a unique value, it can be limiting in terms of scale, complexity, and consistency. Metal forming machines address these challenges in several ways:

- Increased Efficiency: Modern metal forming machines can produce thousands of uniform pieces in the time it would take to handcraft a few. This efficiency is critical in an industry where demand for precision and mass production is growing.

- Improved Precision: Automated machines ensure that every piece meets exact design specifications, reducing the margin for error. This is especially important for high-end jewelry, where slight variations can impact the overall quality.

- Cost Reduction: By automating key processes, jewelry manufacturers can reduce labor costs and minimize material waste, making high-quality jewelry more affordable to produce.

- Complex Designs Made Easy: Metal forming machines can handle intricate and delicate designs that would be nearly impossible to achieve by hand. This opens up new possibilities for creativity and innovation in jewelry design.

1.3, Modern Automation and Its Impact on Jewelry Production

The jewelry industry is evolving rapidly, with demand for more personalized, intricate, and high-quality pieces growing. Automation is becoming essential in meeting these demands. Metal forming machines, such as those from SuperbMelt, offer cutting-edge technology that simplifies and accelerates jewelry production.

- Speed and Scalability: Automated forming machines can process large volumes of metal in a fraction of the time needed for manual labor. This means that manufacturers can scale their production to meet market demands without compromising on quality.

- Consistency and Quality Control: With automated systems, manufacturers can maintain strict quality control standards. Every piece produced is identical, which is crucial for maintaining brand reputation, especially for high-end or luxury jewelry.

- Reduced Material Waste: Automation minimizes errors and optimizes the use of materials, reducing waste and ensuring that more of the raw material is used efficiently. This leads to more sustainable production practices, a growing concern in today’s jewelry market.

Choosing the Right Metal Forming Machine

Selecting the right metal forming machine depends on your production needs, design complexity, and material requirements. Here are key factors to consider:

- Type of Metal: Different machines are suited to various metals, such as gold, silver, platinum, or copper. Ensure that the machine you choose is compatible with the metals you work with.

- Production Volume: High-production environments require machines that can operate continuously without compromising precision. Ensure the machine’s capacity aligns with your production targets.

- Design Complexity: If your jewelry line includes intricate designs, you’ll need machines capable of handling fine details. Machines with advanced forming capabilities, such as wire-drawing or tube-making, are essential for creating intricate components.

- Budget: While automated metal forming machines require an upfront investment, they often result in long-term savings through increased efficiency and reduced labor costs.

FAQ Guide of Metal Forming Machine

1. What are metal forming machines?

Metal forming machines are specialized industrial machines designed to shape, bend, cut, and manipulate metal materials into specific forms and structures. These machines use various mechanical processes, such as bending, rolling, cutting, drawing, and pressing, to transform raw metal materials like sheets, rods, and wires into finished products or components. Metal forming machines are essential in numerous industries, including automotive, aerospace, construction, and especially in jewelry manufacturing, where they are used to create intricate metal designs and components.

2. What is the difference between forging and forming metal?

The primary difference between forging and forming metal lies in the methods used to shape the metal and the conditions under which the process occurs. Here’s a breakdown of the key differences:

1. Forging Metal:

- Definition: Forging is a manufacturing process that involves shaping metal by applying compressive forces, often by hammering or pressing, typically at high temperatures.

- Process: The metal is usually heated to a high temperature (though cold forging also exists) to make it more malleable, then compressed or hammered into a desired shape using a forging press or hammer.

- Application: Forging is often used for creating strong, durable components like engine parts, tools, and structural elements.

- Strength: The process of forging realigns the grain structure of the metal, which can significantly improve its strength and toughness.

- Types: Includes hot forging (high temperatures) and cold forging (room temperature), with the choice depending on the desired properties and material.

2. Forming Metal:

- Definition: Metal forming refers to a broad category of manufacturing processes that shape metal without necessarily removing material. This process can involve bending, stretching, or compressing metal into specific shapes.

- Process: Forming can be done at room temperature (cold forming) or with the metal heated slightly (warm or hot forming). The metal is typically shaped by applying gradual force using rollers, presses, or dies.

- Application: Metal forming is widely used for shaping thin sheets, wires, tubes, and components in industries like automotive, construction, and jewelry.

- Strength: Forming processes typically do not alter the metal’s internal structure as forging does, but certain forming techniques can still enhance the material’s properties, like increasing hardness through work hardening.

- Types: Includes bending, drawing, stamping, rolling, and extrusion.

Summary:

- Forging involves high temperatures and compressive force to shape metal and improve its strength, mainly used for heavy-duty parts.

- Forming is a broader term that encompasses various shaping processes (bending, stretching, etc.) and can occur at room temperature, typically used for precision parts like sheets, wires, or jewelry components.

Forging focuses more on strength, while forming emphasizes precision and versatility.

3. What are the modern metal forming techniques?

Modern metal forming techniques encompass a range of processes designed to shape metal materials into precise components with high efficiency and accuracy. These techniques are widely used across industries such as automotive, aerospace, construction, and jewelry. Here are some of the key modern metal forming techniques:

1. Rolling:

- Process: Rolling involves passing metal through a series of rollers to reduce its thickness or change its cross-sectional shape. It can be done hot (hot rolling) or cold (cold rolling).

- Application: Used to produce metal sheets, plates, and structural shapes like beams.

2. Stamping:

- Process: Metal stamping uses a press and a die to shape flat metal sheets into desired forms through cutting, punching, or bending.

- Application: Commonly used for mass production of parts in industries like automotive (car bodies) and electronics.

3. Hydroforming:

- Process: Hydroforming uses high-pressure hydraulic fluid to press metal into a die, shaping it into complex forms. It is especially useful for creating hollow or tubular shapes.

- Application: Often used in automotive manufacturing for producing lightweight, strong parts like exhaust components.

4. Deep Drawing:

- Process: Deep drawing involves pulling a sheet of metal into a die using a punch to form a deep, hollow part. It’s typically done with cold metal.

- Application: Used to produce items such as beverage cans, sinks, and automotive parts.

5. Extrusion:

- Process: Metal is forced through a die to create long shapes with a fixed cross-sectional profile, such as pipes or rods. This can be done with heated (hot extrusion) or cold metal (cold extrusion).

- Application: Used for creating metal parts like tubing, rails, and structural components.

6. Spinning:

- Process: Metal spinning involves rotating a metal disc or tube and forming it into an axially symmetric part by applying pressure with a tool.

- Application: Used for creating cylindrical components such as lampshades or parts for aerospace applications.

7. Bending:

- Process: Metal bending uses force to bend metal sheets, bars, or tubes into desired angles or shapes, using machines such as press brakes.

- Application: Commonly used in the fabrication of structural components, enclosures, and frames.

8. Forging (Modern Techniques):

- Process: Modern forging techniques include mechanical, hydraulic, and pneumatic hammers or presses to shape metal under high pressure, typically at high temperatures.

- Application: Used for producing strong parts like crankshafts, gears, and tools.

9. Laser Cutting and Forming:

- Process: Laser cutting uses high-powered lasers to cut or engrave precise shapes into metal sheets. Laser forming involves localized heating by a laser to bend or form metal.

- Application: Used for precision cutting and forming in industries like electronics, aerospace, and jewelry.

10. Additive Manufacturing (3D Metal Printing):

- Process: 3D metal printing uses layer-by-layer deposition of metal powder or wire, fused together by lasers or electron beams, to create complex metal parts.

- Application: Increasingly used for custom parts, prototyping, and components in aerospace, medical devices, and automotive sectors.

11. Superplastic Forming:

- Process: Superplastic forming uses heat and pressure to stretch metal sheets into complex shapes, leveraging the metal’s superplastic properties at high temperatures.

- Application: Used to form lightweight, complex parts in aerospace, such as turbine blades.

12. Electric Discharge Machining (EDM):

- Process: EDM involves shaping metal by using electrical discharges (sparks) to erode material, particularly useful for hard metals or intricate designs.

- Application: Used in aerospace, tool manufacturing, and precision mold-making.

13. Magnetic Pulse Forming:

- Process: This high-speed forming method uses a magnetic field to generate a pulse of force that shapes the metal. It is a non-contact process and works with electrically conductive materials.

- Application: Often used for joining or shaping tubular components in automotive and aerospace industries.

14. Incremental Sheet Forming (ISF):

- Process: ISF is a flexible forming process where a tool gradually deforms the metal sheet into the desired shape, allowing for small-batch or custom production without expensive dies.

- Application: Suitable for prototyping and custom parts production in automotive and aerospace.

15. Electromagnetic Forming:

- Process: This technique uses electromagnetic forces to shape metal, usually at high speeds. It is ideal for non-contact shaping of electrically conductive materials.

- Application: Used for joining or forming thin metals like aluminum and copper in automotive manufacturing.

Summary:

Modern metal forming techniques are increasingly automated, using advanced technologies such as lasers, high-speed presses, and digital controls. They enable manufacturers to achieve greater precision, complexity, and efficiency in creating metal components, often at lower costs compared to traditional methods.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited