Minting Press

Top-tier one-stop solution provider for coin minting equipment

- 20-1000 ton hydraulic coin minting machine

- Automatic coin minting is easy to operate

- Fast speed and high efficiency, capable of stamping 10 coins per minute.

- Whether it's gold, silver, or iron, we offer a versatile solution for all your stamping needs。

Apply Our Best Quotation

The history of coins and gold coins dates back thousands of years, with the first gold coins appearing in ancient Greece. The materials for coins evolved from precious metals to copper, iron, and other metals. Early coin minting relied on manual hammering of molds, which was inefficient and inconsistent. With the Industrial Revolution, steam-powered coin presses replaced manual methods, significantly increasing production speed and precision.

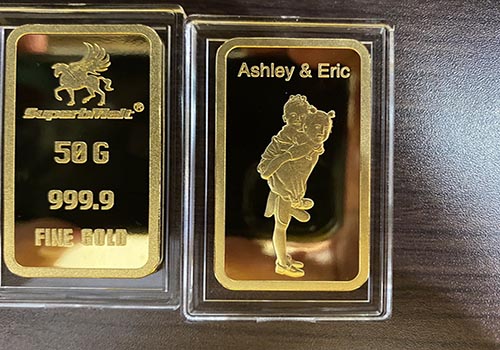

Today, coin minting has entered the era of automation. SuperbMelt’s automatic hydraulic coin press features advanced control systems and high-pressure hydraulic technology, capable of stamping 10 coins per minute, greatly enhancing efficiency and accuracy. It is ideal not only for regular currency production but also for high-quality commemorative coins and gold coins.

In modern society, coins and gold coins are not only used for currency but also for collecting and investment. SuperbMelt’s automatic coin press, known for its efficiency, stability, and quality, holds a significant position in the minting industry and will continue to lead the way in technological innovation.

Superbmelt Minting Press list

Coin Press Machine

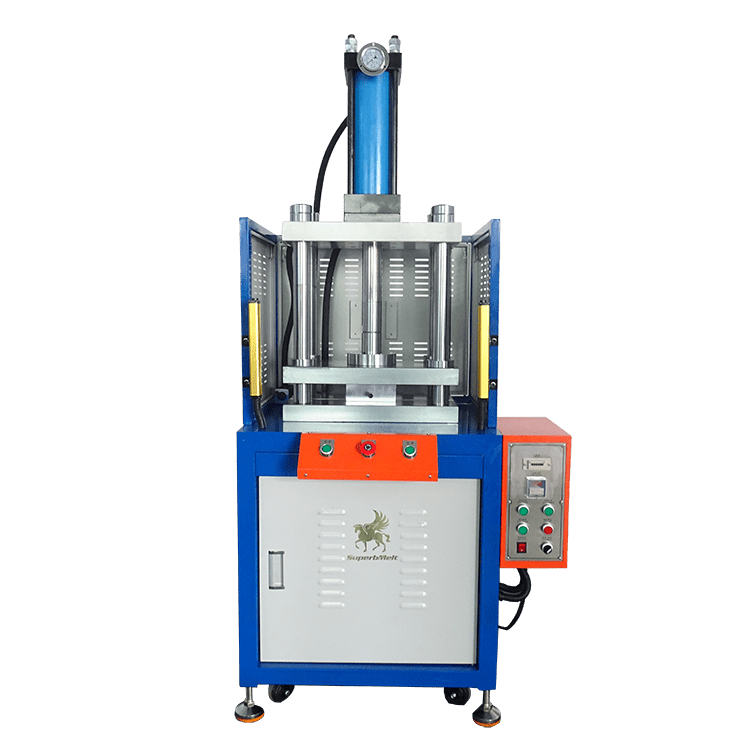

The machine lets you mint gold and silver metals and bars at a fair speed to meet the market demand. It comes with hydraulic power pack that consists of Piston Pump, relief valve, electric control panel board operated directional control valve, and standard hydraulic accessories. To get the most applicable features to meet your expectations, consider getting this product from reputable manufacturers such as SuperbMelt.

Our coin making machine can realize 1-1kg metal pressing, and you can choose 20-1000ton machines according to your production capacity, including manual, servo, and automatic equipment.

Parameter

- Rated capacity:100T

- Power: 4kw

- Application:Gold, silver, copper and other coins and bullion

Automatic Coin Stamping Machine

Superbmelt coin stamper machine is a large capacity automated stamping machine that is convenient to use. Once the main switch is flipped, you can choose from the manual mode, semi-automatic mode or automatic mode. The coin stamping machine has automatic features that pick the blank coins, automatically stamps them and pushes the stamped coin from of the die and the next blank coin follows. This process is repeated for as long as possible without affecting the pressure or standard of stamping. This process is completed within seconds which is very suitable for a fast-moving minting industry. The stamping process is highly efficient and reliable for multiple blank coin stamping as the hydraulics does not deform blank coins or ingots.

Parameter

- Rated capacity:300T

- Power: 7.5kw

- Application: Gold, silver, copper and other coins and bullion

Automatic Coin Minting Press

Superbmelt operator panel has the manual mode, semi-automatic mode and automatic mode that allows users to choose the mode of stamping best suitable for them. This means that irrespective of the level of expertise in coin minting, it can easily be used by anybody. Once the “start” button is pressed, the injector and feeding system picks the coins automatically and stamps them within a seconds. The entire process is fast allowing you to stamp large batches of gold, silver and copper coins and bars within few minutes. Thereby, saving cost and time of production. The automatic coin minting press has an adjustable pressure controller that allows you to control the pressure of stamping easily. Superbmelt automatic hydraulic coin minting press is easy to maintain, therefore, ensure a long service life and a good return on investment. The stamping dies can easily be removed and replaced for proper cleaning after each use. The pressing machine by Superbmelt is made of high-quality materials that also ensures long-lasting use.

Parameter

- Rated capacity: 300

- Power: 16kw

- Application: Gold, silver, copper and other coins and bullion

Metal Tag Stamping Machine

Discover the SuperbMelt metal tag stamping machine for sale, a versatile solution perfect for jewelry stamping needs. Whether it’s gold nuggets, silver nuggets, or iron nuggets, this machine excels in embossing and stamping labels with precision and finesse.

The SuperbMelt Jewelry Stamping Machine is not limited to metal tag stamping; it also caters to nameplates, hang tags, and various other jewelry label applications. Its adaptability makes it a must-have tool for jewelers and manufacturers looking to add a professional touch to their products.

Parameter

- Rated capacity:20T

- Power: 3.75kw

- Application: Gold, silver, copper and other coins and bullion

Automatic Gold Coin Making Machine

With its impressive speed of 10 stamps per minute, the SuperbMelt Gold Coin Press Machine significantly reduces labor costs and boosts production efficiency. It’s the perfect solution for the rapidly expanding minting industry. Thanks to its efficient hydraulic system, the stamping process guarantees consistent and reliable multi-blank coin stamping without any deformation of the coins or ingots.

The SuperbMelt Automatic Gold Coin Making Machine stands out as a newly developed, fully automatic solution dedicated to blank coin or gold nugget stamping. Its versatility allows it to handle various materials, including gold, silver, platinum, and others, ranging from 100 to 300 tons in a short period.

Parameter

- Pressure: 300T

- Power:20kw

- Application: Gold, silver, copper and other coins and bullion

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why Choose a SuperbMelt Induction Melting Furnace

How many steps are in the minting process?

- Design: Creating the artwork and design for the coin, which includes choosing themes, images, and inscriptions.

- Modeling: Sculpting the design into a 3D model, often using computer software or traditional sculpting techniques.

- Engraving: Creating the master die from the 3D model. This die is used to imprint the design onto the coin.

- Die Preparation: The master die is used to create working dies. These working dies will be used in the actual coin pressing process.

- Blanks Production: Cutting metal into blank discs or “planchets,” which will be stamped to create coins.

- Annealing: Heating the blanks to soften them, making them easier to strike.

- Cleaning: Removing any impurities or debris from the blanks to ensure a clean strike.

- Stamping (Striking): Using the prepared dies to imprint the design onto the blanks. This is done using a coin press.

- Edge Treatment: Adding any additional features such as reeding (grooves) on the edge of the coin, if required.

- Inspection and Quality Control: Checking the coins for defects, consistency, and quality to ensure they meet the required standards.

- Packaging: Sorting and packaging the finished coins for distribution or sale.

What is the difference between a manual and an automatic minting press?

A manual minting press requires more human intervention for each strike, while an automatic minting press, like those from SuperbMelt, uses advanced technology to automate the process, increasing efficiency and consistency in coin production.

What types of coins can be produced with a minting press?

Minting presses can produce a variety of coins, including currency coins, commemorative coins, and collectible medals. They can also mint coins in various metals, such as gold, silver, copper, and alloys.

What metals can be used in a minting press?

Minting presses can work with various metals, including gold, silver, copper, nickel, and alloys. The type of metal used depends on the coin’s purpose, whether it’s for currency, collectibles, or commemorative purposes.

Can a minting press be used for custom designs?

Yes, minting presses can be configured to produce custom designs. By creating unique dies, companies and organizations can mint custom coins, medals, and tokens with specific logos, images, and text.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited